Flocculant for drilling fluid

A technology of drilling fluid and flocculant, which is applied to coating flocculant for drilling fluid and marine drilling. It can solve the problems of affecting the construction progress, difficult to dissolve, and adding a large amount of inorganic salt, and achieve the effect of good anti-slump effect, fast dissolution speed, and increase of adsorption force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

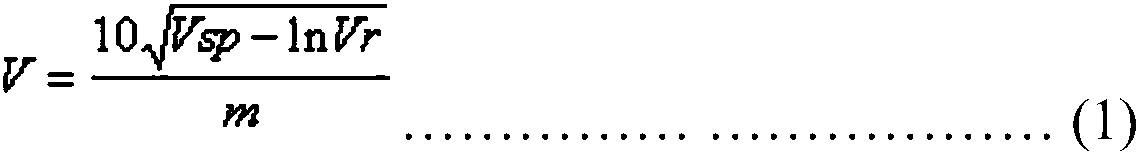

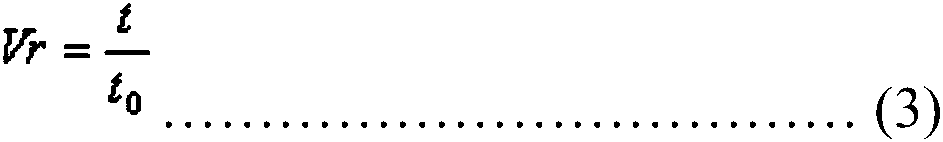

Method used

Image

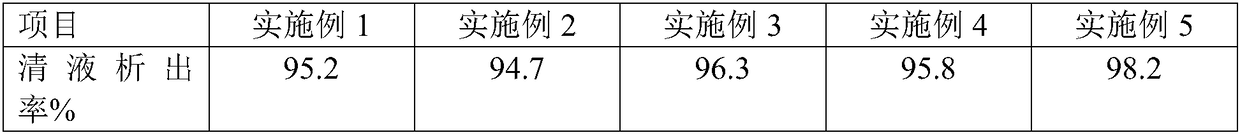

Examples

Embodiment 1

[0021] Coating flocculant for drilling fluid, by mass fraction, including 20 parts of potassium chloride, 10 parts of sodium carbonate, 5 parts of 2-acrylamide-2-methylpropanesulfonic acid, 60 parts of vinyl acetate, and 80 parts of water-soluble silicone oil 1 part, sodium polyacrylate 1 part.

Embodiment 2

[0023] Coating flocculant for drilling fluid, by mass fraction, including 50 parts of potassium chloride, 18 parts of sodium carbonate, 15 parts of 2-acrylamide-2-methylpropanesulfonic acid, 10 parts of acrylamide, 150 parts of vinyl acetate , 120 parts of water-soluble silicone oil, 5 parts of sodium polyacrylate.

Embodiment 3

[0025] Coating flocculant for drilling fluid, by mass fraction, including 30 parts of potassium chloride, 15 parts of sodium carbonate, 10 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5 parts of acrylamide, 100 parts of vinyl acetate , 100 parts of water-soluble silicone oil, 3 parts of sodium polyacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com