A plastic granulation waste gas treatment system and a waste gas treatment process

A technology for waste gas treatment and granulation, which is applied in the direction of gas treatment, dispersed particle separation, combined devices, etc., can solve the problems of large waste gas emissions from plastic granulation, complex and changeable pollution components, and difficulty in meeting environmental protection requirements, so as to achieve promotion and Broad application prospects, reduced pollutant concentration, perfect function and protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

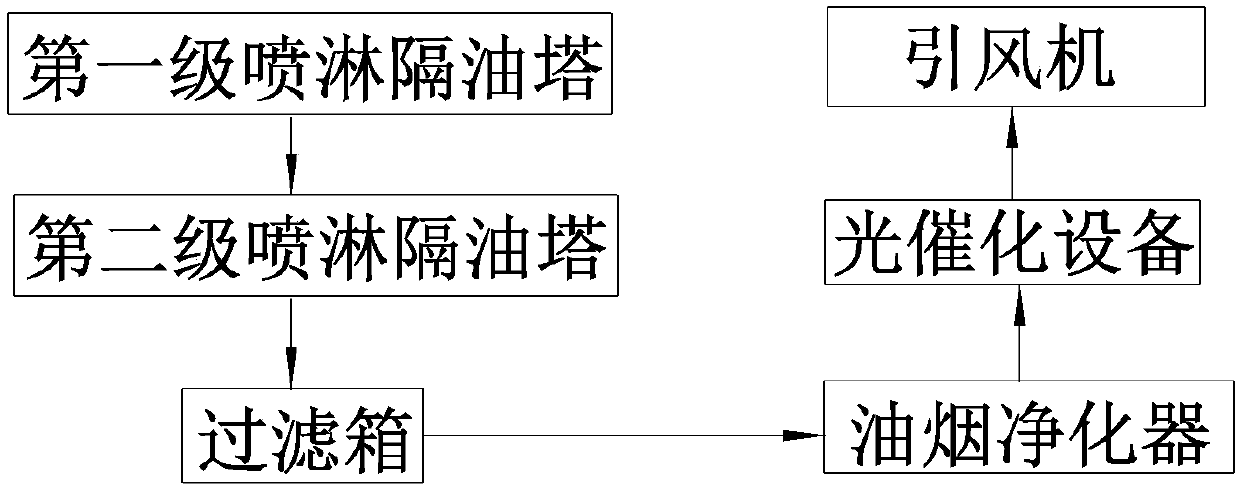

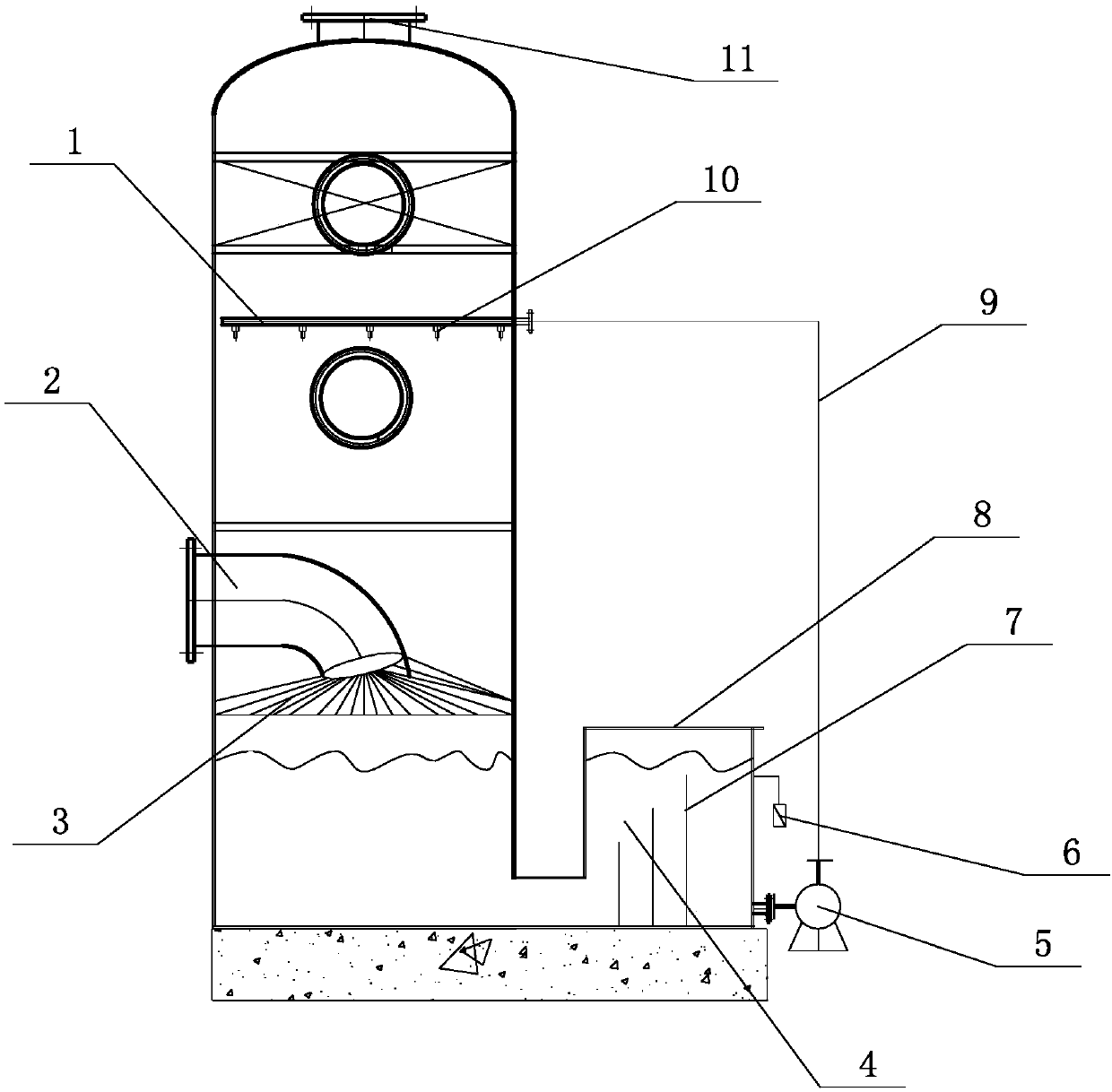

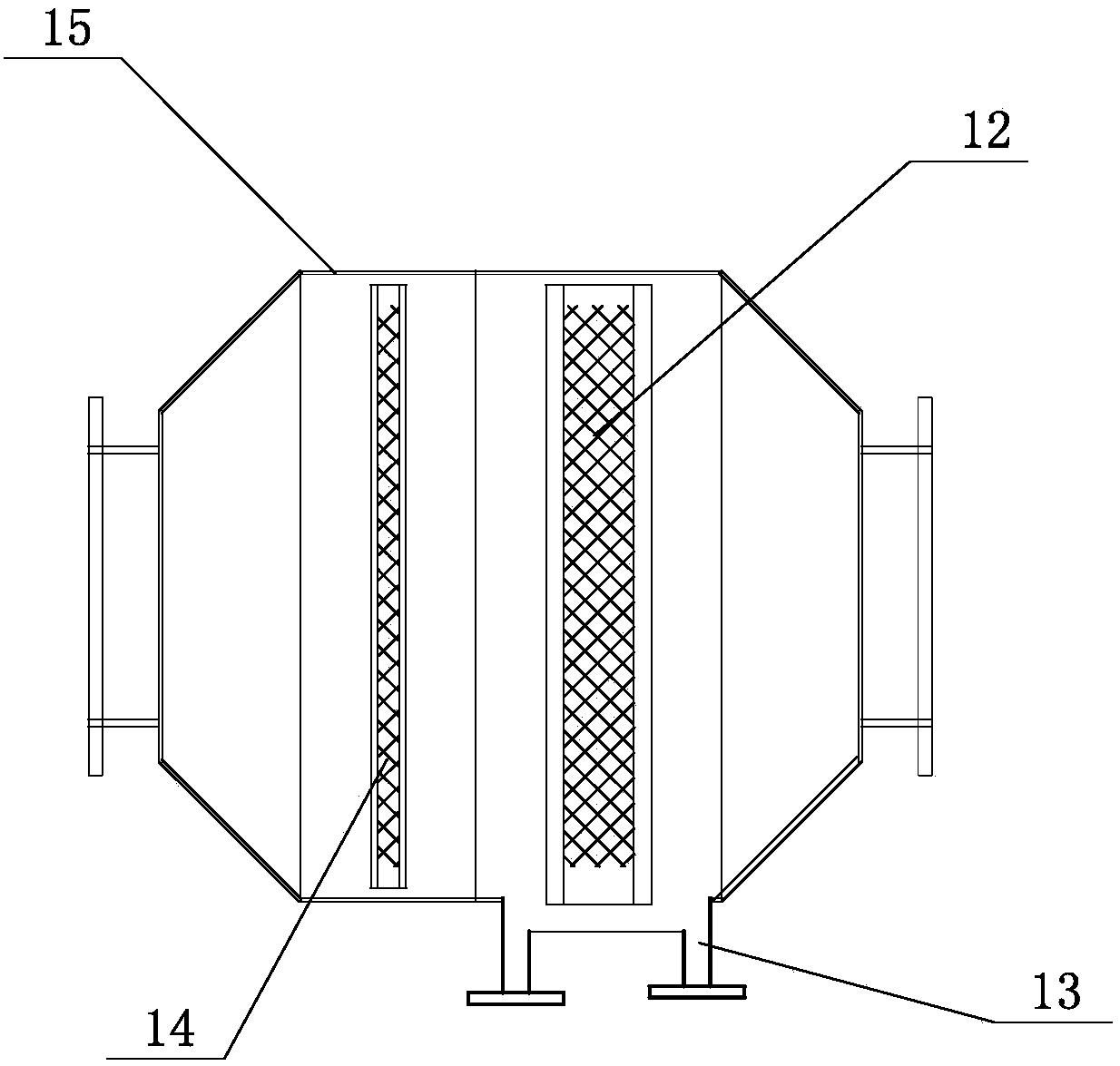

[0032] Such as Figure 1-5 As shown, the plastic granulation waste gas treatment system of the present invention includes two-stage spray oil separation towers, filter boxes, oil fume purifiers and photocatalytic oxidation equipment connected in sequence, and the two-stage spray oil separation towers respectively include the first The first-stage spray oil-separation tower and the second-stage spray oil-separation tower, the first-stage spray oil-separation tower and the second-stage spray oil-separation tower all include a tower body, and the upper end of the tower body is provided with an air outlet port 11, and the tower One side of the body is provided with an air intake pipe 2, the air intake end of the air intake pipe 2 is externally connected to the waste gas pipe, the air outlet end of the air intake pipe 2 is located inside the tower body, and the air distribution plate 3 is arranged at the air outlet end of the air intake pipe 2, the The air distribution plate 3 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com