Novel integrated connected and self-melting PE pipe

An integrated, self-fusing technology, applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, pipes, etc., can solve the problems of PE pipe connection methods that are difficult to work, connection quality is difficult to guarantee, and connection efficiency is low, so as to improve efficiency and Simplicity, improved fluidity, improved uniformity and strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

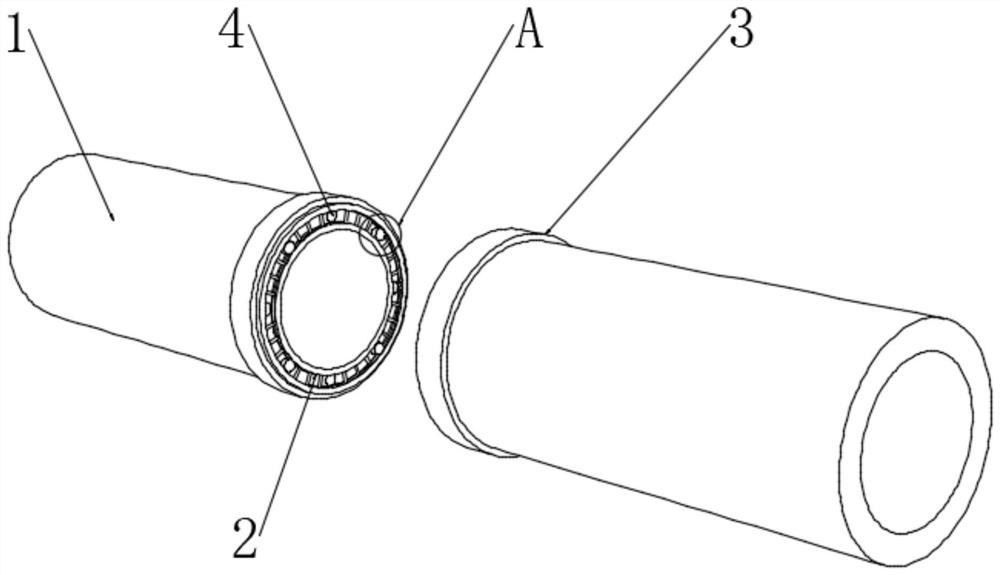

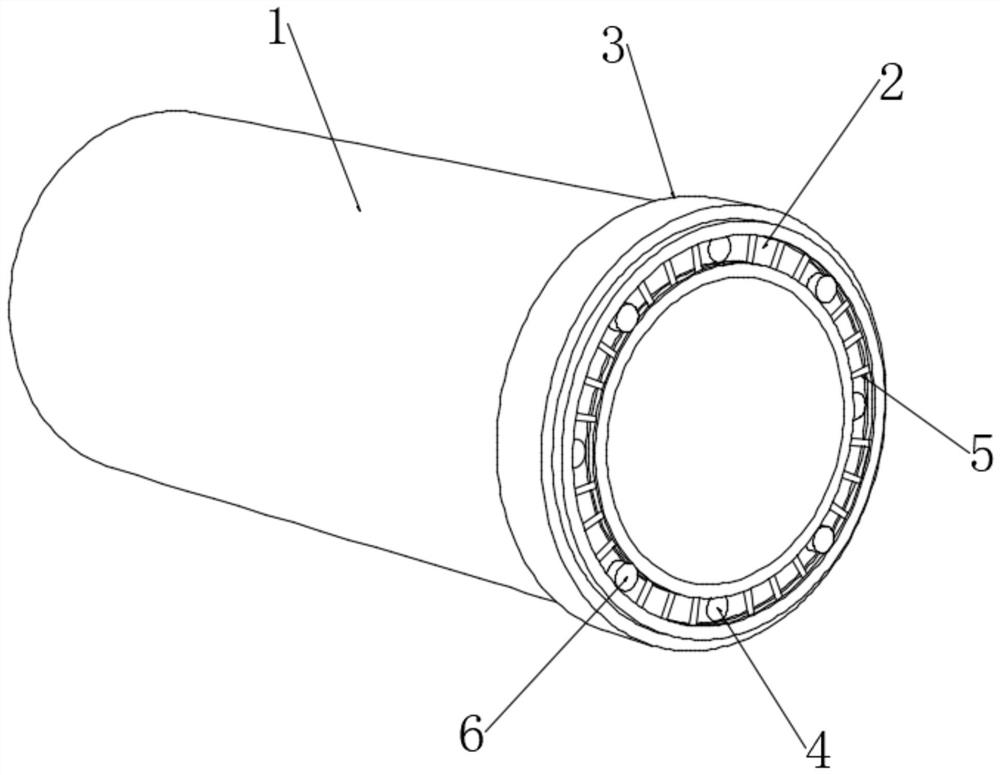

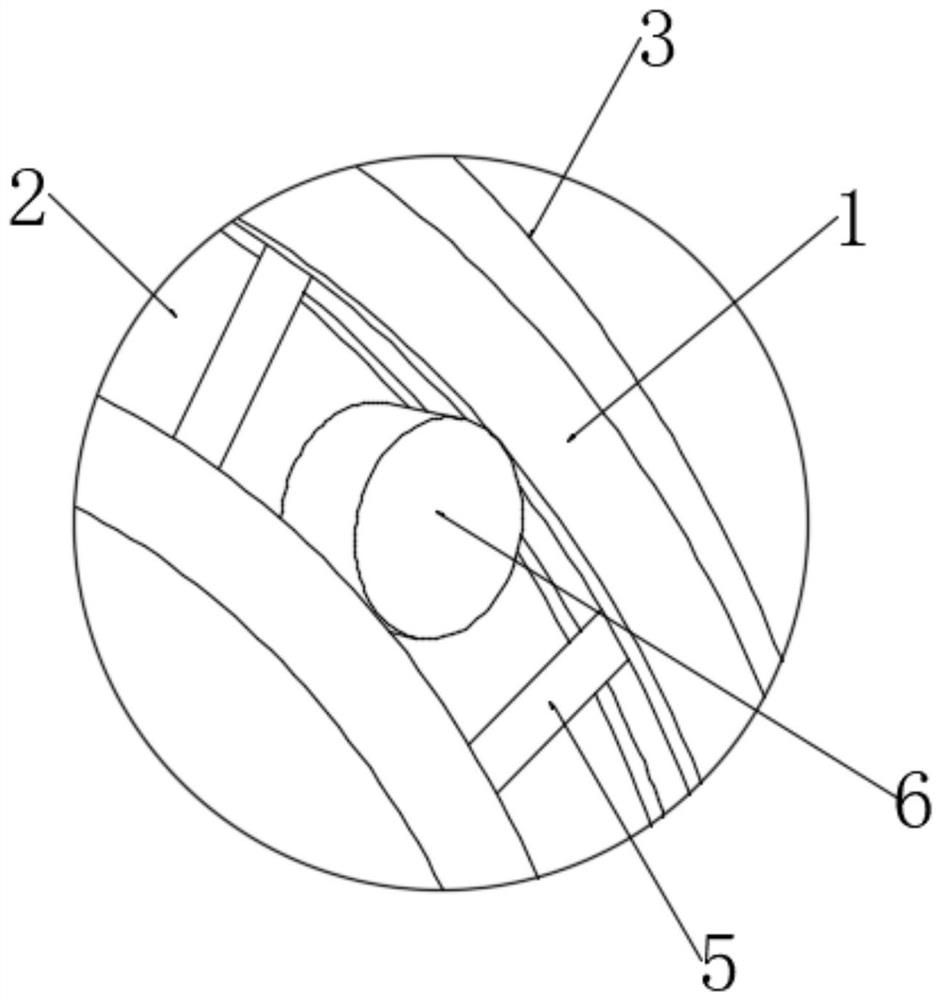

[0049] see Figure 1-3 , a new type of integrally connected self-melting PE pipe, including a pipe body 1, a material guide groove 2 is opened on the side wall of one end of the pipe body 1, and a plurality of evenly distributed material storage tanks are opened on the bottom wall of the material guide groove 2 4. Stretching tentacle airbags 7 are fixedly connected in the storage tank 4, and a plurality of magnetic tentacle columns 6 are fixedly connected to the bottom wall of the material guide groove 2, and the magnetic tentacle columns 6 and the storage tank 4 are alternately distributed An inner annular embedding groove and an outer annular embedding groove are respectively opened on the two side walls of the material guide groove 2, and a plurality of shaping rods 5 distributed in an annular array are fixedly connected between the inner annular embedding groove and the bottom wall of the outer annular embedding groove. To guide the dispersion of hot-melt plastics, improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com