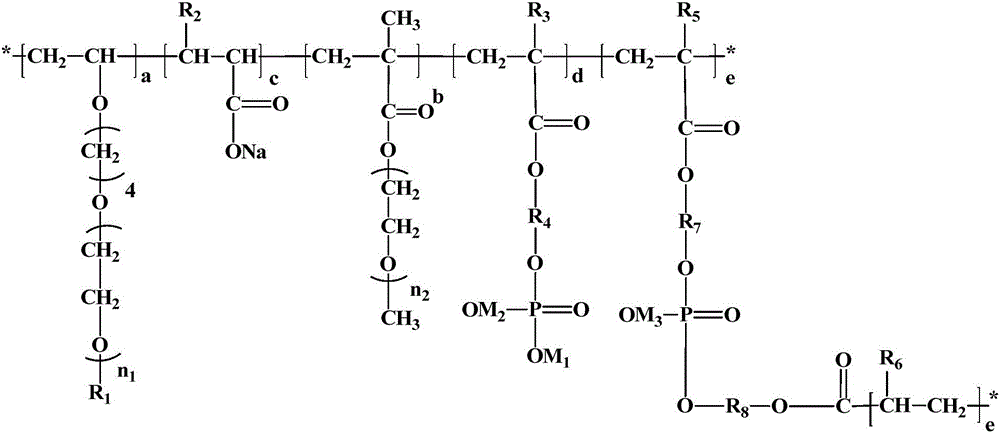

Crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and preparation method thereof

A sensitive ester and cross-linking technology, applied in the field of building materials, can solve the problems of unimproved dosage sensitivity and sensitive superplasticizer dosage, and achieve excellent low-sensitivity performance, good anti-intercalation effect, improved and efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

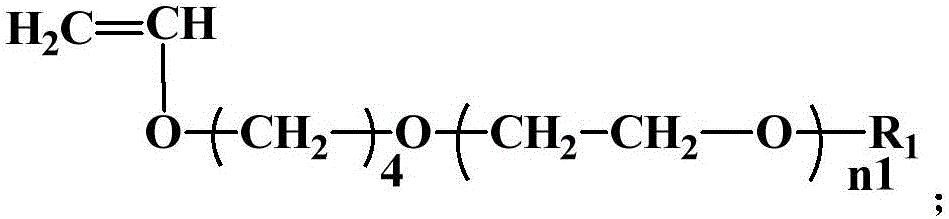

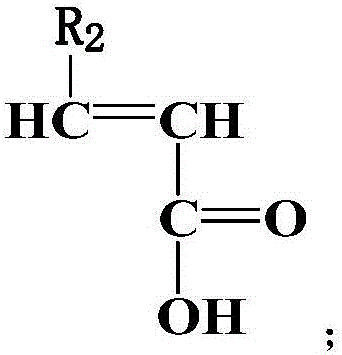

Method used

Image

Examples

Embodiment 1

[0044] (1) 160 g of VPEG-type monomers with a number average molecular weight of 2000 were dissolved in 175 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

[0045] (2) 25 g of acrylic acid and 1.4 g of mercaptopropionic acid were dissolved in 20 g of deionized water, and then 9.5 g of 30% potassium hydroxide solution was added for partial neutralization to obtain a second solution;

[0046] (3) 0.55g sodium formaldehyde sulfoxylate is dissolved in 30g deionized water to obtain the third solution;

[0047] (4) the MPEG type monomer that the number average molecular weight is 2400 is dissolved in deionized water to obtain 45g of the fourth solution with a concentration of 90%. The methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 2.5;

[0048] (5) Add 21g of the second solution dropwise to the first solution, and keep the temperature at 15°C; ...

Embodiment 2

[0052] (1) 140 g of VPEG-type monomers with a number average molecular weight of 2000 were dissolved in 174 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

[0053] (2) 24 g of acrylic acid and 1.4 g of thioglycolic acid were dissolved in 20 g of deionized water, and then 9 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0054] (3) 0.6gFF6 was dissolved in 30g deionized water to obtain the third solution;

[0055] (4) Dissolving the MPEG type monomer with the number average molecular weight of 2000 in deionized water to obtain 60 g of the fourth solution with a concentration of 90%, the methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 3.5;

[0056] (5) Add 20 g of the second solution dropwise to the first solution, and keep the temperature at 15°C;

[0057] (6) 3 g of 2-methacryloxyprop...

Embodiment 3

[0060] (1) Dissolving 100 g of a VPEG-type monomer with a number average molecular weight of 3000 in 170 g of deionized water, and adjusting its temperature to 14° C. to obtain the first solution;

[0061] (2) 20 g of acrylic acid and 1.2 g of mercaptoethanol were dissolved in 20 g of deionized water, and then 8 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0062] (3) 0.5g sodium hypophosphite is dissolved in 30g deionized water to obtain the third solution;

[0063] (4) Dissolving the MPEG type monomer with the number average molecular weight of 2000 in deionized water to obtain 100 g of the fourth solution with a concentration of 90%, the methacrylic acid (MAA) and polyethylene glycol in the above MPEG type monomer The acid-alcohol ratio of alcohol monomethyl ether (MPEG) is 2.5;

[0064] (5) Add 15 g of the second solution dropwise to the first solution, and keep the temperature at 14°C;

[0065] (6) Add 2.5 g of ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com