Safety blowout preventer for oilfield wellhead

A blowout preventer, safe technology, used in isolation devices, wellbore/well components, springs/shock absorbers, etc., to solve problems such as fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

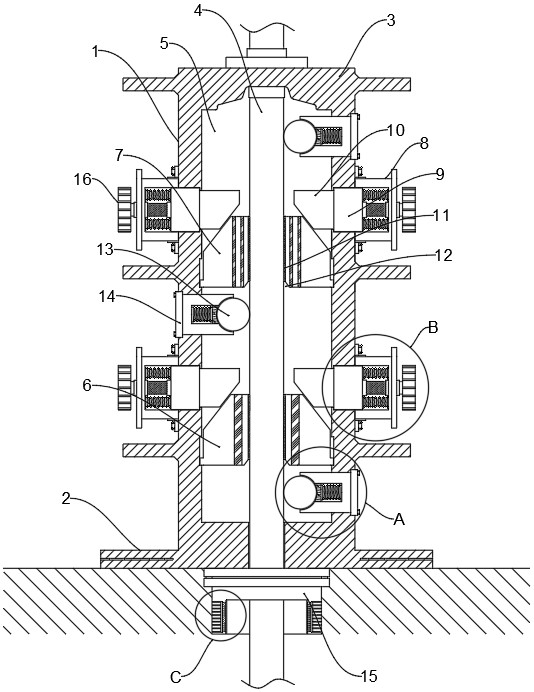

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

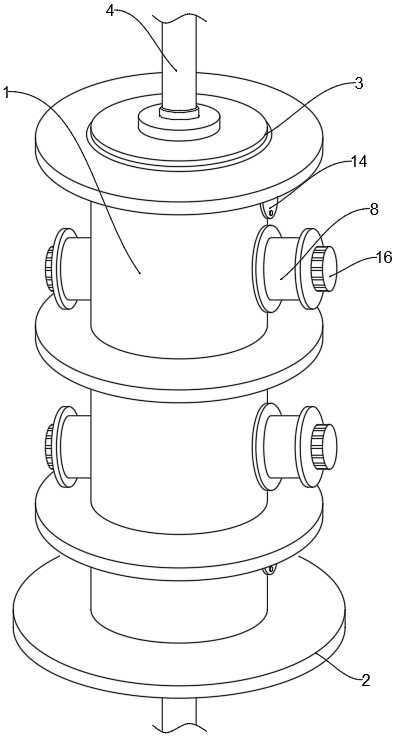

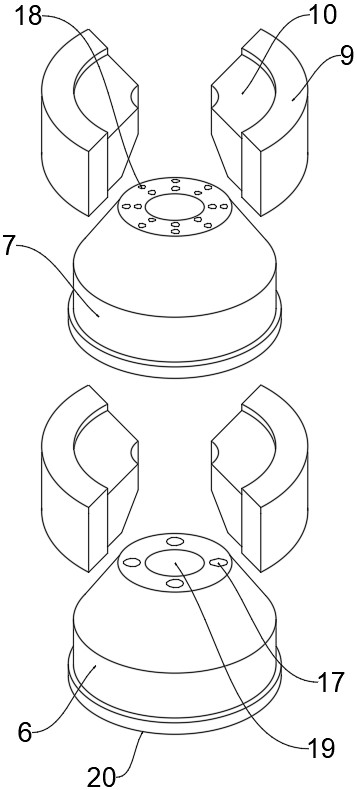

[0027] see Figure 1-7 , an embodiment provided by the present invention: an oil field wellhead safety blowout prevention device, including a mounting joint 2, the upper end of the mounting joint 2 is integrally provided with a casing 1, and a sealing cover 3 is installed on the upper end of the casing 1, and the sealing cover The plate 3 and the shell 1 are sealed and fixed by bolts. The inside of the shell 1 is provided with a blowout prevention and pressure relief chamber 5. The lower end of the blowout prevention pressure relief chamber 5 is installed with a first polished rod fixing seat 6. The second polished rod holder 7, the middle position inside the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com