Heat sink wall panel structure arrangement for increasing absorption of plume gas

A technology of gas adsorption and structural layout, which is applied in the testing of machines/structural components, testing of engines, measuring devices, etc. It can solve problems such as differences in the capture rate of gas molecules on helium plates, and achieve high plume adsorption efficiency and high pumping speed , the effect of increasing the capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

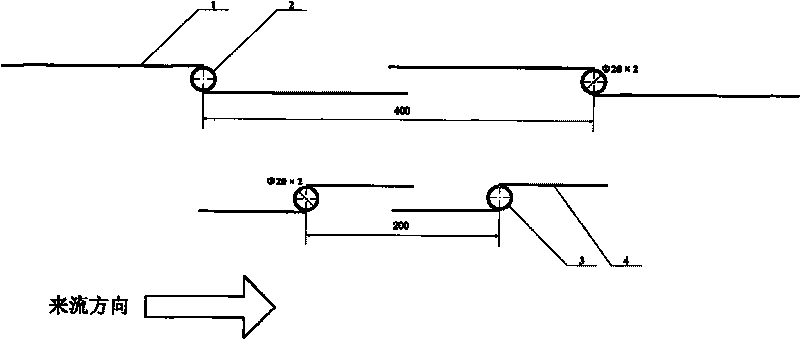

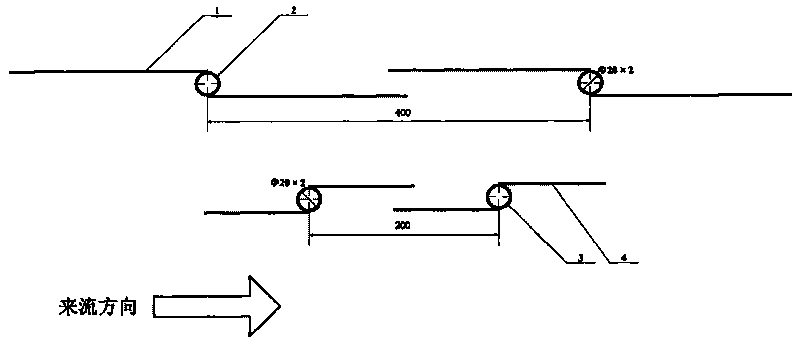

[0014] figure 1 The heat sink wall plate used for the plume test is mainly composed of liquid nitrogen heat sink fins (1), liquid nitrogen heat sink branch pipes (2), liquid helium heat sink branch pipes (3), liquid helium heat sink fins ( 4) Composition, the commonly used wall panels are welded by copper fins and stainless steel branch pipes, in which liquid nitrogen or liquid helium refrigeration medium is passed through the stainless steel branch pipes.

[0015] The distance between the stainless steel tubes of the liquid nitrogen heat sink is 400mm, and the size of the stainless steel tubes is Φ20×2; the distance between the stainless steel tubes of the liquid helium heat sink is 200mm, and the size of the stainless steel tubes is Φ20×2. The size form of the heat sink wall plate can ensure the uniformity of the heat sink temperature and meet the experimental requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com