Preparation method of self-supporting molecularly imprinted polymer film

A molecular imprinting, polymer membrane technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of inability to material self-support, complex process, and insufficient bonding , to achieve the effect of easy to enlarge the application, improve the elution efficiency, and shorten the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

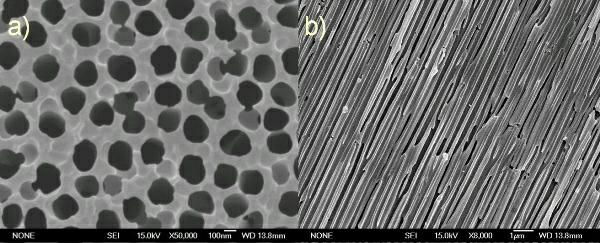

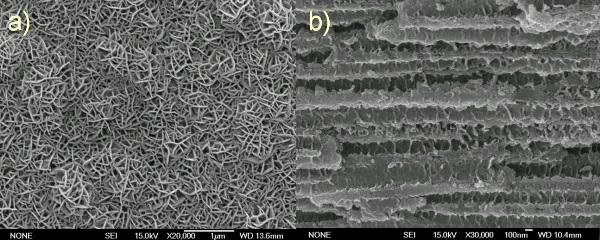

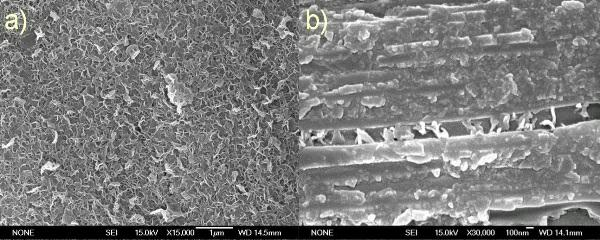

[0026] Embodiment one: Specific steps are as follows:

[0027] in Ni 2+ (Ni(NO 3 ) 2 ) and hexamethylenetetramine concentration of 0.0125 mol / liter mixed aqueous solution, add porous aluminum oxide (AAO) film with 0.4 times the total molar amount of divalent metal ions, and react at 90°C for 1.5 hours to get the product Wash and dry to obtain porous alumina-based double hydroxide (AAO-LDH); in the NaOH aqueous solution of SBC with a molar concentration of 0.012 mol / L and a pH value of 8.0~9.0, add 1 times the total molar amount of SBC The porous alumina-based layered double hydroxide was reacted at 60°C for 1 hour, and the product was washed with water and dried at 60°C to obtain SBC-intercalated porous alumina-based layered double hydroxide (SBC-LDH); Then 0.5g of methacrylic acid, 0.09g of SBC intercalated porous alumina layered double hydroxide, 5.9g of ethylene glycol dimethacrylate, 0.09g of theophylline and 10g of chloroform were mixed and dispersed by ultrasonic wa...

Embodiment 2

[0029] in Ni 2+ (Ni(NO 3 ) 2 ) and hexamethylenetetramine concentrations of 0.02 mol / liter mixed aqueous solution, add a porous aluminum oxide (AAO) film with 0.3 times the total molar amount of divalent metal ions, and react at 20°C for 72 hours. Wash and dry to obtain porous alumina-based double hydroxide (AAO-LDH); in the NaOH aqueous solution of SBC with a molar concentration of 0.02 mol / L and a pH value of 7.0~8.0, add 0.2 times the total molar amount of SBC The porous alumina-based double hydroxide was reacted at 10°C for 24 hours, and the product was washed with water and dried at 30°C to obtain SBC-intercalated porous alumina-based double hydroxide (SBC-LDH); Then 0.5g of methacrylic acid, 0.03g of SBC-intercalated porous alumina-layered double hydroxide, 3.9g of divinylbenzene, 0.07g of glucose and 6g of tetrahydrofuran were mixed and dispersed by ultrasonic waves, and the oxygen was removed by sealing nitrogen; Then 0.038 g of azobisisoheptanonitrile was dispersed...

Embodiment 3

[0031] in Zn 2+ (Zn(NO 3 ) 2 ) and hexamethylenetetramine concentrations of 0.015 mol / liter mixed aqueous solution, add a porous aluminum oxide (AAO) film with 0.2 times the total molar amount of divalent metal ions, and react at 80°C for 5 hours to produce the product Washing and drying to obtain porous alumina-based double hydroxide (AAO-LDH); in the NaOH aqueous solution of SBC with a molar concentration of 0.03 mol / L and a pH value of 9.0~10.0, add 0.5 times the total molar amount of SBC The porous alumina-based layered double hydroxide was reacted at 30°C for 12 hours, and the product was washed with water and dried at 50°C to obtain SBC-intercalated porous alumina-based layered double hydroxide (SBC-LDH); Then 0.5 g of 4-vinylbenzoic acid, 0.05 g of SBC-intercalated porous alumina layered double hydroxide, 3.4 g of ethylene glycol dimethacrylate, 0.06 g of polyacetylglucosamine and 3.8 g of dimethyl Base sulfoxide was mixed and dispersed by ultrasonic waves, and nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com