A low-valence variable valence cation-modified polycarboxylate water-reducing agent masterbatch and a low-temperature preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of polycarboxylate water reducing agent, can solve the problems of short half-life, molecular disorder of water reducing agent, poor effect of water reducing agent, etc., and achieve poor high temperature stability and side chain distribution. The effect of uniform, high polymerization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

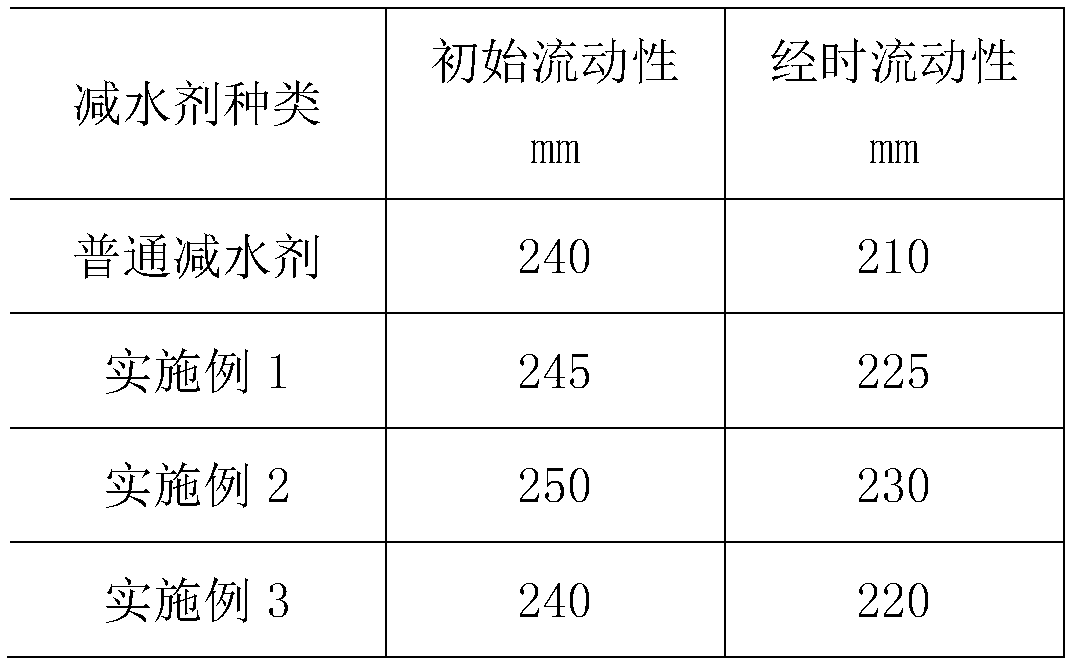

Embodiment 1

[0037] A low-valence variable cation modified polycarboxylate superplasticizer masterbatch, which is formed by polymerizing the following components by mass percentage. The total mass of raw materials is 1000 parts. The components and process parameters are as follows:

[0038] Primer: 2400 molecular weight isopentenol polyoxyethylene ether: 352, water: 200;

[0039] Oxidant solution: hydrogen peroxide: 5, water: 5;

[0040] The temperature of the base material: 10°C;

[0041] Within 10 minutes after adding the oxidant solution, add the initiator and the small monomer solution dropwise in sequence. After adding the initiator dropwise for 5 minutes, add ferric sulfite heptahydrate at one time; after another 5 minutes, start adding the small monomer solution dropwise;

[0042] Iron sulfate heptahydrate: 0.035;

[0043] Initiator: thioglycolic acid: 1.5, ascorbic acid: 0.85, water: 120;

[0044] Small monomer solution: acrylic acid: 39.5, water: 50;

[0045] Initiator dropping ...

Embodiment 2

[0053] Primer: 2400 molecular weight vinyl butyl ether polyoxyethylene ether: 355, water: 220;

[0054] Oxidant solution: peracetic acid: 5.0, water: 10;

[0055] The temperature of the bottom material: 7 ℃;

[0056] Within 10 minutes after adding the oxidant solution, add the initiator and the small monomer solution dropwise in sequence. After adding the initiator dropwise for 5 minutes, add ferric sulfite heptahydrate at one time; after another 5 minutes, start adding the small monomer solution dropwise;

[0057] Ferric sulfate heptahydrate: 0.057;

[0058] Initiator: sodium methacrylate sulfonate: 2.7, glucose monohydrate: 3.5, water: 120;

[0059] Small monomer solution: acrylic acid: 36.2, water: 50;

[0060] Initiator dropping time: 4.0h;

[0061] The small monomer solution dripping time is 3.5h;

[0062] Adjust the opening of the cooling water valve to ensure that the reaction temperature during the dropping process is controlled at 20-30°C;

[0063] After the dro...

Embodiment 3

[0068] Primer: 2400 molecular weight vinyl butyl ether polyoxyethylene ether: 342, water: 250;

[0069] Oxidant solution: hydrogen peroxide: 4.5, water: 15;

[0070] The temperature of the base material: 13°C;

[0071] Within 10 minutes after adding the oxidant solution, add the initiator and the small monomer solution dropwise in sequence. After adding the initiator dropwise for 5 minutes, add ferric sulfite heptahydrate at one time; after another 5 minutes, start adding the small monomer solution dropwise;

[0072] Cobalt sulfate heptahydrate: 0.065;

[0073] Initiator: sodium hypophosphite: 3.0, sodium bisulfite: 1.5, fructose: 1.5, water: 120;

[0074] Small monomer solution: acrylic acid: 48.5, water: 50;

[0075] Initiator dropping time: 3.5h;

[0076] The small monomer solution dripping time is 3.0h;

[0077] Adjust the opening of the cooling water valve to ensure that the reaction temperature during the dropping process is controlled at 20-30°C;

[0078] After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com