Method for removing heavy metals from sludge and special device thereof

A heavy metal and sludge dehydration technology, which is applied in sludge treatment, fertilization equipment, sewage/sludge fertilizer, etc., can solve the problems of long retention time of biological leaching, slow proliferation of sulfur bacteria, secondary pollution of heavy metal leachate, etc. , to achieve the effect of realizing harmless recycling, promoting utilization, and solving heavy metal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

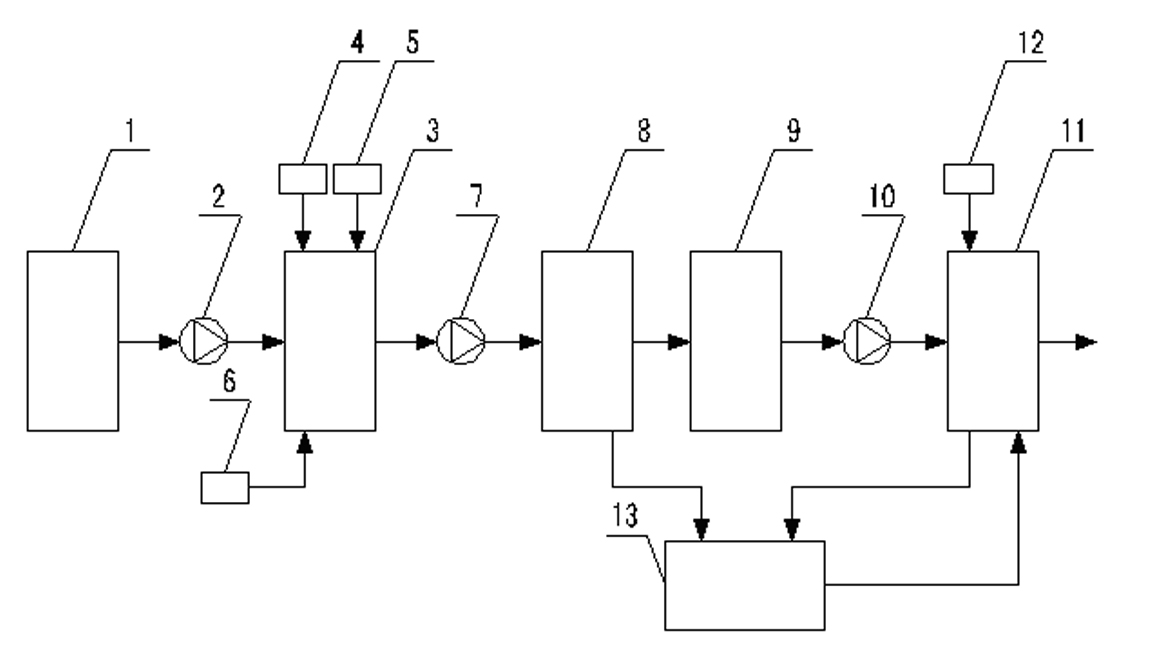

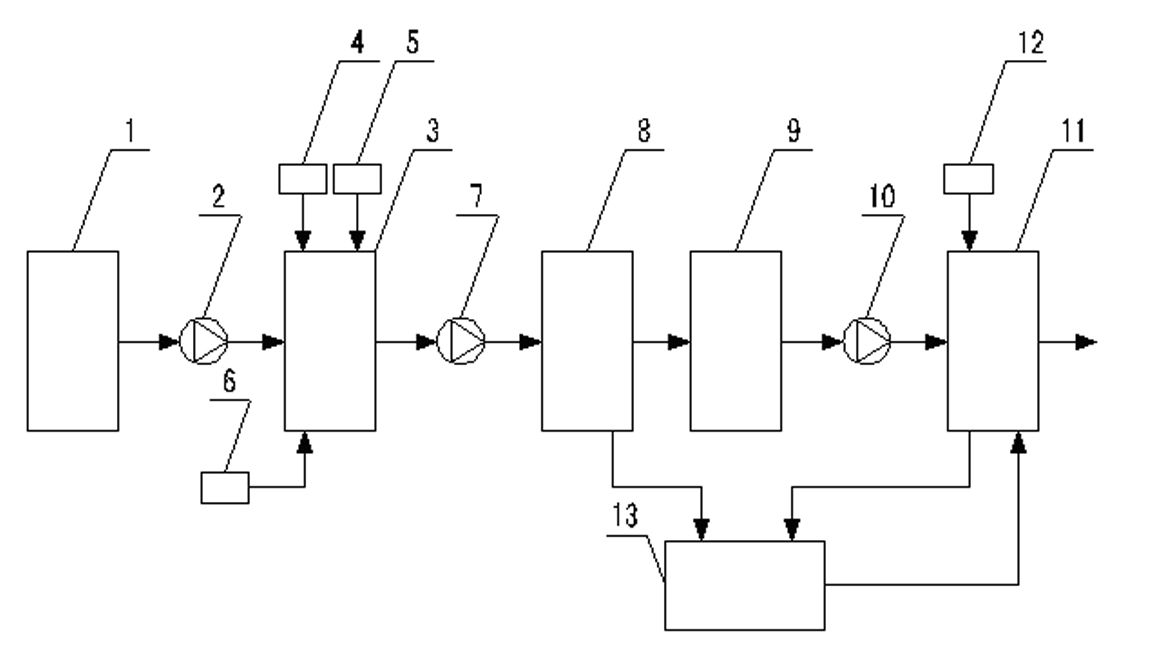

[0016] Example 1: Copper and zinc metal removal device and treatment process in sludge

[0017] refer to Attached picture:

[0018] (1) The sludge placed in the regulating tank 1 is sent into the bioleaching tank 3 through the sludge pump 2, and a low-frequency ultrasonic generator 4 is installed above the bioleaching tank 3. The frequency of the low-frequency ultrasonic generator 4 in this embodiment The frequency is 20Hz, and the amplitude is 20%. The sludge in the biological leaching tank is pretreated with low-frequency ultrasonic generator for 1min-15min; the mass transfer in the sludge system in the next step can be accelerated after the low-frequency ultrasonically enhanced pretreatment speed, and promote the utilization of substrate by acidophilic thiobacillus;

[0019] (2) After the ultrasonic enhanced pretreatment is completed, the substrate dosing device 5 is turned on, and ferrous sulfate and sulfur powder are added to the bio-forest filter 3 as the leaching sub...

Embodiment 2

[0022] Embodiment 2: Treatment effect of copper and zinc sludge

[0023] The solid content of the sludge in this example is 4.3%, and the contents of copper and zinc are 14.8g / kg and 620014.8g / kg respectively.

[0024] (1) The sludge regulating tank is 3200×3200×5000mm; the sludge placed in the regulating tank 1 is sent to the biological leaching tank 3 through the sludge pump 2, and the biological leaching tank is Φ2800×5000mm; There is a low-frequency ultrasonic generator 4, the frequency of the low-frequency ultrasonic generator 4 of the present embodiment is 20 Hz, and the amplitude is 20%; the sludge in the bioleaching tank is first carried out with a low-frequency ultrasonic generator for low-frequency ultrasonic intensive pretreatment for 1min-15min;

[0025] (2) After the ultrasonic enhanced pretreatment is completed, the substrate dosing device 5 is turned on, and ferrous sulfate and sulfur powder are added to the biological forest filter 3 as the leaching substrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com