Roller cladding heating kiln

A roll and kiln technology, applied in the field of heaters, can solve problems such as cracking, and achieve the effects of high efficiency, simple structure and flexible assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

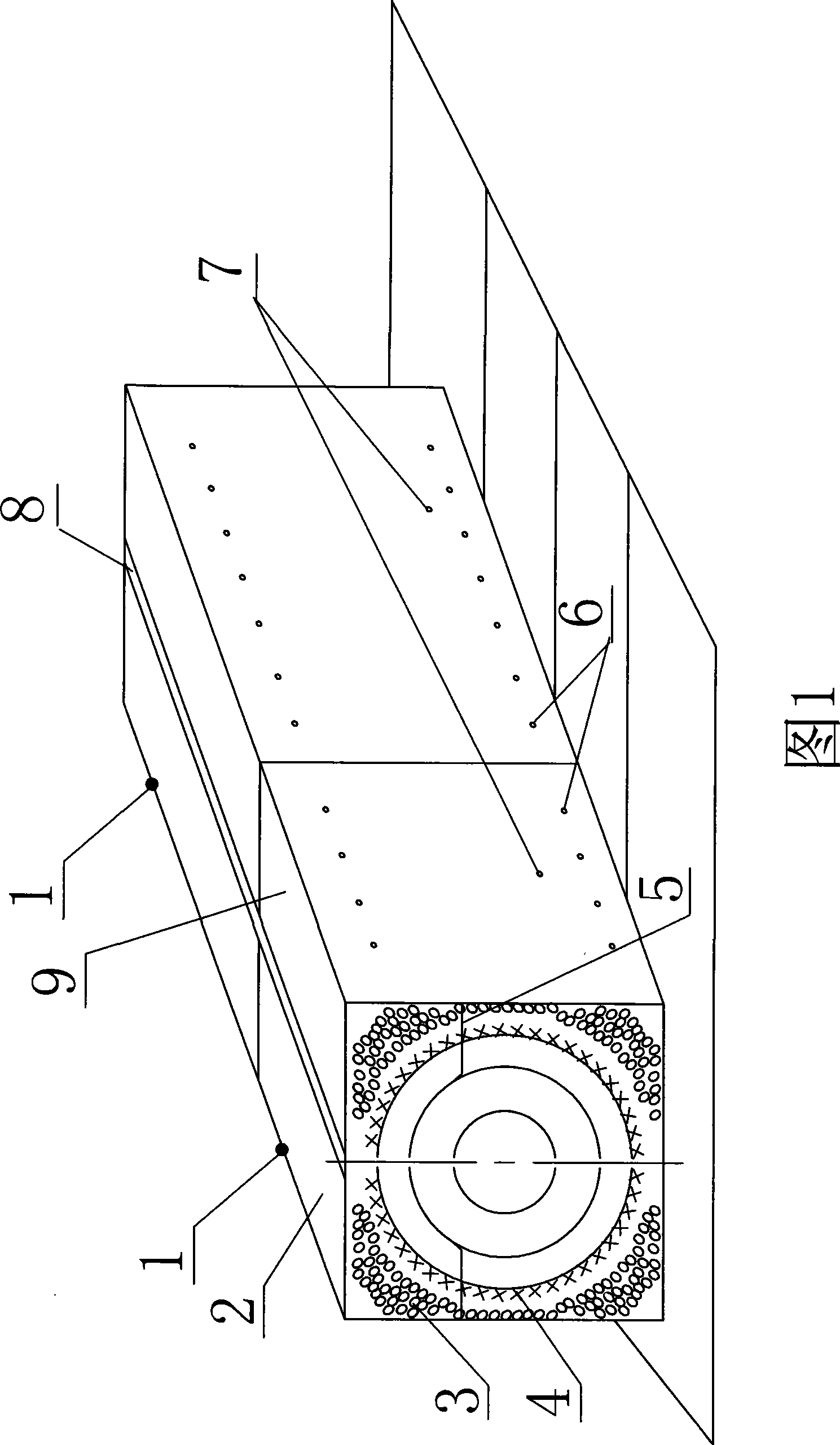

[0018] Roller cladding heating kiln, including furnace body 1, heating belt 4, insulation layer 3, powder receiving tray 5; A powder receiving tray 5, the powder receiving tray 5 is fixedly connected with the inner walls of the furnace box 2 and 9. Temperature test points 7 are respectively arranged on the sides of the furnace boxes 2 and 9, and the temperature test points 7 are connected to the temperature control input end of the controller through wires. The left and right furnace boxes 2 and 9 are butted with each other to form a furnace body 1, and the upper cover of the furnace body 1 is provided with a laser operation window 8; a semicircular insulation layer is provided on the upper, lower and side inner walls of the furnace boxes 2 and 9 3. The insulation layer 3 is fixedly connected to the inner wall of the furnace box 2 and 9, and a semicircular heating belt 4 is arranged on the inner circle of the insulation layer 3, and the heating belt 4 is insulated and fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com