Preparation process of waterborne coating

A preparation process and technology of water-based coatings, applied in the direction of polyurea/polyurethane coatings, coatings, filter screens, etc., can solve the problems of troublesome cleaning, clogging of screening holes, high labor intensity, etc., and achieve easy cleaning, convenient disassembly, labor strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

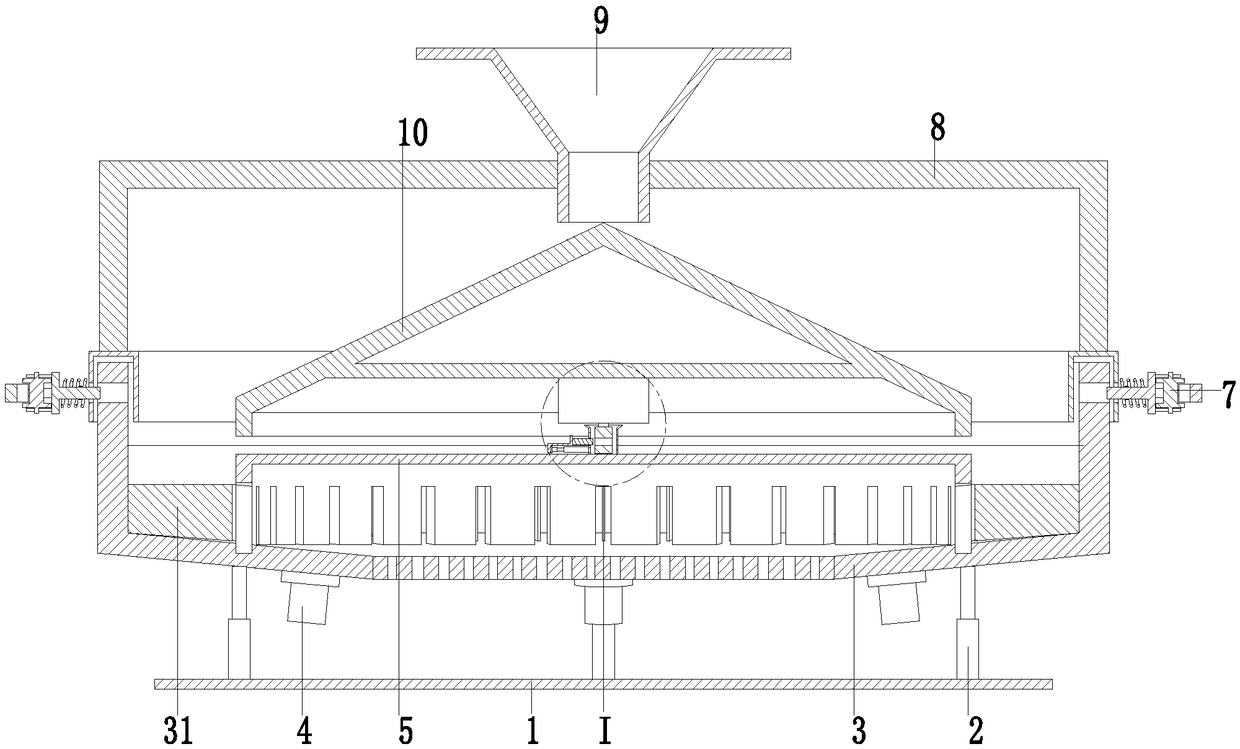

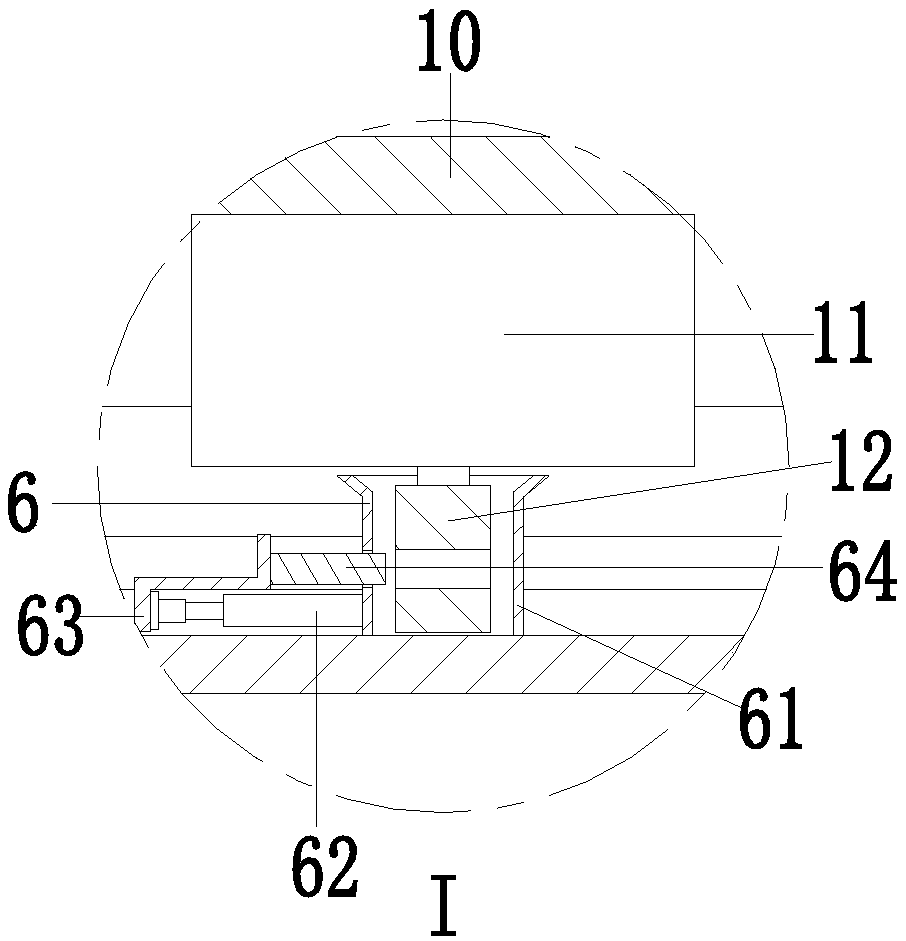

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

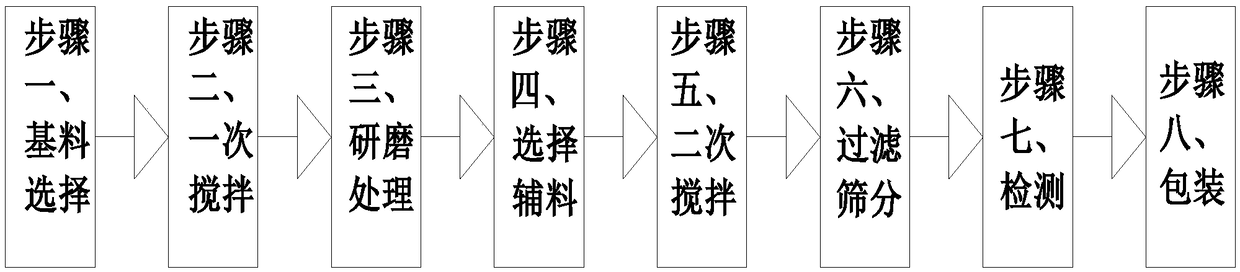

[0026] Such as Figure 1 to Figure 4 Shown, a kind of preparation technology of waterborne coating comprises the following steps:

[0027] Step 1, base material selection, select the following raw materials by weight: select the following raw materials by weight: polyurethane adhesive 80-100, realgar 30-50, mica powder 18-20, silicone oil defoamer 28-30, solvent dispersant 25 -27;

[0028] Step 2, stir once, put the prepared base material into the mixer for stirring, the speed is 5-3r / s, the time is 15-20min, and the mixer is ZJH-I self-mixing high-uniformity powder mixer;

[0029] Step 3, grinding treatment, putting the raw materials obtained after one stirring into a horizontal grinder for grinding processing;

[0030] Step 4, select auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com