Pressure spring self-locking type power battery quick release device applied to new energy truck

A power battery, self-locking technology, applied in power units, electric power units, battery pack components, etc., can solve problems such as difficulty in maintenance and repair, inability to handle fast, and inability to lock or unlock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

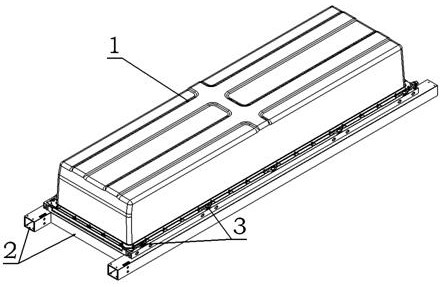

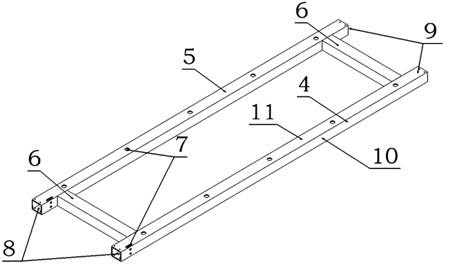

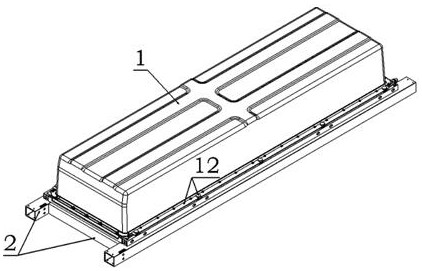

[0052] A pressure spring self-locking power battery quick release device applied to new energy trucks in this embodiment is arranged between the power battery 1 and the battery mounting bracket 2 to realize the connection between the power battery 1 and the battery mounting bracket 2 Quick lock unlock. There are battery installation holes 3 on both sides of the bottom of the power battery 1, through which the battery installation holes 3 are fixedly connected with the battery installation bracket 2; the battery installation bracket 2 is used to carry the power battery, which is composed of two opposite bracket longitudinal The frame structure formed by welding with two opposite bracket beams, the bracket longitudinal beam as the locking beam is called the first locking beam 4 and the second locking beam 5 in this embodiment, the two locking beams and the two bracket beams 6 are all made of square steel pipes, the side of the locking beam in contact with the base of the power b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com