Novel coke tower and needle coke production method

A production method and coking tower technology, applied in the field of needle coke preparation, to achieve good viscosity reduction and lubrication effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

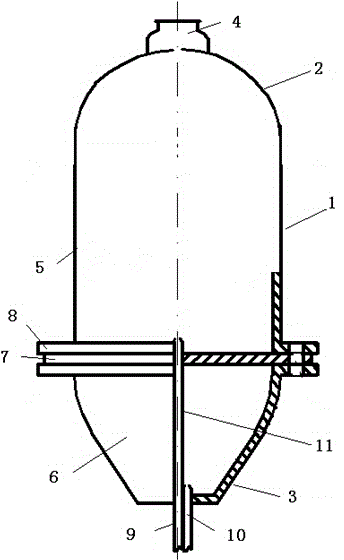

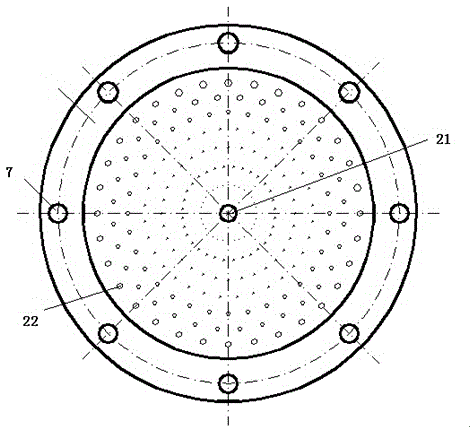

[0039] The fresh raw oil mixed with circulating oil enters the coking section 5 of the delayed coking tower from the upper feeding port 9 after being heated by the coking heating furnace; the other circulating oil also enters the delayed coking tower from the lower feeding port 10 after being heated by the coking heating furnace The packing section 6, and the circulating oil enters the coking section 5 through the mesh 21 on the baffle plate 7. The coking heating furnace is controlled by a variable temperature program. The initial temperature is 430°C for 4 hours, and then the temperature is raised to 470°C at a rate of 4°C / h. The mass of the circulating oil is 20%, that is, the circulation ratio is 0.5 at this time, and the pressure at the top of the delayed coking tower is 1.5MPa; the feed is fed at a constant temperature at 470°C for 4 hours, and the mass of the circulating oil in the lower feed port 10 is raised to 50% at the same time , that is, the circulation ratio is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com