Experimental device and experimental method for hydrothermal catalytic pyrolysis in heavy oil layer by means of ultrasonic wave

A technology of catalytic cracking and experimental device, applied in the field of ultrasonic-assisted hydrothermal catalytic cracking experimental device in heavy oil layer, can solve problems such as other reports that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

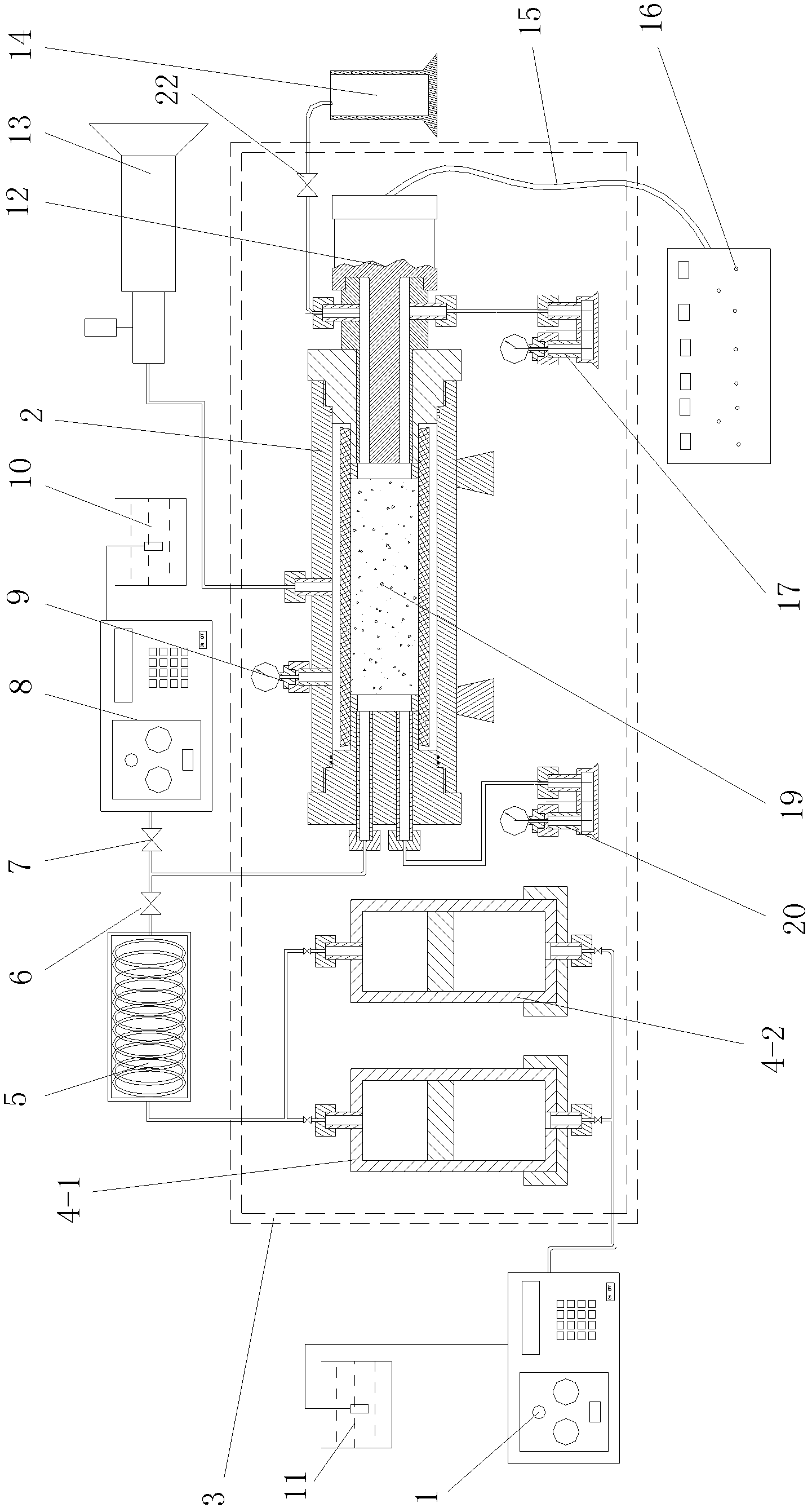

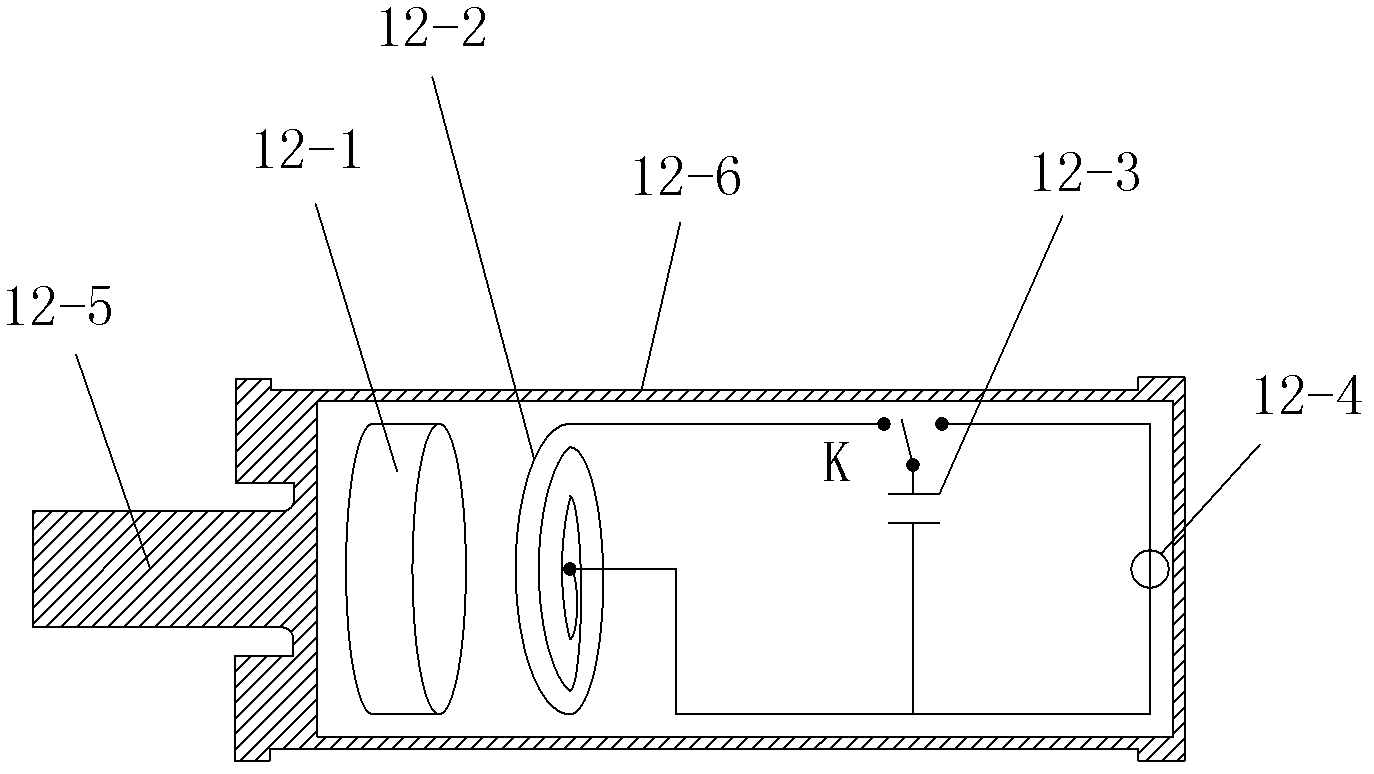

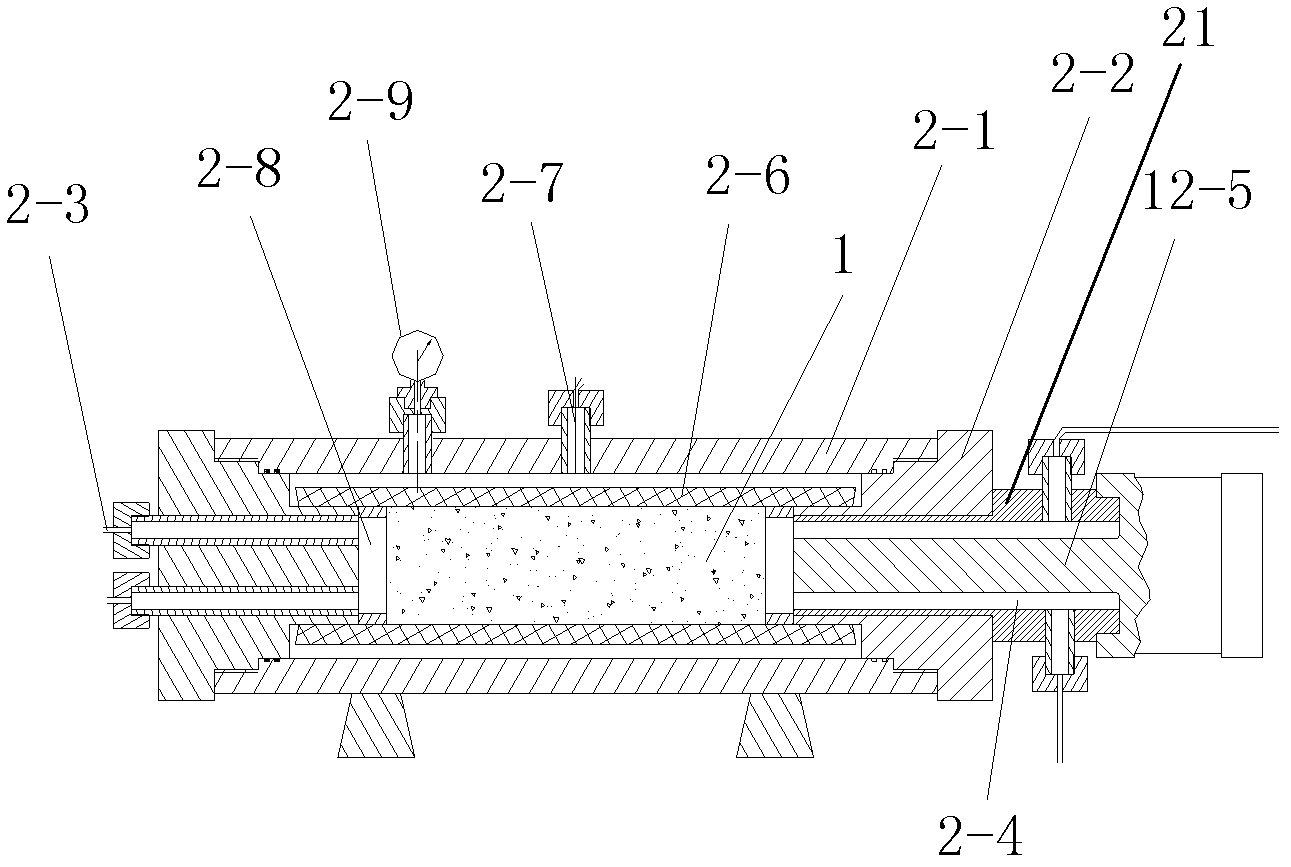

[0064] Such as figure 1 The shown ultrasonic-assisted hydrothermal catalytic cracking experimental device in heavy oil layer includes a ring pressure supply device, a water storage tank 4-1, an oil storage tank 4-2, a storage device for a catalyst and a reaction aid, and a The rock core holder 2 of the test rock core 19 and the ultrasonic transducer 12 that carries out ultrasonic treatment to the tested rock core 19, and is connected with the ultrasonic transducer 12 and provides a high-frequency alternating current signal for the ultrasonic transducer 12 The ultrasonic generator 16 and the liquid container connected to the liquid outlet of the core holder 2 through an external pipeline, the ring pressure supply device is connected to the ring pressure interface of the core holder 2 through a hydraulic pipeline and is connected to the The tested rock core 19 located inside the core holder 2 exerts a circumferential pressure, the water storage tank 4-1 is connected to the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com