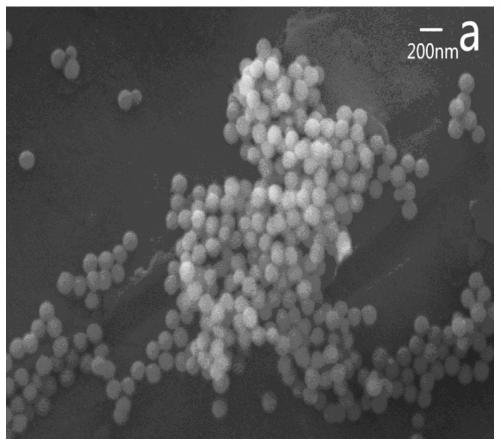

Nano spherical lithium hydroxide and preparation method thereof

A lithium hydroxide and nanosphere technology, applied in the preparation of microspheres, lithium oxide;/hydroxide, microcapsule preparation, etc., to achieve the effects of improving economy, increasing dispersibility, and improving physical appearance and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

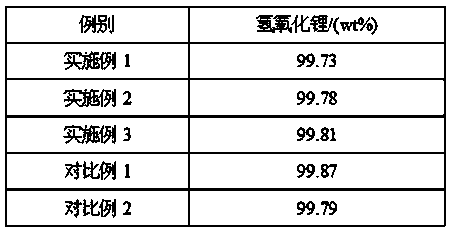

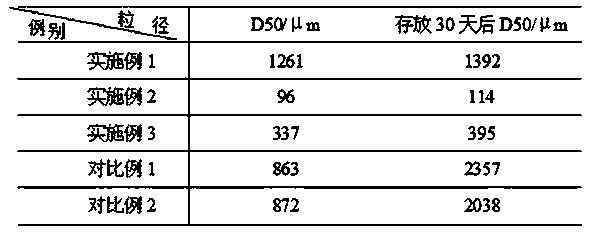

Embodiment 1

[0028] This example is made through the following steps:

[0029] (1) Preparation of lithium hydroxide solution: Take 125.7 parts by mass of lithium hydroxide (analytically pure, with a purity of 99.9%), put it into 1000 parts by mass of deionized water and stir to dissolve it, and prepare a lithium hydroxide solution with a concentration of 3mol / L ;

[0030] (2) Preparation of lithium hydroxide emulsion: add 40 parts by mass of sulfonated kerosene to the lithium hydroxide solution prepared in step (1), add 0.20 parts by mass of sodium tetradecyl sulfate, and stir evenly to obtain lithium hydroxide emulsion;

[0031] (3) Ball making: the lithium hydroxide emulsion prepared in step (2) is dried by spray drying equipment at 250°C to make lithium hydroxide nanospheres;

[0032] (4) Drying: place the lithium hydroxide nanospheres prepared in step (3) in a drying device at 220°C for sufficient drying to remove organic matter and structural water, and obtain nano-spherical lithium...

Embodiment 2

[0034] This example is made through the following steps:

[0035] (1) Preparation of lithium hydroxide solution: Take 41.9 parts by mass of lithium hydroxide (analytically pure, with a purity of 99.9%), put it into 10,000 parts by mass of deionized water, stir and dissolve it fully, and prepare lithium hydroxide with a concentration of 0.1mol / L solution;

[0036] (2) Preparation of lithium hydroxide emulsion: add 2072 parts by mass of propylene glycol to the lithium hydroxide solution prepared in step (1), add 0.02 parts by mass of sodium dodecylsulfonate, and stir evenly to obtain lithium hydroxide emulsion turbid liquid;

[0037] (3) Ball making: the lithium hydroxide emulsion prepared in step (2) is dried by spray drying equipment at 100°C to make lithium hydroxide nanospheres;

[0038] (4) Drying: The lithium hydroxide nanospheres prepared in step (3) are placed in a drying device at 400°C for sufficient drying to remove organic matter and structural water to obtain nano...

Embodiment 3

[0040] This example is made through the following steps:

[0041] (1) Preparation of lithium hydroxide solution: Take 41.9 parts by mass of lithium hydroxide (analytically pure, with a purity of 99.9%), put it into 1000 parts by mass of deionized water and fully stir and dissolve it to prepare a lithium hydroxide solution with a concentration of 1mol / L ;

[0042] (2) Preparation of lithium hydroxide emulsion: add 127 parts by mass of polyethylene glycol to the lithium hydroxide solution prepared in step (1), add 0.02 parts by mass of sodium dodecylsulfonate, and stir evenly to obtain hydrogen Lithium oxide emulsion;

[0043] (3) Ball making: the lithium hydroxide emulsion prepared in step (2) is sprayed and dried at 400°C by spray drying equipment to prepare lithium hydroxide nanospheres;

[0044] (4) Drying: After the lithium hydroxide nanospheres prepared in step (3) are fully stirred by a three-dimensional mixer, they are placed in a drying device for sufficient drying at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com