Fusing and mixing device

A technology of fusion mixing and guide tube, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of reduced diameter of stirring blade, reduced stirring intensity, and reduced tangential speed, etc., to reduce heat loss, strengthen mixing, and save energy. The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

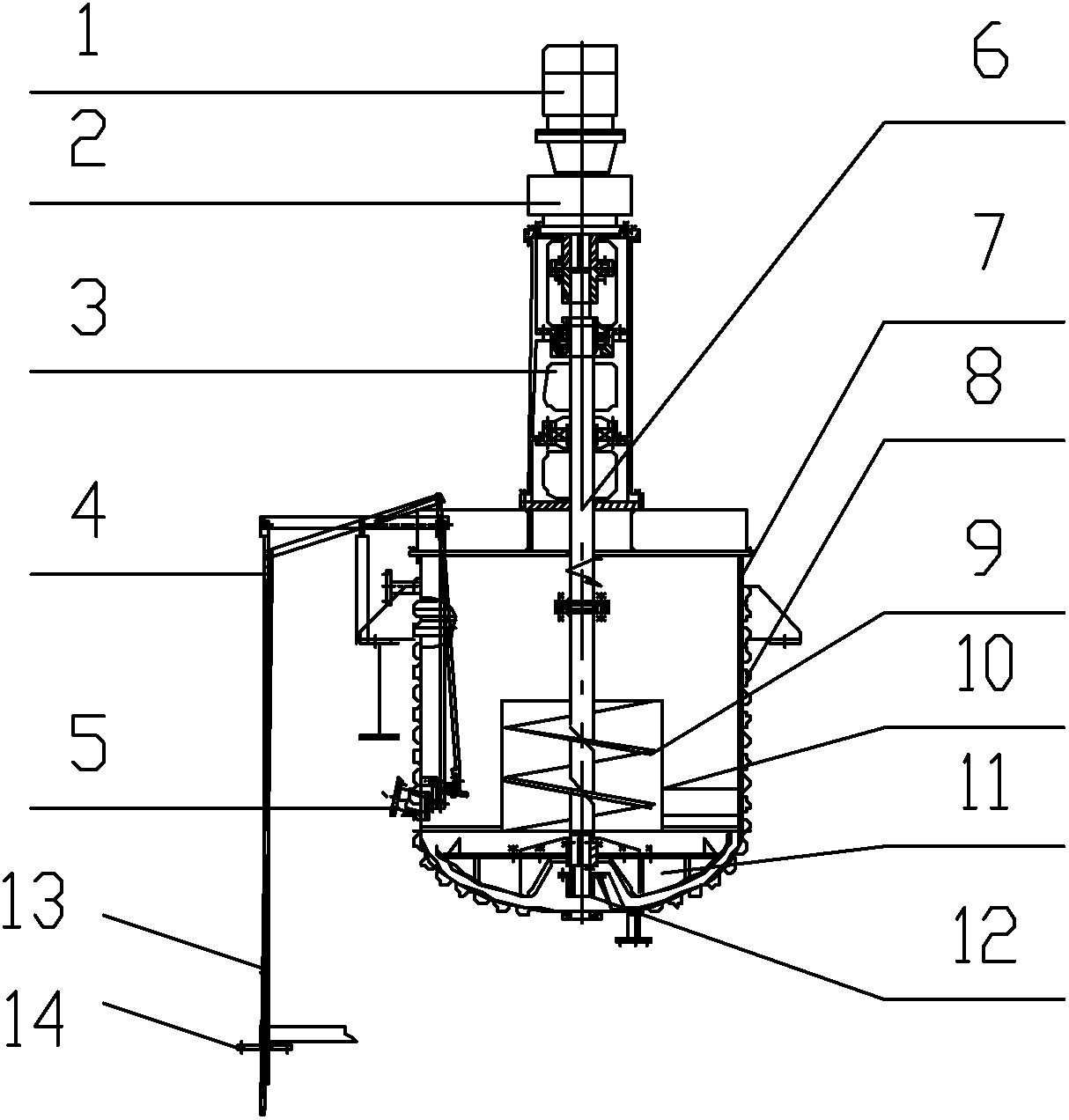

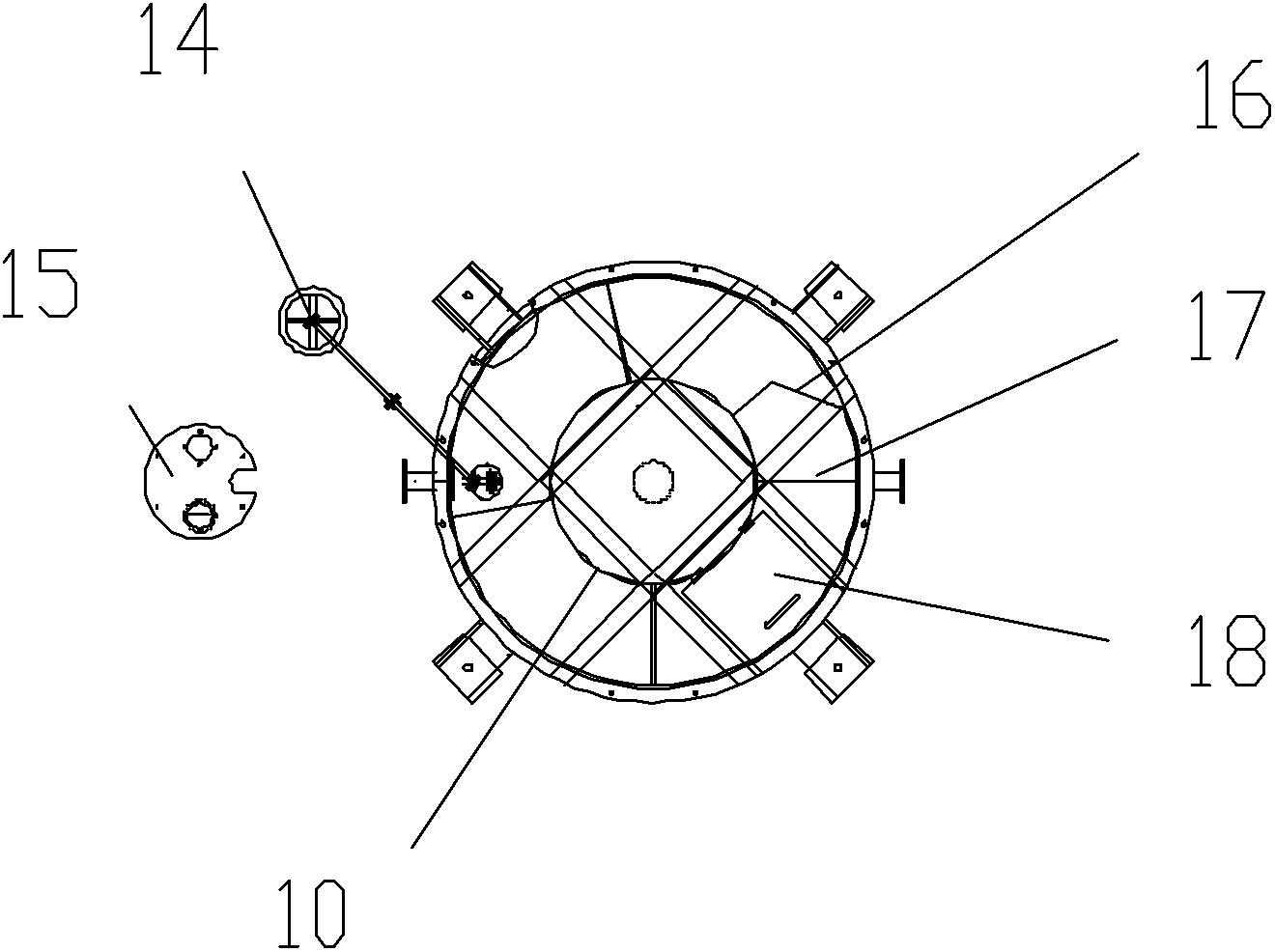

[0033] A melting and mixing device includes a transmission device, a pot cover, a discharge valve assembly, a discharge pipe, a stirring shaft, a pot body, an external heat preservation device, a stirring device and a shaft sleeve.

[0034] The stirring device includes a screw stirring paddle and a guide tube, and the guide tube is a hollow cylindrical body which is sheathed outside the screw stirring paddle and has upper and lower openings.

[0035] The rotating device includes a transmission motor 1 , a reducer 2 and a reducer support 3 .

[0036]An explosion-proof transmission motor 1 is mounted on a reducer 2 . The helical gear reducer 2 is installed on the reducer support 3, and the double fulcrum type reducer support 3 is fixed on two channel steels on the pot cover surface. The pot body 7 is made of thick 12mm304 stainless steel, and the bottom of the pot uses an elliptical head. The diameter of the pot body is 1.8m, and the height of the pot body is 1.8m. Open a weld...

Embodiment 2

[0040] A melting and mixing device includes a transmission device, a pot cover, a discharge valve assembly, a discharge pipe, a stirring shaft, a pot body, an external heat preservation device, a stirring device and a shaft sleeve.

[0041] The stirring device includes a screw stirring paddle and a guide tube, and the guide tube is a hollow cylindrical body which is sheathed outside the screw stirring paddle and has upper and lower openings.

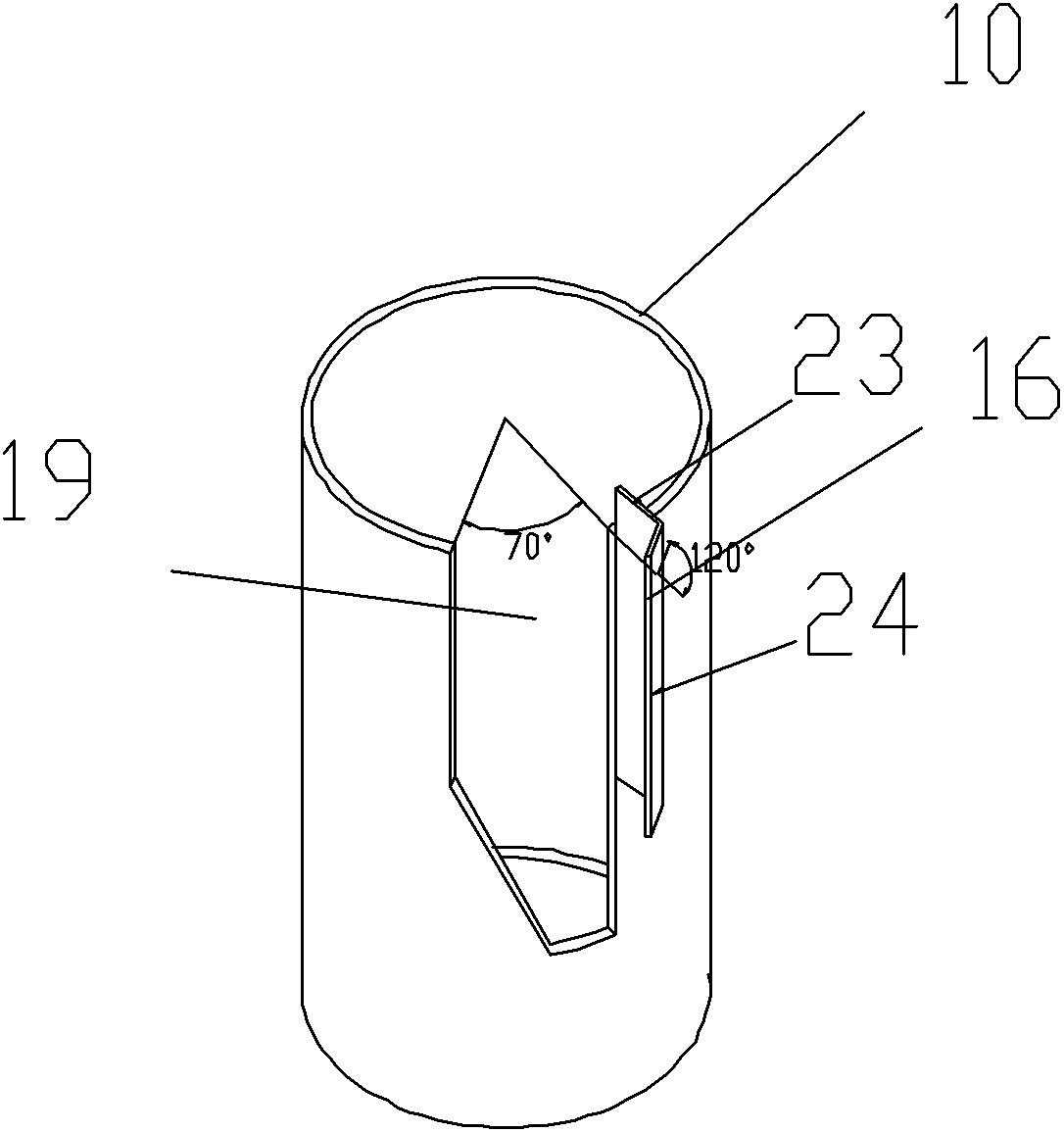

[0042] A notch extending downward from the upper edge of the draft tube is provided on the tube wall of the draft tube, and the gap is located at the angle between the two end points of the upper edge of the draft tube and the center point of the upper edge of the draft tube. 60°. Other structures are the same as in Embodiment 1.

[0043] Through the implementation of the invention, heat loss can be reduced by 8%-13%, electric energy can be saved by 7%-16%, construction cost can be saved by 15%-30%, and production capacity can be increa...

Embodiment 3

[0045] A melting and mixing device includes a transmission device, a pot cover, a discharge valve assembly, a discharge pipe, a stirring shaft, a pot body, an external heat preservation device, a stirring device and a shaft sleeve.

[0046] The stirring device includes a screw stirring paddle and a guide tube, and the guide tube is a hollow cylindrical body which is sheathed outside the screw stirring paddle and has upper and lower openings.

[0047] A notch extending downward from the upper edge of the draft tube is provided on the tube wall of the draft tube, and the gap is located at the angle between the two end points of the upper edge of the draft tube and the center point of the upper edge of the draft tube. 80°. Other structures are the same as in Embodiment 1.

[0048] Through the implementation of the invention, heat loss can be reduced by 7%-12%, electric energy can be saved by 8%-18%, construction cost can be saved by 15%-30%, and production capacity can be increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com