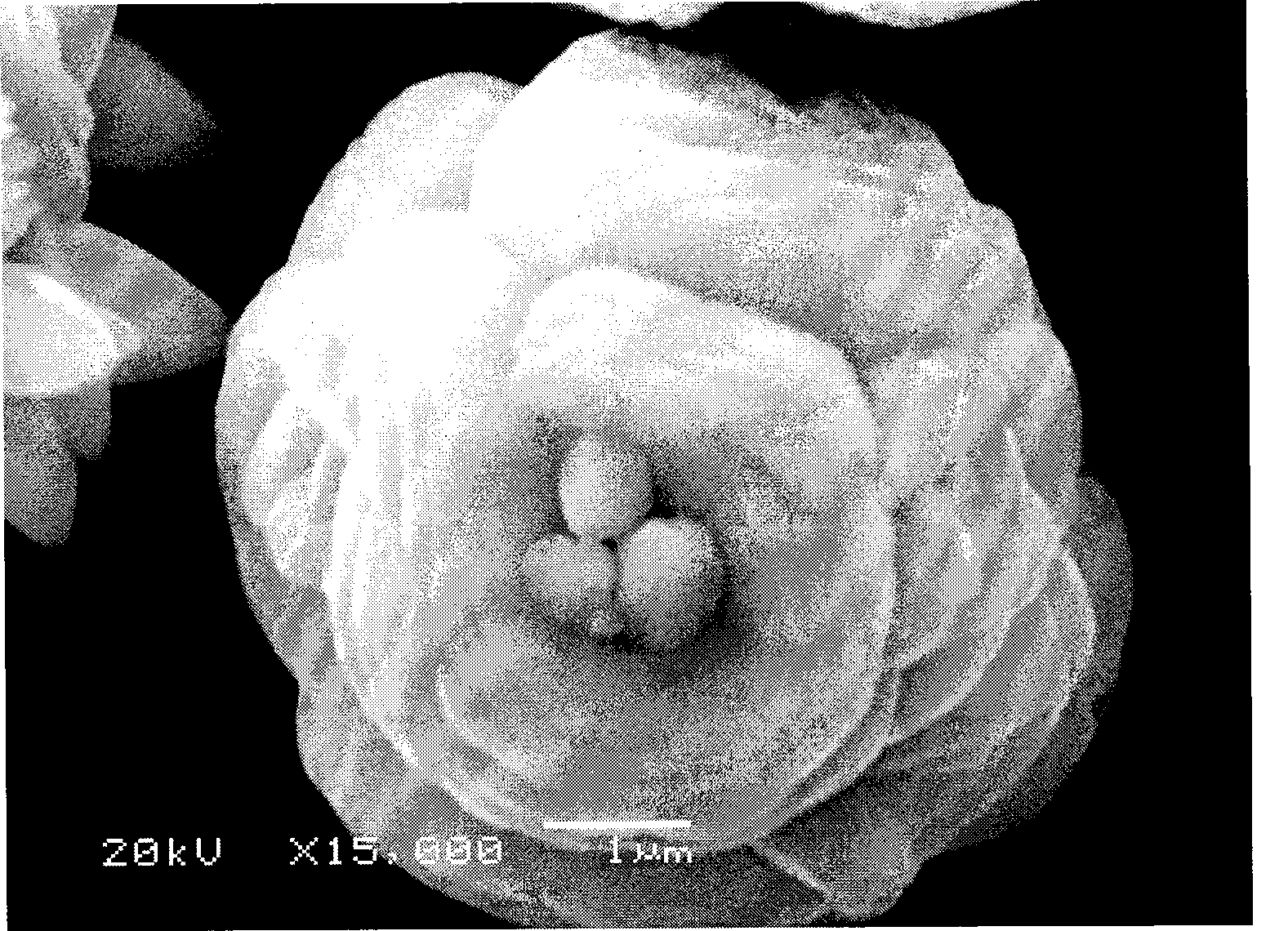

Rose-shaped nano zinc oxide and preparation method thereof

A nano-zinc oxide and rosette technology, which is applied in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve problems such as unfavorable large-scale production, surfactant unfavorable product cleaning, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1mmolZn(NO 3 ) 2 ·6H 2 O is put into the autoclave of the polytetrafluoroethylene liner that absolute ethanol is housed, and is sealed. Then put the autoclave containing the reaction reagents into an oven and add heat to 180° C., and keep the temperature constant for 2 hours. The obtained product was separated by centrifugation, washed several times with deionized water, and then placed in a vacuum drying oven at 25° C. for 12 hours to obtain rose-like nano-zinc oxide.

Embodiment 2

[0017] After maintaining the reaction in an oven at 180° C. for 4 hours, it was naturally cooled to room temperature, and the others were the same as above.

Embodiment 3

[0019] After maintaining the reaction in an oven at 180° C. for 6 hours, it was naturally cooled to room temperature, and the others were the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com