Patents

Literature

84results about How to "Play a role in dispersing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

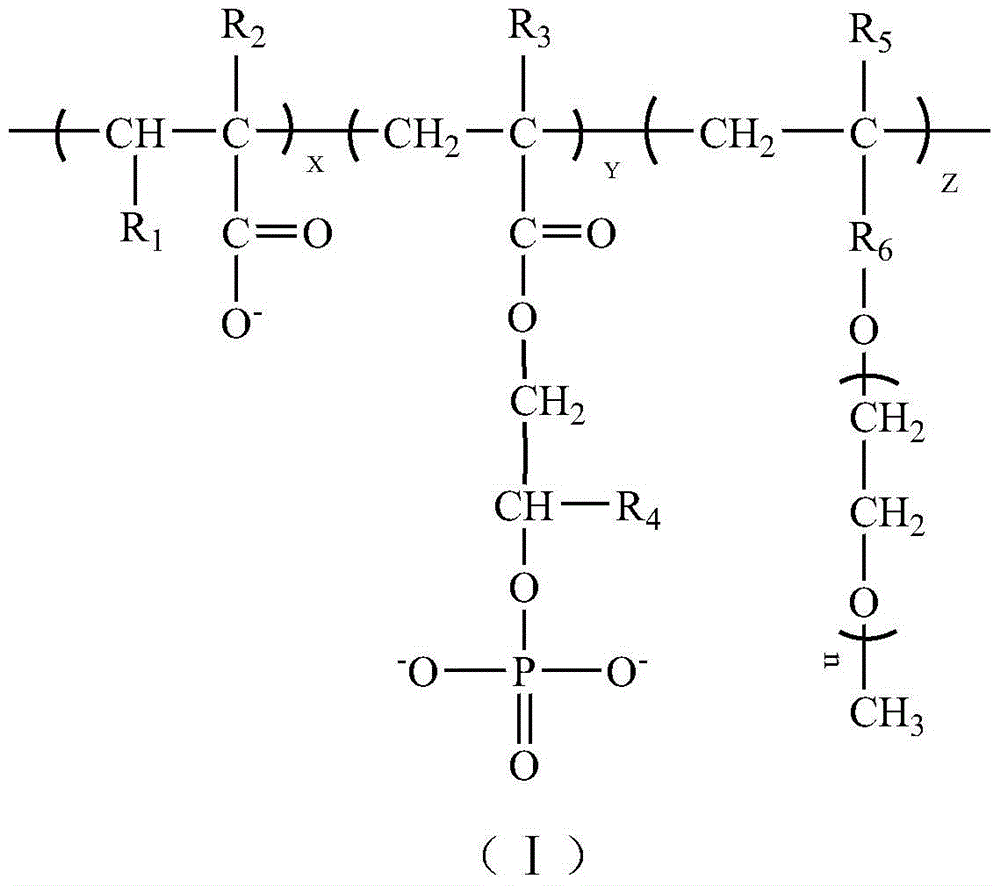

High-performance polycarboxylate water reducing agent and preparation method thereof

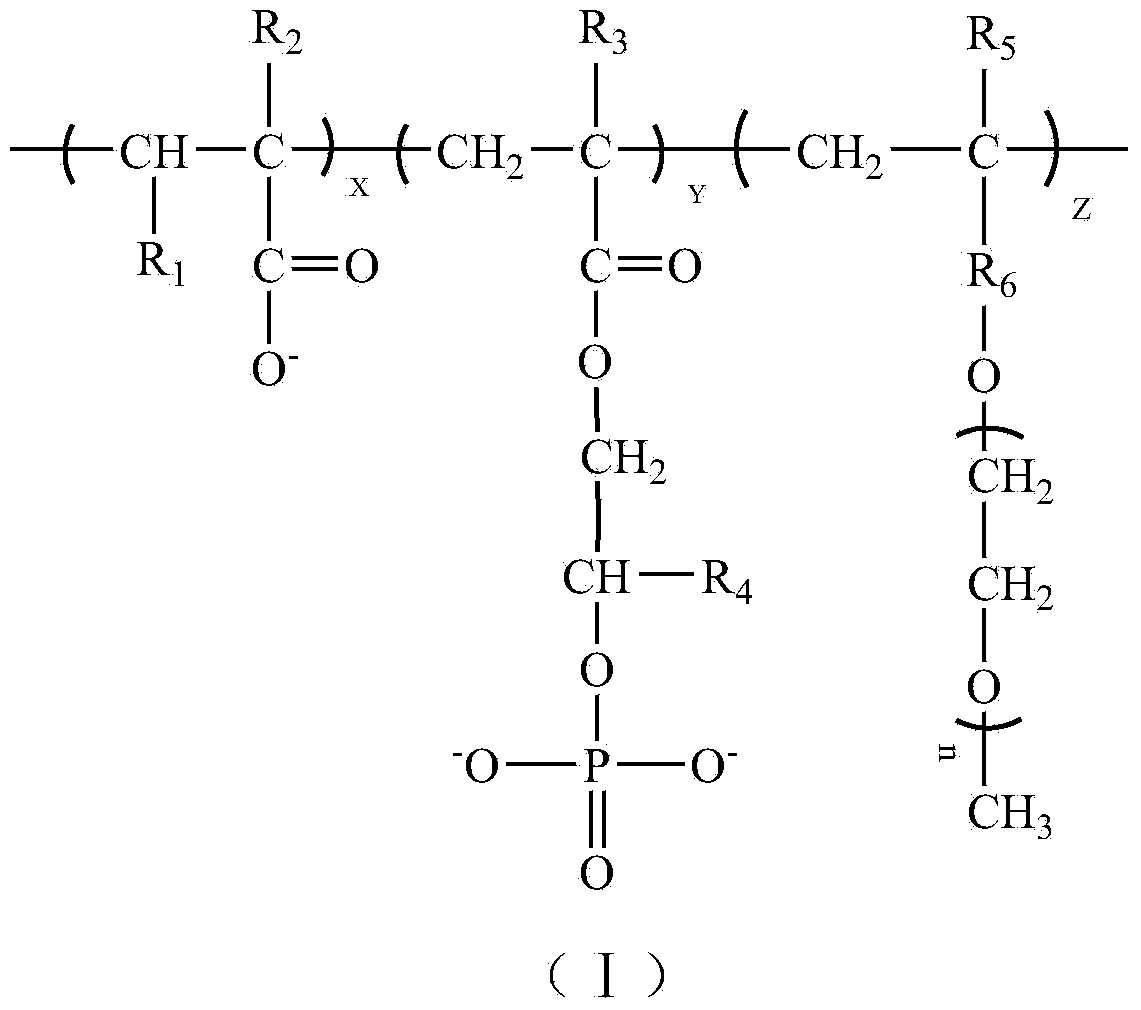

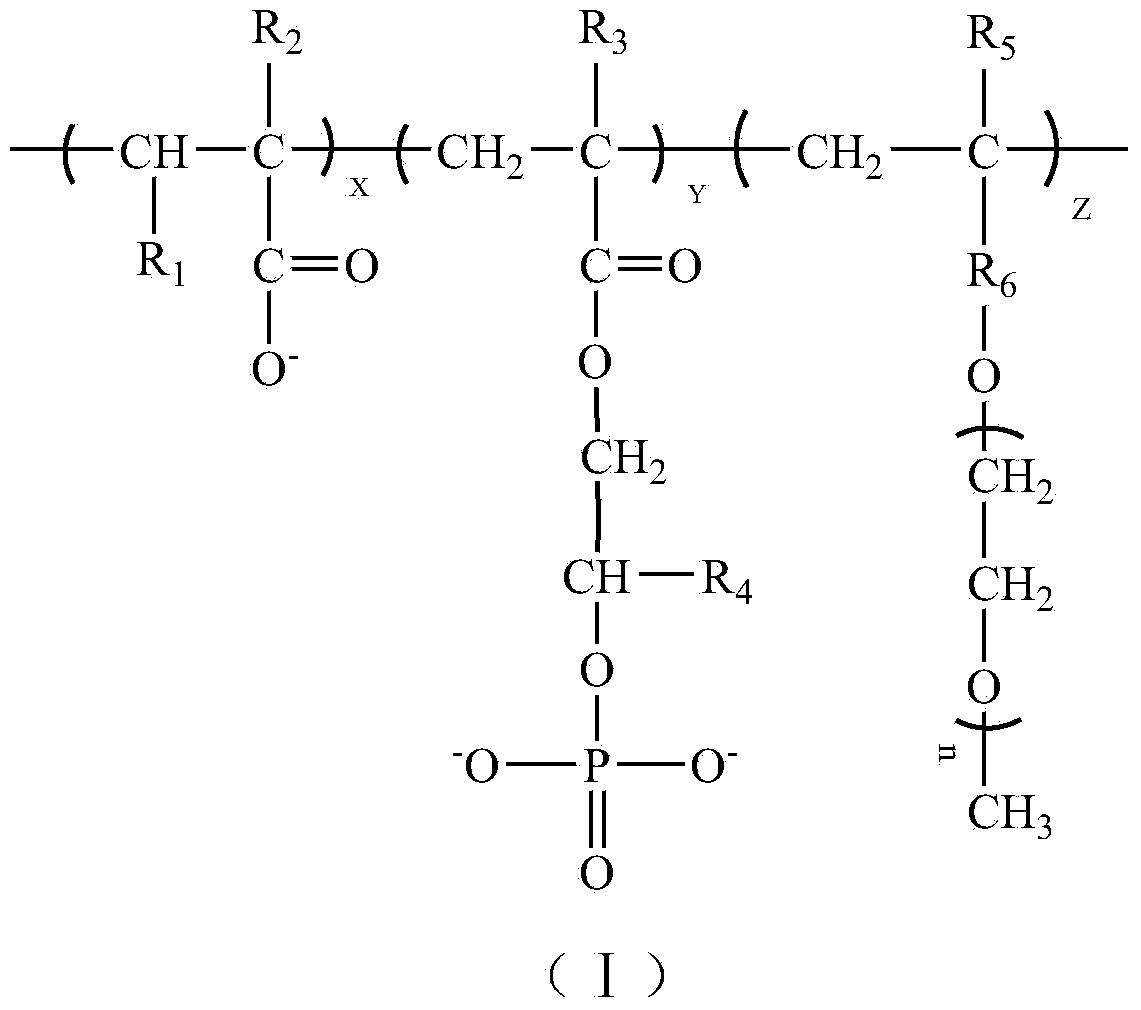

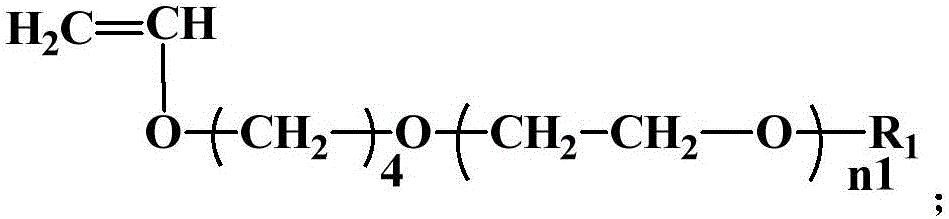

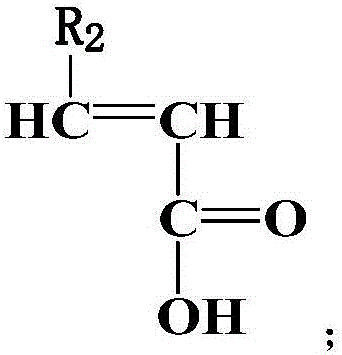

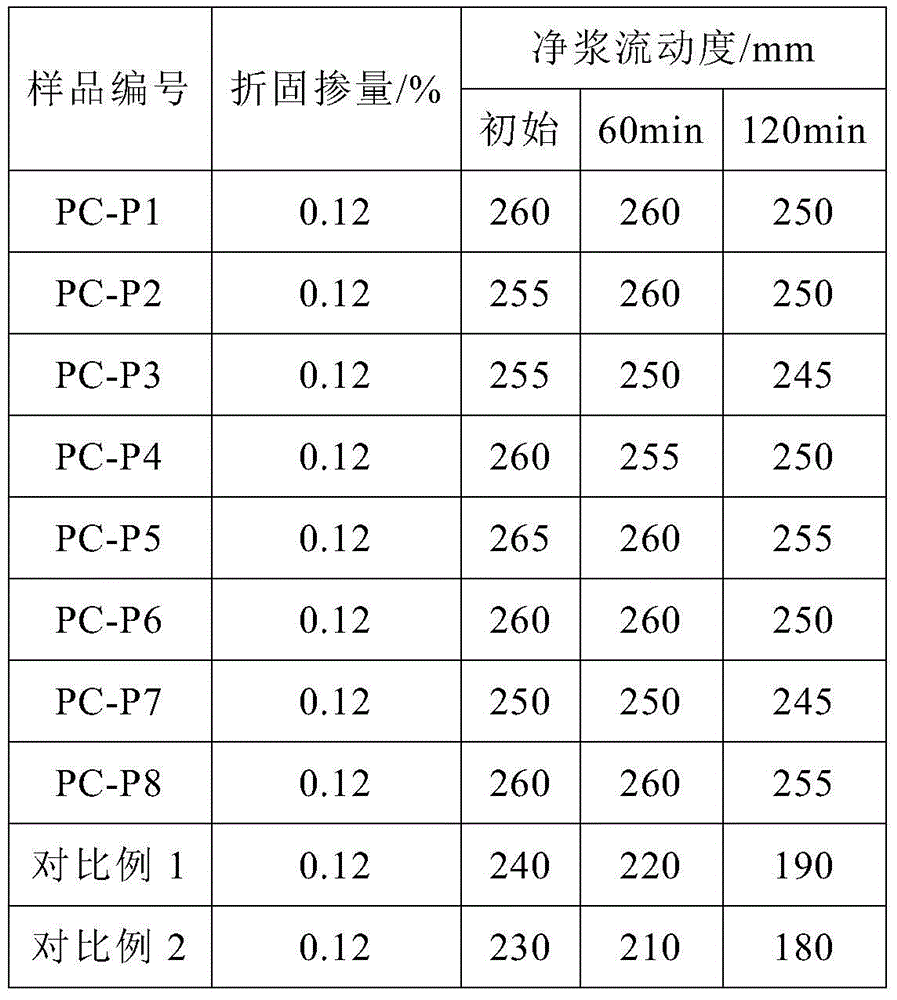

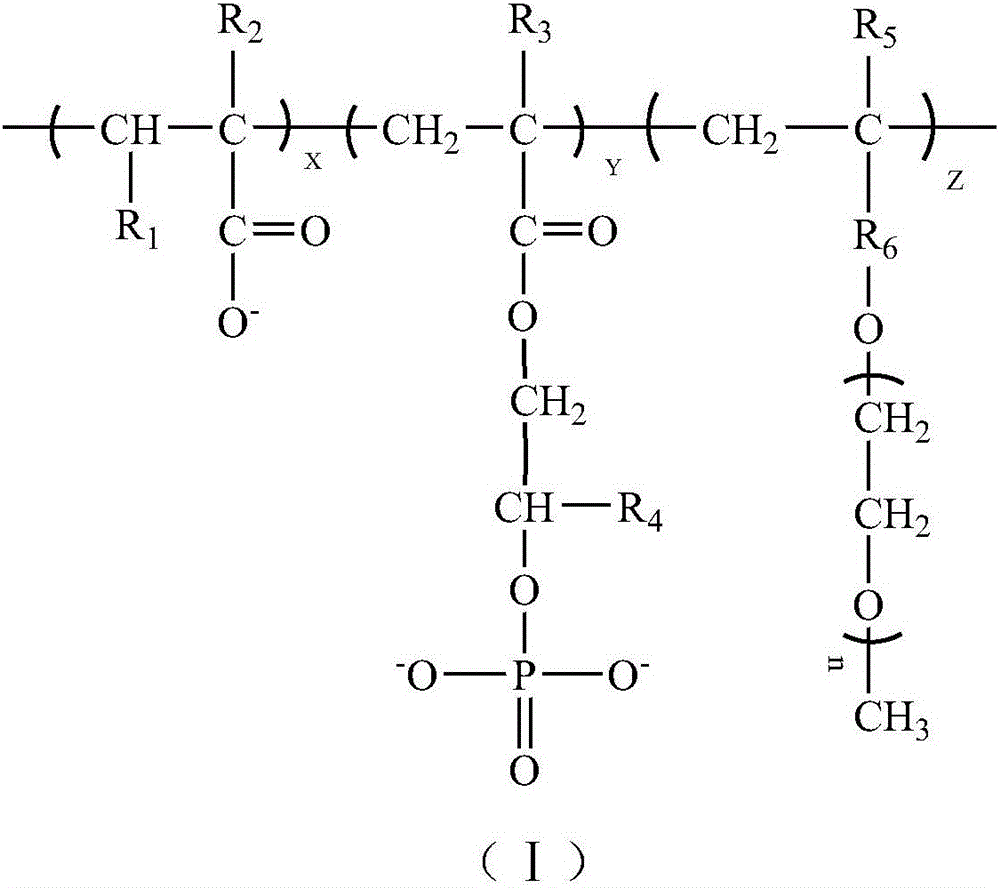

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and preparation method thereof

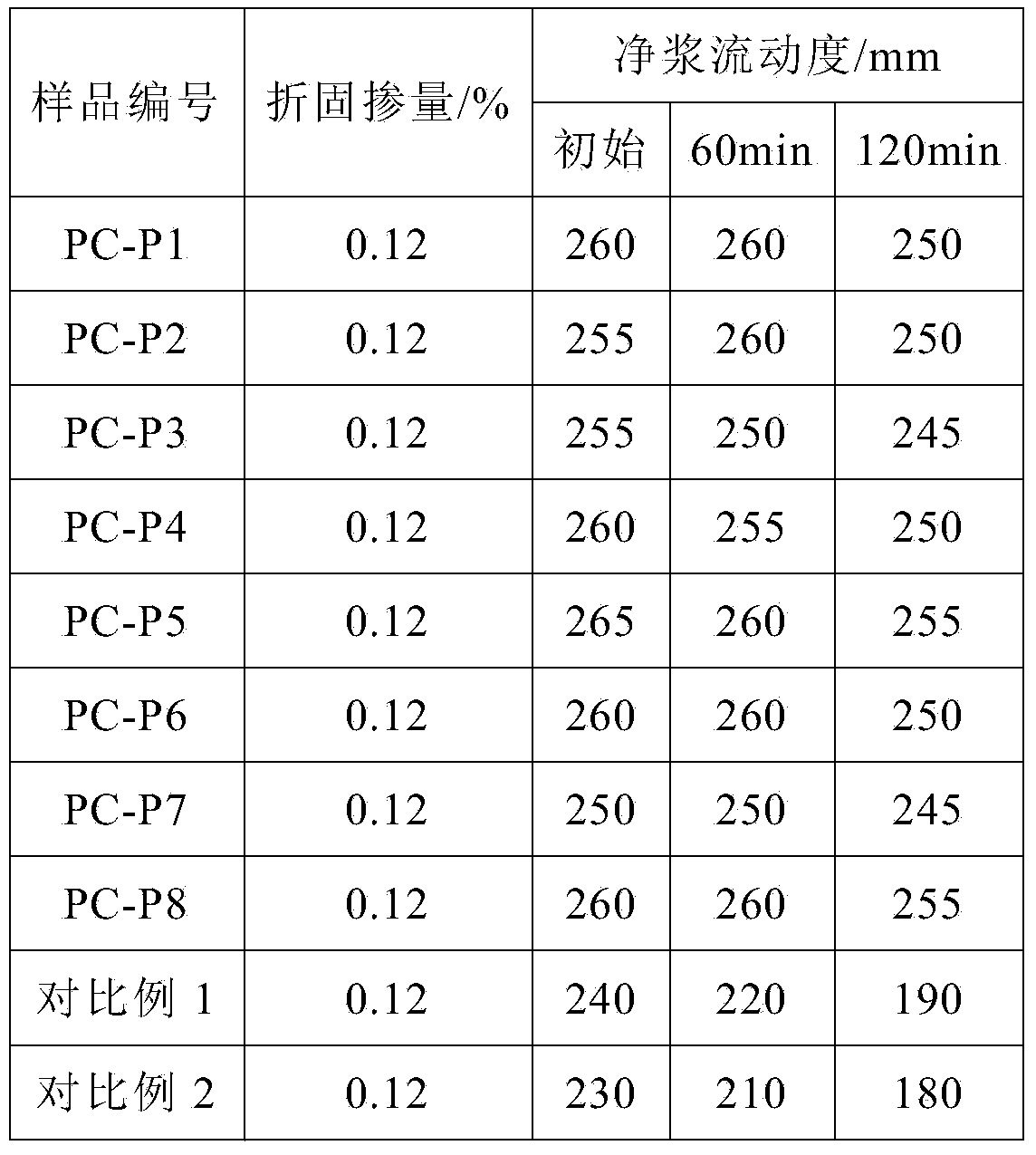

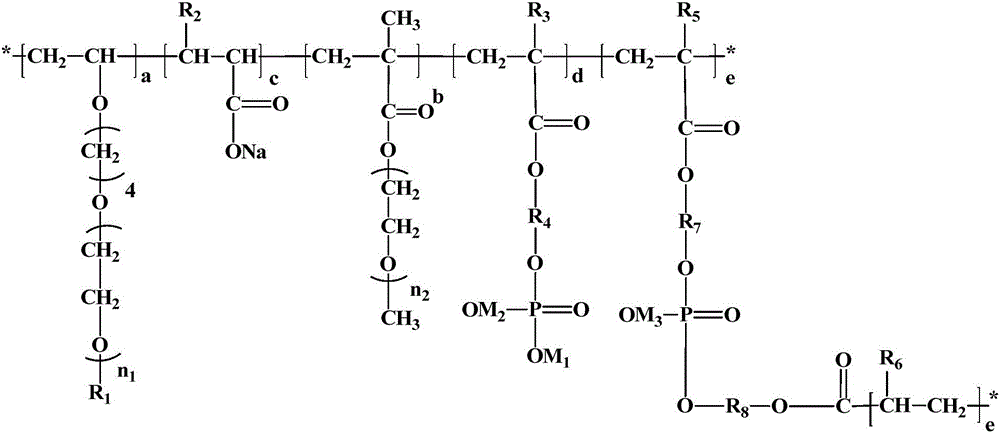

ActiveCN106046269AEven distribution of side chainsImprove workabilityPolymer sciencePhosphomonoesters

The invention discloses a crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and a preparation method thereof. The crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer has the number-average molecular weight of 10000-100000 and has a structural formula as shown in the specification. Under the synergistic effect of various groups, the polycarboxylate superplasticizer formed by copolymerization of 4-hydroxybutyl-vinyl polyoxyethylene ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester has the advantages of high water-reducing rate, high slump loss resistance, high peaceability, mud-resistant property and low dosage sensibility.

Owner:KZJ NEW MATERIALS GROUP CO LTD

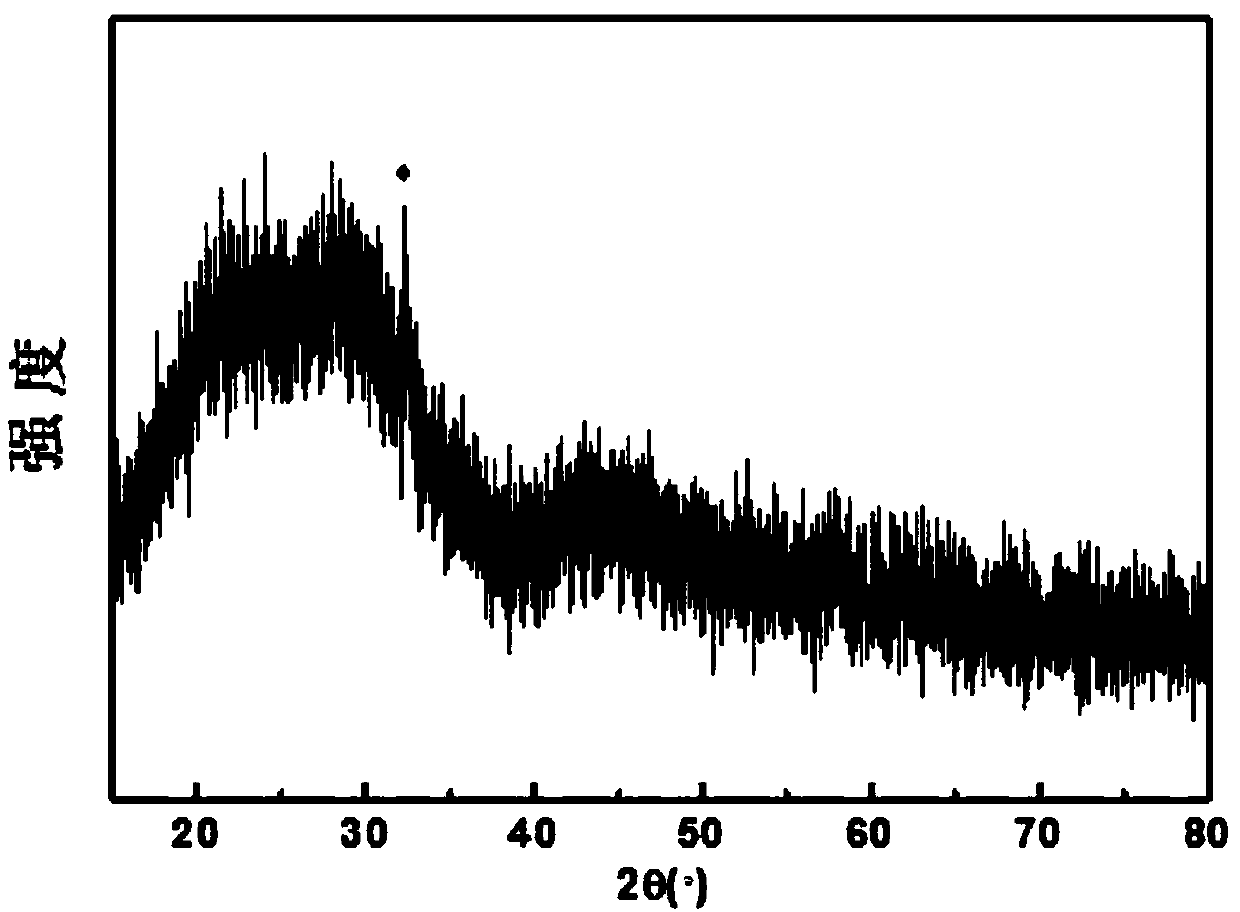

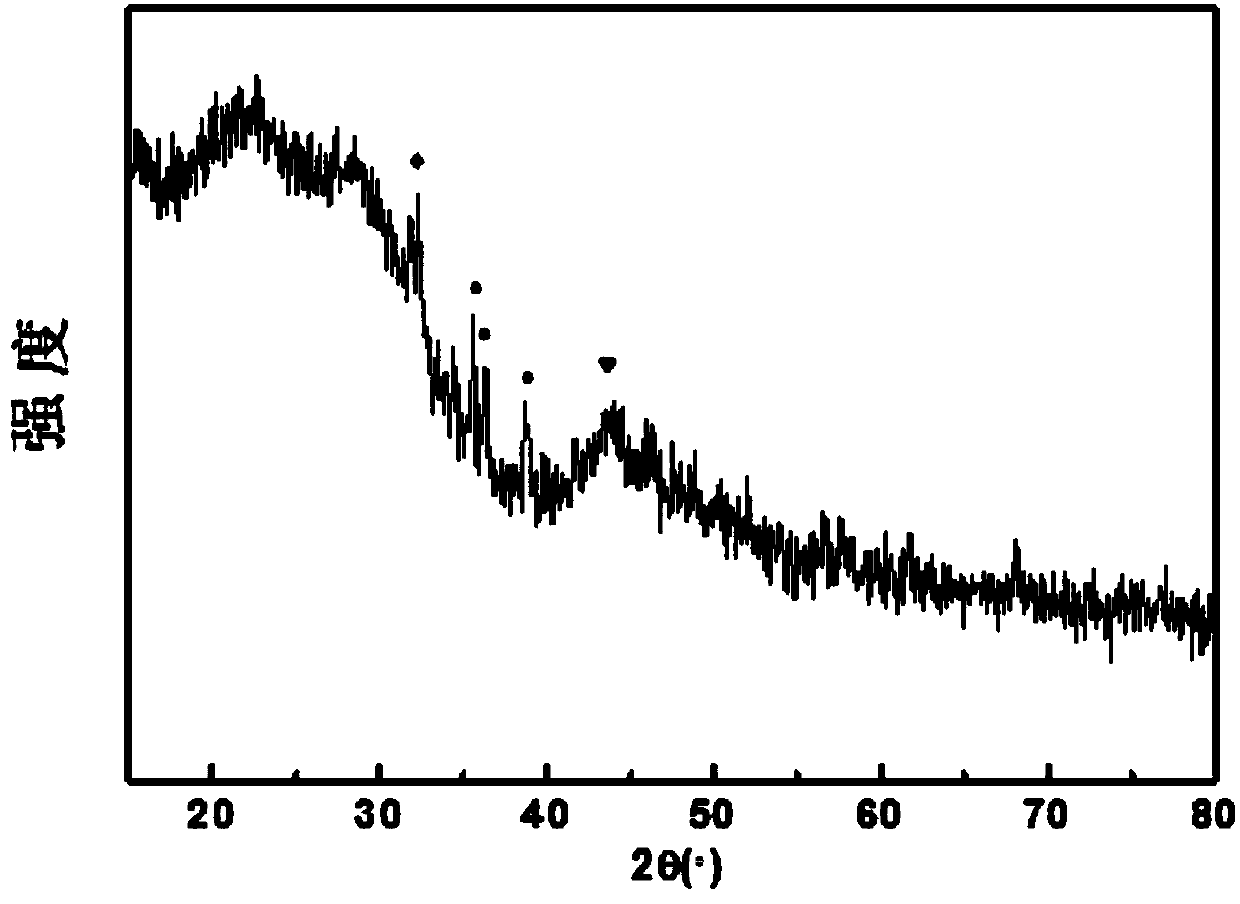

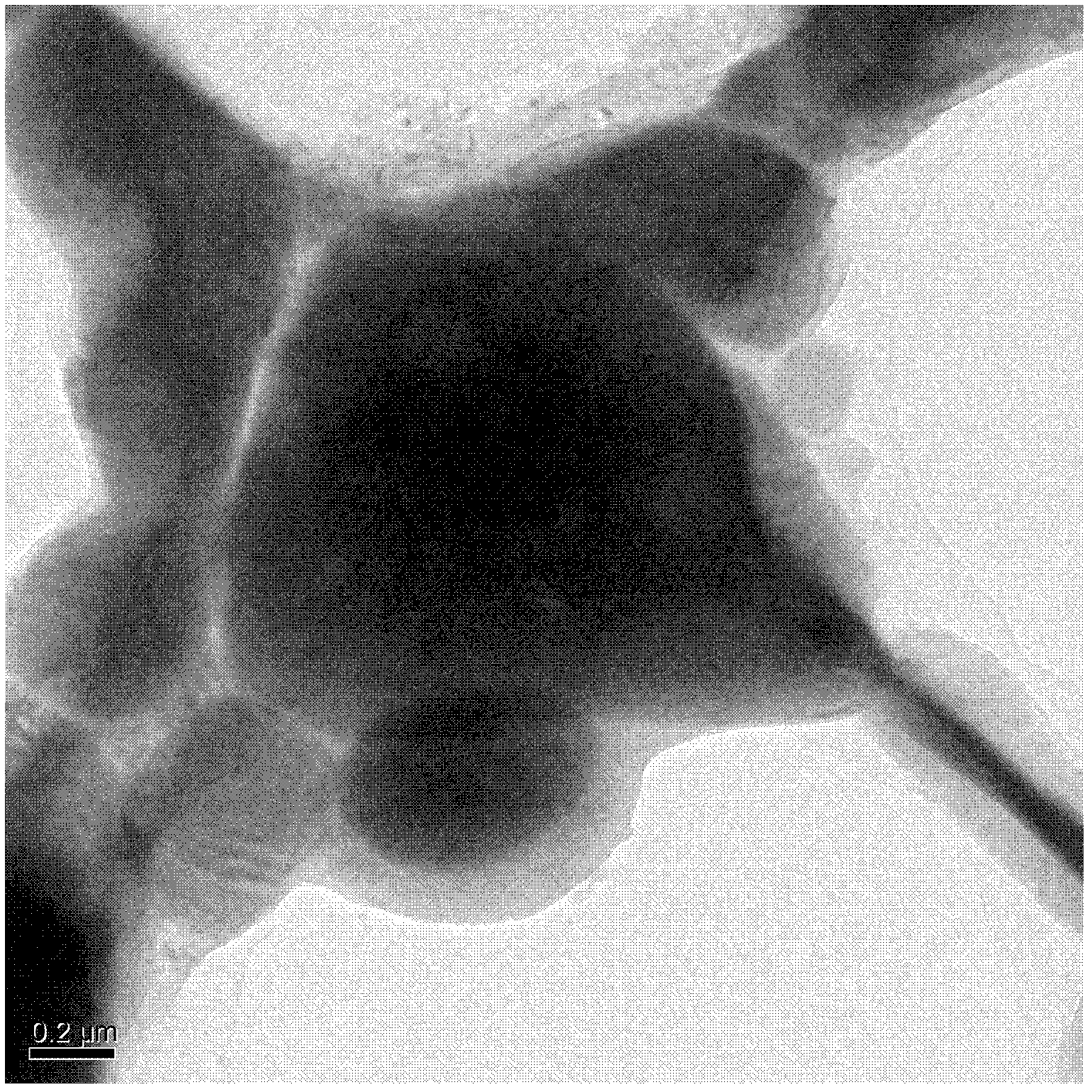

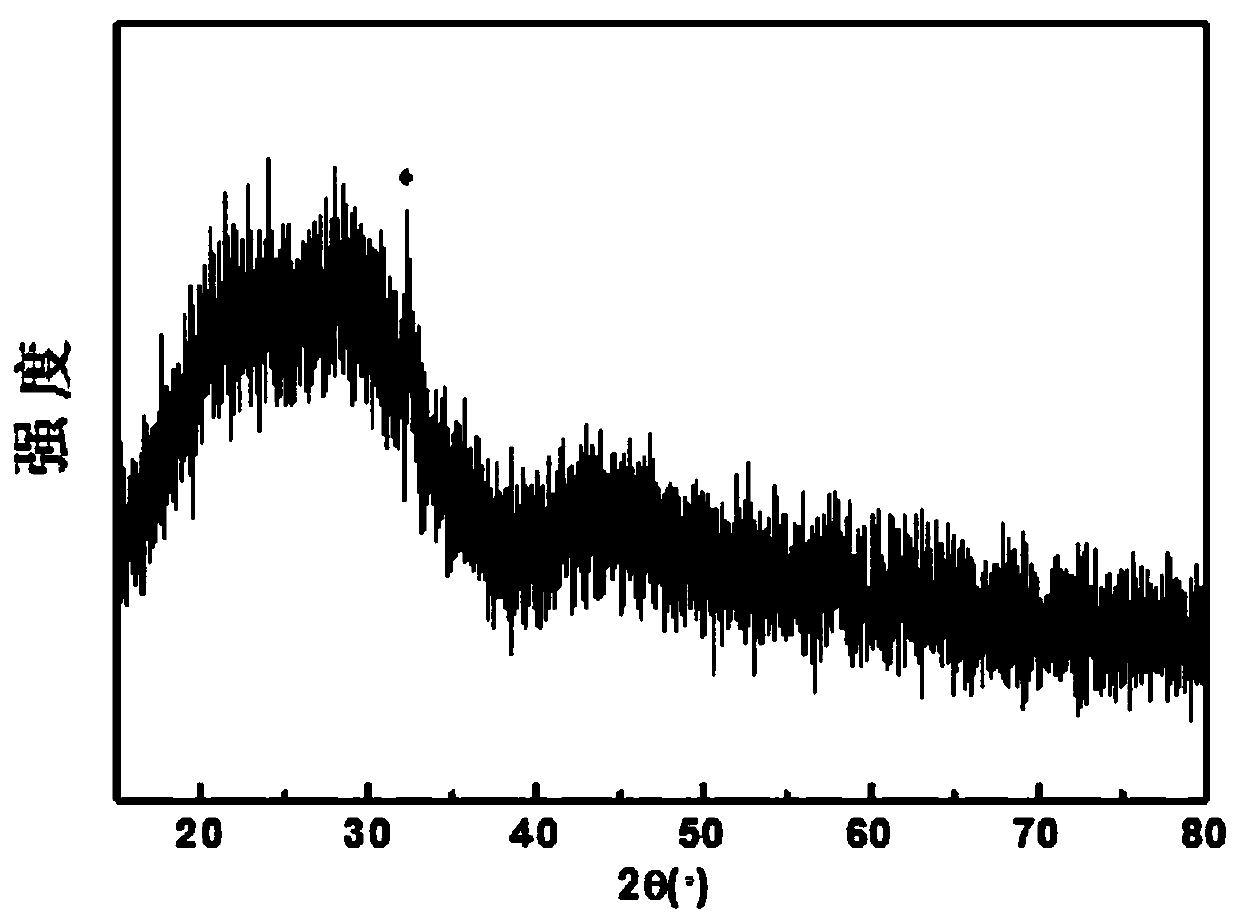

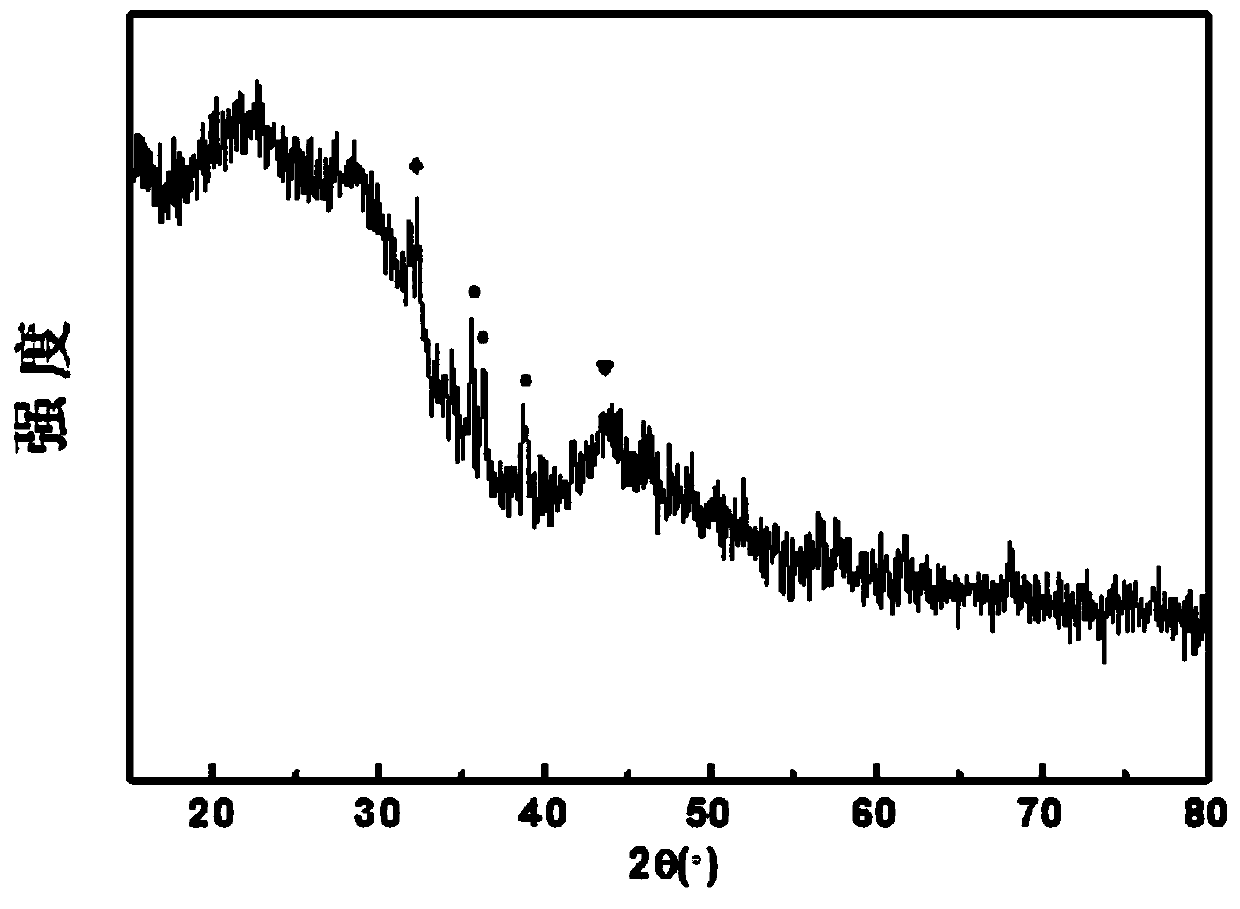

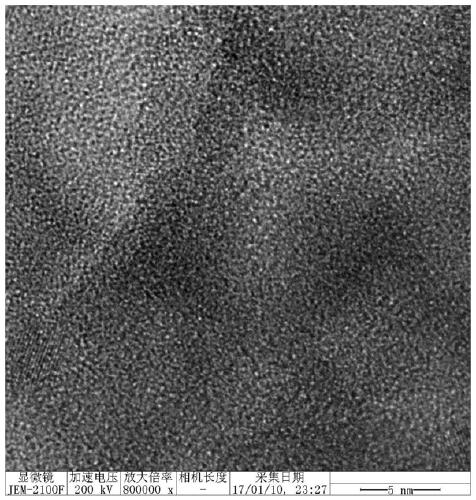

Platinum based catalyst highly dispersed in carrier silicon dioxide as well as preparation method and application thereof

InactiveCN108067249ANot easy to aggregate and sinterImprove stabilityHeterogenous catalyst chemical elementsCatalystsDehydrogenationSilicon dioxide

The invention discloses a Pt based catalyst highly dispersed in a carrier SiO2 as well as a preparation method and application thereof. The catalyst takes SiO2 as the carrier, takes metal Pt as an active component, and takes NiO, La2O3 and LaFeO3 as auxiliaries; based on the total mass of the catalyst, the Pt based catalyst is prepared from the following components in percentage by mass: 0.1-0.3%of metal Pt, 0.05-4% of NiO, 0.25-9.0% OF La2O3, 17.0-30.0% of LaFeO3 and 55.0-85.0% of SiO2, and the catalyst can be applied to isobutylene dehydrogenation. The selected SiO2 has a big specific surface area, so that each component can be highly dispersed, and therefore, the catalyst is not liable to gather and sinter; meanwhile, Pt is doped into a perovskite structure, so that the reduced Pt particles are small, and perovskite particles, lanthanum oxide particles and nickel oxide particles among the Pt particles achieve the dispersion effect as a result of the special structure of perovskite,and therefore, more active sites are exposed; and Pt is not liable to reunite at a high temperature, so that stability and reaction activity of the catalyst are improved.

Owner:TIANJIN UNIV

Polycarboxylic acid super-fluidifying agent synergist compounded composition and application thereof

The invention relates to the field of cement additives and provides a polycarboxylic acid super-fluidifying agent synergist compounded composition which is composed of polycarboxylic acid, alcohol amine and water, wherein the mass ratio of the polycarboxylic acid to the alcohol amine is 1:2-10 and the adding amount of the polycarboxylic acid is 0.02-0.12%. Because that the mass ratio of the polycarboxylic acid to the alcohol amine is 1:2-10, a compound problem of the polycarboxylic acid super-fluidifying agent with the alcohol amine can be solved successfully. By means of the polycarboxylic acid being less than the conventional use amount, wrapping of the polycarboxylic acid on the surface of cement granules can be reduced. By means of the alcohol amine being more than the conventional use amount, an adsorption, wrapping and dispersing effect can be achieved with combination of the polycarboxylic acid, so that excessive coagulation promotion is reduced, namely, a suitable early strength and water reduction effect can be achieved unexpectedly.

Owner:赵圣光

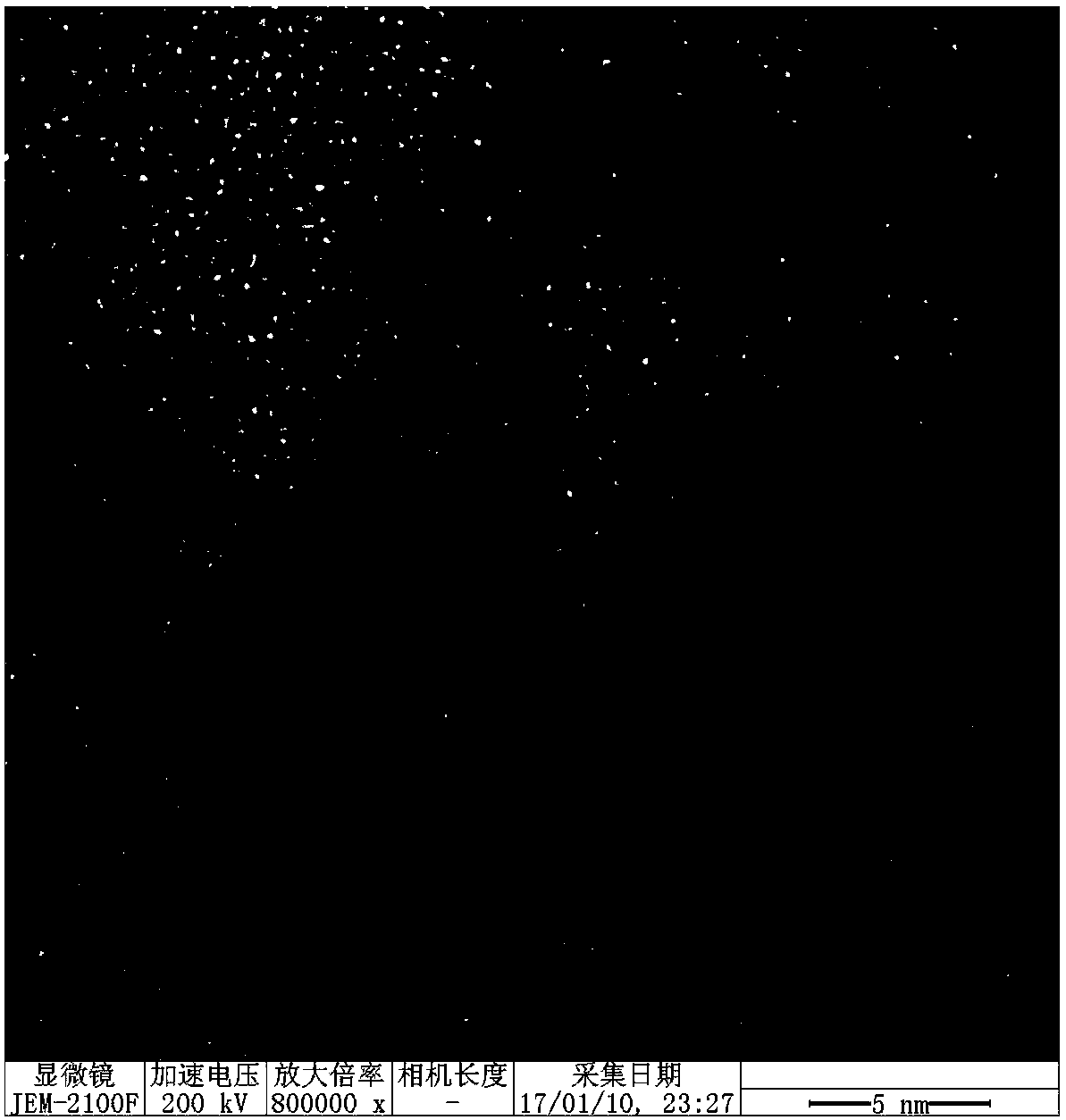

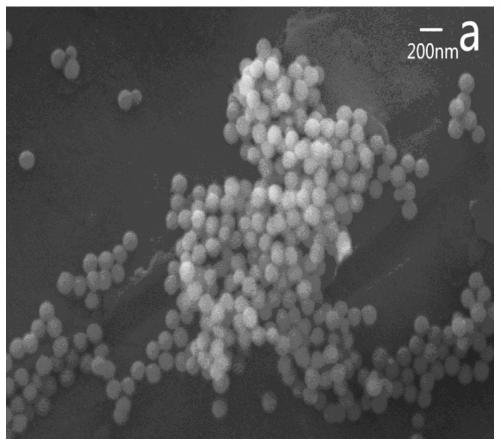

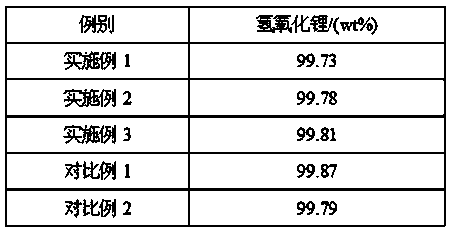

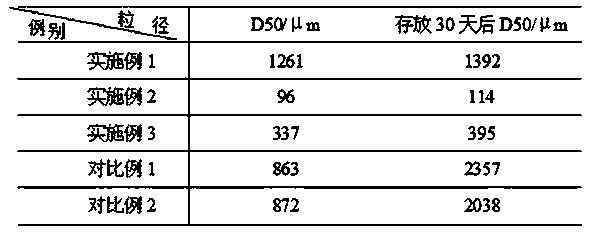

Nano spherical lithium hydroxide and preparation method thereof

ActiveCN111115663AGood dispersionPrevent compactionLithium oxides/hydroxidesMicroballoon preparationLithium oxideDispersity

The invention discloses nano spherical lithium hydroxide and a preparation method thereof. The nano spherical lithium hydroxide and the preparation method thereof are characterized in that the particle size of primary particles of the lithium hydroxide nanospheres is 10-600nm, the particle size D50 of laser particle size test is 50-2000nm, the purity of the lithium hydroxide nanospheres is greaterthan 99.7%, and the balance is 0.01-0.2% of non-polar organic matters and a proper amount of impurities. According to the nanospheres, a lithium hydroxide solution is matched with a non-polar organicsolvent and an ionic surfactant with a hydrophobic group according to a certain proportion to form stable water-in-oil, namely the structure is a structure that an organic matter wraps a water phase(W / O), the solution system is enabled to form emulsion liquid beads with nanometer and micrometer sizes, then, the lithium hydroxide of the liquid beads can be dried in the spraying process to separate out spherical nanoparticles, and in the drying process, a small amount of non-polar organic matters are remained, so that the dispersity of the lithium hydroxide nanospheres is improved, the hardening of the lithium hydroxide particles is favorably prevented, and the better physical morphology and size of the lithium hydroxide nanospheres are maintained.

Owner:苏州众鑫凯能源科技有限公司

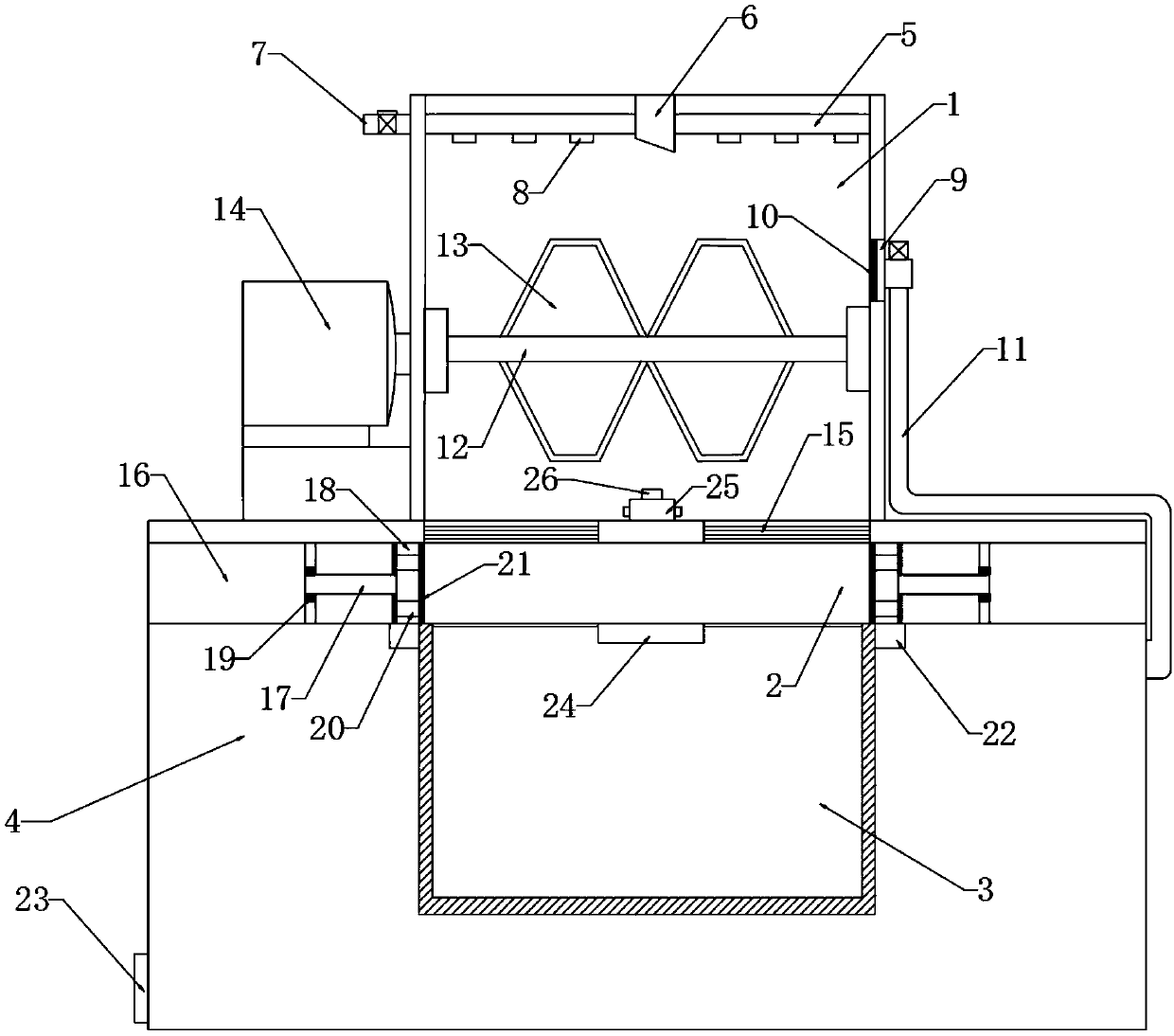

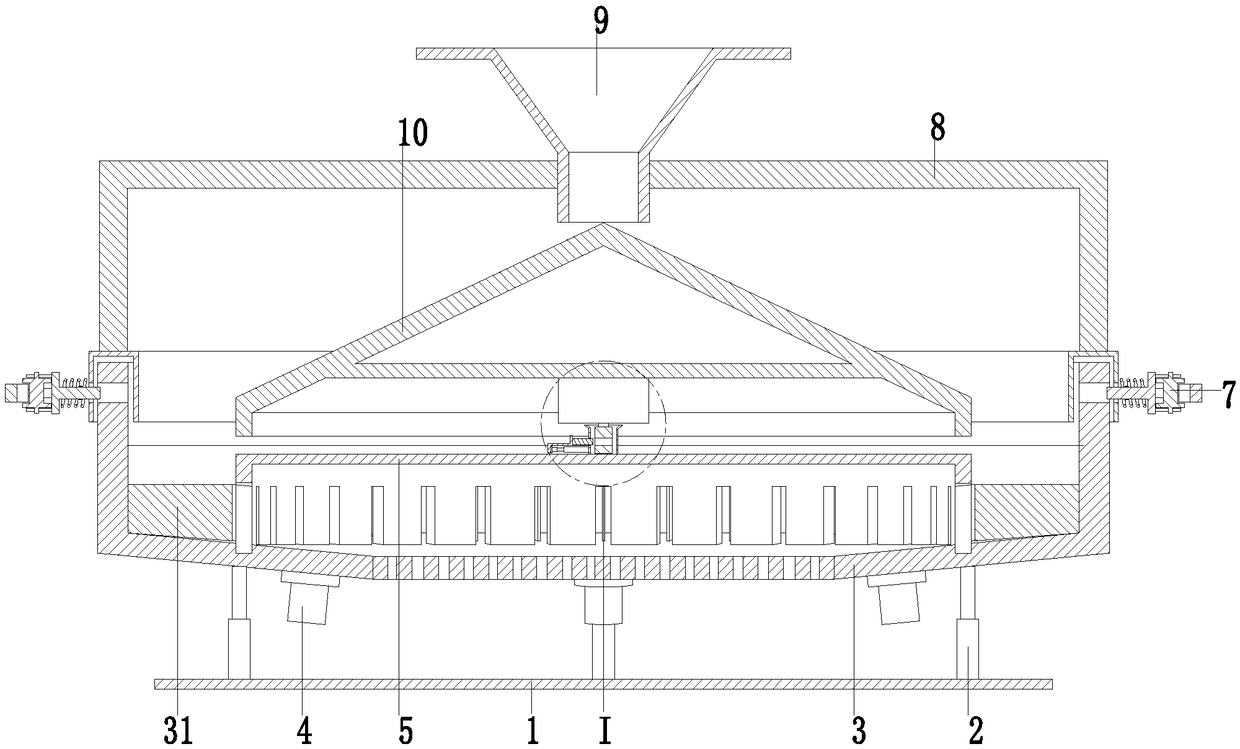

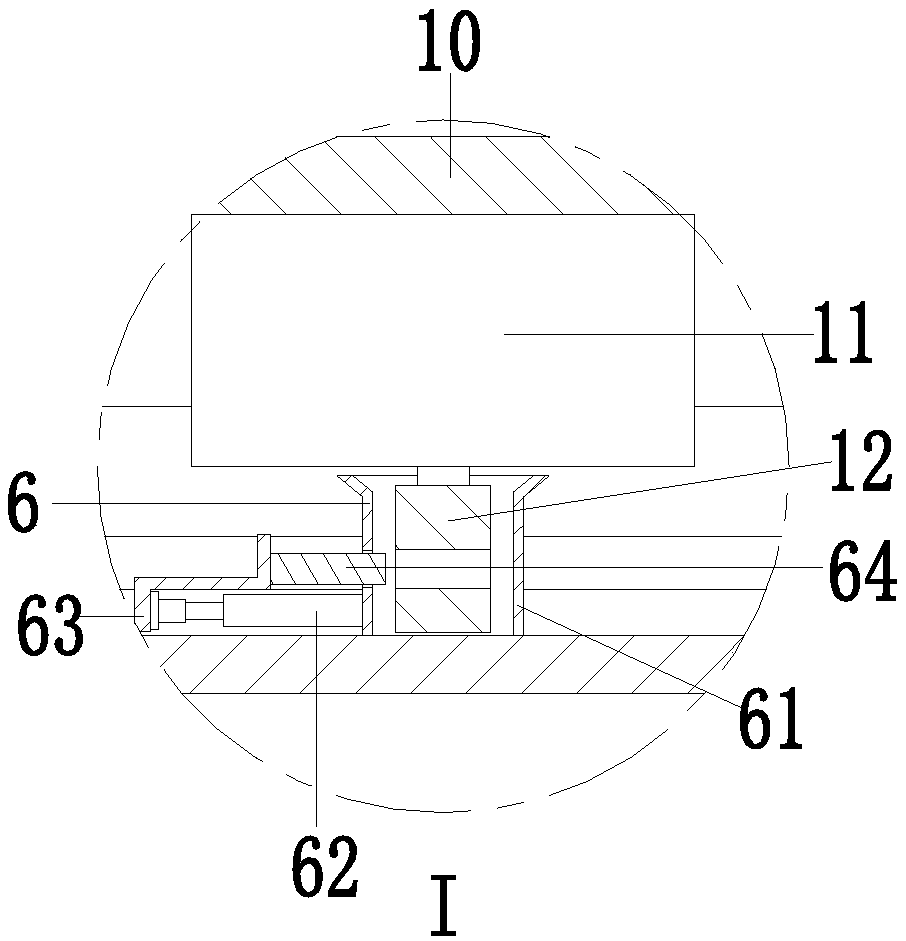

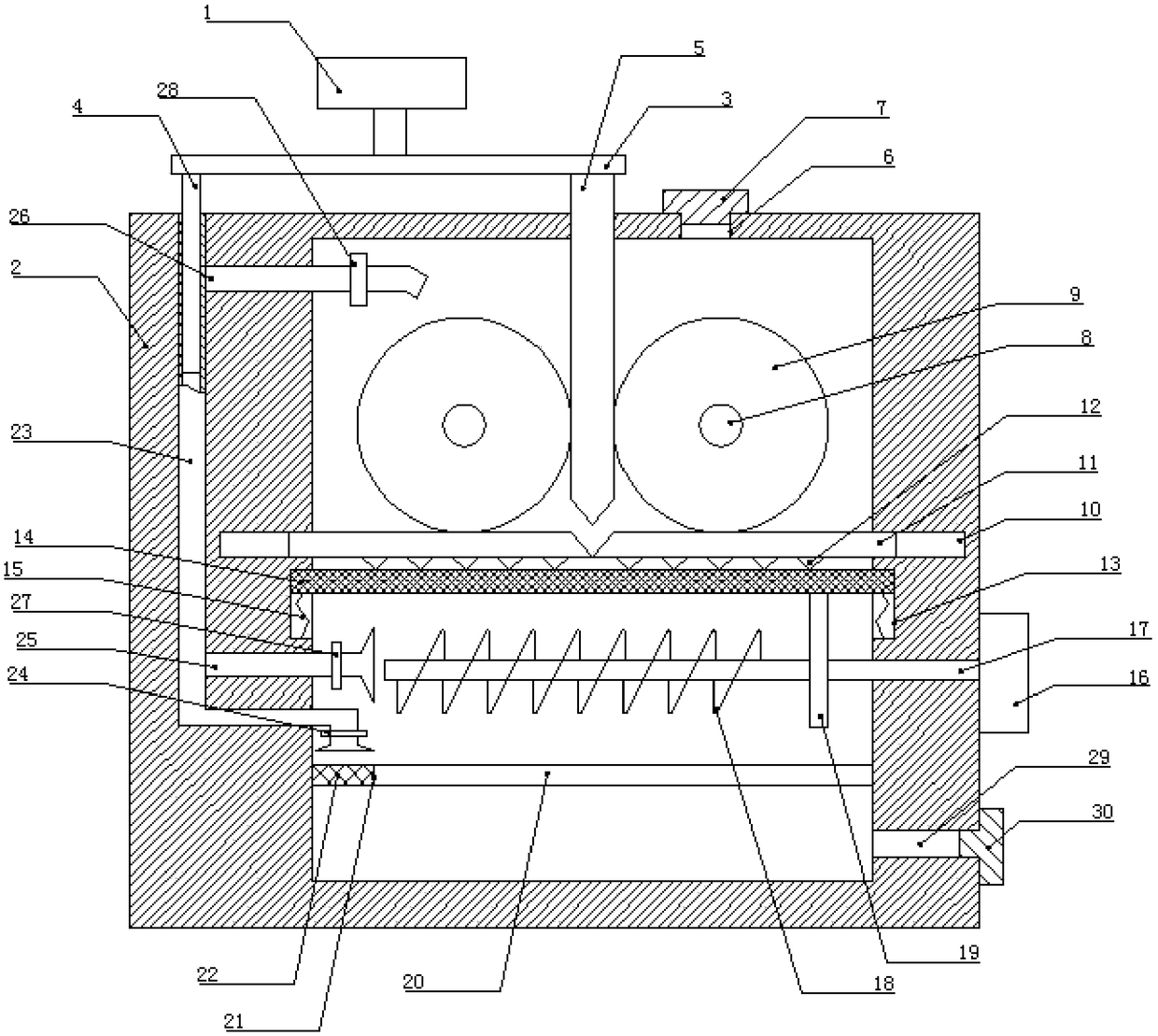

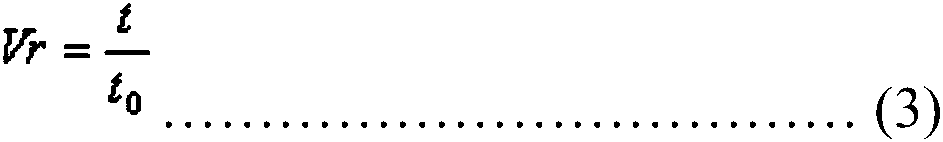

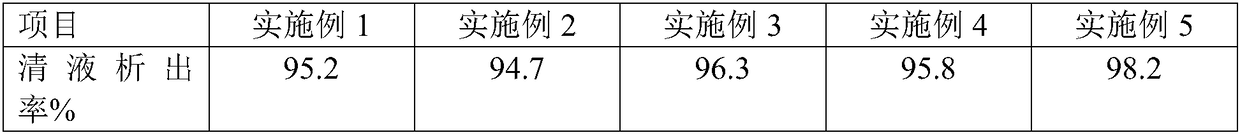

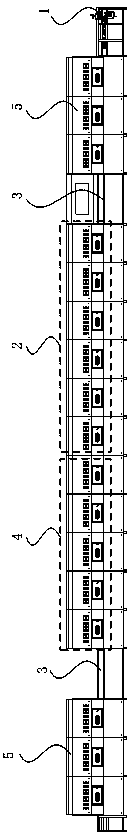

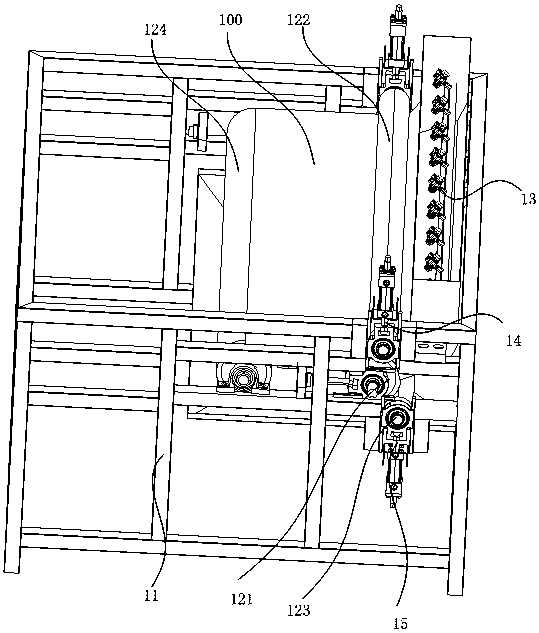

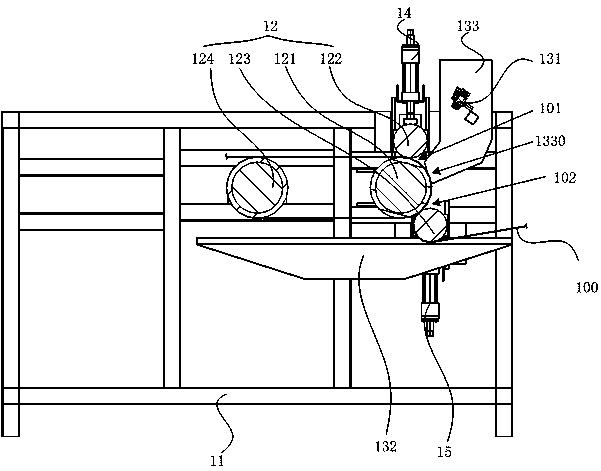

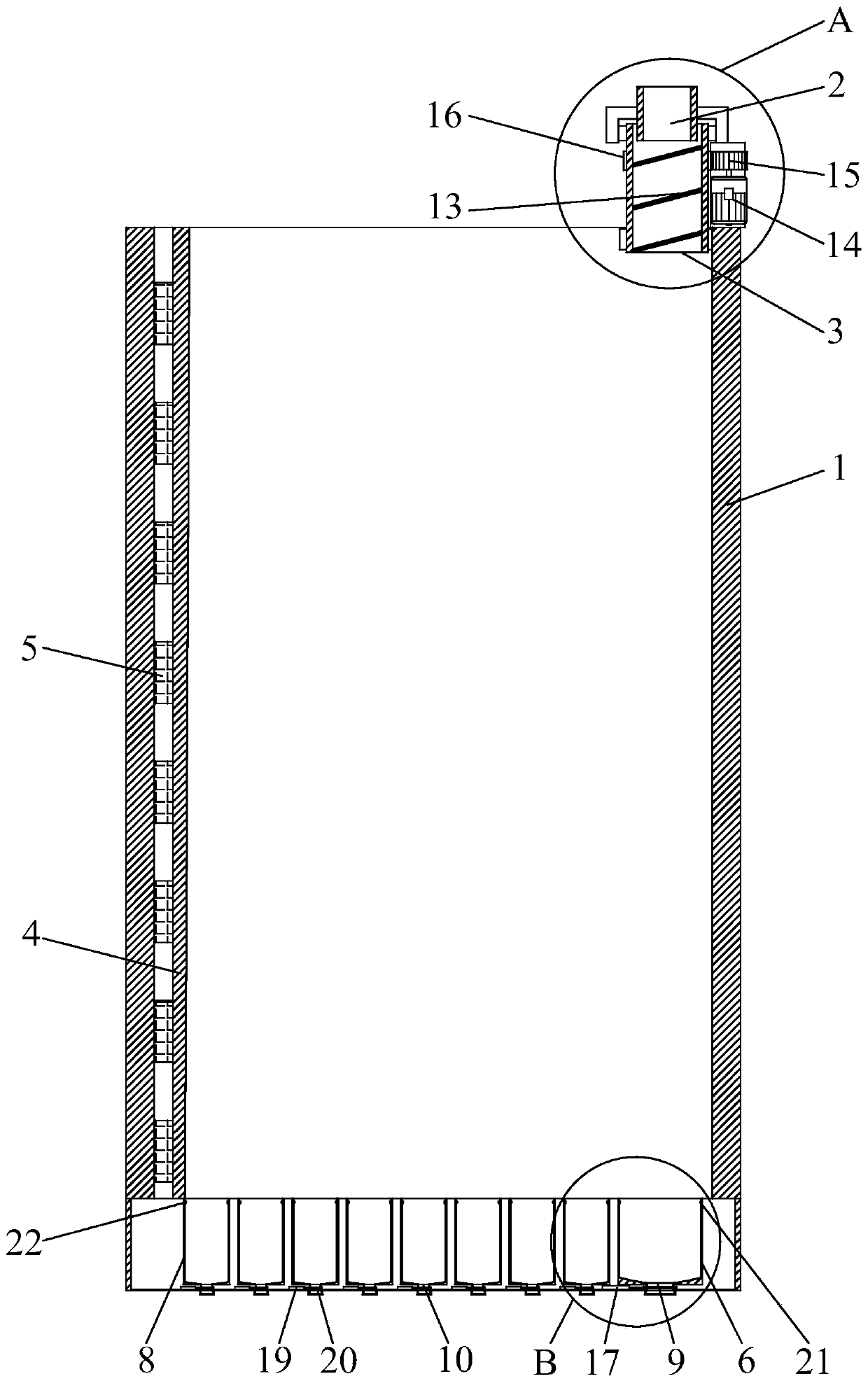

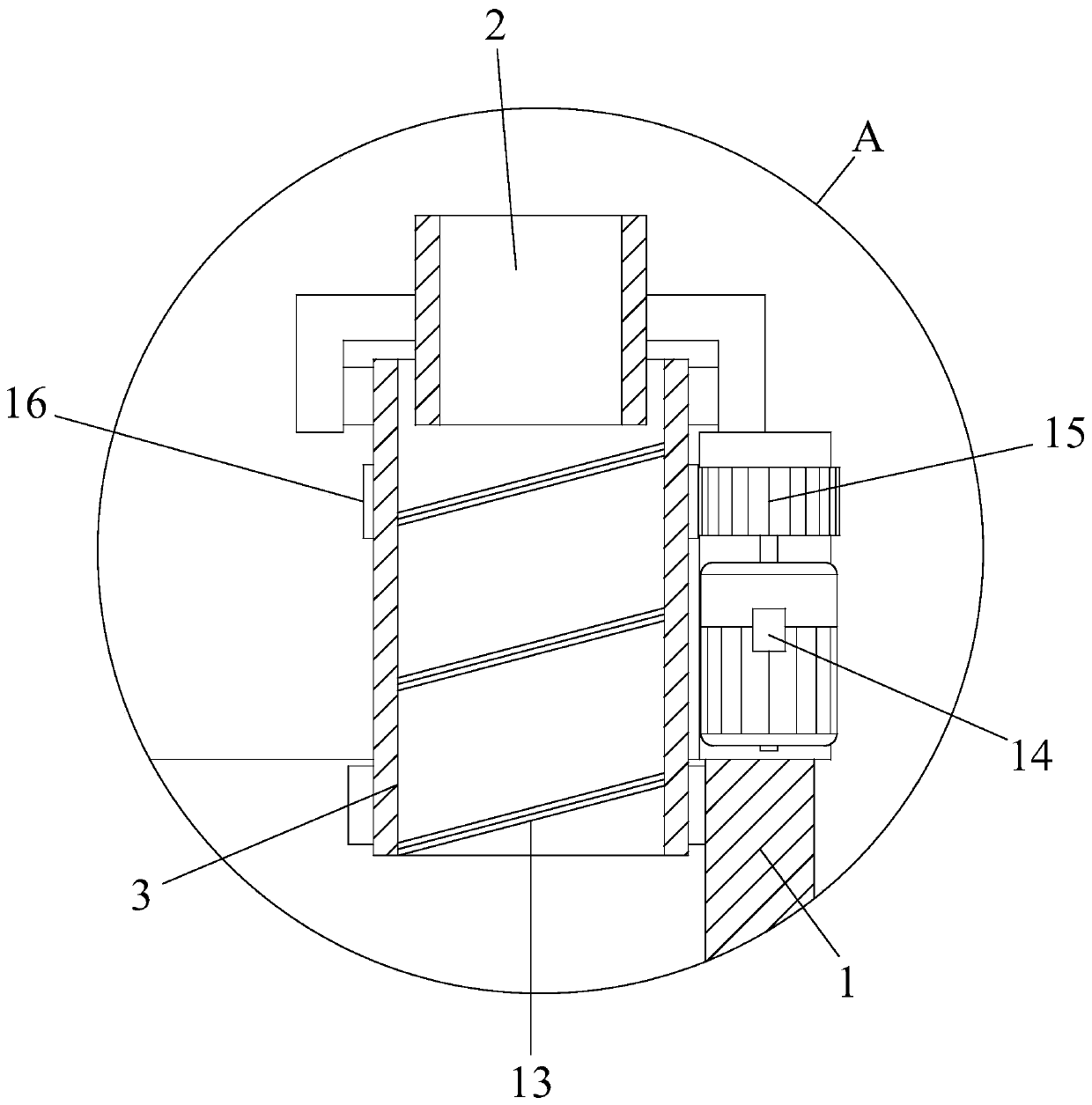

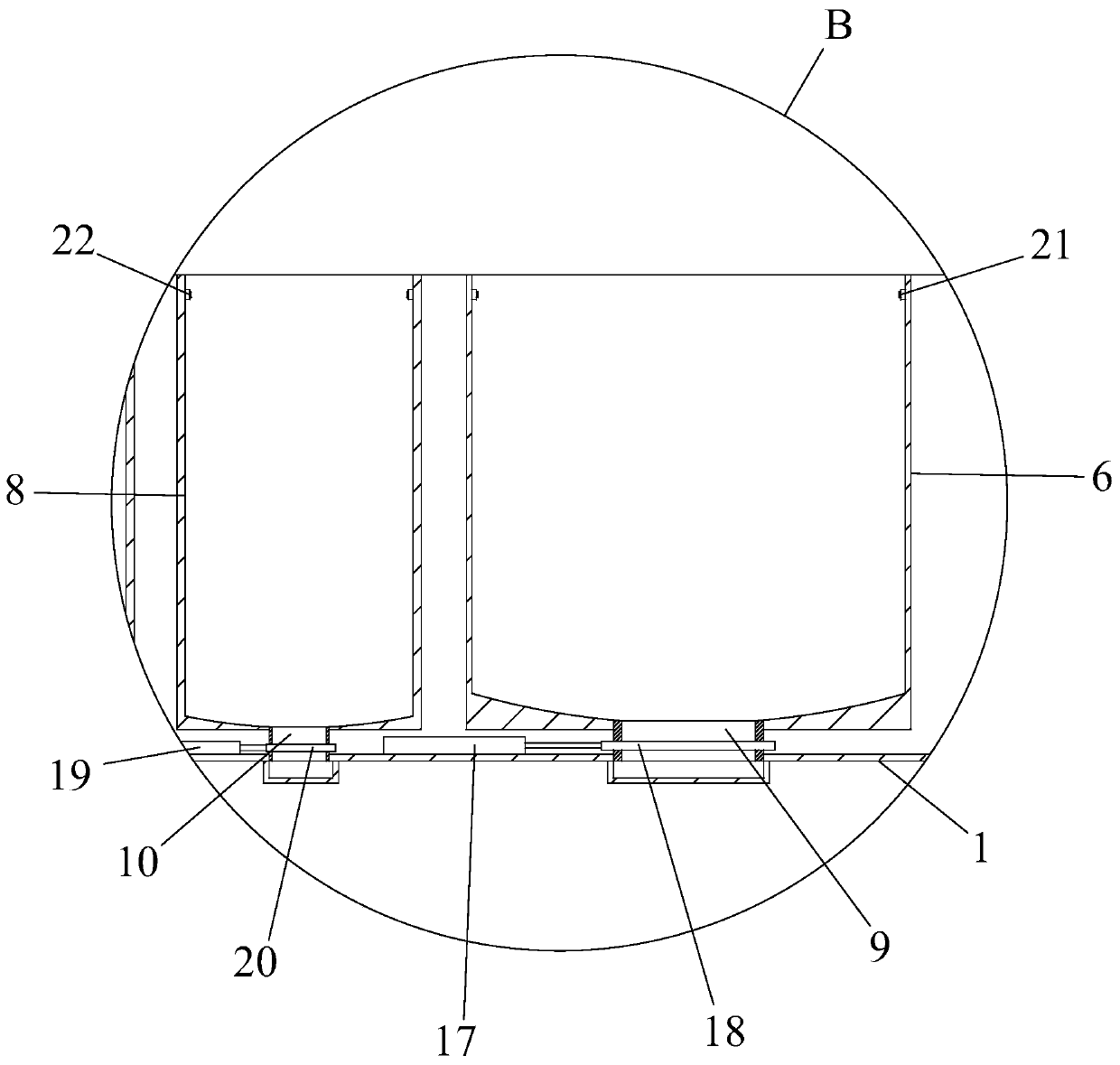

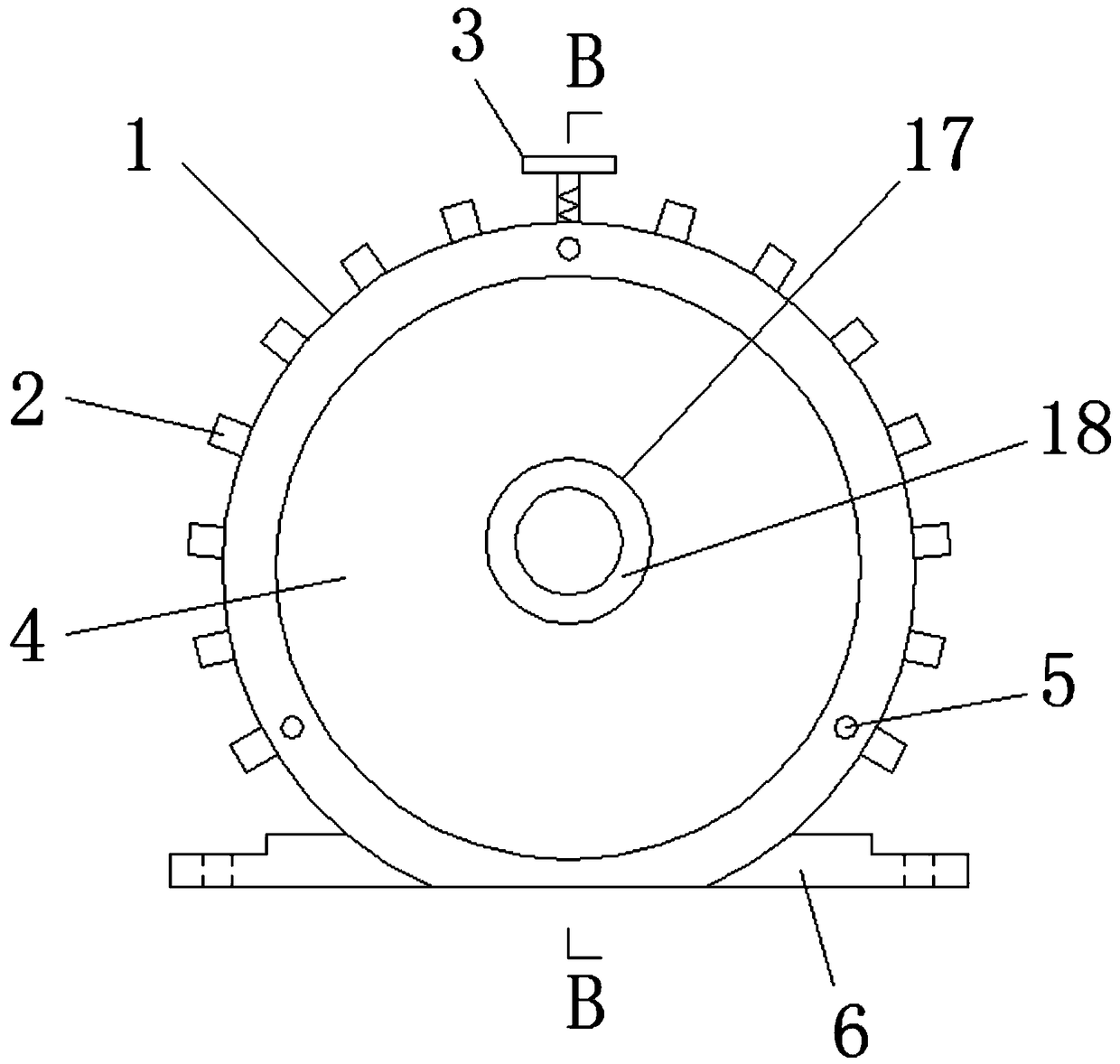

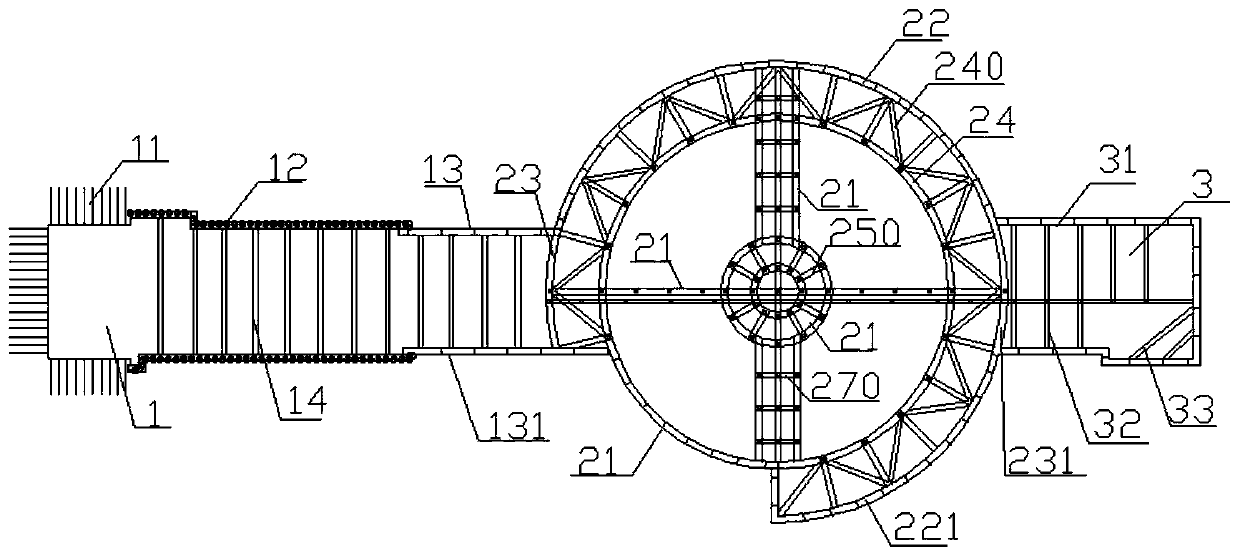

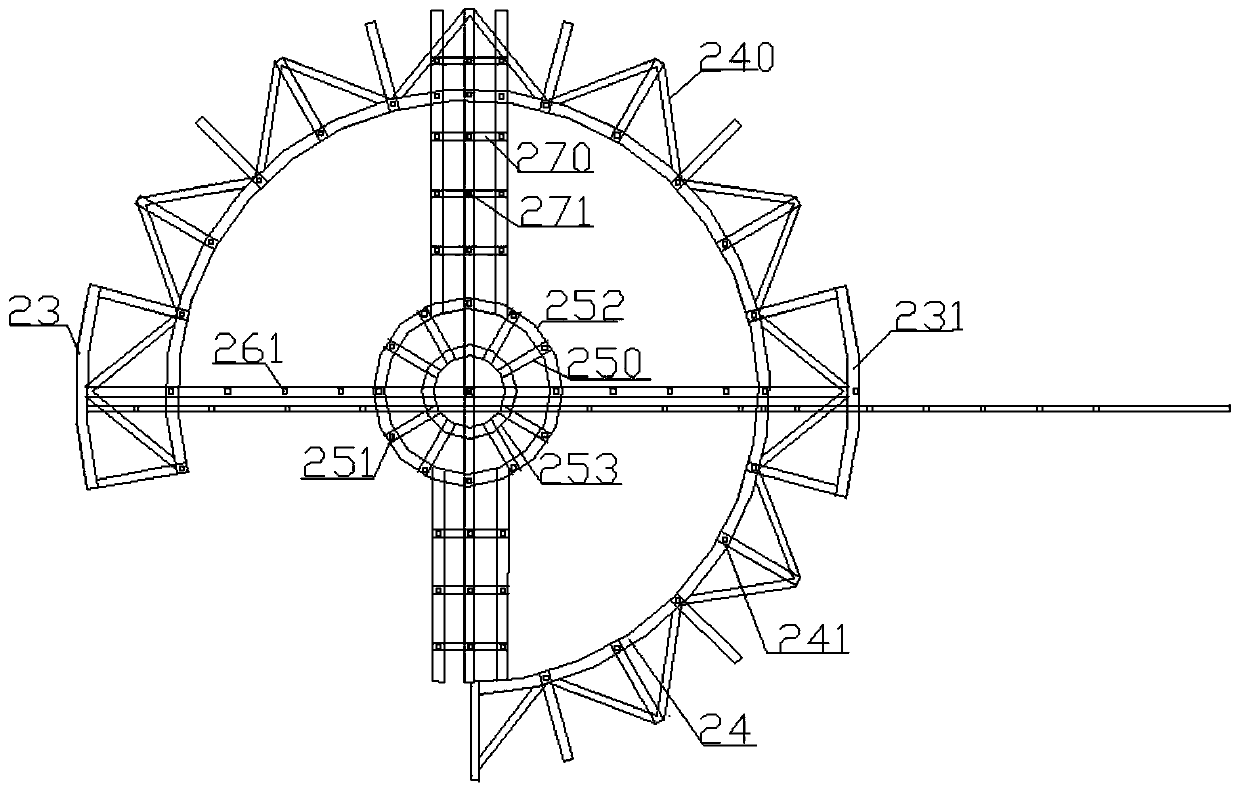

Flushing and filter pressing integrated device

ActiveCN109091939APlay a role in dispersingImprove the mixing effectMembrane filtersCleaning using liquidsWastewaterHigh pressure water

The invention is suitable for the field of industrial material flushing, and provides a flushing and filter pressing integrated device. A horizontally arranged stirring device of the flushing and filter pressing integrated device drives a material to be flushed to roll up and down, and also achieves the function of dispersing the material, and the stirring effect is good. The material moving up isflushed by clean water sprayed from a high-pressure water nozzle. The material tumbles for several times to be flushed by the high-pressure water nozzle for several times. The flushing effect is thorough. After flushing for a certain period, a switch door is opened to press-filter the material. Wastewater is discharged into a wastewater tank through a filter screen and through holes in a filter press piston, the material is separated from the wastewater, and finally the press-filtered material is discharged from a central discharge pipe so as to reduce the residual wastewater or compounds ofthe material as much as possible. The material and the wastewater are completely separated.

Owner:JINGMEN GEM NEW MATERIAL

UV facial oil for paper packaging and printing and preparation method of UV facial oil

The invention provides UV facial oil for paper packaging and printing and a preparation method of the UV facial oil, which relates to the technical field of printing ink. The UV facial oil for the paper packaging and printing is mainly prepared from connecting resin, glycerol-phthalic resin, vegetable oil, mineral oil, organic aluminum gelatinizing agent, antioxidant, light initiator, dispersion resin and defoaming agent. The connecting resin and the light initiator initiate the instantaneous light chemical reaction under the illumination of ultraviolet rays, and a netted chemical structural coating is formed on the surface of a printed product; the glycerol-phthalic resin can improve the leveling property of the light-cured connecting material; the vegetable oil can play a role in dispersing the light-cured connecting material; and the organic aluminum gelatinizing agent can improve the viscosity of the light-cured connecting material. The UV facial oil for the paper packaging and printing obtained by compounding the components has the advantages of high glossiness, good wear resistance, good leveling property, high adhesion force, yellowing resistance, good anti-explosive performance.

Owner:广州市恒远彩印有限公司

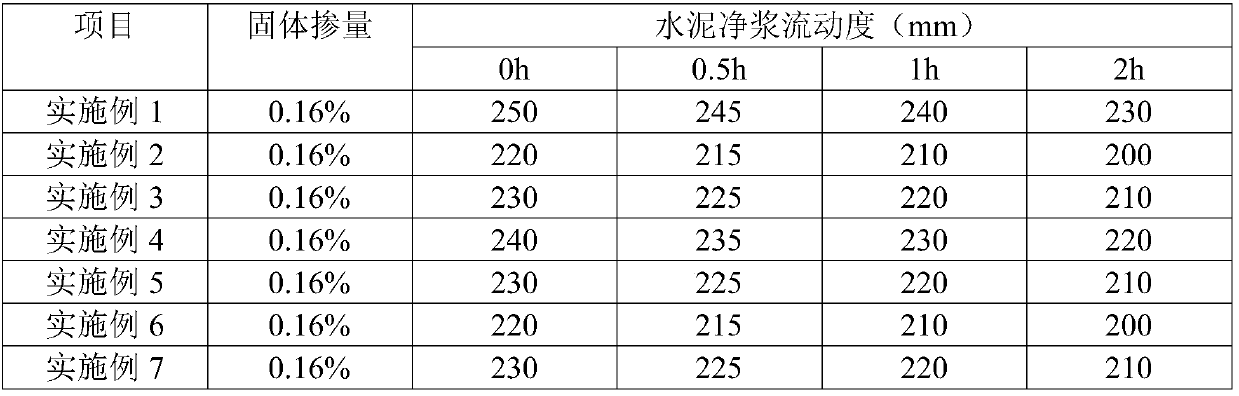

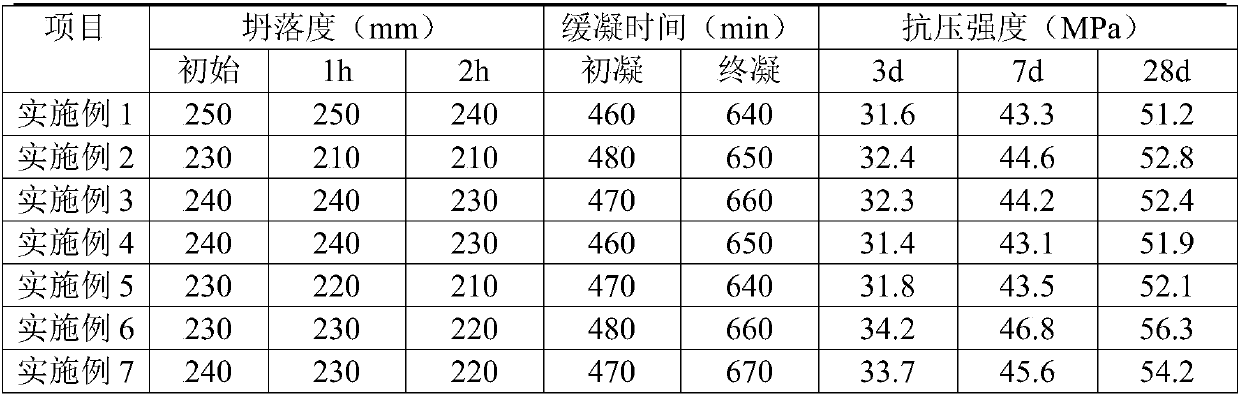

High-performance compound polycarboxylate superplasticizer

The invention provides a high-performance compound polycarboxylate superplasticizer and belongs to the technical field of superplasticizers. The high-performance compound polycarboxylate superplasticizer is prepared from components in parts by weight as follows: 10-20 parts of a polycarboxylate superplasticizer, 1-4 parts of methacrylate, 2-3 parts of tertiary carbonic ester, 0.2-0.3 parts of N-oleoylsarcosine, 2-4 parts of hydroxypropyl starch ether, 1-3 parts of glycerin, 1-3 parts of sodium dodecyl benzene sulfonate and 15-25 parts of water. The high-performance compound polycarboxylate superplasticizer is a compound superplasticizer and has excellent water reducing performance, slump loss resistant property, dispersity and workability.

Owner:河北合众建材有限公司

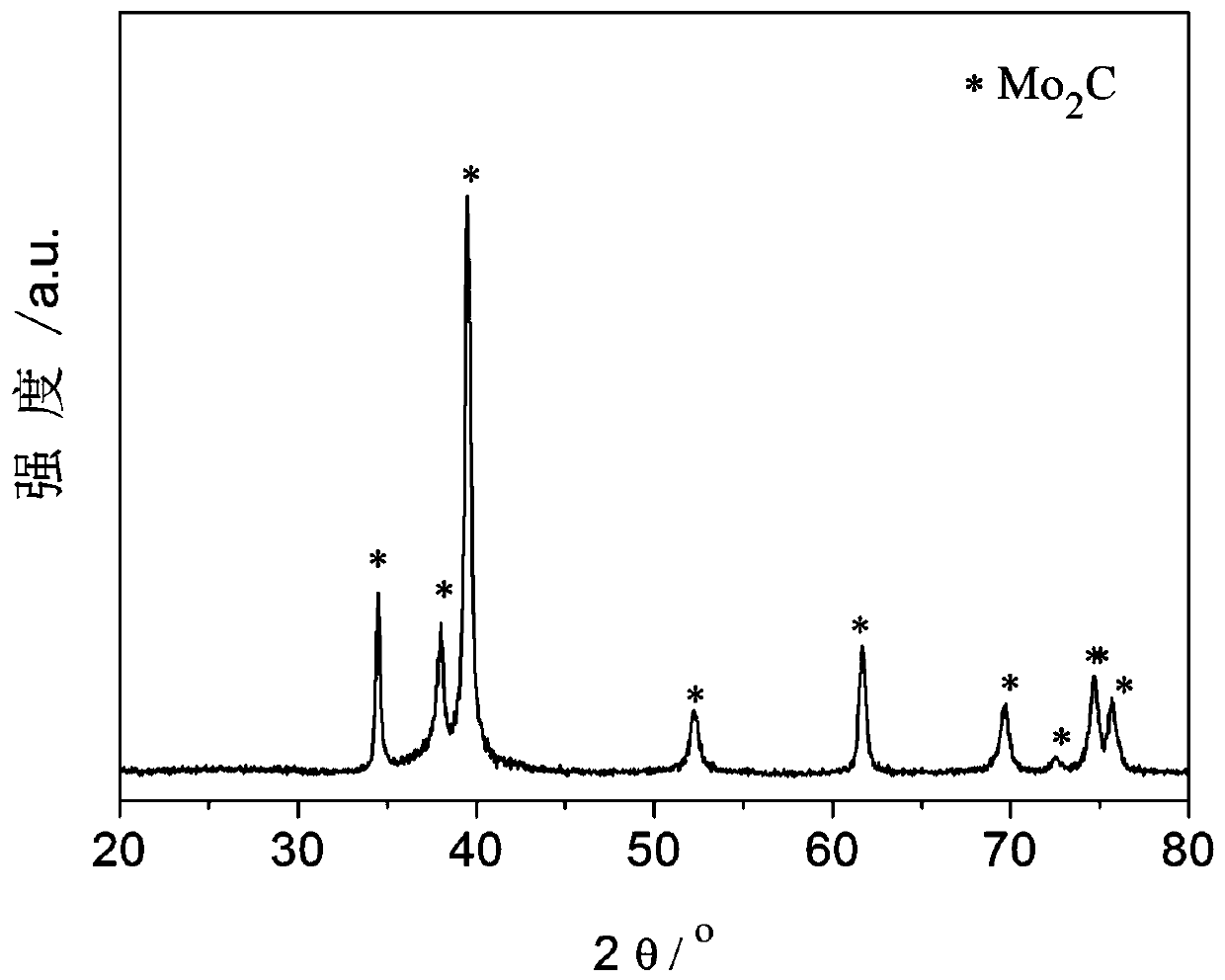

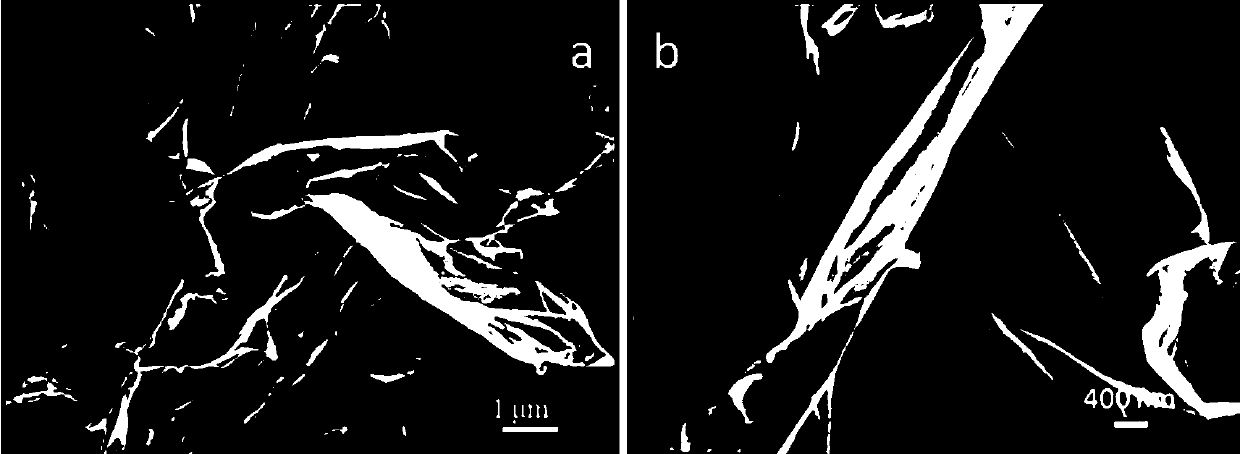

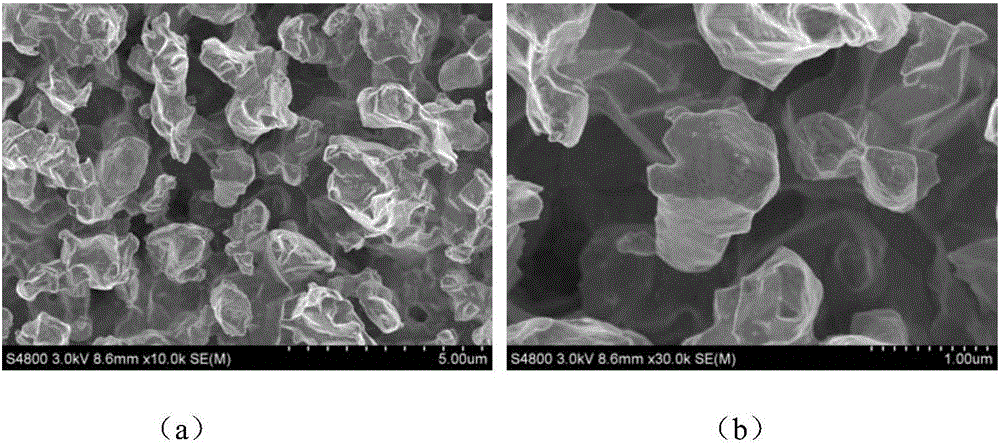

Preparation method of two-dimensional molybdenum carbide/graphene nanosheet composite material

ActiveCN110575840ALow cost of preparationEasy to operateCatalyst activation/preparationElectrodesLow activityHydrogen production

The invention discloses a preparation method of a two-dimensional molybdenum carbide / graphene nanosheet composite material, wherein the preparation method comprises the steps: adding a graphene oxideethanol dispersion solution dissolved with hexadecyl trimethyl ammonium bromide into a soluble molybdenum source aqueous solution, carrying out a hydrothermal reaction, and carbonizing the reaction product to obtain the two-dimensional molybdenum carbide / graphene nanosheet composite material. The two-dimensional molybdenum carbide / graphene nanosheet composite material is prepared by a simple method, the problems of less exposure of molybdenum carbide active sites and low activity are solved, and the catalytic performance of the molybdenum carbide material is improved. The two-dimensional molybdenum carbide / graphene nanosheet composite material prepared by the method is used as a catalyst material to be applied to water electrolysis hydrogen production reaction, and shows relatively high activity.

Owner:TAIYUAN UNIV OF TECH

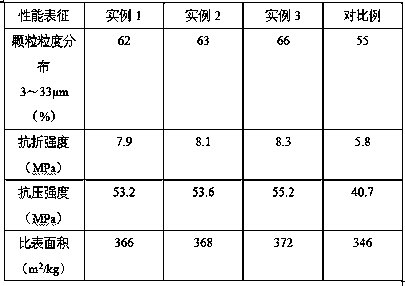

Preparation method of organic silicon modified high-molecular cement grinding aid

The invention relates to a preparation method of an organic silicon modified high-molecular cement grinding aid, and belongs to the technical field of cement production. According to the preparation method, sodium lignin sulfonate containing a large number of functional groups is introduced into diethanol amine, then a reaction with modified silicone oil is carried out for preparing an organic silicon modified high-molecular polymer. The organic silicon modified high-molecular polymer has long polyether side chains, and short chains contain a plurality of functional groups of Si-O bonds, hydroxyl groups, carboxyl groups and the like, so that the high-molecular polymer can be easily adsorbed on the surfaces of cement particles, an effect of particle dispersion is exerted, an effect of preventing the healing of cracked interfaces is achieved, the free energy of the surfaces of the cement particles can be effectively reduced, a larger steric hindrance effect can be achieved for the long polyether side chains, the dispersion property of the cement particles is further enhanced, and an effect of accelerating the crack propagation can be exerted. Energy generated in cement production areapplied to crushing the cement particles more, so that the particles are more uniform and fine, and thereby the goals of improving the cement powed grinding efficiency and reducing the energy consumption of the cement are realized.

Owner:胡果青

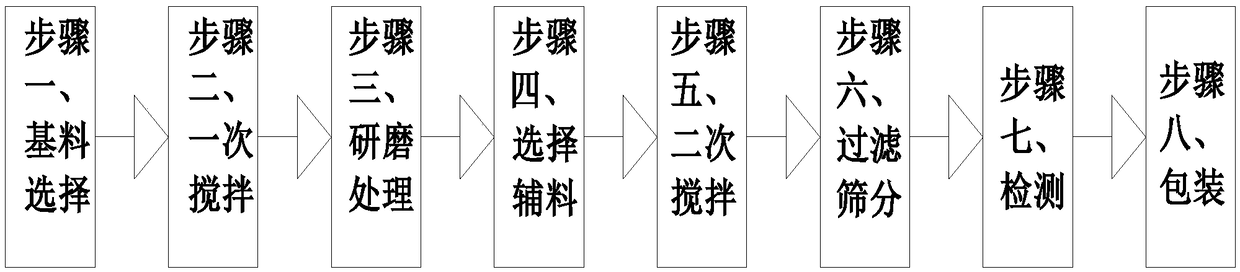

Preparation process of waterborne coating

ActiveCN109433590APlay a role in dispersingAvoid accumulationSievingScreeningFiltrationLarge particle

The invention relates to a preparation process of waterborne coating. The preparation process comprises the following specific steps of base material selection, first-time stirring, grinding treatment, auxiliary material selection, second-time stirring, filtration and screening, detecting, packaging and other procedures. According to the preparation process, the problems that in the production andmanufacturing process of existing waterborne coating, raw materials for manufacturing the waterborne coating need to be filtered and screened manually, smell emitted in the waterborne coating causeshuman body discomfort, the raw materials are filtered through manual control, consequently substandard raw material particles are prone to being mixed, the using effect of the waterborne coating is affected, the size of the raw material particles has the precise requirements, when the raw materials are filtered manually through filtering tools, sieving holes of the filtering tools are prone to being blocked by the large particles, the raw material filtering efficiency is affected, the waterborne coating manufacturing time is affected, when the filtering tools are controlled manually for sieving and filtering the raw materials, the raw materials are prone to being spilled in the jolting process, the closed filtering tools are selected, and consequently, clearing is troublesome after work can be solved.

Owner:广东百川化工有限公司

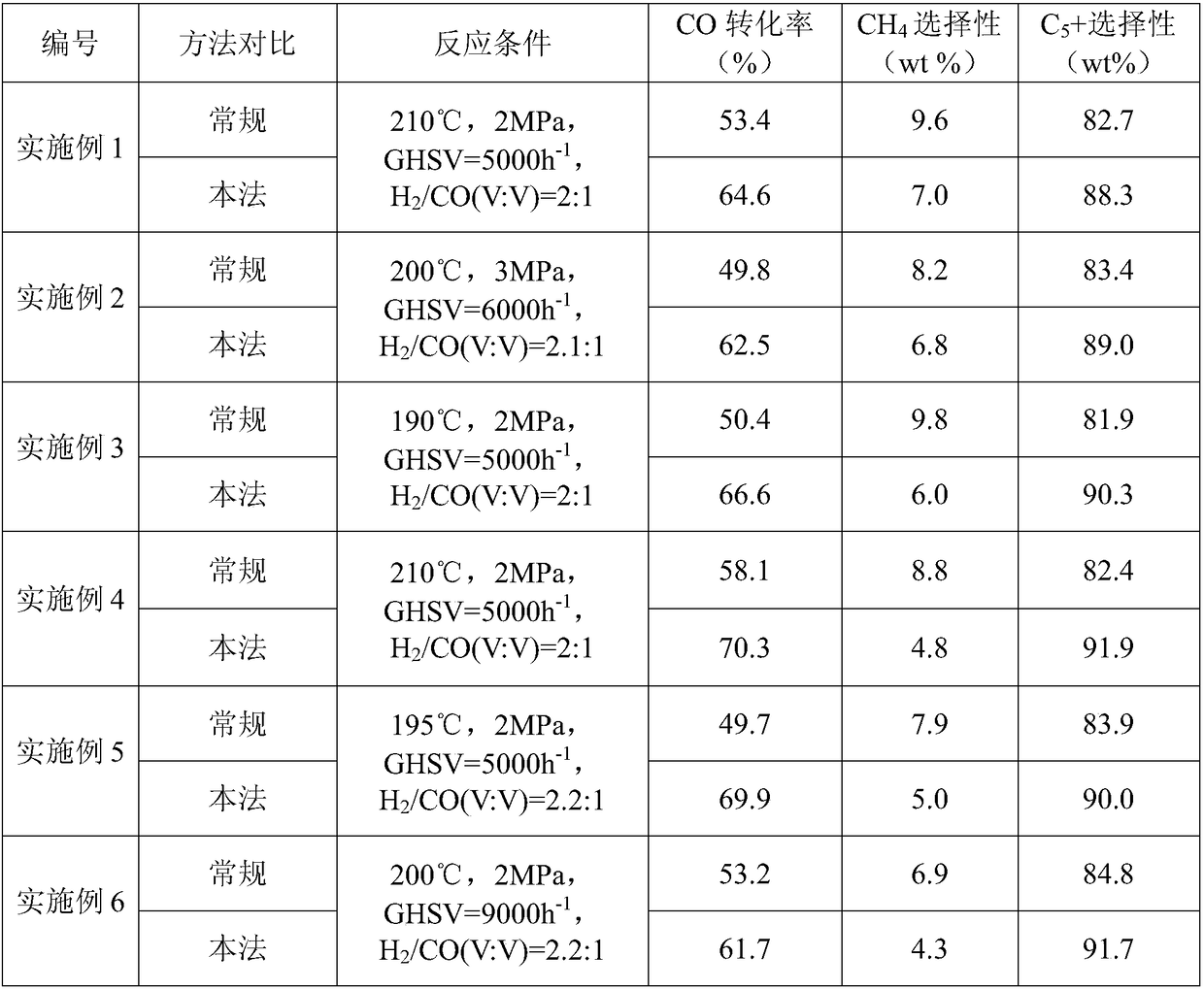

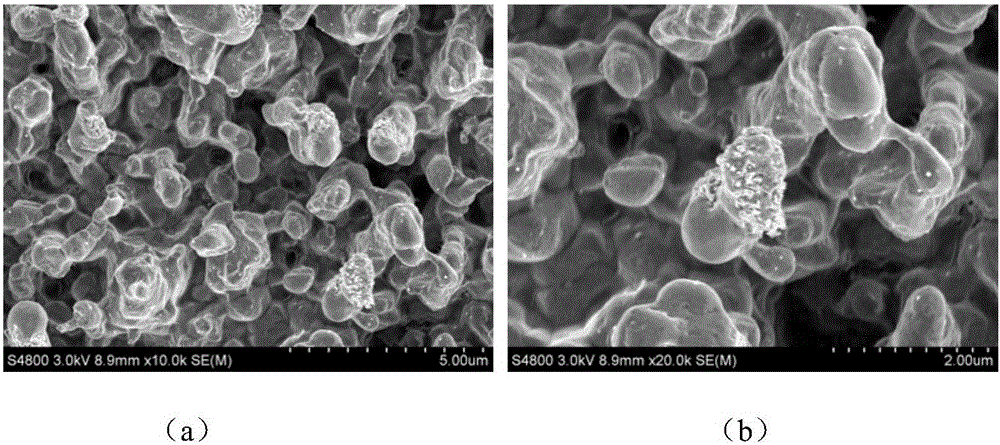

High-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst based on carbonization processing method and preparation method thereof

ActiveCN108246313AHigh activityHigh selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionSyngasCobalt salt

The invention discloses a high-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst based on a carbonization processing method and a preparation method thereof. The preparation method of the high-dispersion heavy-hydrocarbon Fischer-Tropsch synthetic catalyst comprises the following steps: loading a soluble salt of a metal additive on a formed carrier by using an impregnation method, drying and roasting to obtain a pre-processed carrier; loading a soluble cobalt salt and an organic matter on the pre-processed carrier by using the impregnation method, and drying to obtain the catalyst. According to the preparation method, a process of carbonization processing is introduced into a conventional evaluation step of reduction-Fischer-Tropsch synthesis of the catalyst, and the evaluation step is optimized as a step of reduction - synthesis gas processing - carbonization - H2 reprocessing, so the Co average grain size of the catalyst through the above actions is reduced. The secondary reduction is performed on the carbonized catalyst, the excess carbon deposition is eliminated, and thereby the Fischer-Tropsch reactivity of the catalyst is improved. Through the secondary reduction, the grain size is reduced, the activity point location is increased, and the reduction degree of the catalyst is further improved, so the performance of the catalyst is improved.

Owner:SYNFUELS CHINA INNER MONGOLIA CO LTD

Bifenthrin purification and granulation method

InactiveCN107032997AReduce pollutionReduce health threatsOrganic compound preparationCarboxylic acid esters preparationSlow coolingMoisture

The invention relates to the field of chemical engineering and discloses a bifenthrin purification and granulation method. The bifenthrin purification and granulation method comprises the following steps that S1, bifenthrin crude oil, an organic solvent, water and an emulsifying agent are added into a stirring kettle, and stirring and heating are performed to 60-70 DEG C till the bifenthrin crude oil in the mixture is completely dissolved in a reflux state; S2, slow cooling is performed to reach 15-25 DEG C at the cooling speed of 8-12 DEG C / hour till a bifenthrin crystal precipitates on the wall of the kettle, and then heat preservation is performed for 0.5-1.5 hours; S3, slow cooling is performed to reach 4-6 DEG C at the cooling speed of 1-3 DEG C / hour, and heat preservation is performed for 1.5-2.5 hours; S4, granular bifenthrin is obtained after discharging centrifugation, filtering and drying. The granular bifenthrin can be obtained, the specific gravity is up to 0.65-0.75, the same size of packaging buckets can contain heavier bifenthrin, and thus the transportation cost is greatly reduced; the moisture content is smaller, the centrifugation time is short, the dust amount is small, and thus environmental pollution is reduced.

Owner:JIANGSU HUANGMA AGROCHEM

Lightweight limesand brick and production process

ActiveCN109225557ALow densityHigh strengthSolid waste managementAuxillary shaping apparatusCompression moldingBrick

The invention relates to the technical field of artificial stone and discloses a lightweight limesand brick and a production process. The raw materials of the lightweight limesand brick are composed of hard construction and industrial wastes, machine-made sand, medium-coarse sand, powdered wastes and binding materials. The production process comprises the following steps: 1, crushing various raw materials to obtain crushed particles; 2, taking out various crushed particles from a box and storing the particles in different bins; 3, stirring and mixing the various crushed particles with water soas to obtain a mixture; and performing compression molding on the mixture to obtain a brick body; and 4, steaming the brick body in steam, thereby obtaining the lightweight limesand brick. Accordingto the scheme, the problem that the conventional limesand brick is inconvenient to transport and use due to high weight is mainly solved.

Owner:CHONGQING JUWEI ENERGY SAVING BUILDING MATERIALS CO LTD

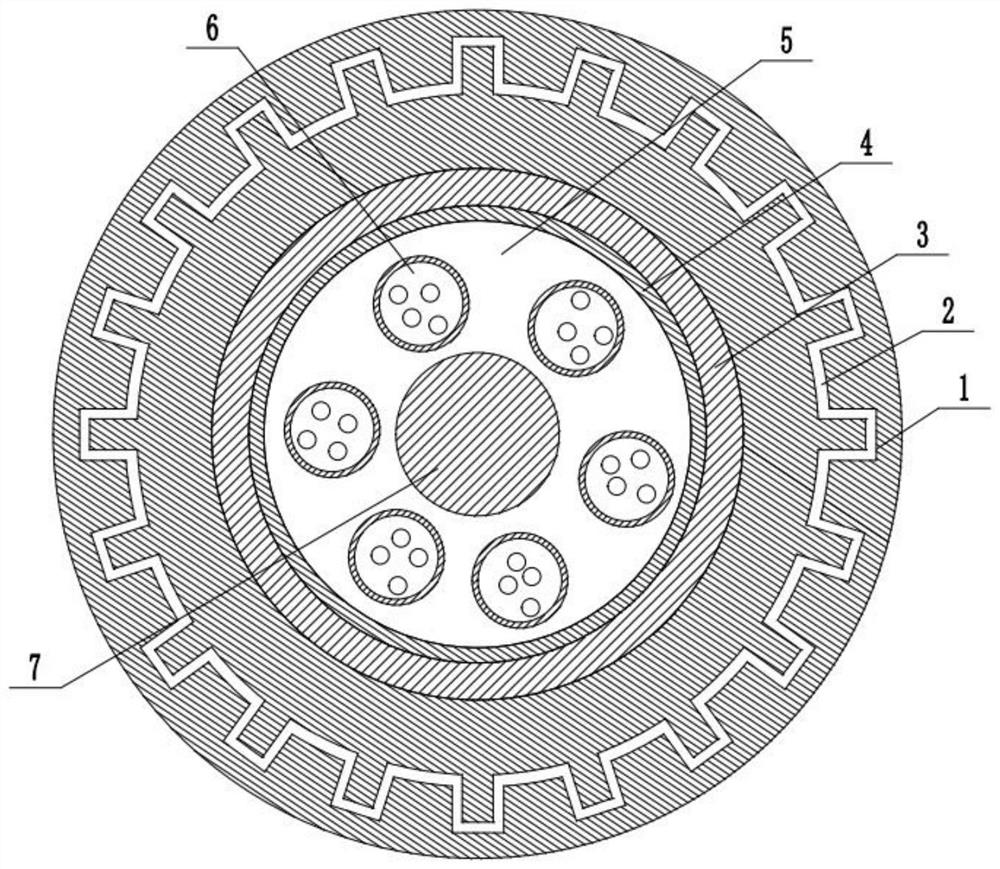

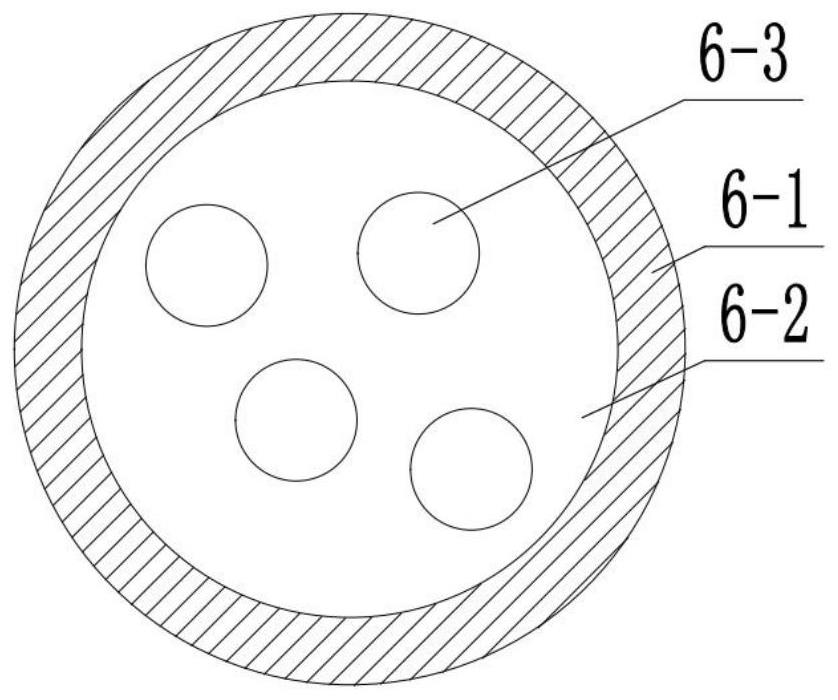

Layer-stranded rat-bite-proof optical cable

PendingCN113985550APlay the function of repelling micePlay the role of bite resistanceFibre mechanical structuresAnimal repellantsYarnSteel belt

The invention belongs to the field of rat-bite-proof optical cables, and particularly relates to a layer-stranded rat-bite-proof optical cable which comprises a protective jacket, a yarn binding layer, cable core filling glue, optical fibers and reinforcing steel wires, the yarn binding layer is coaxially arranged in the protective jacket, the cable core filling glue is loaded in the yarn binding layer, the optical fibers are arranged in the cable core filling glue, a reinforcing steel wire is coaxially arranged in the protective jacket, the reinforcing steel wire is located in the cable core filling glue, and a composite steel belt is arranged between the yarn binding layer and the protective jacket. The device can adopt multi-layer rat repelling, the rat repelling effect is better, and the device can prevent the optical fiber from being squeezed and crushed.

Owner:天津立孚光电科技股份有限公司

Preparation method for porous Au coating inhibiting microdischarge effect

InactiveCN106835077AGuaranteed coverageSuppresses microdischarge effectsLiquid/solution decomposition chemical coatingPorosityChemical plating

The invention discloses a preparation method for a porous Au coating inhibiting the microdischarge effect. Firstly, a porous structure is constructed on the surface of silver-coated aluminum alloy; secondly, a TiO2 film is deposited on the surface of the porous structure in a profile-followed mode through a sol-gel method; and finally, an Au film is prepared on the surface of the TiO2 through a chemical plating method, so that the porous Au coating inhibiting the microdischarge effect is formed on the surface of the silver-coated aluminum alloy, the porosity and the number of pores of the surface of the silver-coated aluminum alloy can be greatly increased, and thus the microdischarge inhibiting characteristic and environment stability of the silver-coated aluminum alloy are improved.

Owner:SHAANXI UNIV OF SCI & TECH +1

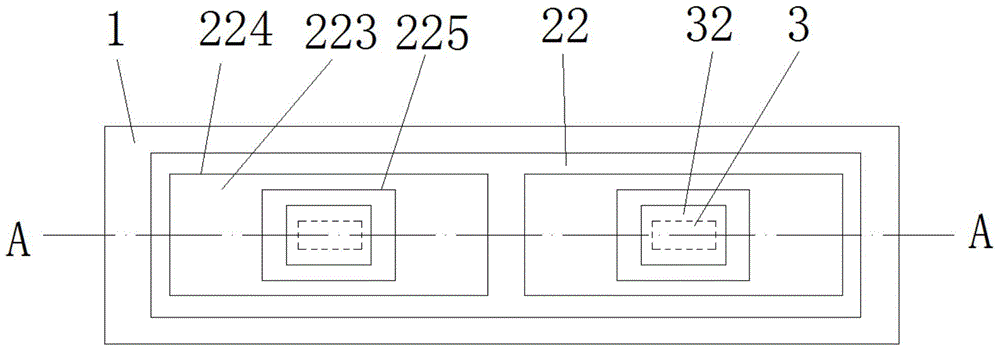

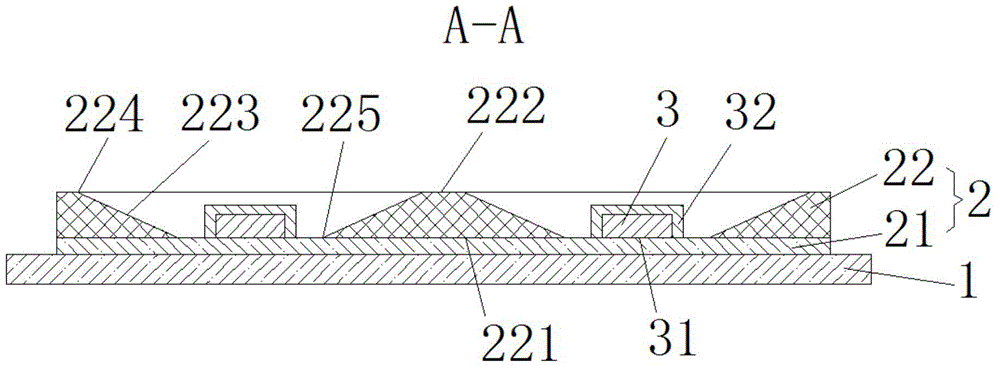

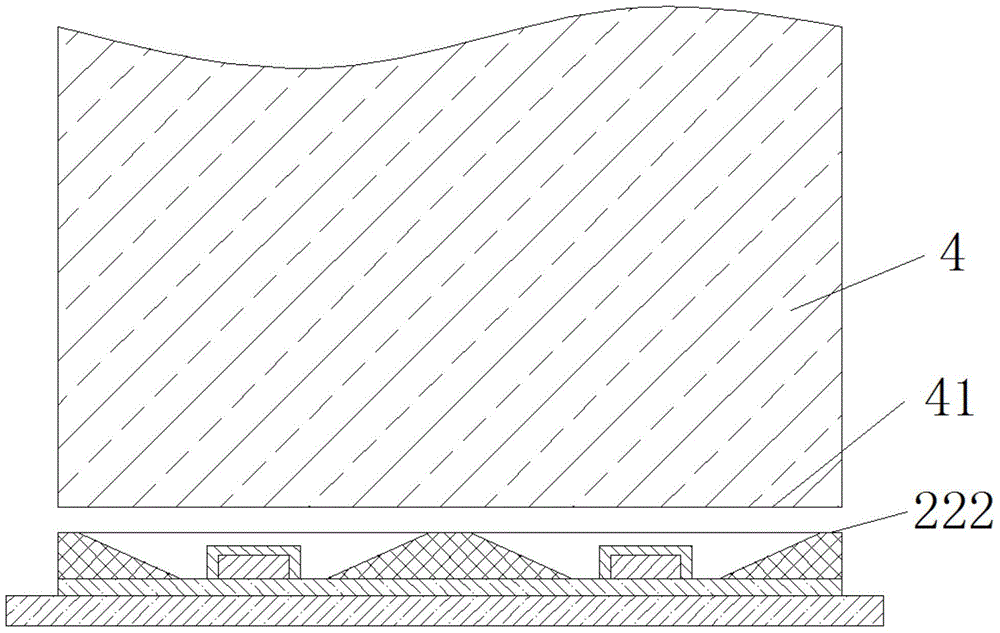

Light source assembly and backlight module

InactiveCN105242456AImprove light energy utilizationPlay a role in dispersingNon-linear opticsLight-emitting diodeBrightness perception

The invention discloses a light source assembly. The light source assembly comprises a circuit board, a reflection assembly and multiple emitting diode chips. The reflection assembly comprises a reflection sheet and a reflection support. The reflection sheet is stacked between the circuit board and the reflection support. The circuit board is attached to the reflection support. The reflection support comprises a first surface, a second surface and multiple reflection ring surfaces. The first surface is opposite to the second surface. One ends of the multiple reflection ring surfaces are communicated with the first surface and multiple first openings are formed. The other ends of the multiple reflection ring surfaces are communicated with the second surface and multiple second openings are formed. The area of the first opening is smaller than that of the second opening. The multiple emitting diode chips are attached to the reflection sheet and accommodated into the multiple first openings in a one-to-one correspondence mode. The light source assembly adopts LEDs and has uniform illumination brightness. The invention further discloses a backlight module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

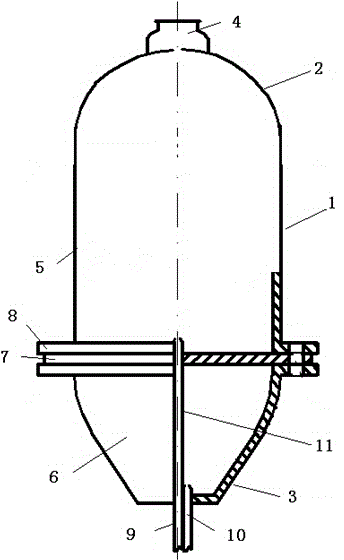

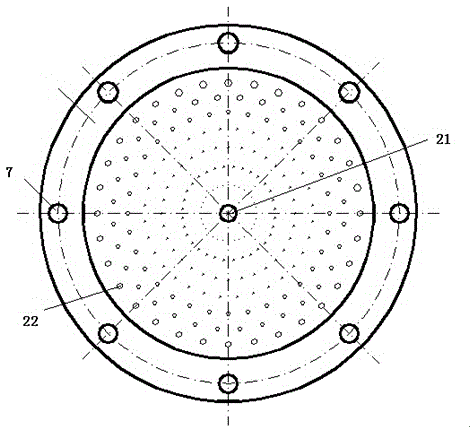

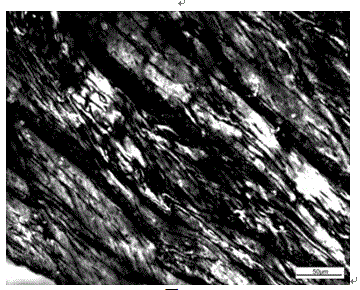

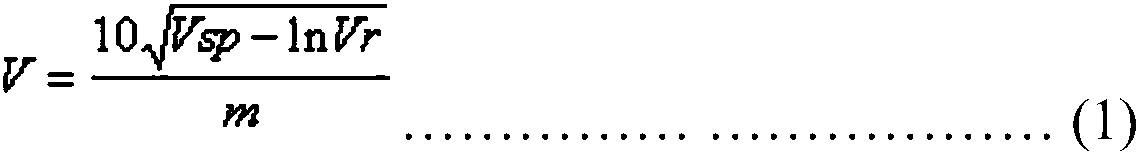

Novel coke tower and needle coke production method

ActiveCN105733650AReduce jet velocityAvoid radial maldistributionThermal non-catalytic crackingProcess engineeringMechanical engineering

The present invention relates to a novel coke tower and a needle coke production method. The coke tower includes a cylinder, an upper end socket and a lower end socket. The upper end socket is provided with a decoking port; the cylinder is provided with a coking segment and a filler segment; a baffle plate is between the coking segment and the filler segment; a feed inlet is arranged in the center of the baffle plate; the lower end socket is provided with an upper feed port and a lower feed port; the upper feed port communicates with the feed inlet of the baffle plate through a feed tube; and the lower feed port communicates with the filler segment. The invention also provides a needle coke production method, which employs the coke tower for production of needle coke. The needle coke prepared by the coke tower and process has strong needle texture structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flocculant for drilling fluid

The invention relates to a flocculant for drilling fluid, which belongs to the technical field of drilling fluid. The flocculant for the drilling fluid consists ofis prepared from 20 to 50 parts by weight of potassium chloride, 10 to 18 parts by weight of sodium carbonate, 5 to 15 parts by weight of 2-acrylamide-2-methylpro panesulfonic acidate, 0 to 10 parts by weight of acrylamide, 60 to 150 parts by weight of vinyl acetate, 80 to 120 parts by weight of water-soluble silicone oil and 1 to 5 parts by weight of sodium polyacrylate. The product, which is milky fluid, has good environment-protecting capability, and is poisonless, pollution-free and particularly applicable to offshore drilling.

Owner:HEBEI SILICON VALLEY CHEM CO LTD

Non-woven microwave sterilization equipment and non-woven processing system

InactiveCN110339380APlay a role in dispersingEffective dispersionLavatory sanitoryTextile treatment by spraying/projectingSuppressorEngineering

The invention provides non-woven microwave sterilization equipment and a non-woven processing system. The non-woven microwave sterilization equipment comprises: a microwave heating tunnel, a microwavesuppressor and a conveyor belt, wherein the microwave heating tunnel is provided with a microwave generator; the microwave suppressor includes a metal sleeve and an inner bushing disposed in the metal sleeve, a plurality of comb plates for blocking microwave transmission are disposed between the metal sleeve and the inner bushing, a microwave absorbing member for absorbing microwaves is disposedbetween two adjacent comb plates; wherein the comb plates are mounted on an inner wall of the metal sleeve, and a comb structure of the comb plates extends by facing the inner bushing direction; the microwave suppressor is respectively disposed at both ends of the microwave heating tunnel, and the conveyor belt penetrates the microwave heating tunnel and the microwave suppressor and is used for conveying the nonwoven fabric. The equipment can reduce the amount of microwave leakage during microwave sterilization to improve production safety.

Owner:孙晓宇 +1

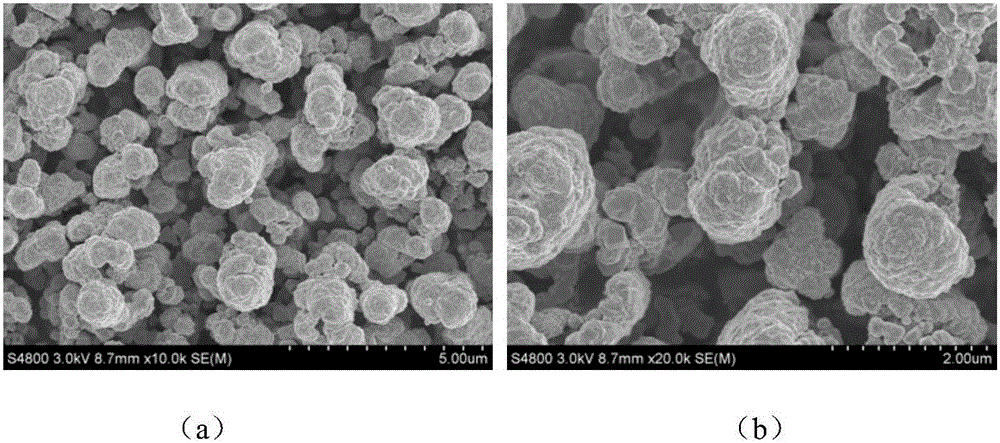

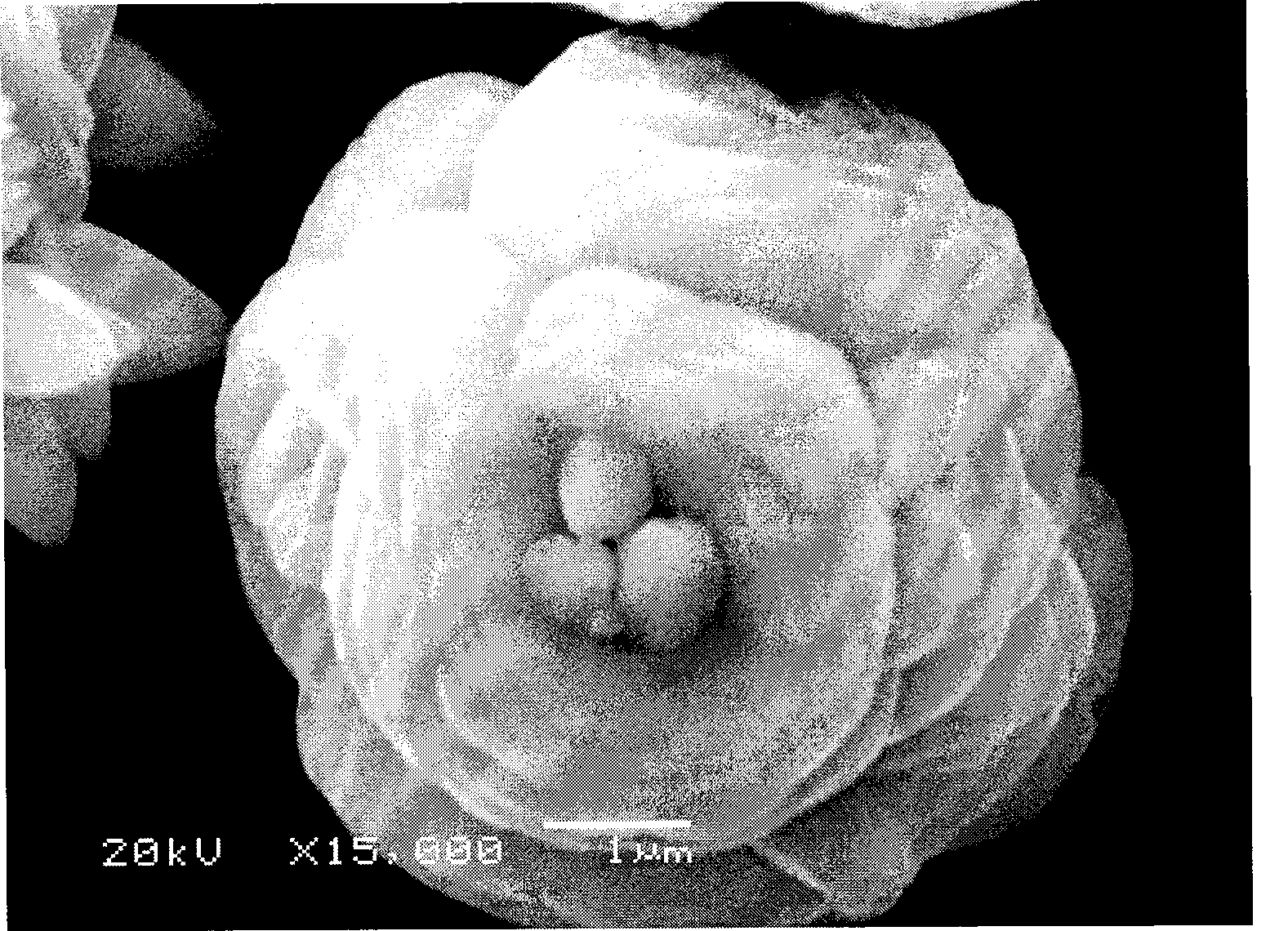

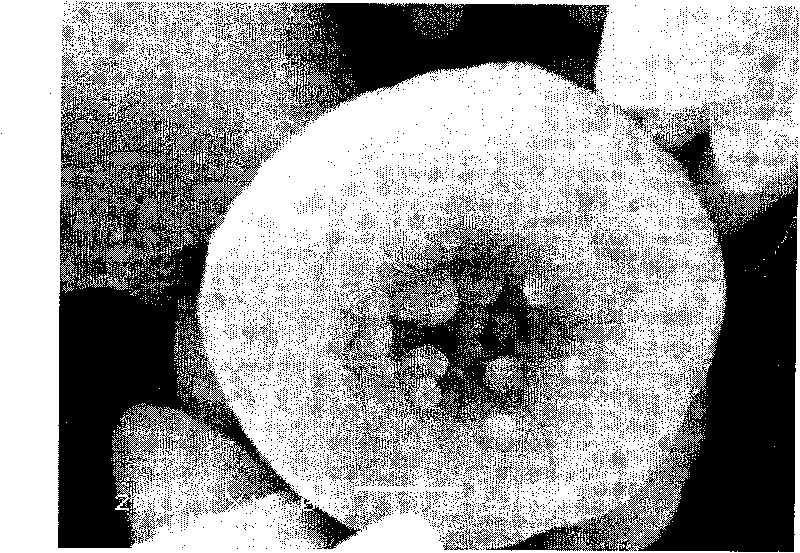

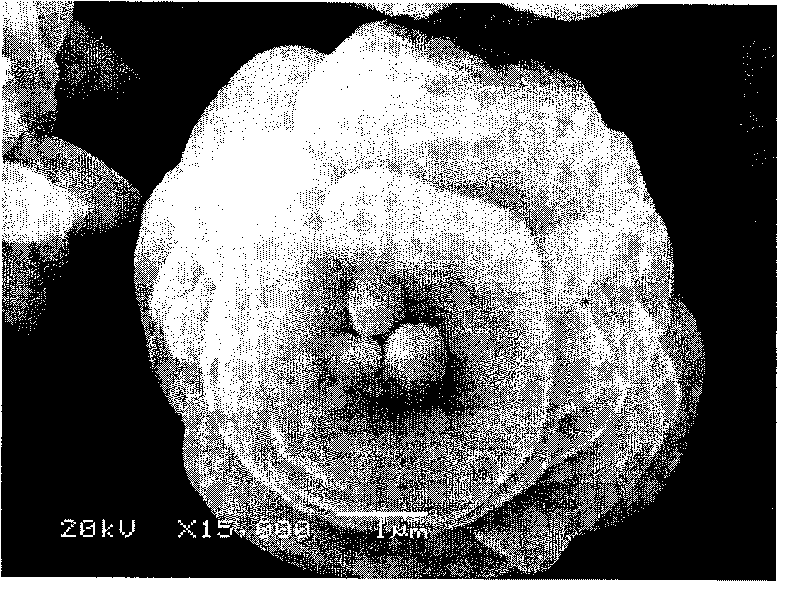

Rose-shaped nano zinc oxide and preparation method thereof

InactiveCN101391801AWith bionic structurePlay a role in dispersingZinc oxides/hydroxidesIndividual molecule manipulationAlcoholZno nanoparticles

The invention provides rosette nanometer zinc oxide and a preparation method thereof. Zn(NO3) question mark 6H2O is added into absolute ethyl alcohol solution to obtain reaction mixture; then the reaction mixture is injected into a high pressure reaction kettle with an inside lining polyfluortetraethylene liner and sealed; the reaction kettle which has reaction mixture is heated to 180 DEG C, and the temperature is kept for 2 to 10 hours; after the kettle is naturally cooled to room temperature, the obtained products are centrifugalized and washed with deionized water, and then put into a vacuum drying cabinet for drying for 12 hours at the temperature of 25 DEG C; finally the rosette nanometer zinc oxide is obtained. The invention adopts more accessible absolute ethyl alcohol with nontoxic and low price as revulsant which simultaneously plays the function of scattering so as to reduce agglomeration. The single and uniform rosette nanometer zinc oxide is obtained by the method, which adds a new member to nanometer zinc oxide family; in addition, the rosette nanometer zinc oxide has bionics structure and gives a new thought to bionics intelligent nanophase materials.

Owner:HARBIN ENG UNIV

Rose-shaped nano zinc oxide preparation method

InactiveCN101391801BWith bionic structurePlay a role in dispersingZinc oxides/hydroxidesIndividual molecule manipulationAlcoholZno nanoparticles

The invention provides rosette nanometer zinc oxide and a preparation method thereof. Zn(NO3) question mark 6H2O is added into absolute ethyl alcohol solution to obtain reaction mixture; then the reaction mixture is injected into a high pressure reaction kettle with an inside lining polyfluortetraethylene liner and sealed; the reaction kettle which has reaction mixture is heated to 180 DEG C, andthe temperature is kept for 2 to 10 hours; after the kettle is naturally cooled to room temperature, the obtained products are centrifugalized and washed with deionized water, and then put into a vacuum drying cabinet for drying for 12 hours at the temperature of 25 DEG C; finally the rosette nanometer zinc oxide is obtained. The invention adopts more accessible absolute ethyl alcohol with nontoxic and low price as revulsant which simultaneously plays the function of scattering so as to reduce agglomeration. The single and uniform rosette nanometer zinc oxide is obtained by the method, which adds a new member to nanometer zinc oxide family; in addition, the rosette nanometer zinc oxide has bionics structure and gives a new thought to bionics intelligent nanophase materials.

Owner:HARBIN ENG UNIV

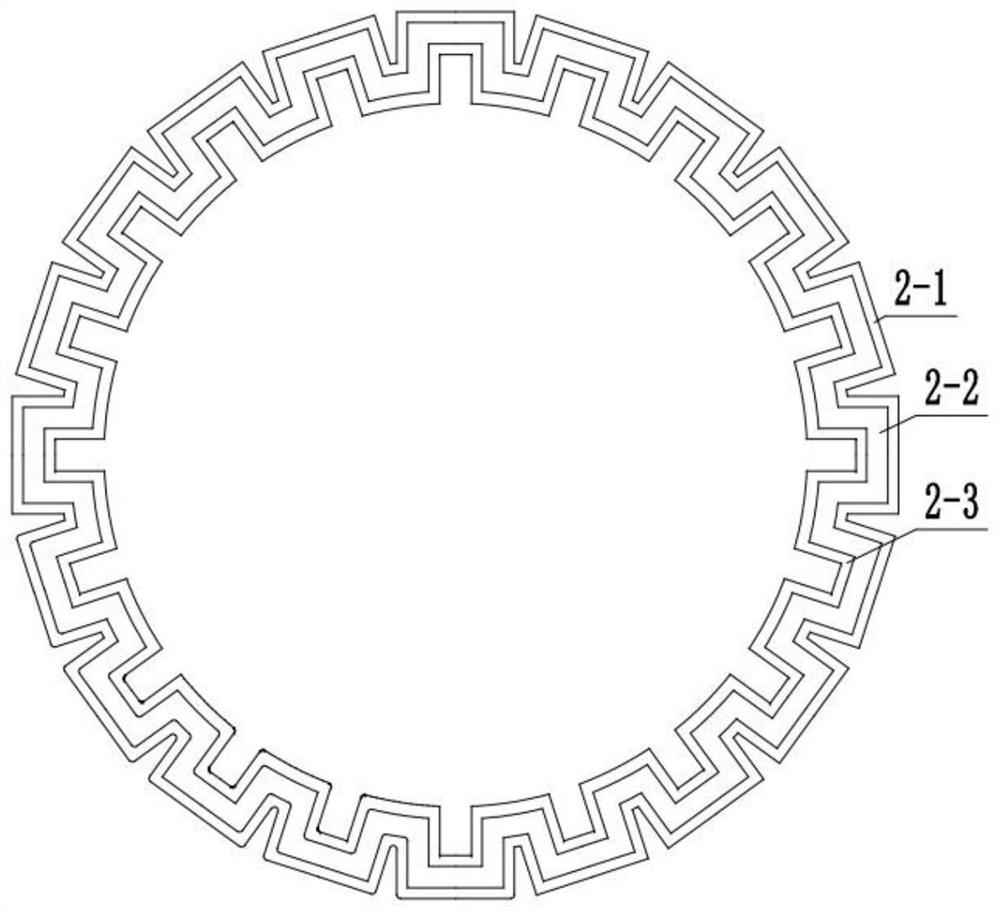

Automatic screening device for neodymium iron boron magnetic powder and automatic screening method thereof

ActiveCN110639698AReal-time speed controlFully screenedMagnetic separationGrain treatmentsScreening effectMetallurgy

The invention discloses an automatic screening device for neodymium iron boron magnetic powder and an automatic screening method thereof. The automatic screening device comprises a screening barrel, adispersing mechanism, a deviating mechanism, a collecting mechanism, a detecting mechanism and a controller. The dispersing mechanism comprises a feeding pipe, a rotating cylinder, a cutting assemblyand a driving assembly. The deviating mechanism comprises a protection plate and a plurality of magnets. The collecting mechanism comprises a first collecting barrel, a first telescopic assembly, a plurality of second collecting barrels and a plurality of second telescopic assemblies. The detecting mechanism is used for detecting the collecting amount of the neodymium iron boron magnetic powder in the first collecting barrel and the second collecting barrels. The controller is used for adjusting the rotating speed of the rotating cylinder through the driving assembly according to the specificgravity of blocky powder balls in the neodymium iron boron magnetic powder per unit volume and a data corresponding relation in a preset specific gravity-rotating speed comparison table. The screening efficiency of the neodymium iron boron magnetic powder is improved. The caked neodymium iron boron magnetic powder can be cut up, so that the screening effect is improved, and the screening qualityand purity of the neodymium iron boron magnetic powder are guaranteed.

Owner:安徽万磁电子股份有限公司

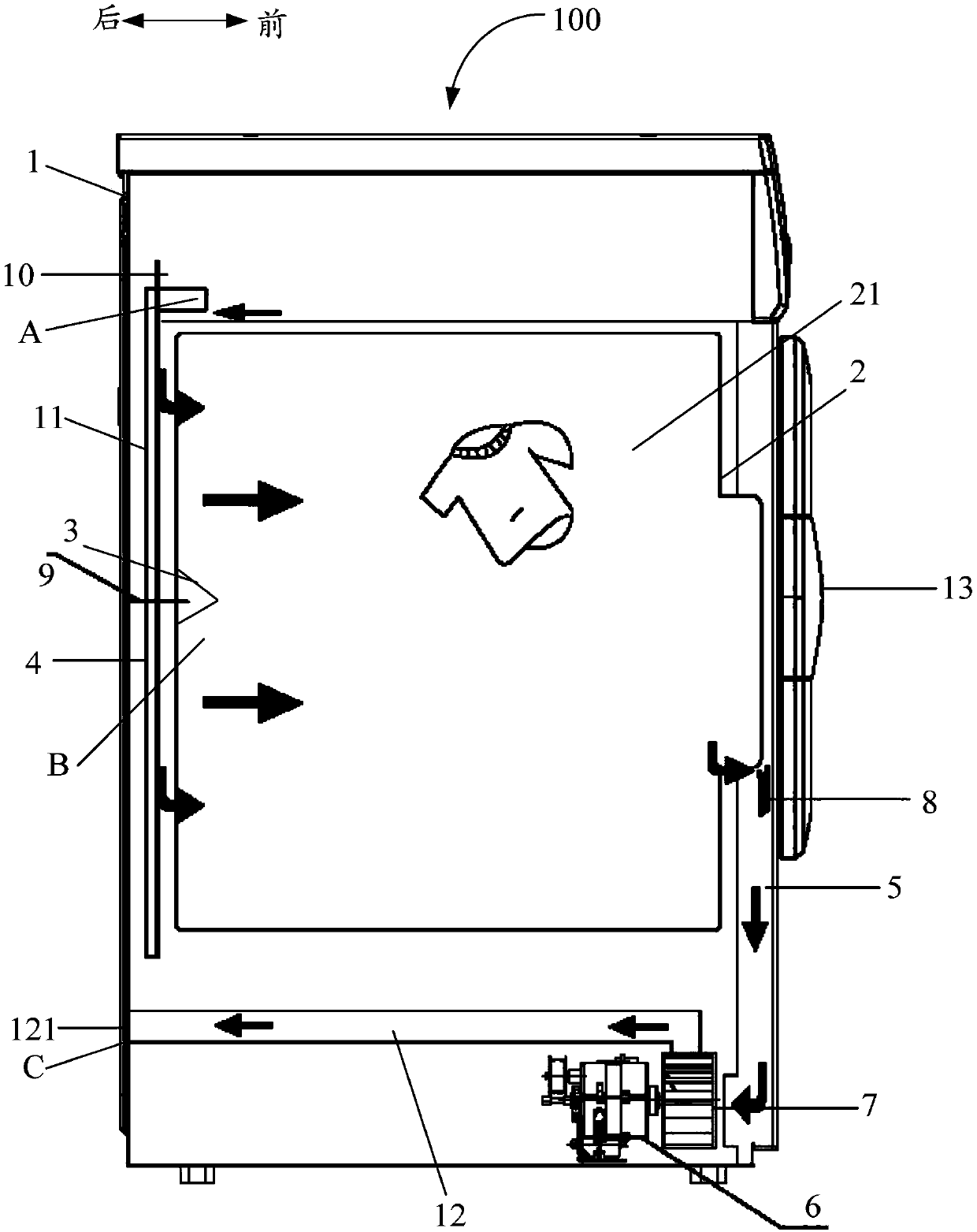

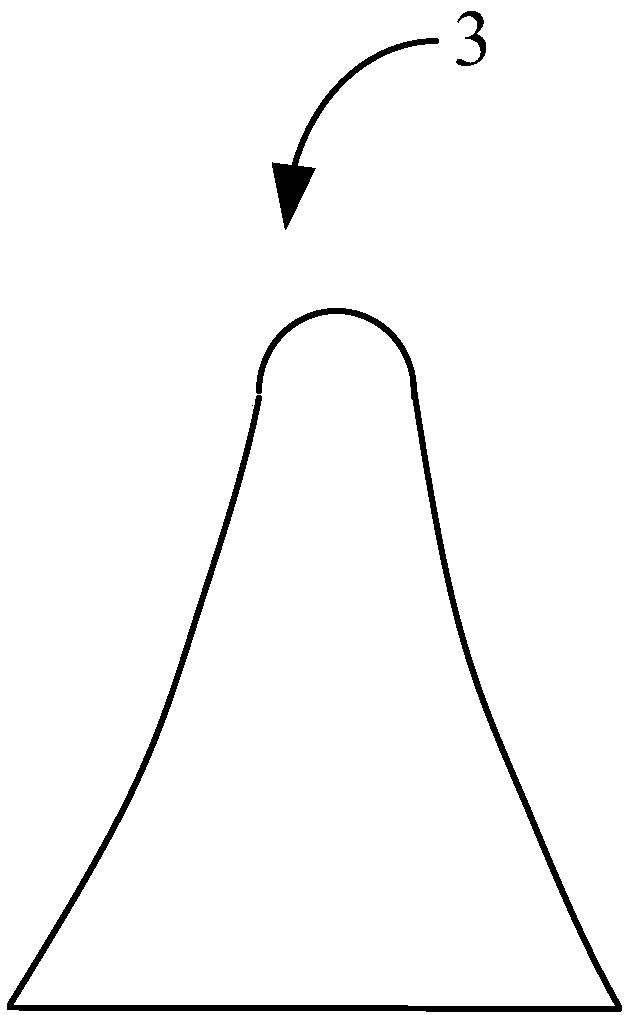

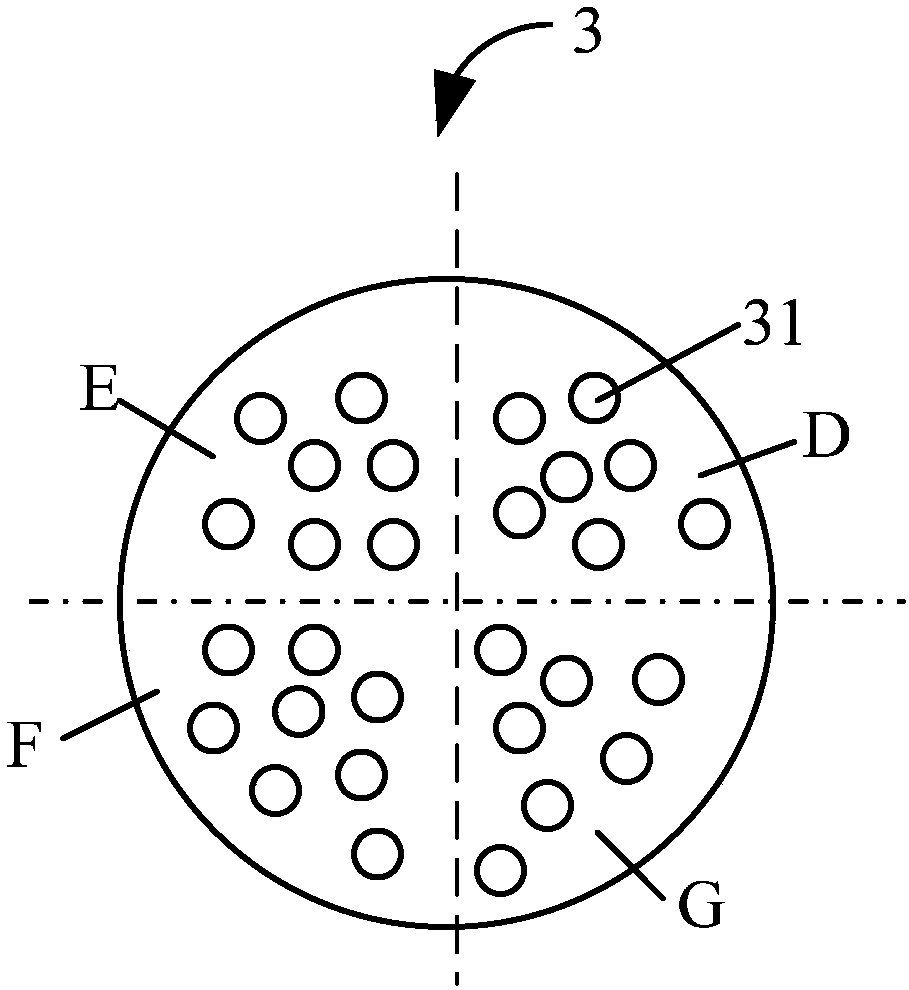

Clothes dryer

ActiveCN107904888AAvoid concentrationAvoid entanglementTextiles and paperLaundry driersAir volumePulp and paper industry

The present invention provides a clothes dryer. The clothes dryer comprises a shell, an inner cylinder, and a raised part, wherein the inner cylinder is located in the shell, the front end of the inner cylinder is open, a containing chamber with one open end is defined in the front end of the inner cylinder, a door body capable of opening or closing the containing chamber is arranged at the open position of the inner cylinder, an air inlet duct and an air outlet duct are both arranged in the shell and are communicated with the containing chamber respectively, the raised part is located at themiddle part of the inner cylinder or near the middle part of the inner cylinder, a communication air duct is arranged on the raised part, the air inlet of the communication air duct is communicated with the air inlet duct, and the air outlet of the communication air duct is communicated with the containing chamber. According to the clothes dryer, as the communication air duct is arranged on the raised part, the air volume in the middle part of the inner cylinder is increased, the uniformity of the air blown to the clothes to be dried is increased, and the drying efficiency can be effectively improved, and especially when the clothes dryer is fully loaded with the clothes to be dried, the air blown from the raised part can effectively increase the drying efficiency and shorten the drying time.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

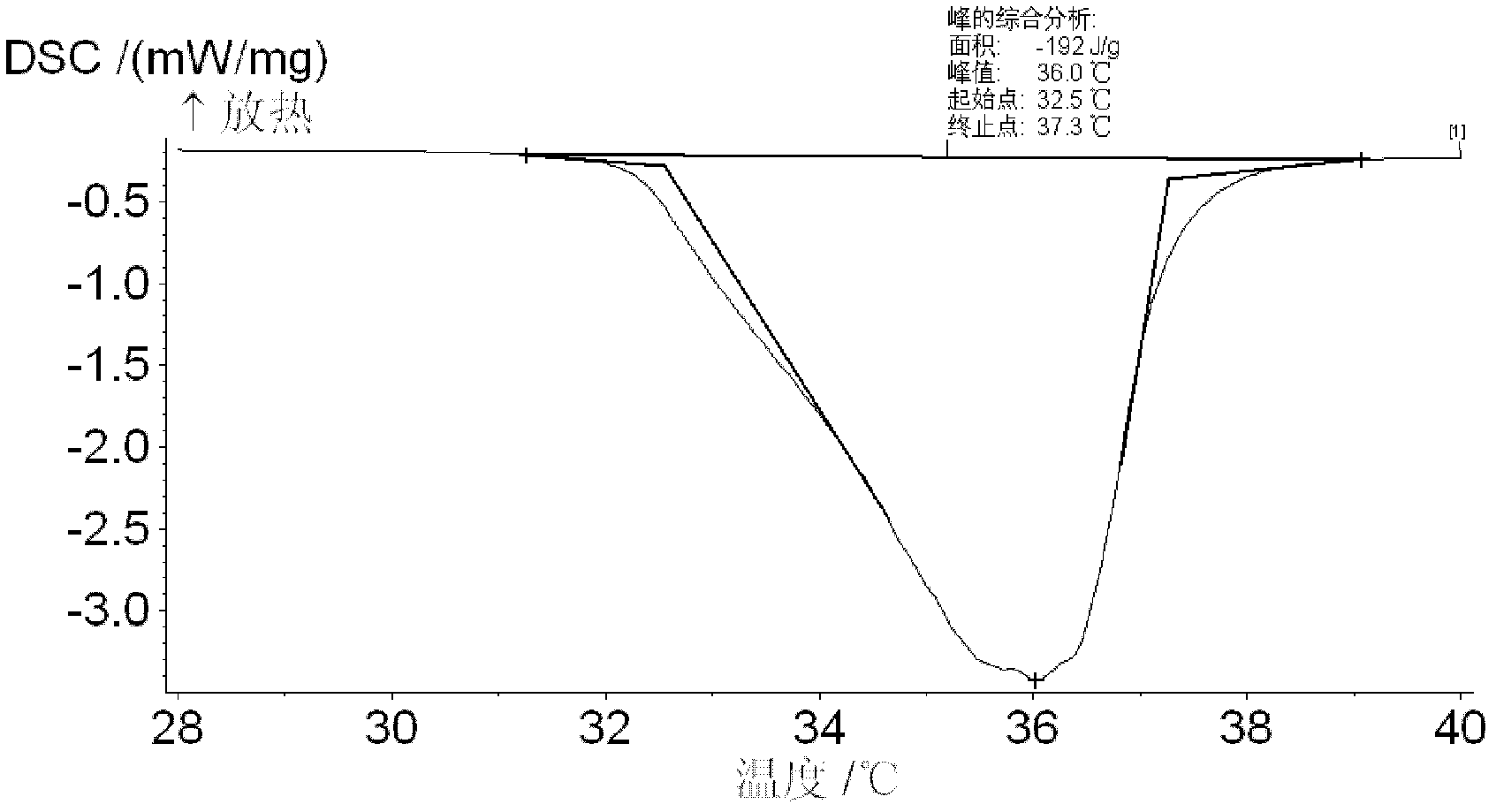

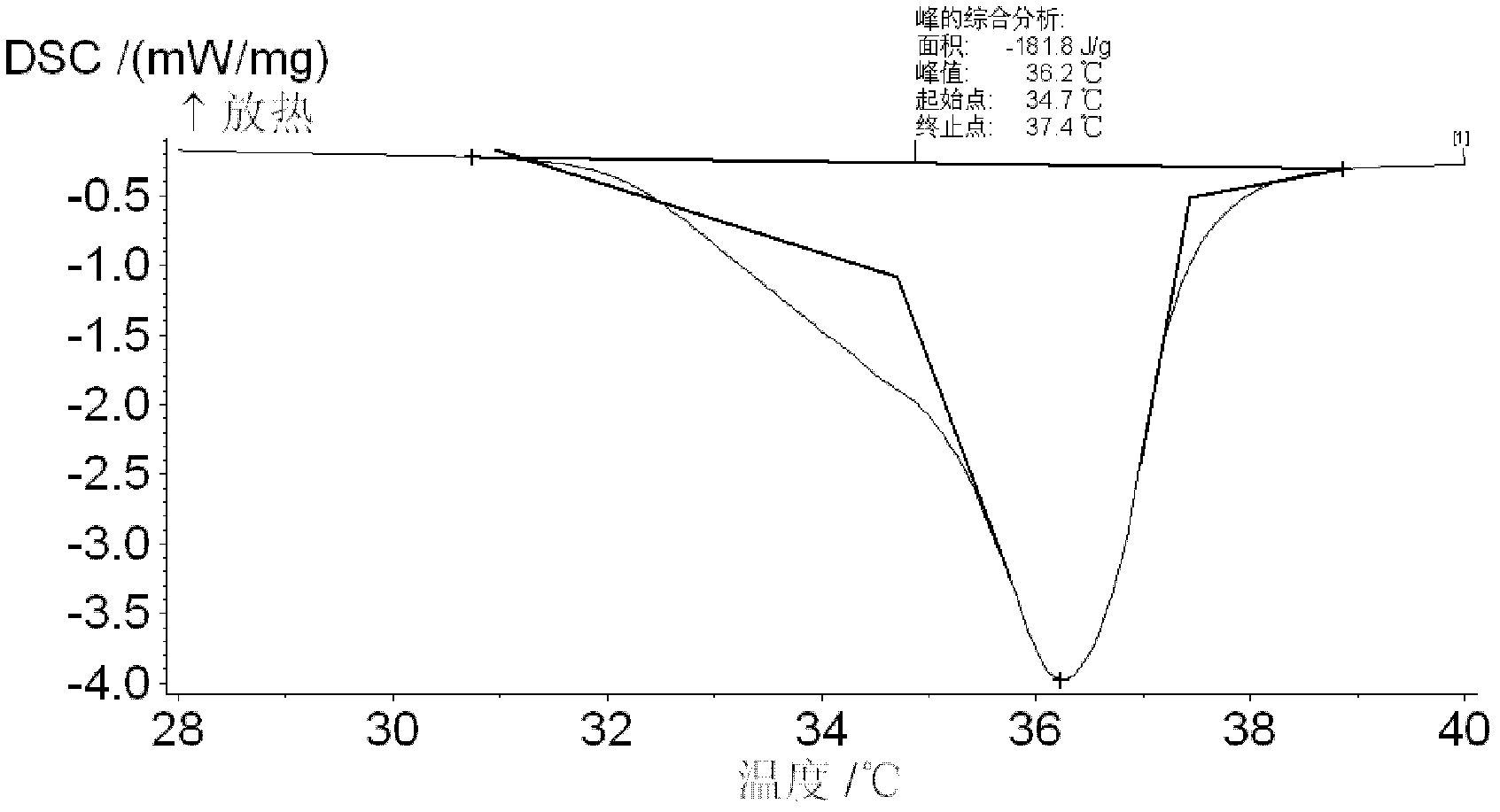

Phase change energy storage material of microscale polyvinyl chloride coated sodium sulfate decahydrate and preparation method of phase change energy storage material

InactiveCN102604598APlay a role in dispersingReduce solubilityHeat-exchange elementsWater bathsAlcohol

The invention discloses phase change energy storage material of microscale polyvinyl chloride coated sodium sulfate decahydrate and a preparation method of the phase change energy storage material. The material adopts phase change energy storage material of polyvinyl chloride coated Na2SO4.10H2O, the granularity is 100nm to 1.5um, the mass ratio of polyvinyl chloride to Na2SO4 is 15:400, and the product initial thermal value is larger than 190J / g. The preparation method comprises the following steps: firstly, putting polyvinyl chloride and tetrahydrofuran in a container, stirring the polyvinyl chloride and the tetrahydrofuran into clear solution 1, with the ration being 1.15g / 20ml; secondly, preparing the pour Na2SO4 into saturated solution, stirring while dripping mixed solution of oleic acid and absolute ethyl alcohol into a water bath at 16 to 20 DEG C, so as to obtain microscale Na2SO4.10H2O solid, thirdly, performing centrifugation to remove liquid, and fourthly, adding the solution 1 into the solid obtained in the third step, and performing air seasoning at 25 DEG C, so as to obtain the phase change energy storage material. The phase change energy storage material has high latent heat, and is simple to prepare and environmentally friendly.

Owner:XUCHANG UNIV +1

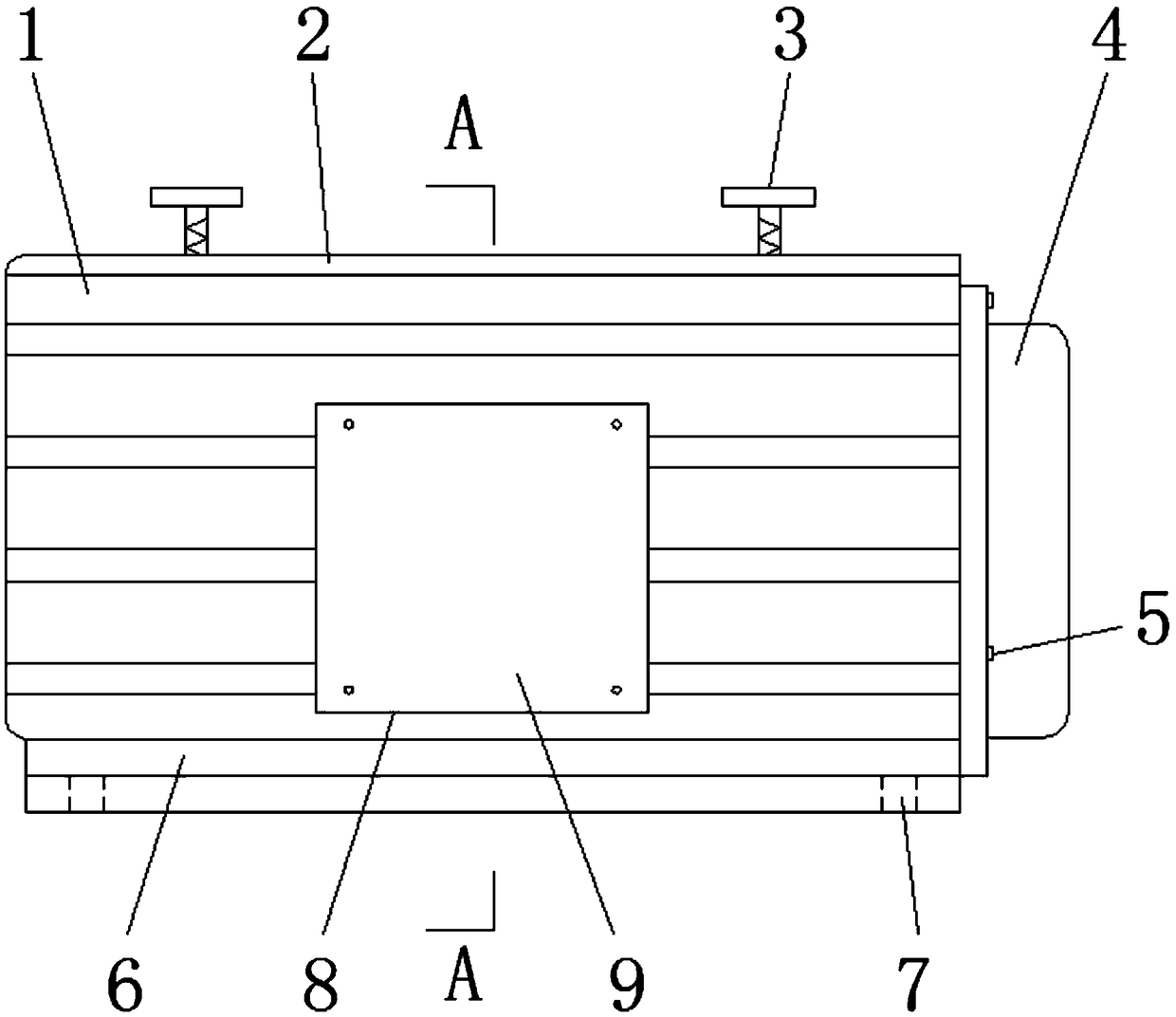

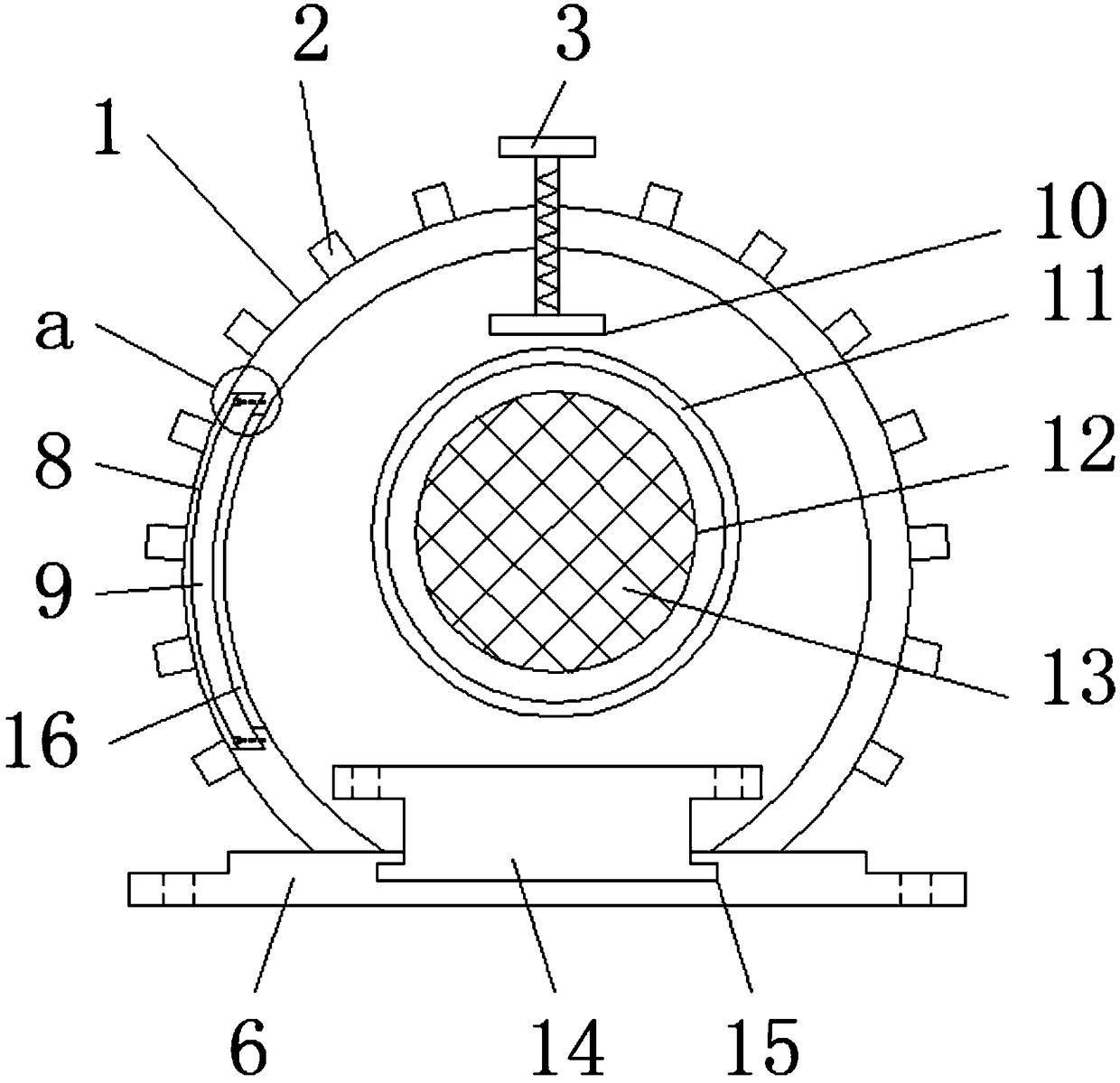

A DC motor having a plurality of sealed housing structures

InactiveCN109104022AEasy to installPlay a role in cooperating with the installationSupports/enclosures/casingsEngineeringHeat sink

A DC motor having a plurality of sealed housing structures is disclosed, including a housing body, a securing cover, a protective plate, a tightening block and a heat sink, the outer side of the housing body is provided with heat dissipation ribs, and the bottom end of the housing main body is provided with a housing fixing seat, the fixing cover is arranged on the right side of the housing main body through fixing bolts, the protective plate is arranged inside the placing groove through fixing bolts, the jacking block bearing is connected with the lower end of the screw rod, and the screw rodis threadably connected with the top of the housing body. The heat dissipation port is located at the left end of the housing main body. The inside of the housing main body is provided with a motor fixing seat, and the lower end of the motor fixing seat is connected with a sliding groove, and the sliding groove is located above the housing fixing seat. A DC motor with a plurality of sealed housing structures set a motor fixing seat inside the housing body in a slidable pullout form, facilitates installation of the motor on the motor fixing seat, and protects the motor.

Owner:JIANGSU JINFENG ELECTROMECHANICAL CO

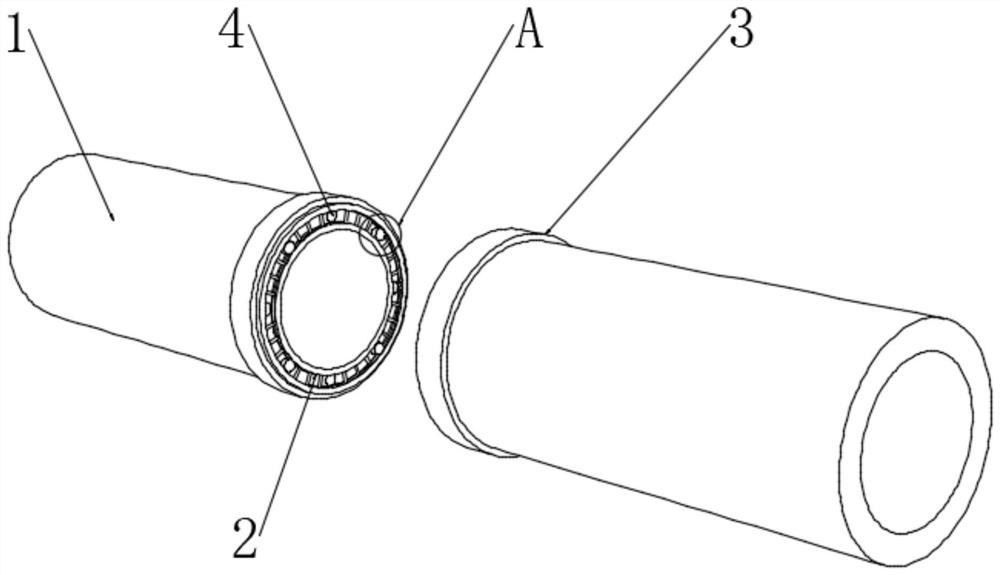

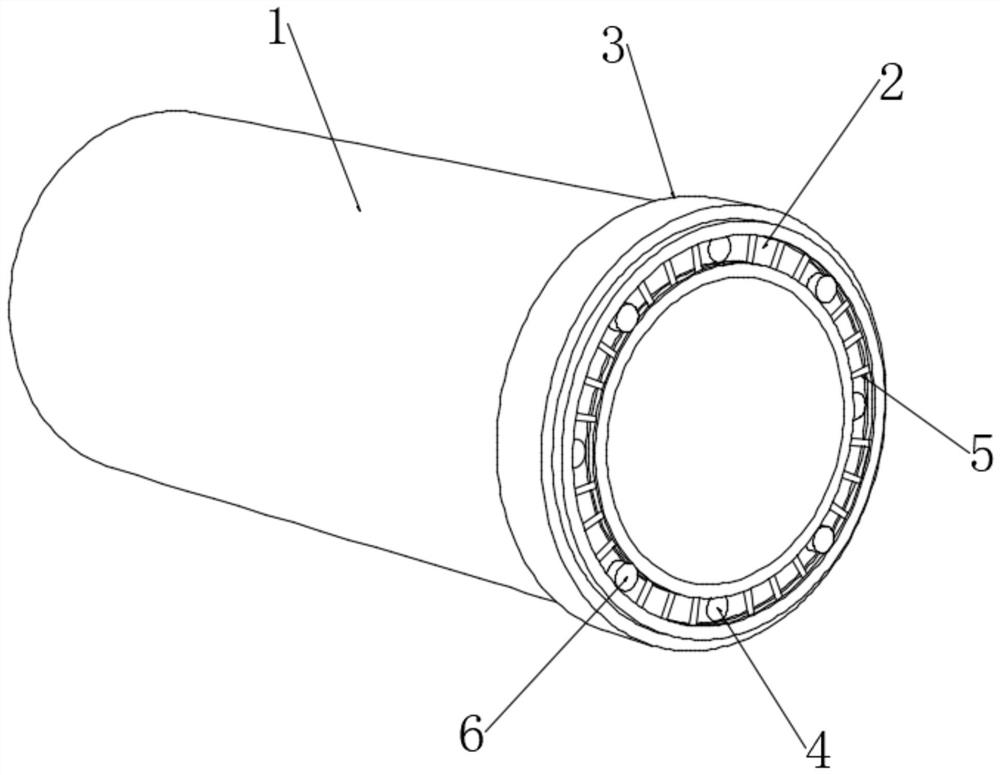

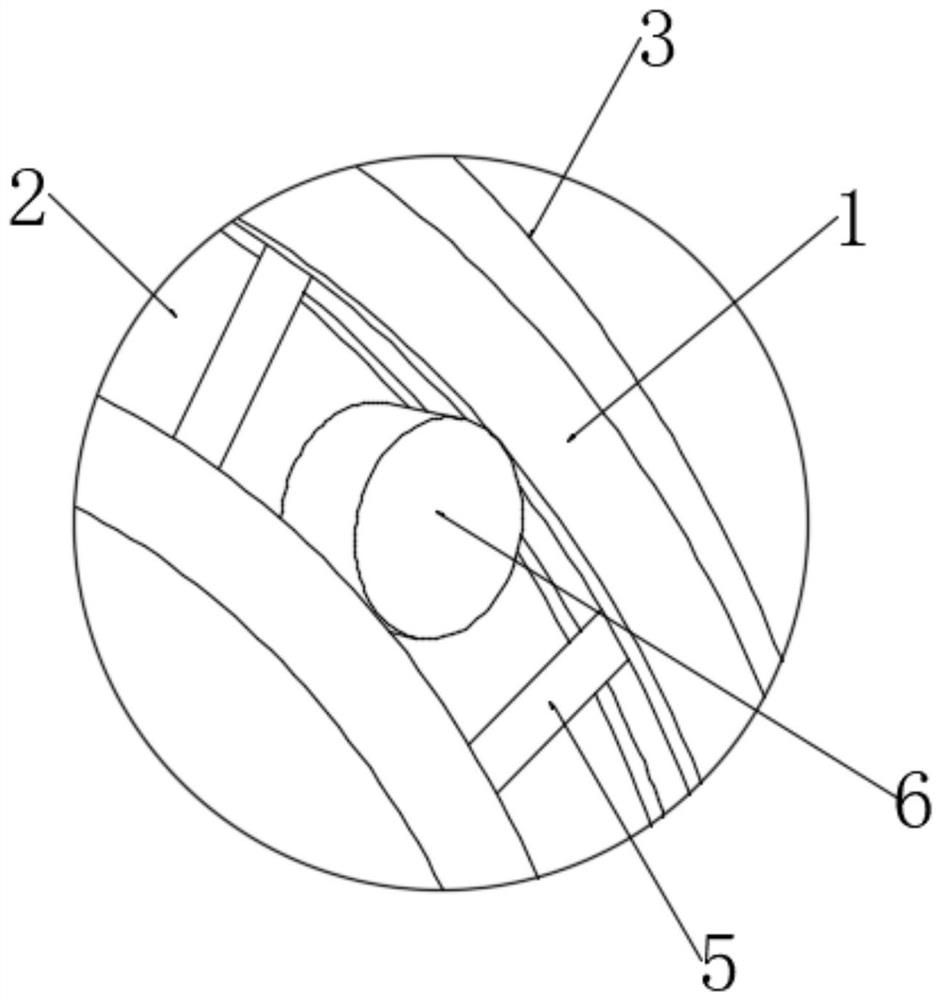

Novel integrated connected and self-melting PE pipe

ActiveCN111637304AImprove docking efficiencyImprove simplicityPipe connection arrangementsRigid pipesThermodynamicsSuction force

The invention discloses a novel integrated connected and self-melting PE pipe, and belongs to the technical field of PE pipes. Only two sections of pipelines need to be aligned and matched during buttjointing, the connection action is triggered by magnetic attraction, through the automatic extension and the internal exothermic effect of an extending tentacle air bag, a ball filled in advance is released and hot-melted, through a melt assisting ball arranged on a magnetic suction tentacle column, the temperature is used as the melt assisting power to force an internal microseismic balloon to be in contact with the high-temperature surface to produce a small explosion impact, and force a melt assisting heat conducting needle to vibrate in a hot-melt plastic with high frequency. On the on hand, the heat conductivity efficiency of the magnetic suction tentacle column to the resin ball is improved, on the other hand, the hot-melt plastic can be stirred and mixed in the overall situation scope, the fluidity of the hot-melt plastic is improved, thus the degree of uniformity and strength after curing are improved, the integrated and high-strength connection of the two sections of pipelines is effectively conducted, the butt-jointing efficiency and simplicity of the pipelines are greatly improved, and the novel integrated connected and self-melting PE pipe is especially suitable for the pipeline butt-jointing in narrow environment.

Owner:内蒙古华塑节水灌溉科技有限公司

A platinum-based catalyst highly dispersed in carrier silica and its preparation method and application

InactiveCN108067249BNot easy to aggregate and sinterImprove stabilityHeterogenous catalyst chemical elementsCatalystsPtru catalystDehydrogenation

The invention discloses a Pt based catalyst highly dispersed in a carrier SiO2 as well as a preparation method and application thereof. The catalyst takes SiO2 as the carrier, takes metal Pt as an active component, and takes NiO, La2O3 and LaFeO3 as auxiliaries; based on the total mass of the catalyst, the Pt based catalyst is prepared from the following components in percentage by mass: 0.1-0.3%of metal Pt, 0.05-4% of NiO, 0.25-9.0% OF La2O3, 17.0-30.0% of LaFeO3 and 55.0-85.0% of SiO2, and the catalyst can be applied to isobutylene dehydrogenation. The selected SiO2 has a big specific surface area, so that each component can be highly dispersed, and therefore, the catalyst is not liable to gather and sinter; meanwhile, Pt is doped into a perovskite structure, so that the reduced Pt particles are small, and perovskite particles, lanthanum oxide particles and nickel oxide particles among the Pt particles achieve the dispersion effect as a result of the special structure of perovskite,and therefore, more active sites are exposed; and Pt is not liable to reunite at a high temperature, so that stability and reaction activity of the catalyst are improved.

Owner:TIANJIN UNIV

A kind of high-performance polycarboxylate water reducer and preparation method thereof

The invention discloses a high-performance polycarboxylate water reducer, the polycarboxylate water reducer has a general structural formula (I), and the invention also provides a preparation method of a high performance polycarboxylate water reducer, In addition to polyether macromonomers and unsaturated carboxylic acid monomers, unsaturated phosphate ester monomers are added to obtain a high-performance polycarboxylate water reducer with a phosphate ester structure. The polycarboxylate water reducer disclosed by the invention has a safe and simple preparation process, is environmentally friendly, has low energy consumption and low cost, and is suitable for industrial scale production. Among them, R 1 is ‑H, ‑COO‑ or ‑CH 2 COO‑;R 2 is ‑H or ‑CH 3 ; 3 is ‑H or ‑CH 3 ; 4 is ‑H or ‑CH 3 ; 5 is ‑H or ‑CH 3 ; 6 for-CH 2 ‑or‑CH 2 CH 2 -; X, Y, Z and n are all integers, X=1-100, Y=1-100, Z=1-100, n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

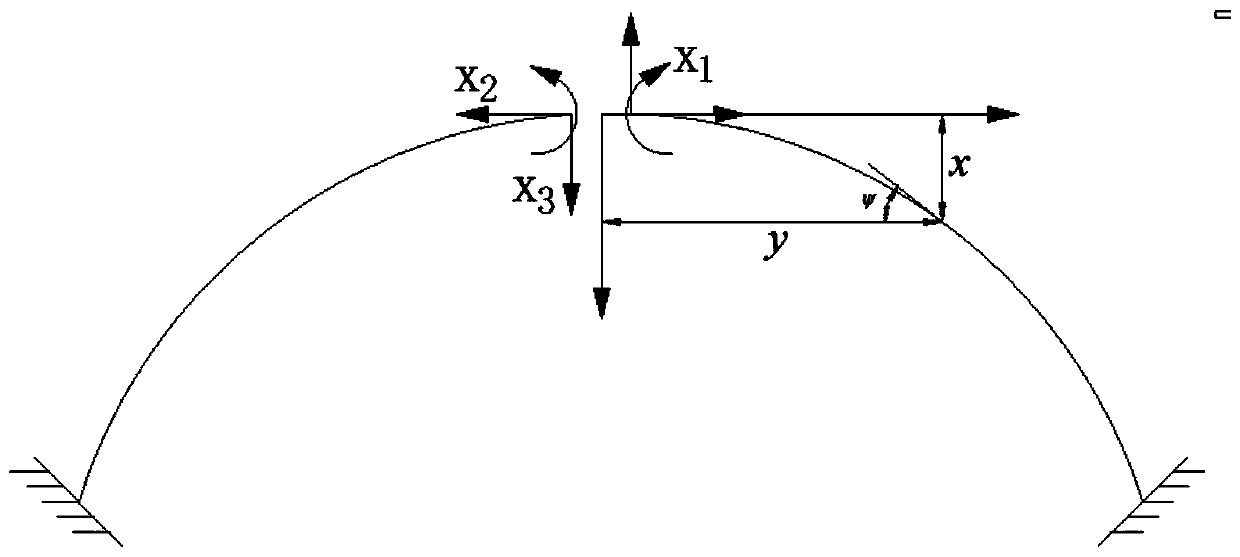

Composite retaining structure of variable stratum non-equal-size double-circular-arc foundation pit

ActiveCN110528536AHigh strengthPlay a role in a reasonable distributionExcavationsBulkheads/pilesStructure of the EarthUltimate tensile strength

The invention relates to the technical field of engineering construction, specifically to a composite retaining structure of a variable stratum non-equal-size double-circular-arc foundation pit. A double-circular-arc retaining mechanism is arranged in a non-equal-size double-circular-arc section foundation pit; the double-circular-arc retaining mechanism comprises a double-circular-arc continuouswall and more than three layers of annular supporting mechanisms; the three layers of the annular supporting mechanisms are connected by using an internal ring connecting beam and one pair of perpendicular straight supporting beam mechanisms so that a stress transmission passage is formed between the internal ring connecting beam and an external circular supporting beam; on the one hand, a reasonable distribution effect on the stress of the side wall of the double-circular-arc section foundation pit is realized; and on the other hand, the deformation of the annular supporting mechanisms can also be controlled; and as the annular supporting mechanisms are connected with each other through upright mechanisms in the axial direction in a through manner, the integral intensity of the double-circular-arc retaining mechanism is enhanced.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com