A low-sensitivity anti-mud cross-branched polycarboxylate water reducer and its preparation method

A branched, low-sensitivity technology, applied in the field of concrete water reducers, can solve problems such as concrete segregation, bleeding, lower compressive strength ratio, lower water-reducing dispersibility, etc., and achieve good slump retention and good Anti-mud performance, good anti-intercalation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

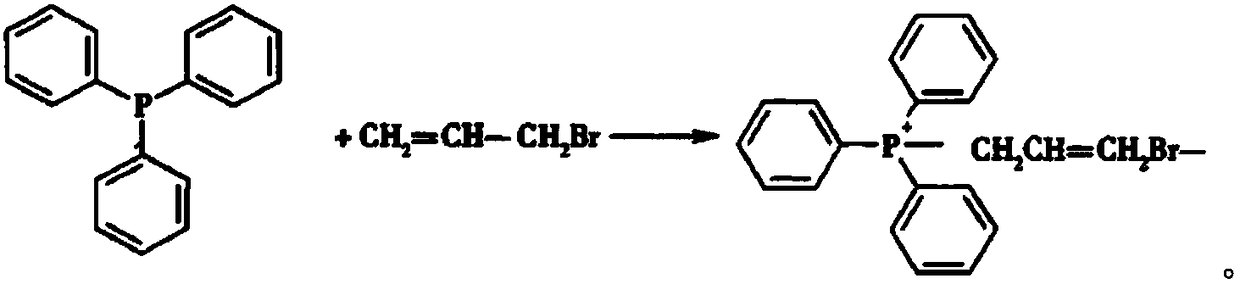

[0036] (1) Take each raw material component by the following parts by weight: 30 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene base ether (VPEG molecular weight 2000), 40 parts by weight of allyl polyoxyethylene polyether (APEG molecular weight 500) Parts, 20 parts by weight of methallyl polyoxyethylene polyether (HPEG molecular weight 1000), 10 parts by weight of isopentenyl polyoxyethylene polyether (TPEG molecular weight 2400), 8 parts by weight of acrylic acid, 6 parts by weight of hydroxyethyl acrylate Parts, 2 parts by weight of dibutyl maleate, 2 parts by weight of unsaturated amphoteric quaternary phosphorus salt, 2 parts by weight of dimethylaminoethyl methacrylate, 0.5 parts by weight of hydrogen peroxide, Brüggolit TM 0.7 parts by weight of FF6, 0.04 parts by weight of azobisisobutylimidazoline hydrochloride, 0.35 parts by weight of mercaptoacetic acid, 4 parts by weight of potassium hydroxide aqueous solution with 50% mass concentration, and 5 parts by we...

Embodiment 2

[0042] (1) Take each raw material component according to the following parts by weight: 40 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene base ether (VPEG molecular weight 2400), 30 parts by weight of allyl polyoxyethylene polyether (APEG molecular weight 1000) Parts, 30 parts by weight of methallyl polyoxyethylene polyether (HPEG molecular weight 2000), 20 parts by weight of isopentenyl polyoxyethylene polyether (TPEG molecular weight 3000), 6 parts by weight of acrylic acid, hydroxyethyl methacrylate 3 parts by weight, 3 parts by weight of dibutyl maleate, 1 part by weight of unsaturated amphoteric quaternary phosphonium salt, 3 parts by weight of dimethylaminoethyl methacrylate, 0.6 parts by weight of sodium persulfate, 0.8 parts by weight of sodium formaldehyde sulfoxylate Parts by weight, 0.02 parts by weight of azobisisobutylamidine hydrochloride, 0.4 parts by weight of mercaptopropionic acid, 2 parts by weight of potassium hydroxide aqueous solution of 50% mass ...

Embodiment 3

[0048] (1) Take each raw material component by weight as follows: 50 parts by weight of 4-hydroxybutyl vinyl polyoxyethylene base ether (VPEG molecular weight 3000), 20 parts by weight of allyl polyoxyethylene polyether (APEG molecular weight 2000) Parts, 40 parts by weight of methallyl polyoxyethylene polyether (HPEG molecular weight 2400), 5 parts by weight of isopentenyl polyoxyethylene polyether (TPEG molecular weight 500), 7 parts by weight of methacrylic acid, hydroxypropyl acrylate 3 parts by weight, 5 parts by weight of dibutyl maleate, 3 parts by weight of unsaturated amphoteric quaternary phosphonium salt, 4 parts by weight of dimethylaminoethyl methacrylate, 0.4 parts by weight of ammonium persulfate, Brüggolit TM 0.7 parts by weight of FF6, 0.06 parts by weight of azobis N-hydroxyisobutylamidine hydrate, 0.5 parts by weight of mercaptoethanol, 3 parts by weight of potassium hydroxide aqueous solution of 50% mass concentration, and 3 parts by weight of aqueous sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com