Method for preventing explosion venting after converter blowing interruption

A converter blowing and explosion venting technology, which is applied in the metallurgical field, can solve problems such as equipment accidents, explosion venting, dry dust removal, carbon-oxygen reaction explosion venting, etc., and achieve the effects of stable smelting control, smooth production organization, and prevention of explosion venting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. When the blowing is resumed after the blowing is interrupted, shake the converter to zero.

[0020] 2. Select the manual "slag splashing" mode for the oxygen lance, and the position of the oxygen lance is 2.5m away from the furnace mouth.

[0021] 3. Manually open the valve to blow nitrogen, the nitrogen flow rate is 40000Nm3 / h, the nitrogen blowing time is 3.5min, and a nitrogen curtain is made in the flue.

[0022] 4. After the nitrogen blowing is over, the oxygen lance selects the manual "blowing" mode.

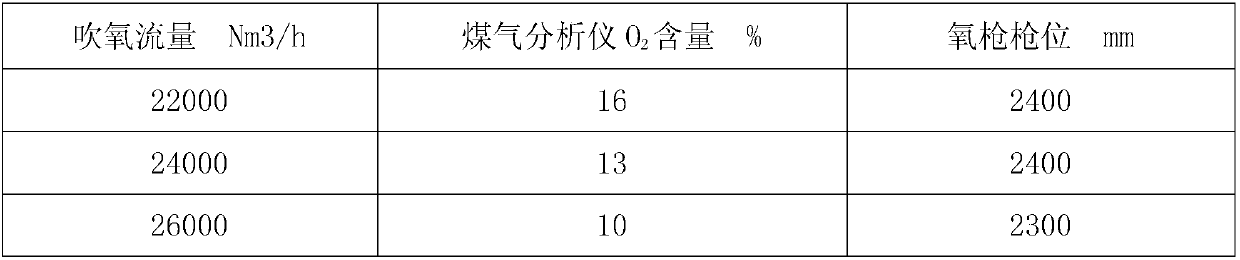

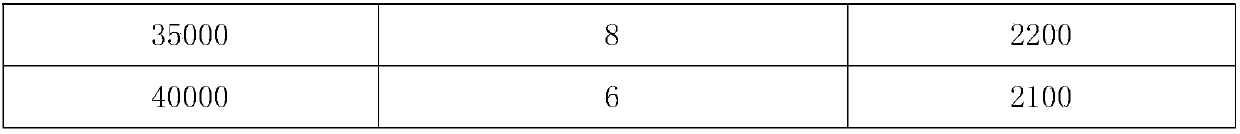

[0023] 5. When blowing oxygen with the oxygen-reducing lance, the position of the oxygen lance and the flow rate of oxygen are controlled according to the automatic mode, and the flow rate of oxygen blowing and gas analyzer O are as listed in the table below. 2 The corresponding relationship between content and oxygen lance position is carried out for blowing:

[0024] Oxygen blowing flow Nm3 / h

[0025] 6. When O in the gas analyzer 2 The content is ...

Embodiment 2

[0027] 1. When the blowing is resumed after the blowing is interrupted, shake the converter to zero.

[0028] 2. Select the manual "slag splashing" mode for the oxygen lance, and the position of the oxygen lance is 2.8m away from the furnace mouth.

[0029] 3. Manually open the valve to blow nitrogen, the nitrogen flow rate is 43000Nm3 / h, the nitrogen blowing time is 3.2min, and a nitrogen curtain is made in the flue.

[0030] 4. After the nitrogen blowing is over, the oxygen lance selects the manual "blowing" mode.

[0031] 5. When blowing oxygen with the oxygen-reducing lance, the position of the oxygen lance and the flow rate of oxygen are controlled according to the automatic mode, and the flow rate of oxygen blowing and gas analyzer O are as listed in the table below. 2 The corresponding relationship between content and oxygen lance position is carried out for blowing:

[0032] Oxygen blowing flow Nm3 / h

[0033] 6. When O in the gas analyzer 2 The content is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com