Plate turning mechanism for tableware cleaning equipment

A tableware cleaning and equipment technology, applied in the direction of tableware washing machine/rinsing machine parts, etc., can solve the problems of waste, high cost, space occupation and large personnel demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

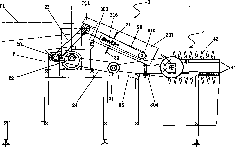

[0017] see Figure 1~3 , the present invention is provided with motor 1, transmission mechanism, dinner plate guiding device 3 and dinner plate turning over cleaning device 4. The motor 1 and the transmission mechanism are arranged on the body P. The transmission mechanism is provided with a torque limiter 20, a transmission 21, chains 22, 23, 24 and 25 and associated drive sprockets. The motor 1 output shaft passes through the sprocket through the chain 22 and the torque limiter 20, and through the transmission shaft ( figure 1 Not shown in ~4) drives the double-row chain assembly of the plate guiding device 3 to work, which can realize the transmission of the double-row chain assembly and the transmission of the front tableware automatic conveyor belt to achieve equal station transmission (that is, the station distance is the same , which guarantees synchronization). Simultaneously motor 1 output shaft drives dinner plate through sprocket through chain 22, torque limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com