Follow-up combining and conveying device for strip packages

A technology for conveying devices and strips, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve problems such as mutual collision, broken products, impact detection, counting into large packages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

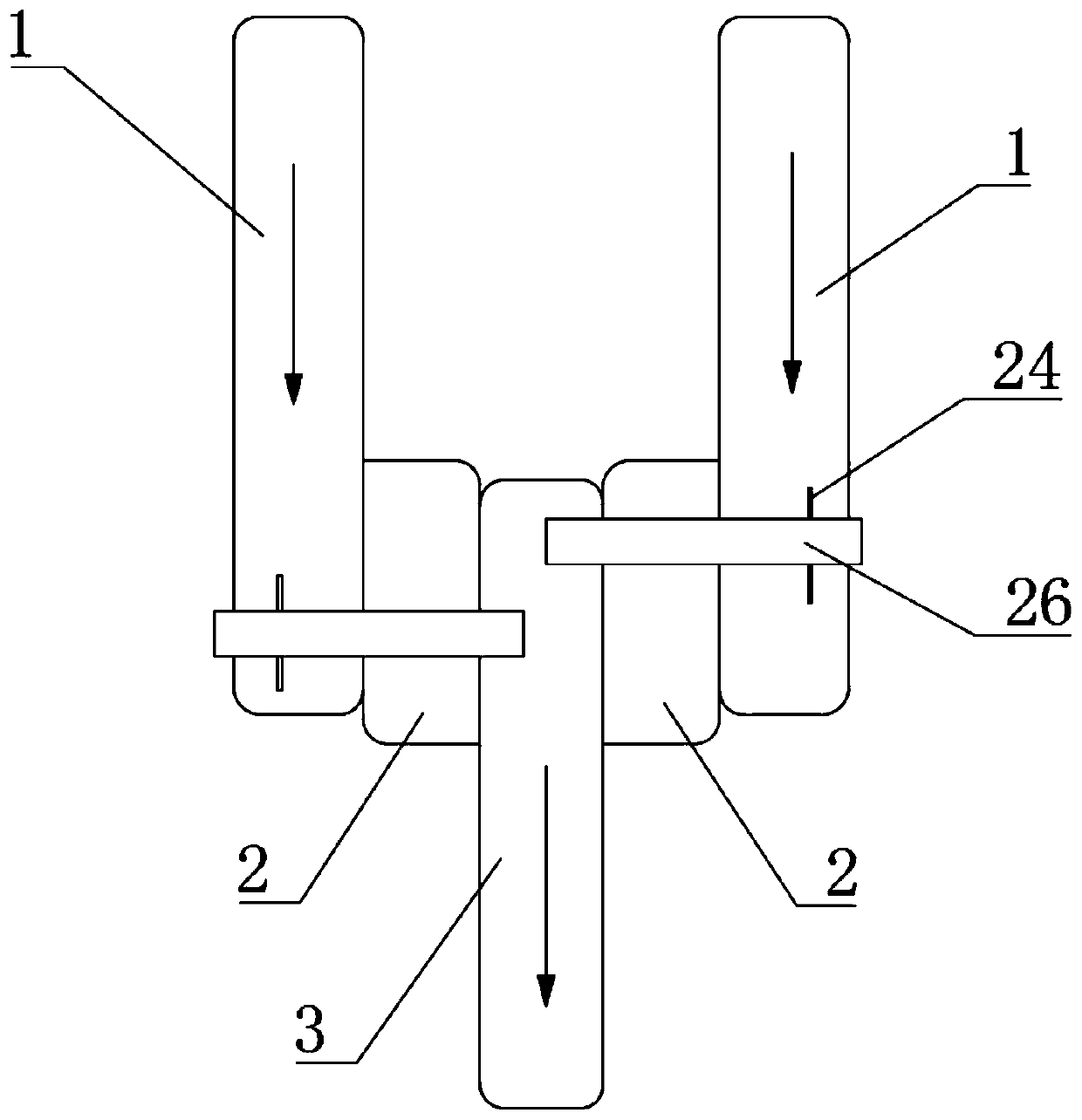

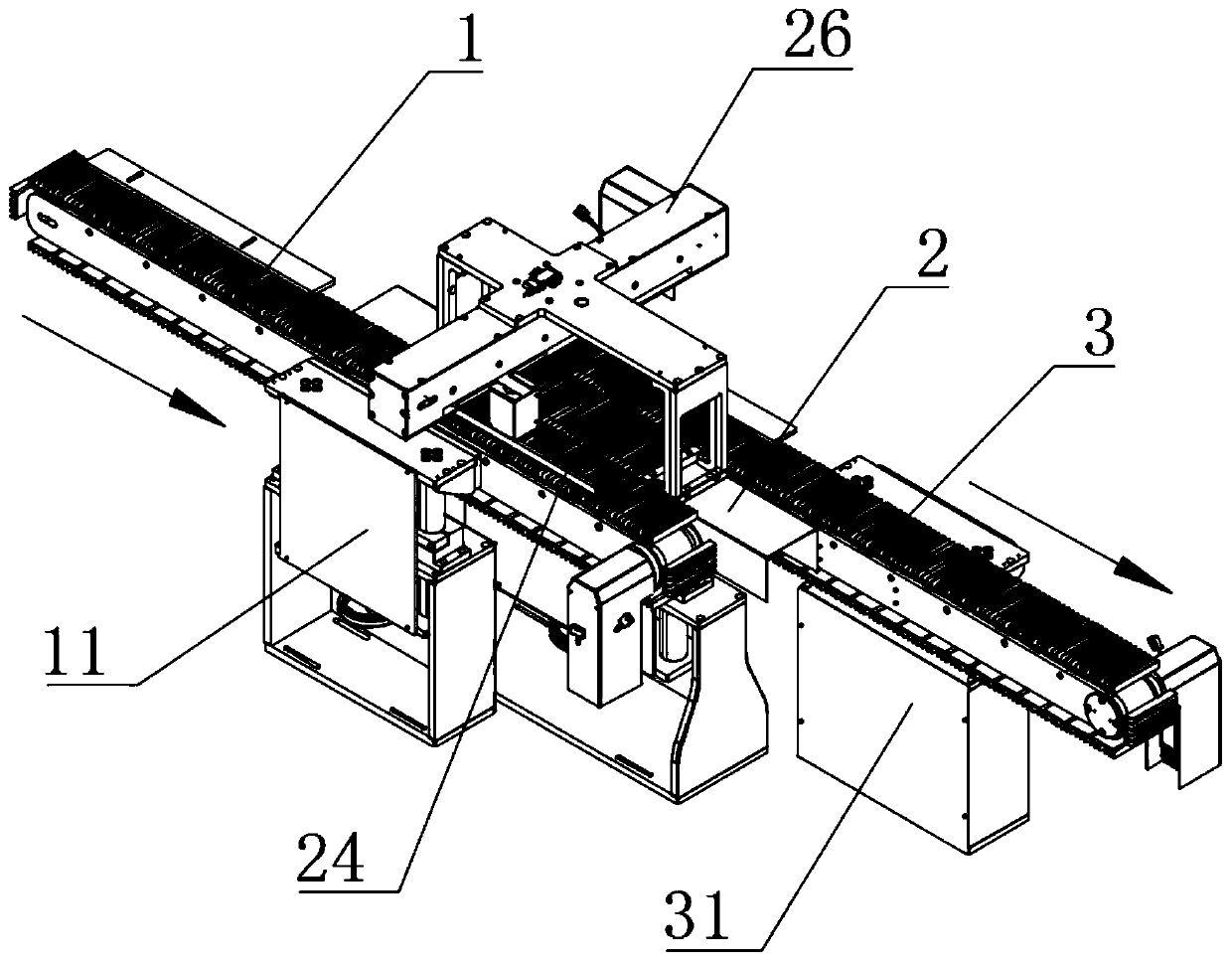

[0023] A kind of bar bag follow-up and road conveying device, such as figure 1 , including two feed servo conveyor belts 1, one discharge servo conveyor belt 3 and two follow-up paralleling mechanisms 2, each feed servo conveyor belt 1 is equipped with a follow-up merge mechanism 2, two feed servo conveyor belts Conveyor belts 1 are respectively arranged in parallel on both sides of the discharge servo conveyor belt 3 , and each feed servo conveyor belt 1 is connected to the discharge servo conveyor belt 3 through its corresponding follow-up merging mechanism 2 . The follow-up merging mechanism 2 is used to transfer the strips on the feed servo conveyor belt 1 to the discharge servo conveyor belt 3 . figure 2 Taking a single feed servo conveyor belt 1, a discharge servo conveyor belt 3, and a single follow-up parallel mechanism 2 as examples, the connection relationship between each part is further demonstrated.

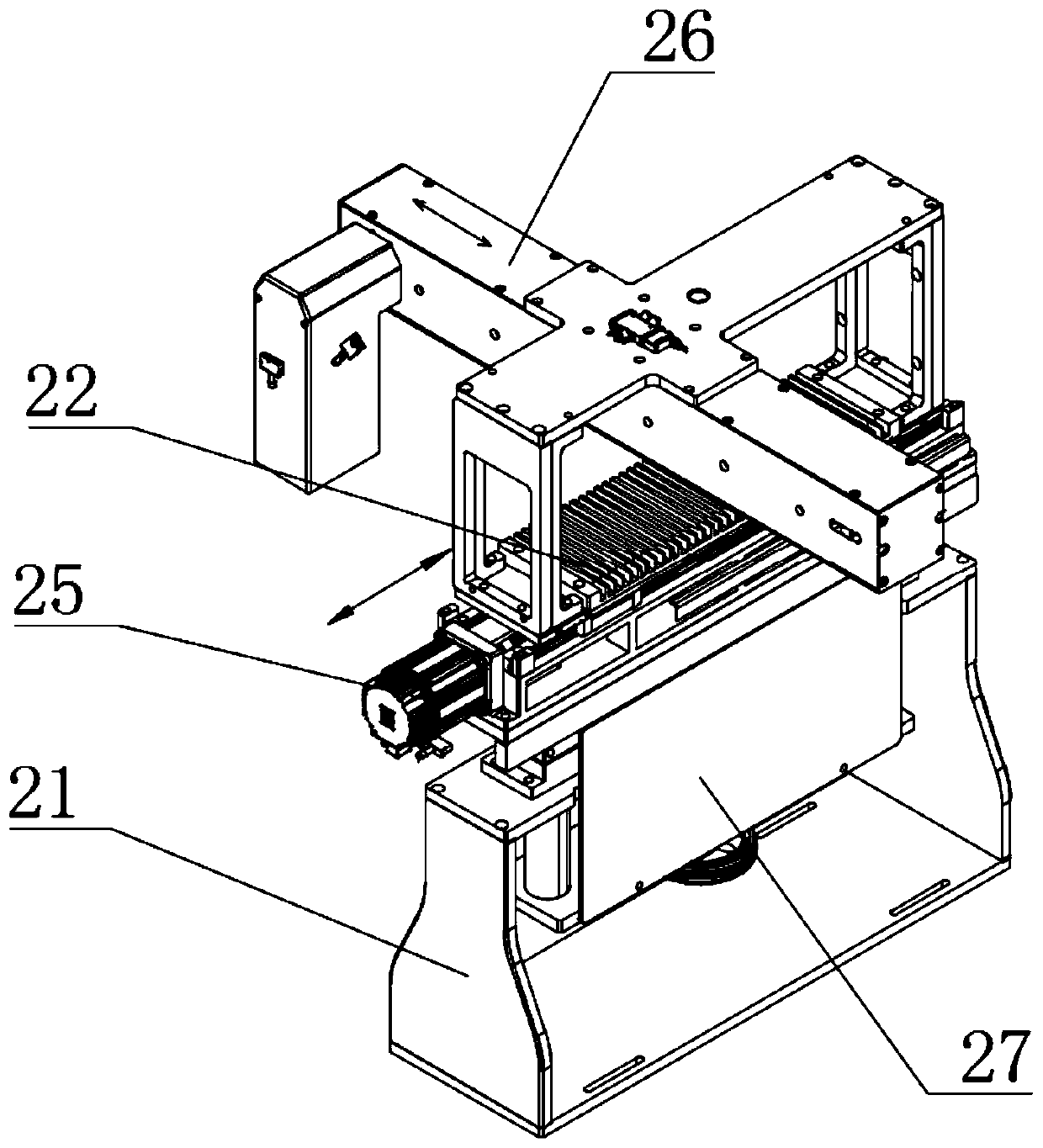

[0024] Such as Figure 2 to Figure 4 , the follow-up merging...

Embodiment 2

[0031] The difference from Example 1 is that, as Figure 5 As shown, the feed servo conveyor belt 1 has three parallel to each other, each feed servo conveyor belt 1 is equipped with a follow-up and parallel mechanism 2, and one feed servo conveyor belt 1 is arranged in parallel on the discharge servo conveyor belt On one side of the belt 3, the other two feed servo conveyor belts 1 are arranged in parallel on the other side of the discharge servo conveyor belt 3, and each feed servo conveyor belt 1 is connected to the The discharge servo conveyor belts 3 are connected, and the width of the transition chute platform 22 on each of the follow-up merging mechanisms 2 is equal to the distance between the corresponding feed servo conveyor belt 1 and the discharge servo conveyor belt 3. spacing. The two feeding servo conveyor belts 1 on the same side are misaligned with each other, and the width of the transition chute platform 22 corresponding to the feeding servo conveyor belt 1 ...

Embodiment 3

[0033] The difference from Example 1 is that, as Figure 6 As shown, the feed servo conveyor belts 1 have four parallel to each other, and each feed servo conveyor belt 1 is equipped with a follow-up merging mechanism 2, and two feed servo conveyor belts 1 are arranged in parallel on the discharge servo conveyor belt 1. On one side of the conveyor belt 3, the other two feed servo conveyor belts 1 are arranged in parallel on the other side of the discharge servo conveyor belt 3, and each feed servo conveyor belt 1 passes through its corresponding follow-up merging mechanism 2 Connected with the discharge servo conveyor belt 3, the two feed servo conveyor belts 1 on the same side are misaligned with each other.

[0034] The difference from Embodiment 1 is that the forward speed of all transition chute platforms 22 is consistent with the speed of the feeding servo conveyor belt 1, and the speed of the discharging servo conveyor belt 3 is greater than that of the feeding servo con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com