High strength lead alloy and manufacturing method thereof

A lead alloy, high-strength technology, applied in the field of shielding lead alloy materials and its preparation, can solve the adverse effects of alloy ductility and impact resistance, poor mechanical strength and heat resistance of composite materials, and it is difficult to prepare large-scale composite materials Materials and other issues to achieve the effect of improving the surrounding international environment, supporting domestic economic construction, and increasing international influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

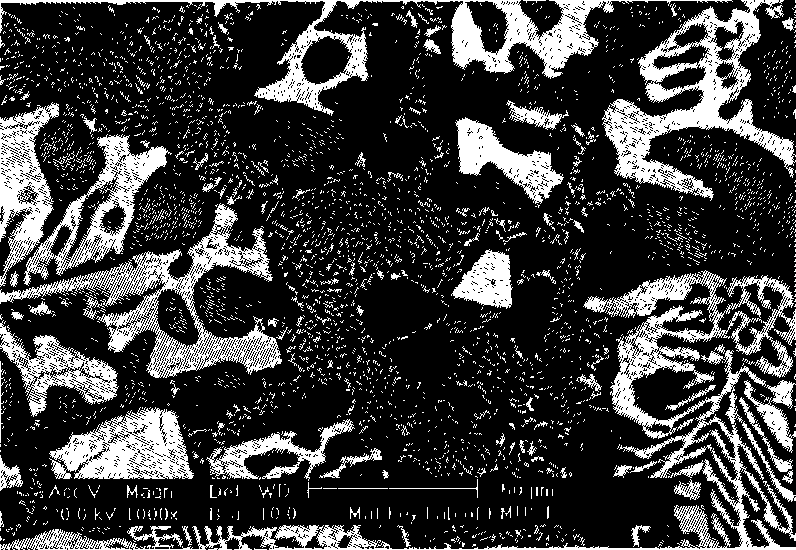

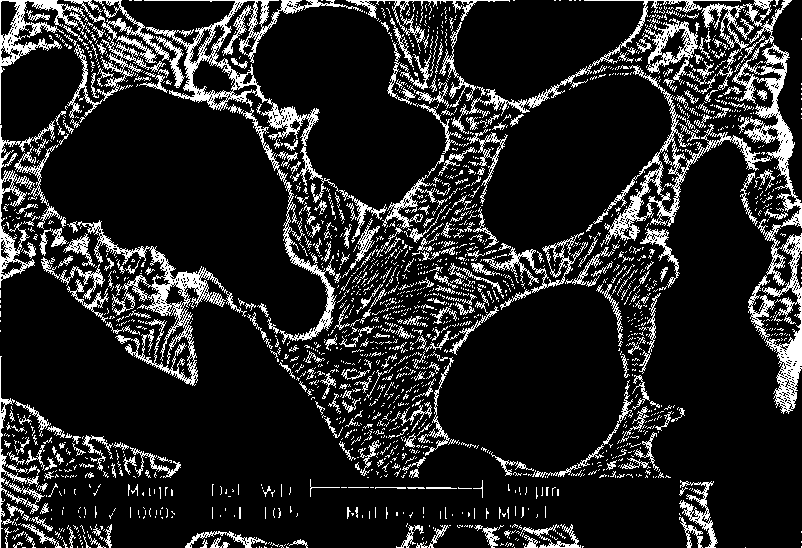

[0015] Embodiment 1: Adopt in-situ reaction method, add 50% lead, 40% Ba, Ca, Li, Mg, Pd, Pt or Dy, La, Y, Gd and other second component metals and 10 in the induction electric furnace % Al, the adding sequence is: first add the second component metal with a higher melting point, and then add lead with a lower melting point after it is melted. Stir for 1-2 minutes to make the magnesium and lead fully react to form a lead-rich intermetallic compound, stand still for 2 minutes, and cast by bottom casting, and finally prepare an ultra-high-strength lead alloy material. And make test samples for testing and analysis of mechanical properties and microstructure. The test results are as follows:

[0016] ①Tensile strength test: Prepare a test sample rod and carry out the tensile strength test on the tensile mechanical testing machine. The test results show that the tensile strength of the ultra-high-strength lead alloy reaches 228MPa, which is 10-15MPa of the traditional lead and le...

Embodiment 2

[0019] Embodiment 2: Adopt in-situ reaction method, add 55% lead, 40% Ba, Ca, Li, Mg, Pd, Pt or Dy, La, Y, Gd and other second component metals and 5 in the induction electric furnace % Al, the adding sequence is: first add the second component metal with a higher melting point, and then add lead with a lower melting point after it is melted. Stir for 1-2 minutes to make the magnesium and lead fully react to form a lead-rich intermetallic compound, stand still for 2 minutes, and cast by bottom casting, and finally prepare an ultra-high-strength lead alloy material. And make test samples for testing and analysis of mechanical properties and microstructure. The test results are as follows:

[0020] ①Tensile strength test: Prepare a test sample bar for tensile strength test on a tensile mechanical testing machine. The test results show that the tensile strength of ultra-high-strength lead alloy reaches 154MPa, which is more than 7 times that of traditional lead and lead alloy ....

Embodiment 3

[0023] Embodiment 3: adopt the in-situ reaction method, add 60% lead, 40% Ba, Ca, Li, Mg, Pd, Pt or Dy, La, Y, Gd and other second component metals in the induction furnace, add The sequence is: first add the second component metal with a higher melting point, and then add lead with a lower melting point after it is melted. Stir for 1-2 minutes to make the magnesium and lead fully react to form a lead-rich intermetallic compound, stand still for 2 minutes, and cast by bottom casting, and finally prepare an ultra-high-strength lead alloy material. And make test samples for testing and analysis of mechanical properties and microstructure. The test results are as follows:

[0024] ①Tensile strength test: Prepare a test sample bar and conduct a tensile strength test on a tensile mechanical testing machine. The test results show that the tensile strength of the ultra-high-strength lead alloy reaches 103MPa, which is about 5 times that of traditional lead and lead alloys. .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com