High-uniformity blending device for enzyme milk tea production

A uniformity and enzyme technology, applied in the field of blending equipment for the production of enzyme milk tea, can solve the problems of single fixed stirring position, layering, and poor settlement effect, and achieve enhanced stirring effect, high uniformity, and improved stirring intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

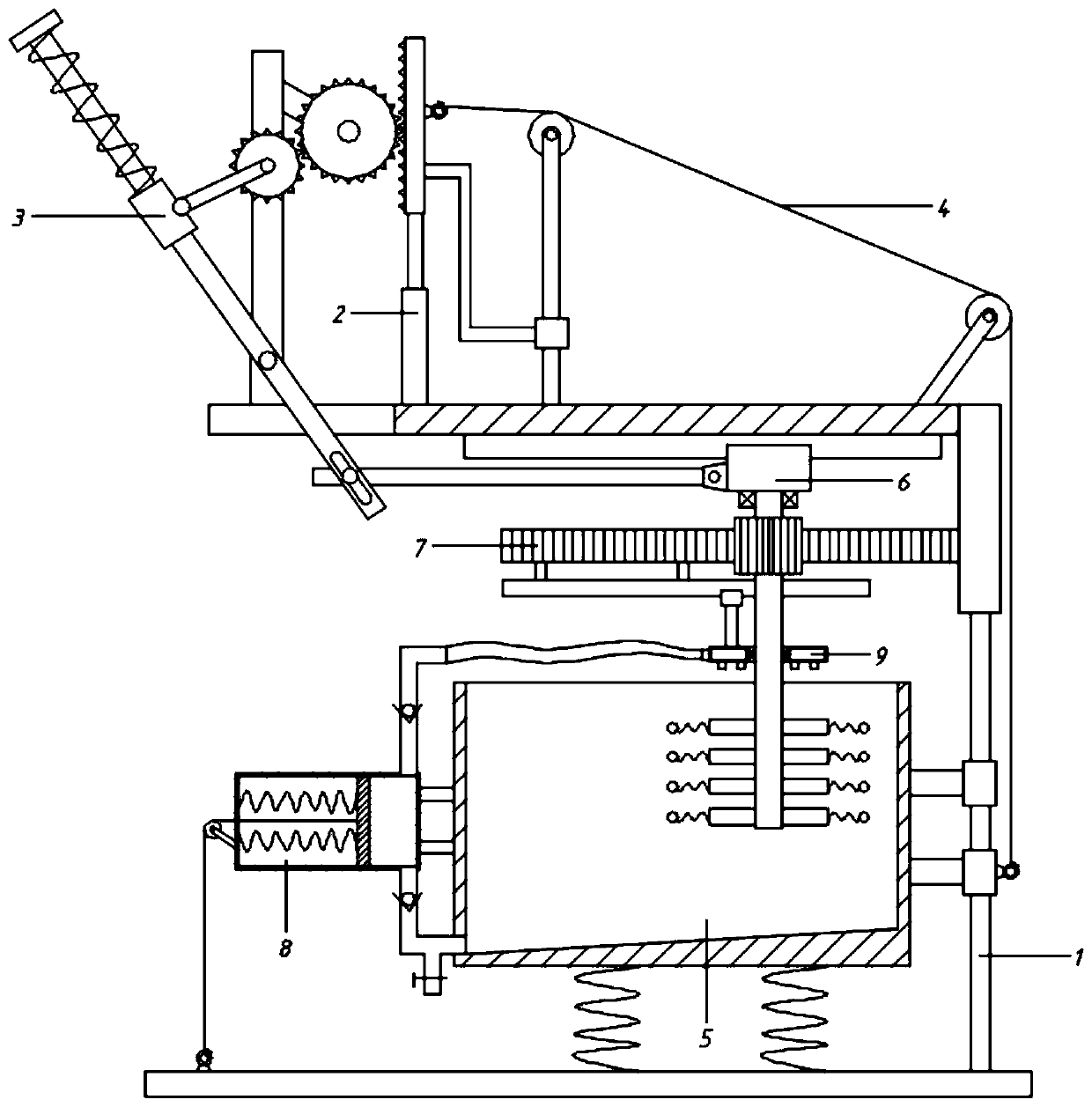

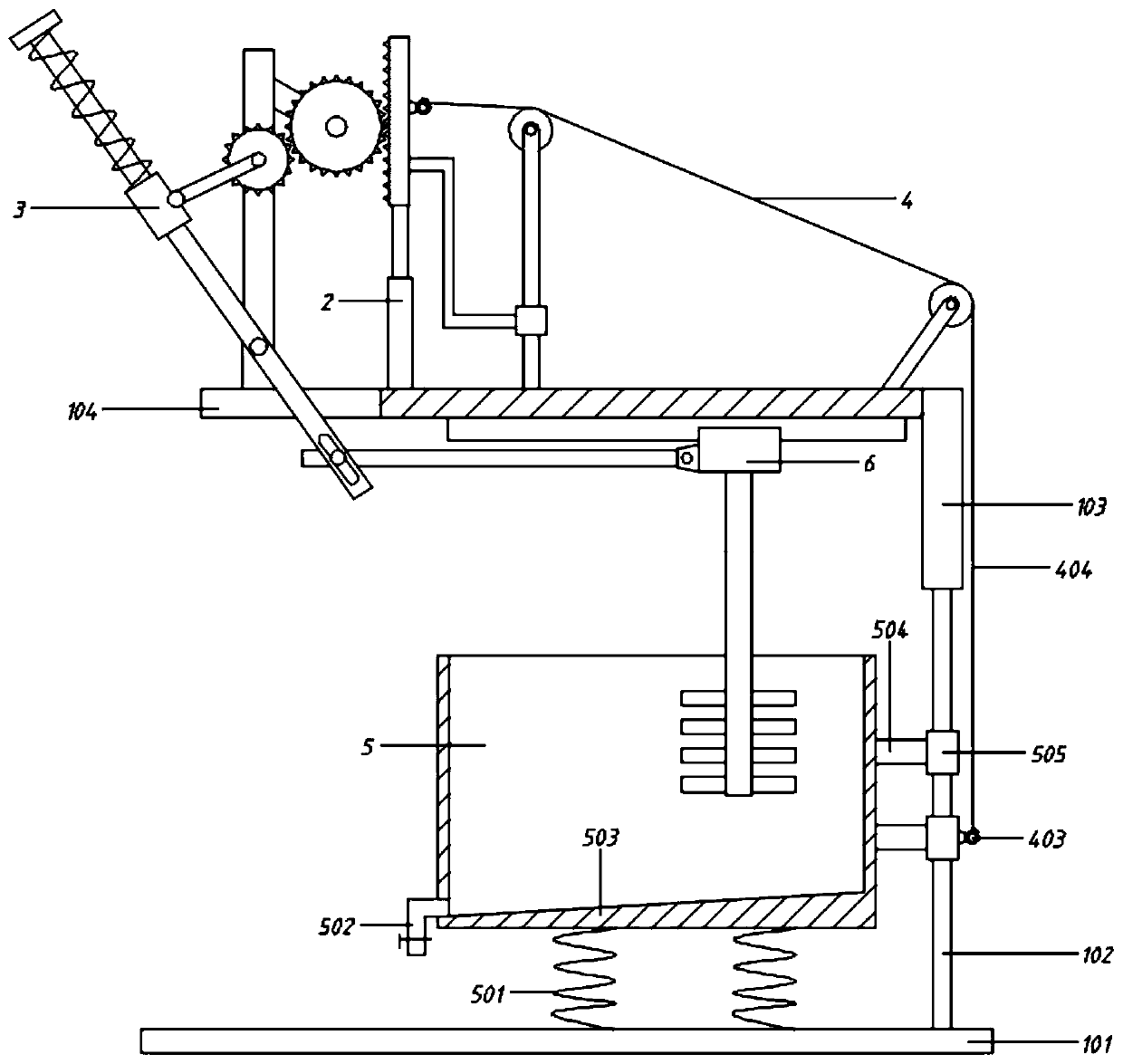

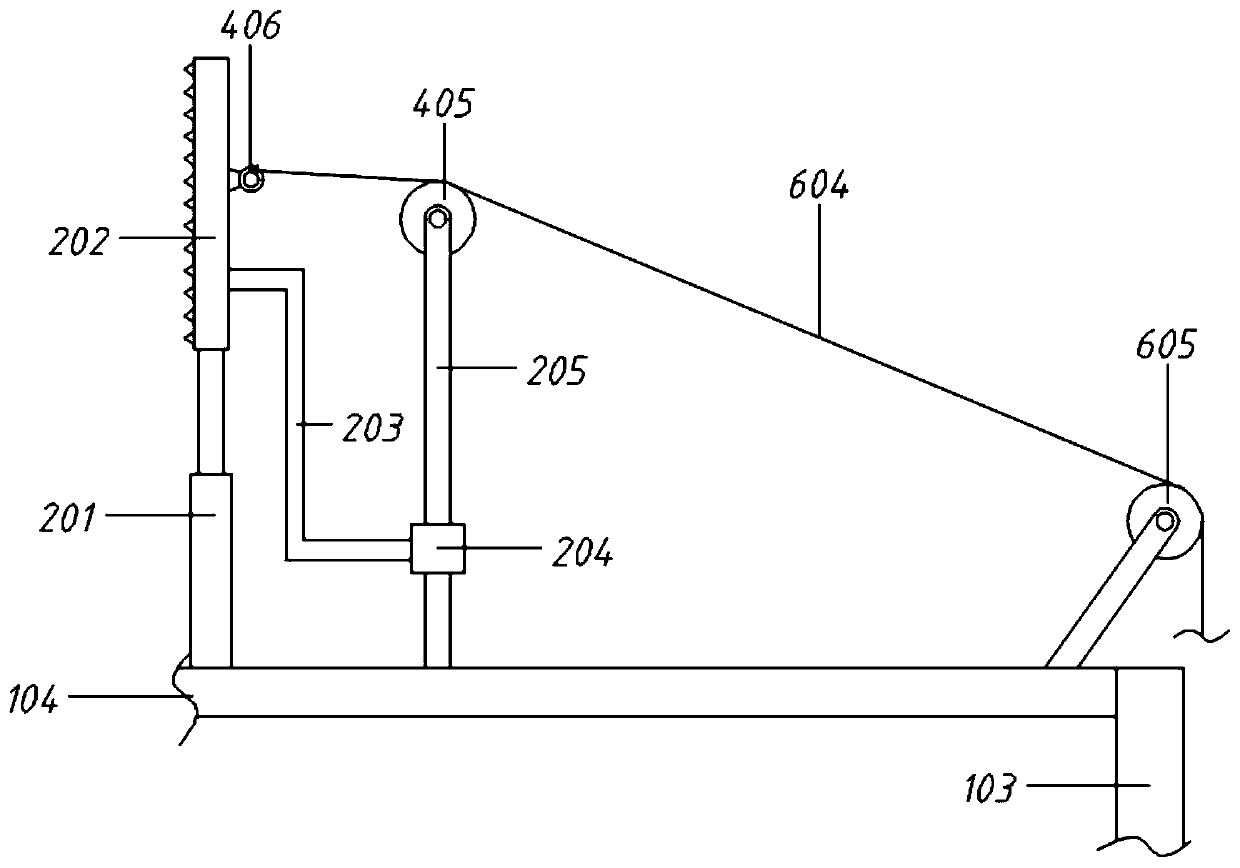

[0060] With reference to the accompanying drawings, a blending device for the production of fermented milk tea with high uniformity includes a frame 1, a telescopic assembly 2, a swing assembly 3, a lifting assembly 4 and a stirring assembly 6;

[0061] Frame 1 comprises base 101, slide bar 102, side plate 103, top plate 104 and preparation box 5, and base 101 right end is vertically connected with slide bar 102, and slide bar 102 top is connected with vertical side plate 103, and side plate 103 top is to The left side is connected with a top plate 104; the preparation box 5 is arranged above the base 101, and a support spring 501 is connected between its bottom and the base 101; the right side of the preparation box 5 is connected with a No. 3 sliding sleeve 505 through a No. 505 fits with the slide bar 102; the telescopic assembly 2 is arranged on the left part of the top plate 104, the swing assembly 3 is arranged on the left side of the telescopic assembly 2, and the liftin...

Embodiment 2

[0063] With reference to the accompanying drawings, a blending device for the production of fermented milk tea with high uniformity includes a frame 1, a telescopic assembly 2, a swing assembly 3, a lifting assembly 4 and a stirring assembly 6;

[0064] Frame 1 comprises base 101, slide bar 102, side plate 103, top plate 104 and preparation box 5, and base 101 right end is vertically connected with slide bar 102, and slide bar 102 top is connected with vertical side plate 103, and side plate 103 top is to The left side is connected with a top plate 104; the preparation box 5 is arranged above the base 101, and a support spring 501 is connected between its bottom and the base 101; the right side of the preparation box 5 is connected with a No. 3 sliding sleeve 505 through a No. 505 fits with the slide bar 102; the telescopic assembly 2 is arranged on the left part of the top plate 104, the swing assembly 3 is arranged on the left side of the telescopic assembly 2, and the liftin...

Embodiment 3

[0079] On the basis of embodiment 2,

[0080] It also includes a rotating assembly 7; the rotating assembly 7 includes a second rack 701 and a driven gear 702, a telescopic spring 607 and a small ball 608;

[0081] The second rack 701 is horizontally arranged below the No. 1 slide block 602, and the right end is fixedly connected to the side plate 103; the top of the stirring shaft 605 is rotationally connected with the No. 1 slide block 602; The moving gear 702 meshes with the second rack 701; the outer end of the stirring rod 606 is connected with a small ball 608 through a telescopic spring 607.

[0082] Specifically, while the No. 1 slider 602 moves left and right with the stirring shaft 605, the driven gear 702 is driven by the No. 2 rack 701, so that the stirring shaft 605 rotates with the stirring rod 606 to improve the stirring intensity; the telescopic spring 607 drives the small ball 608 to shake along with the rotation of the stirring rod 606, which enhances the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com