Preparation method of heat-shrinkable anticorrosive material containing graphene

A technology of anti-corrosion materials and graphene, which is applied in the field of heat-shrinkable anti-corrosion materials containing graphene, can solve the problems of insufficient anti-corrosion performance, heavy product weight, and insufficient strength, and achieve the effects of improved anti-corrosion performance, light weight and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

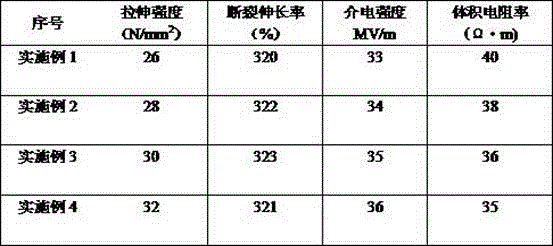

Examples

Embodiment 1

[0018] A kind of preparation method of heat-shrinkable anticorrosion material containing graphene, concrete steps are as follows:

[0019] Radiation modification: adding graphene or modified graphene and additives to polyethylene raw materials, through physical mixing, extrusion granulation to obtain substrate pellets;

[0020] At room temperature, the polyethylene substrate granulation material is placed in a radiation field, under the action of high-energy rays, a variety of active particles are formed in the solid polyethylene, thereby forming a cross-linked three-dimensional network structure inside the polyethylene, Carry out cross-linking or grafting reaction to obtain radiation cross-linked polyethylene material containing graphene.

[0021] As a further solution of the present invention: the added amount of the graphene or modified graphene is 0.1%-5% by weight, the additive is a nano-powder dispersant and a wetting agent, and the high-energy rays are mainly gamma rays...

Embodiment 2

[0024] A kind of preparation method of heat-shrinkable anticorrosion material containing graphene, concrete steps are as follows:

[0025] Radiation modification: adding graphene or modified graphene and additives to polyethylene raw materials, through physical mixing, extrusion granulation to obtain substrate pellets;

[0026] At room temperature, the polyethylene substrate granulation material is placed in a radiation field, under the action of high-energy rays, a variety of active particles are formed in the solid polyethylene, thereby forming a cross-linked three-dimensional network structure inside the polyethylene, Carry out crosslinking or grafting reaction to obtain radiation crosslinked polyethylene material containing graphene;

[0027] Among them, polyethylene + 0.3% graphene or modified graphene is physically blended, extruded and granulated, and then radiated and cross-linked to obtain a radiation polyethylene cross-linked material containing graphene, and the pro...

Embodiment 3

[0029] A kind of preparation method of heat-shrinkable anticorrosion material containing graphene, concrete steps are as follows:

[0030] Radiation modification: adding graphene or modified graphene and additives to polyethylene raw materials, through physical mixing, extrusion granulation to obtain substrate pellets;

[0031] At room temperature, the polyethylene substrate granulation material is placed in a radiation field, under the action of high-energy rays, a variety of active particles are formed in the solid polyethylene, thereby forming a cross-linked three-dimensional network structure inside the polyethylene, Carry out crosslinking or grafting reaction to obtain radiation crosslinked polyethylene material containing graphene;

[0032] Among them, polyethylene + 0.4% graphene or modified graphene is physically blended, extruded and granulated, and then radiated and cross-linked to obtain a radiation polyethylene cross-linked material containing graphene, and the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com