Double-winding six-phase motor

A double-winding six-phase and three-phase winding technology, applied in motors, electromechanical devices, electric vehicles, etc., can solve the problems of magnetic circuit interference, winding temperature rise accumulation, etc., achieve strong heat dissipation, high adaptability to working conditions, and avoid The effect of magnetic circuit interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, and the features of the present invention will be further revealed in the following detailed description.

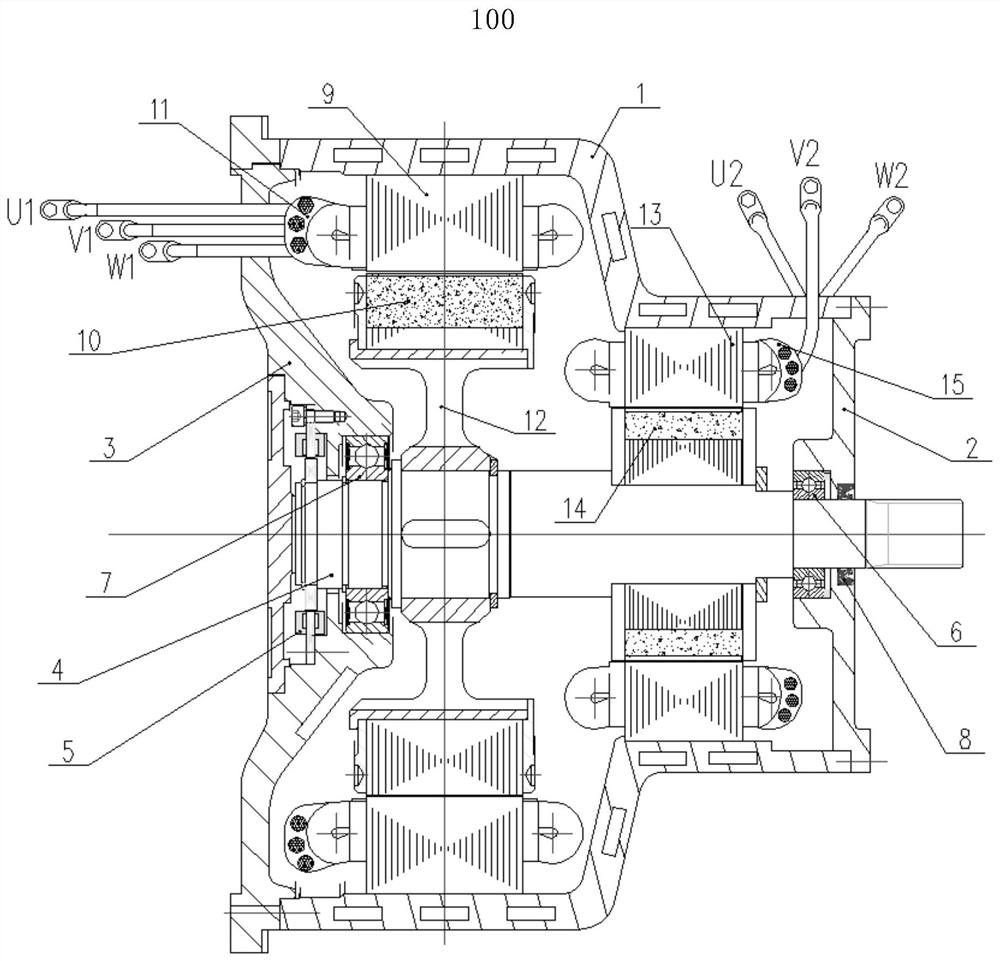

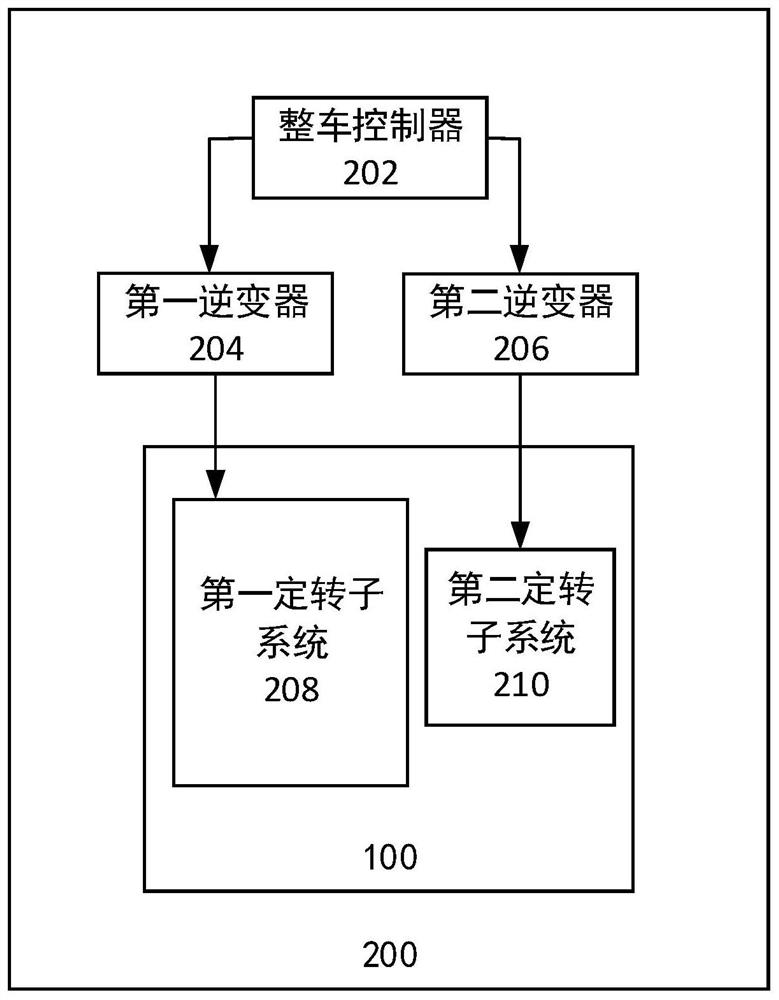

[0037] figure 1 It is a structural schematic diagram of a double-winding six-phase motor according to an embodiment of the present invention. Such as figure 1 As shown in , the double-winding six-phase motor mainly includes the frame 1, the front and rear end covers 2 and 3, the rotating shaft 4, the resolver 5, the bearings 6 and 7, the oil seal 8, the first stator-rotor system and the second stator-rotor system. The first fixed-rotor system includes: a No. 1 stator 9 , a No. 1 rotor 10 , a No. 1 winding 11 and a rotor support 12 . The first winding 11 further includes a first U-phase winding coil U1 , a first V-phase winding coil V1 , and a first W-phase winding coil W1 . The second stator-rotor system includes: a second stator 13 , a second rotor 14 and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com