Lightweight limesand brick and production process

A production process, the technology of lime-sand bricks, applied in the field of artificial stone, can solve the problems of heavy-weight lime-sand bricks, inconvenient transportation and use, etc., and achieve the effects of light weight, easy crushing, convenient transportation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

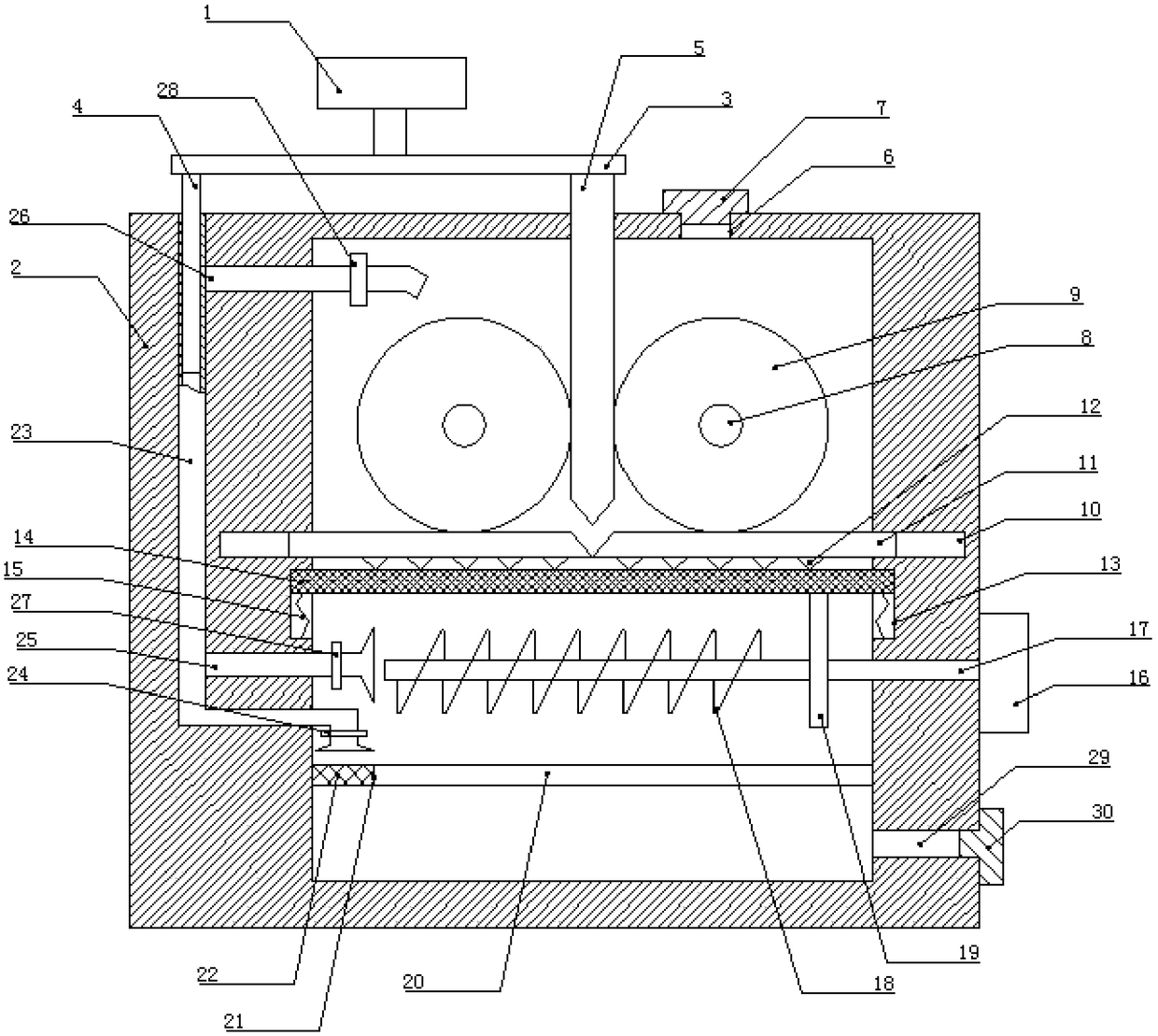

[0023] A lightweight lime-sand brick and its production process. The raw materials are hard construction and industrial waste, machine-made sand (egg machine-made sand or mountain machine-made sand), medium-coarse sand (river sand), powdery waste, and cementitious material (cement) Composition, production steps include:

[0024] Step 1: Crushing the various raw materials separately requires the use of a crushing device;

[0025] Add various raw materials into the box body 2, and carry out the first crushing process on the raw materials through the clockwise and counterclockwise rotation of the gear 9; through the movement of the gear 9 and the rack 11, the two racks 11 can make the two racks 11 face each other or move in the opposite direction. To move to, and then intermittently transport the raw materials after the first crushing to the screen 14; and the gear 9 drives the rack 11 to move back and forth so that the grinding teeth 12 on the rack 11 can act on the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com