Patents

Literature

77 results about "Phosphomonoesters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphomonoesters (or phosphoric esters) are chemical compounds containing one ester bond and a phosphate group. In biology, phosphomonesters are needed as the building blocks for the synthesis of Phospholipid cellular membranes, especially those found on neurons. Enzymes which cleave these bonds are known as phosphomonoesterases, or phosphatases.

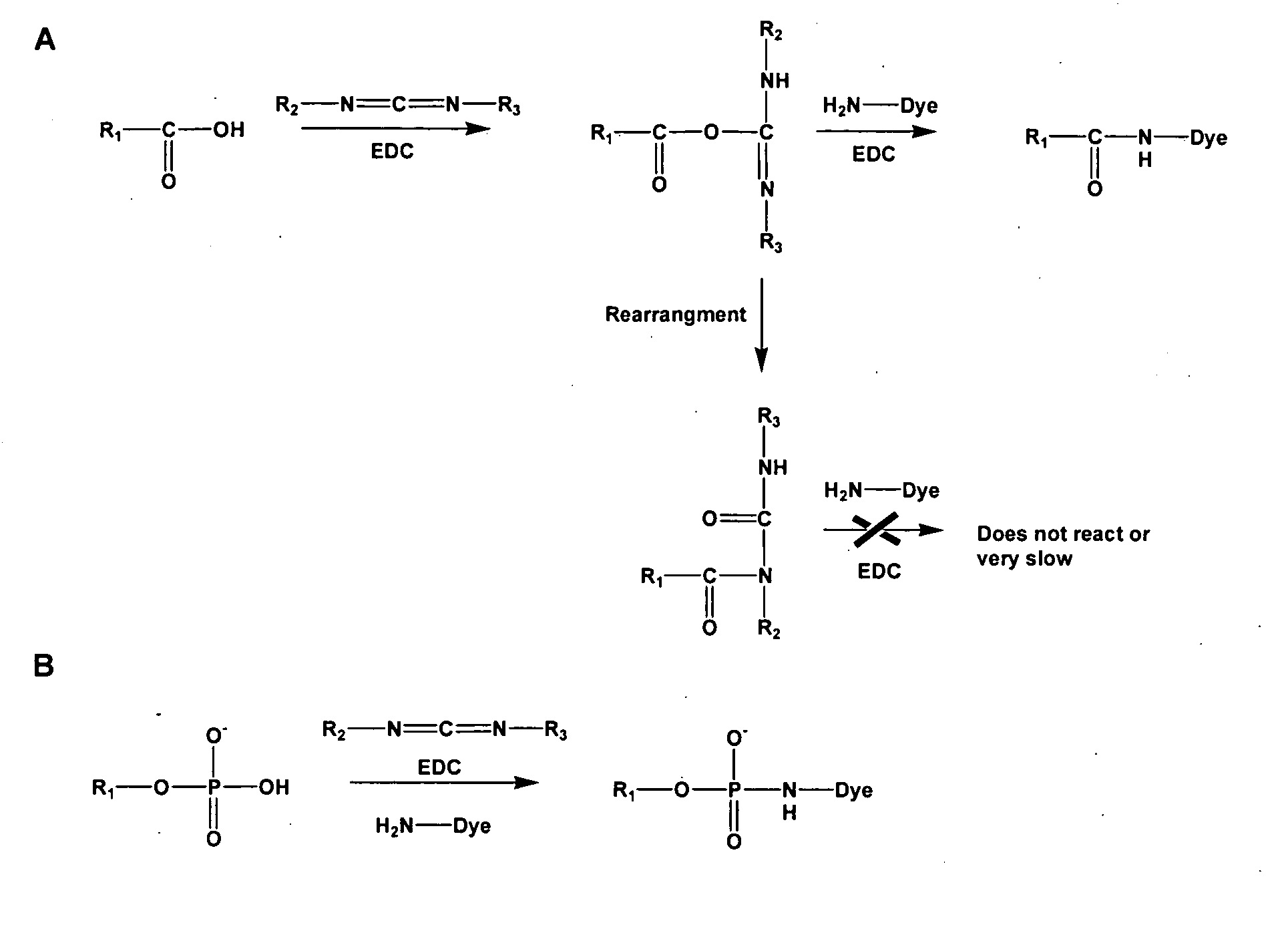

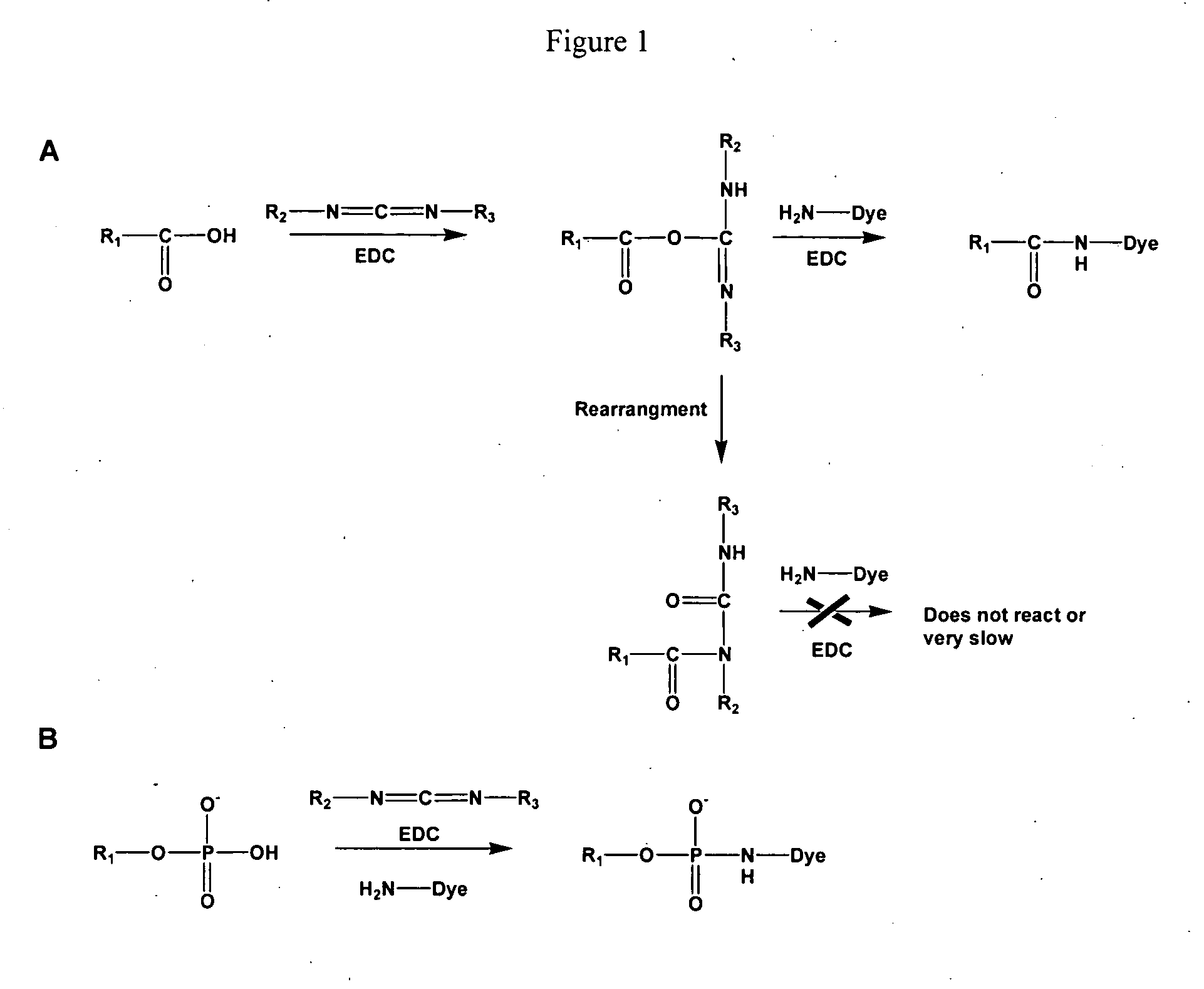

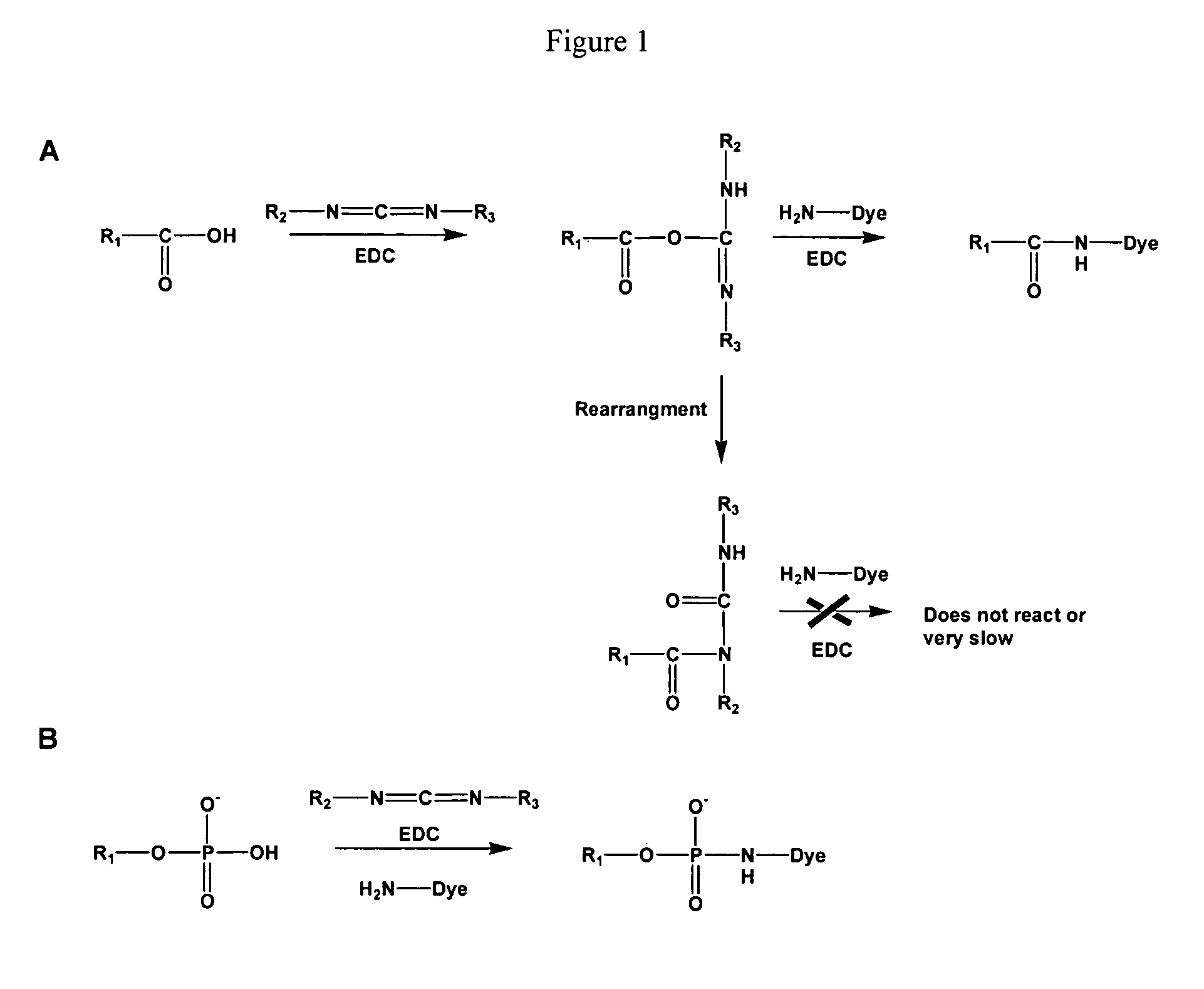

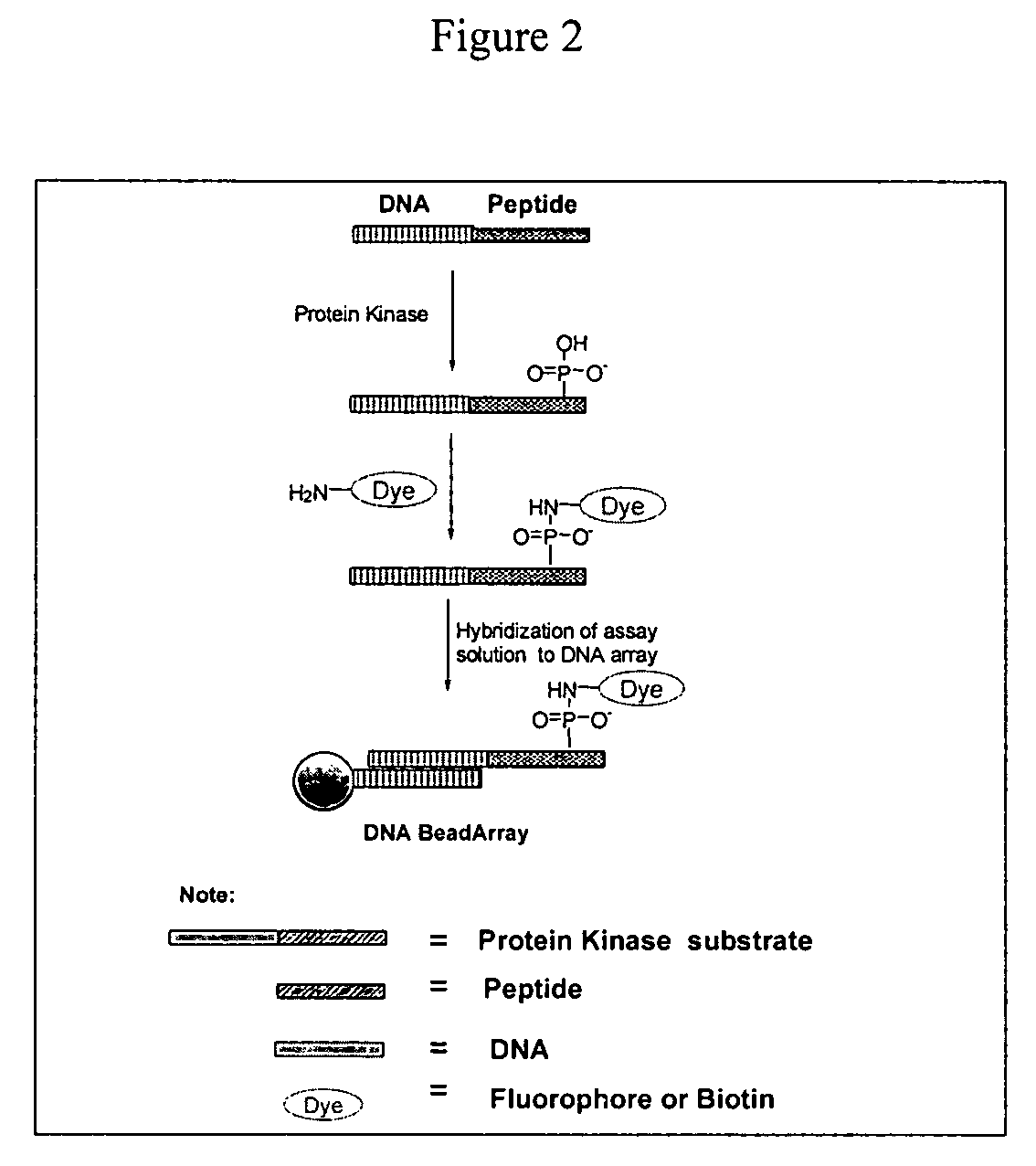

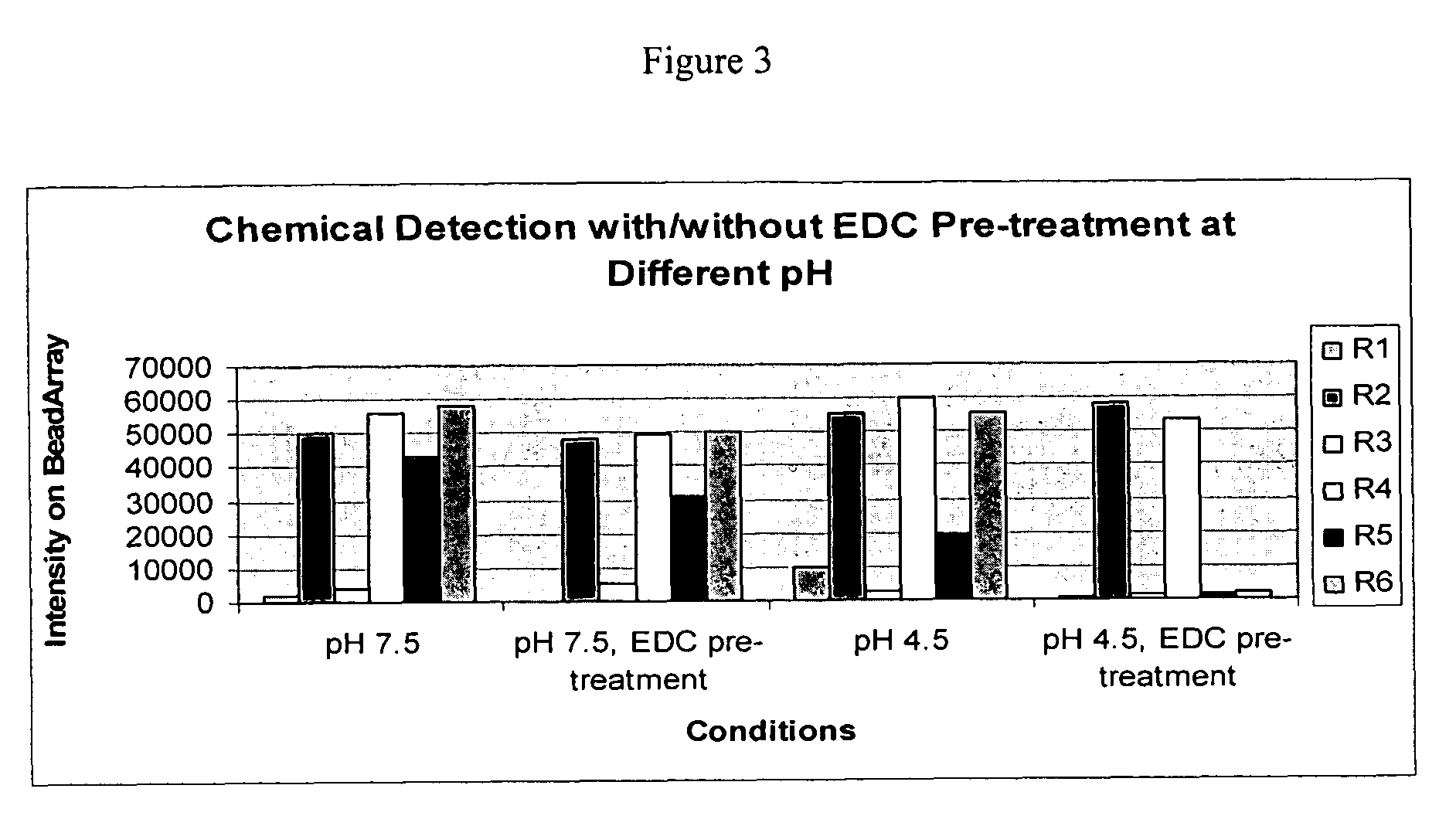

Compositions and methods for detecting phosphomonoester

The invention provides a method of modifying a phosphomonoester moiety of a target compound. The method can include the steps of (a) providing a target compound having an electrophilic moiety and a phosphomonoester moiety; (b) contacting the target compound with a first carbodiimide compound under conditions for preferential addition of the first carbodiimide compound to the electrophilic moiety over the phosphomonoester moiety, thereby forming an electrophile-protected target compound; and (c) contacting the electrophile-protected target compound with a second carbodiimide compound and a nucleophilic compound under conditions for addition of the nucleophilic compound to the phosphomonoester.

Owner:ILLUMINA INC

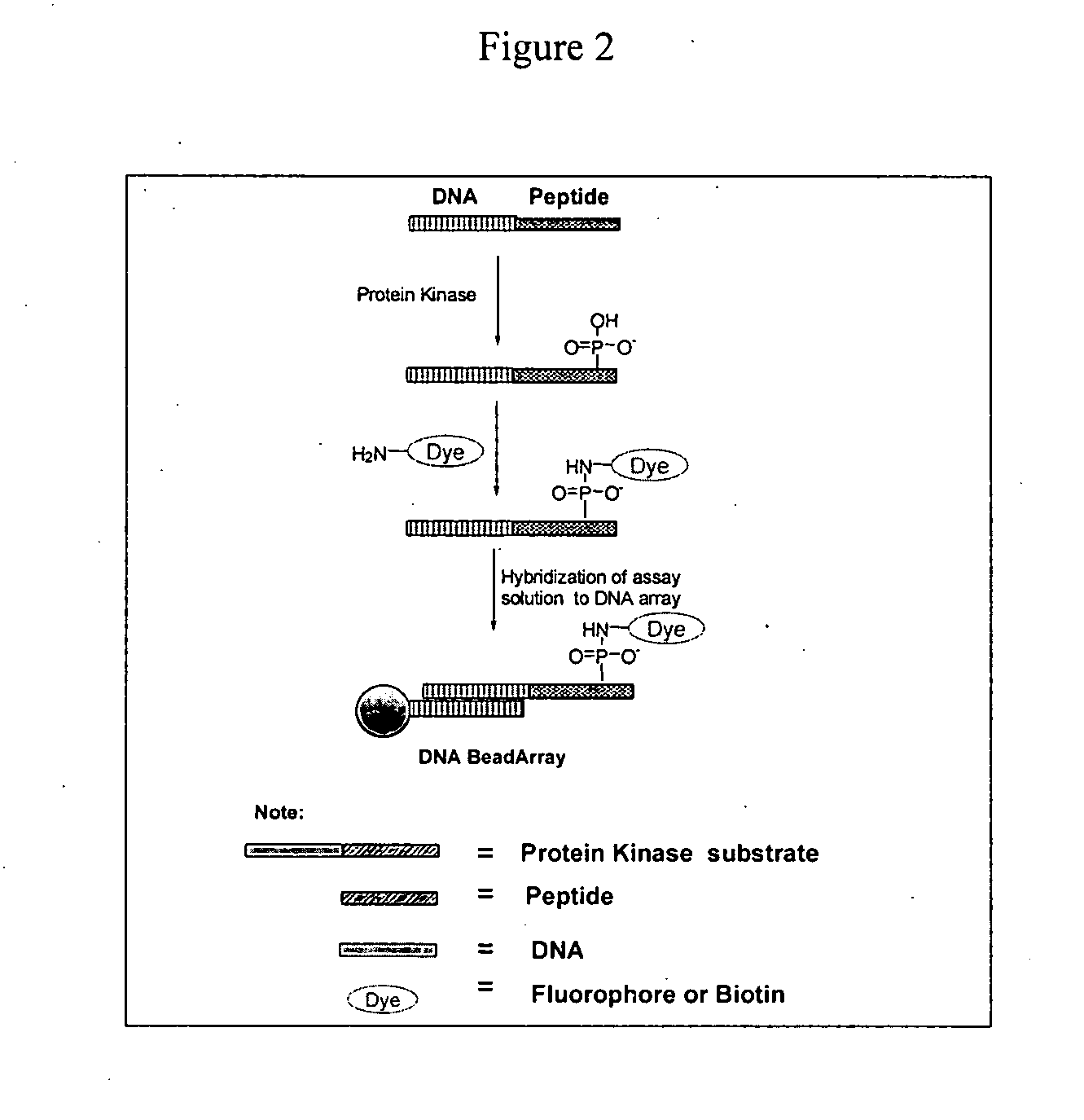

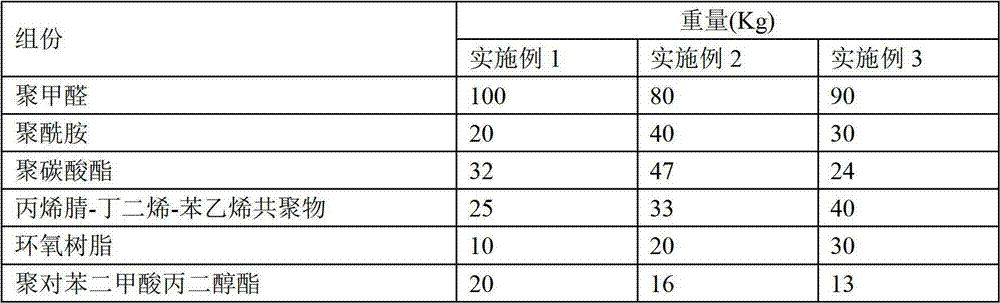

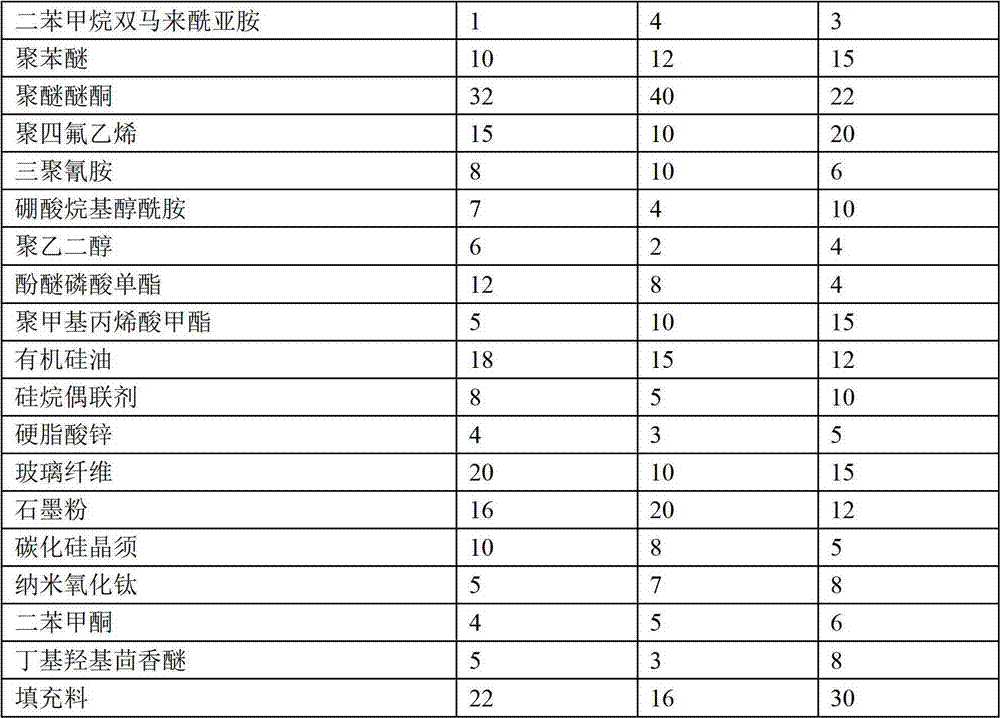

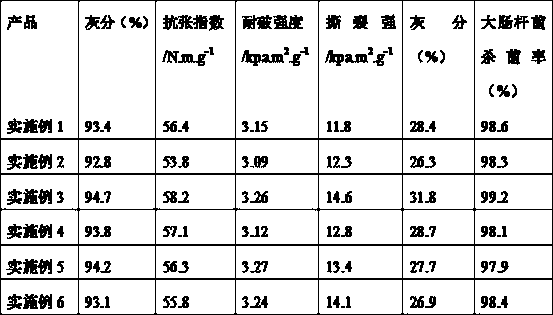

Engineering plastic with high wearing resistance

InactiveCN102875956AGood mechanical propertiesReduce wear ratePolyethylene glycolPolymethyl methacrylate

The invention provides an engineering plastic with high wearing resistance. The engineering plastic is made from the following raw materials by weight: 80-100 parts of polyformaldehyde, 20-40 parts of polyamide, 20-50 parts of polycarbonate, 25-40 parts of acrylonitrile-butadiene-styrene copolymer, 10-30 parts of epoxy resin, 12-20 parts of polytrimethylene terephthalate, 1-5 parts of diphenylmethane bismaleimide, 10-15 parts of polyphenyl ether, 20-40 parts of polyether-ether-ketone, 10-20 parts of polytetrafluoroethylene, 5-10 parts of melamine, 4-12 parts of boric acid alkanolamide, 2-6 parts of polyethylene glycol, 4-12 parts of phenolic ether phosphomonoester, 5-15 parts of polymethyl methacrylate, 10-20 parts of organic silicone oil, 5-10 parts of silane coupling agent, 3-5 parts of zinc stearate, 10-20 parts of glass fibre, 12-20 parts of graphite, 5-10 parts of silicon carbide whisker, 5-8 parts of nanometre titanium oxide, 4-6 parts of diphenyl ketone, 3-8 parts of butylated hydroxyanisole and 15-30 parts of filler. The engineering plastic provided by the invention has a good wear-resisting property.

Owner:SUZHOU YUNYUAN NETWORK TECH

Synergistic mixtures of phosphoric esters with carboxylic acids or carboxylic acid derivatives as asphaltene dispersants

InactiveUS6204420B1Transportation and packagingDistillation purification/separationPhosphoric Acid EstersEther

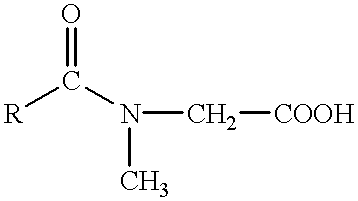

The invention relates to a synergistic mixture ofA from 5 to 99% by weight of a carboxylic acid having more than 4 carbon atoms, an ethercarboxylic acid containing C18-C22-alkyl, C18-C22-alkenyl or C6-C18-alkylaryl substituents, an amidocarboxylic acid, or mixtures thereof,B from 1 to 95% by weight of a phosphoric mono- or diester, or mixtures thereof, which is substituted by C18-C22-alkyl, C18-C22-alkenyl, C6-C18-alkylaryl or alkoxylated groups,where the sum of components A and B is 100% by weight, to crude oils containing such mixtures, and to a process for dispersing asphaltenes in crude oils.

Owner:CLARIANT PROD DEUT GMBH

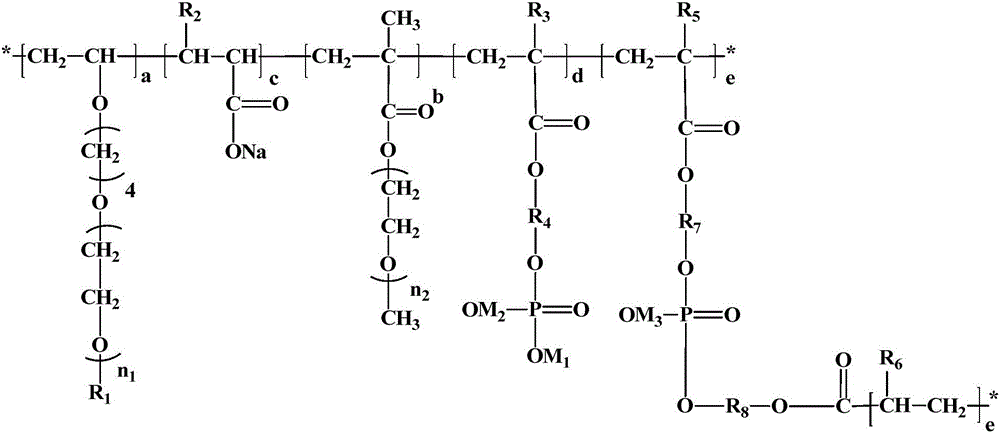

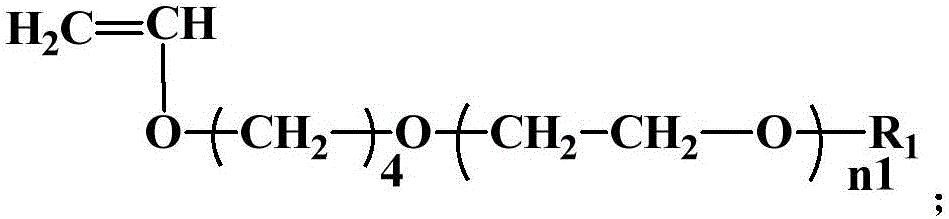

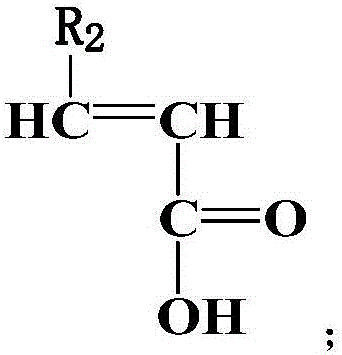

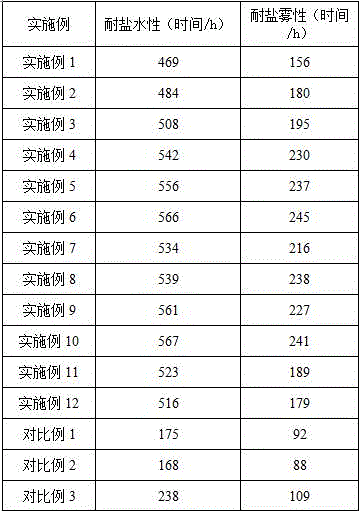

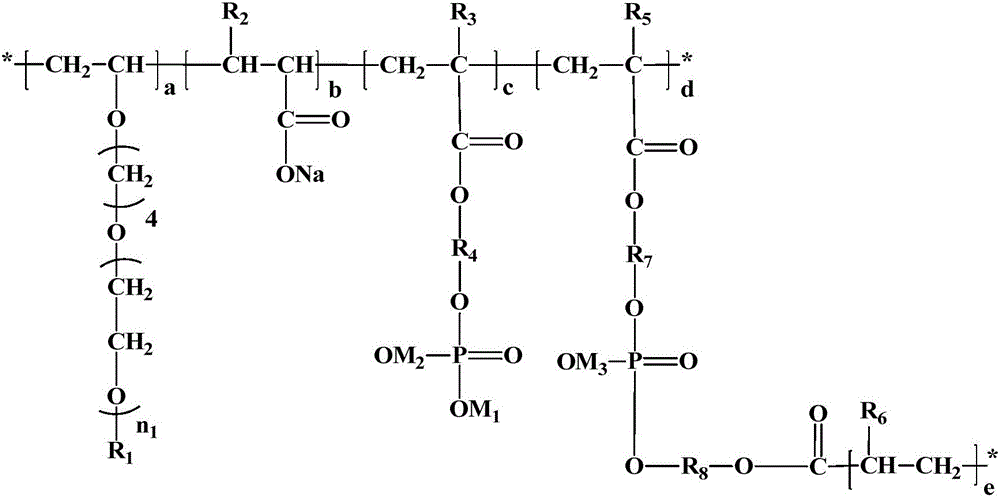

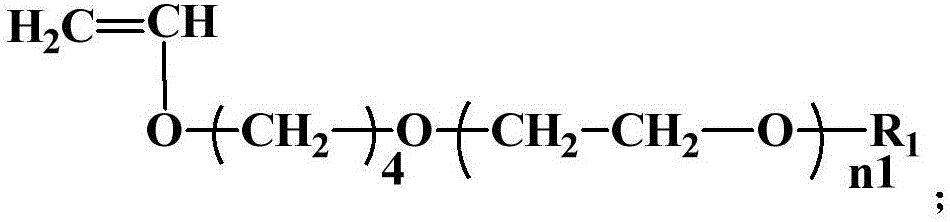

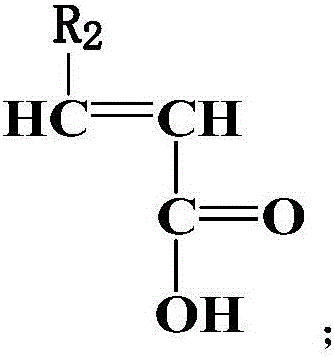

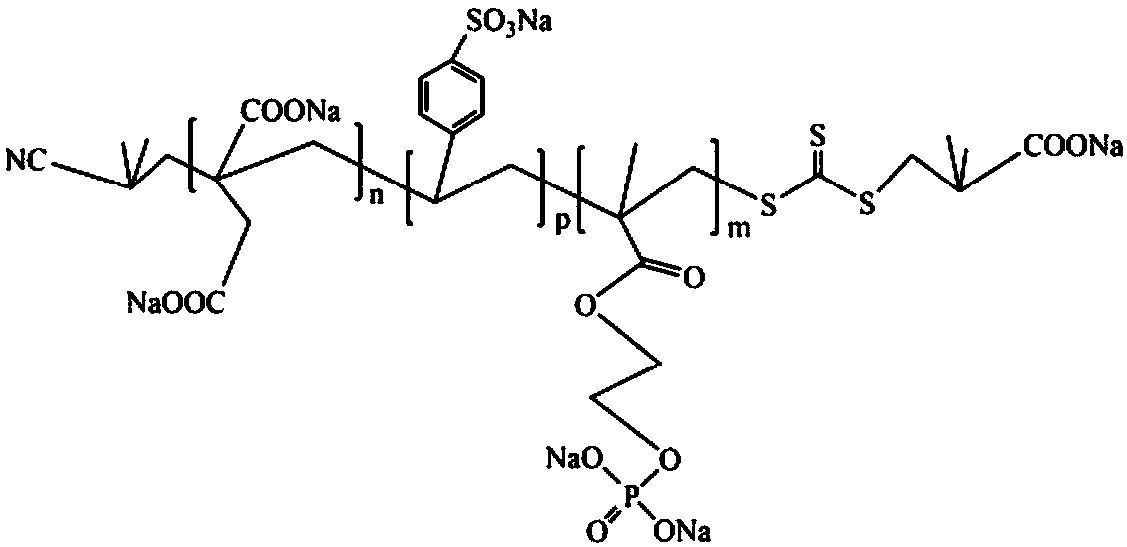

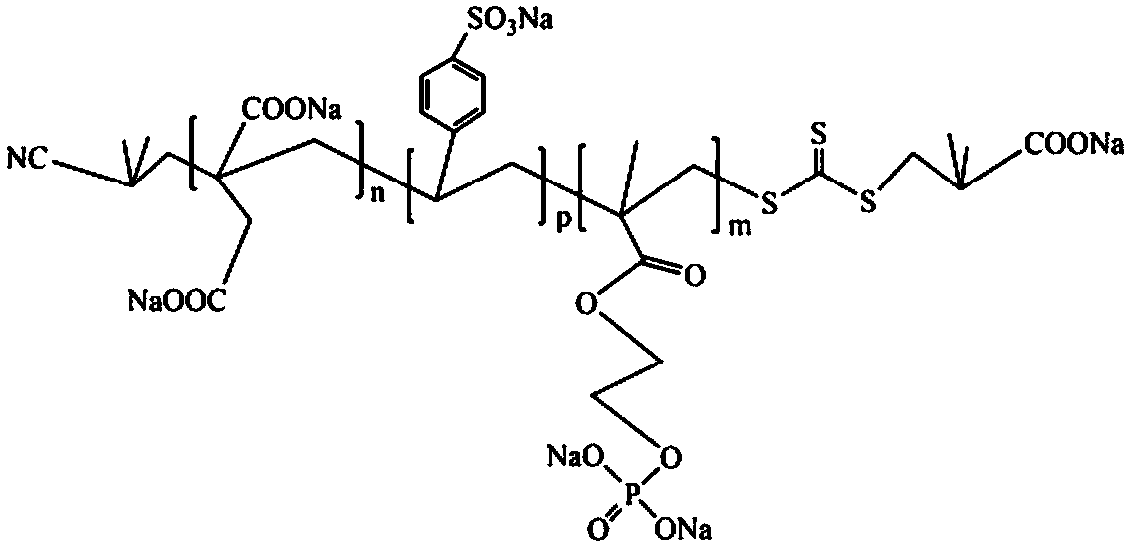

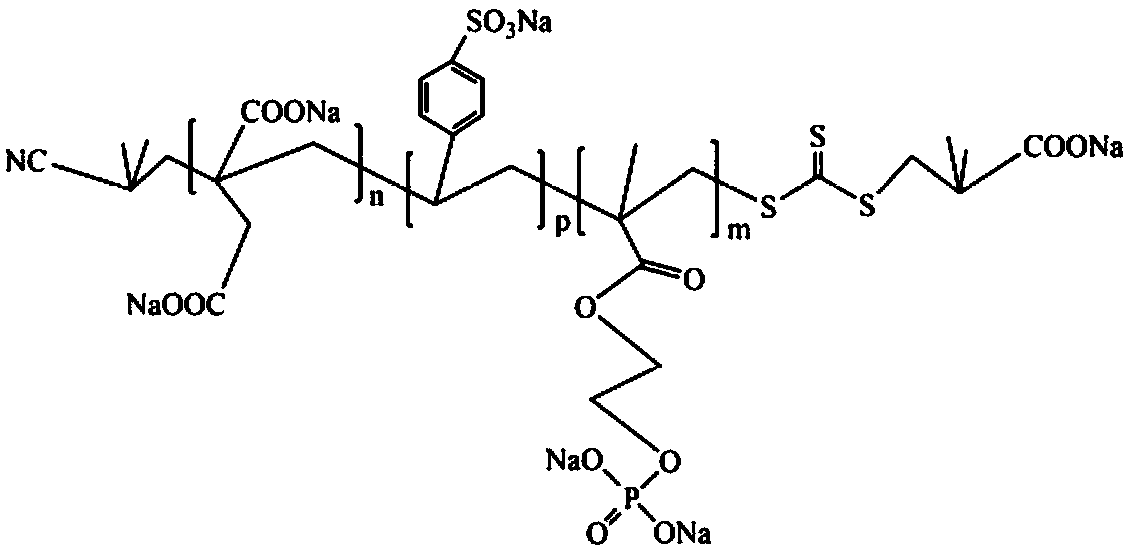

Crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and preparation method thereof

ActiveCN106046269AEven distribution of side chainsImprove workabilityPolymer sciencePhosphomonoesters

The invention discloses a crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer and a preparation method thereof. The crosslinking-type low-sensitivity ester-ether copolymerized polycarboxylate superplasticizer has the number-average molecular weight of 10000-100000 and has a structural formula as shown in the specification. Under the synergistic effect of various groups, the polycarboxylate superplasticizer formed by copolymerization of 4-hydroxybutyl-vinyl polyoxyethylene ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester has the advantages of high water-reducing rate, high slump loss resistance, high peaceability, mud-resistant property and low dosage sensibility.

Owner:KZJ NEW MATERIALS GROUP CO LTD

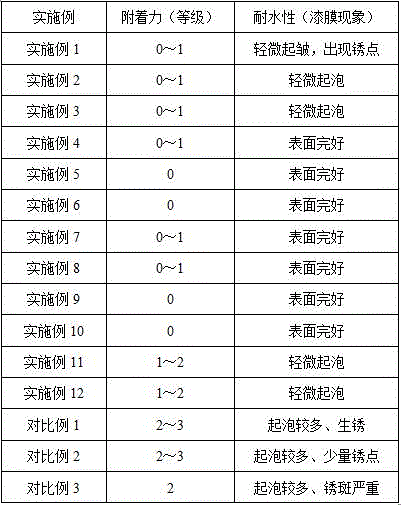

Metal antirust emulsion as well as preparation method and application thereof

ActiveCN105949366AImprove adhesionImprove water resistanceAnti-corrosive paintsMethacrylateFunctional monomer

The invention aims to provide a metal antirust emulsion. The metal antirust emulsion is prepared from raw materials in percentage by weight as follows: 35%-50% of an allyl monomer, 1.5%-5% of a functional monomer, 0.5%-3% of a function monomer, 1%-7% of an emulsifier, 0.1%-0.3% of an initiator, 0.05%-2.5% of a pH regulator and 45%-60% of water, wherein the allyl monomer is a mixture of styrene and at least one of methacrylate or acrylic ester; the functional monomer is a mixture of acrylic phosphate and active organosilane; the function monomer is a mixture of acrylamide and at least one of acrylic acid or methacrylic acid; the emulsifier is a compound emulsifier prepared from two or more of branched alkyl alcohol polyoxyethylene ether phosphomonoester, alkylphenol phosphate, acrylic polyether phosphate, 3-allyloxy-1-hydroxy-1-propane sulfonate and a polymerizable sulphate emulsifier through compounding. Poly(bisphenol A acryloxyethyl phosphate).

Owner:SHANGHAI BAOLIJIA NEW MATERIAL CO LTD

Cross-linking type low-sensitivity polycarboxylate water reducing agent and preparation method thereof

The invention discloses a cross-linking type low-sensitivity polycarboxylate water reducing agent and a preparation method thereof. The structural formula of the polycarboxylate water reducing agent is as shown in the specification. The polycarboxylate water reducing agent is synthesized by copolymerization of 4-hydroxybutyl vinyl polyethenoxy ether, unsaturated acid, unsaturated phosphomonoester and unsaturated phosphodiester, and has high water-reducing rate, high slump loss resistance, mud resistance and low dosage sensibility under the synergetic effect of various groups.

Owner:KZJ NEW MATERIALS GROUP CO LTD

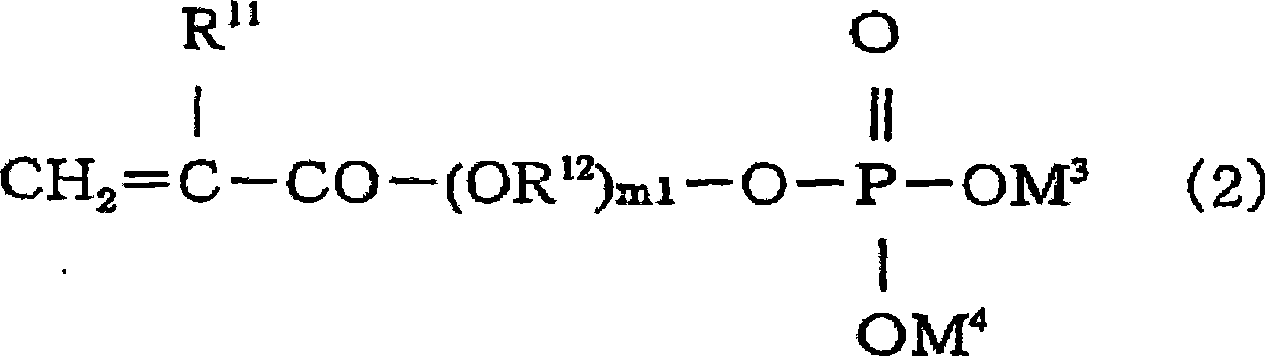

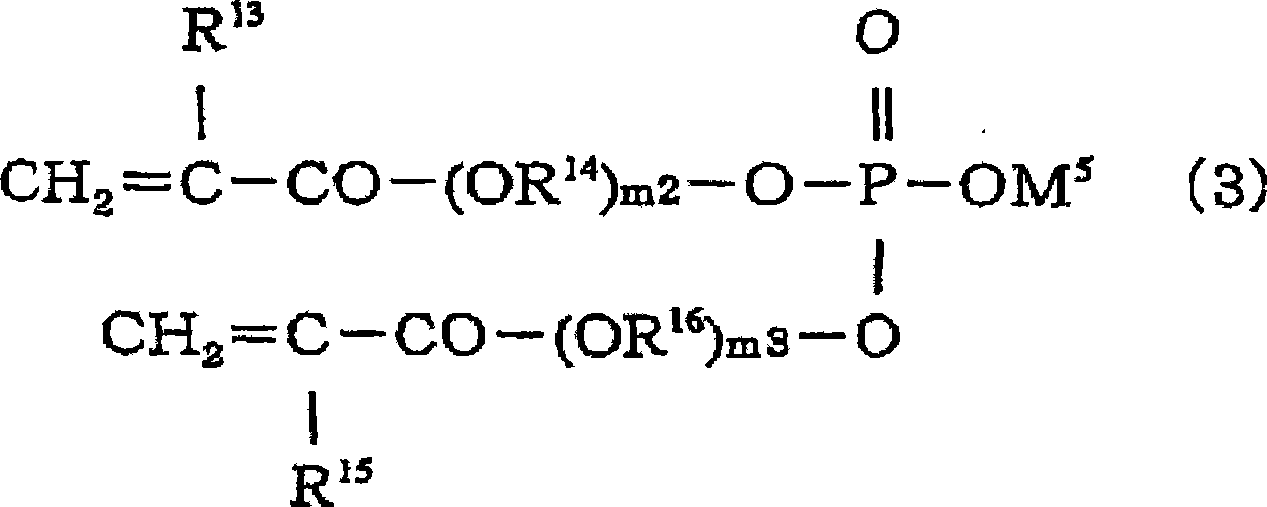

Dispersant for hydraulic composition

Disclosed is a dispersing agent for hydraulic compositions which contains a polymer that is obtained by copolymerizing a specific monomer 1 such as an ethylene unsaturated carboxylic acid derivative having a polyoxyalkylene group, a phosphate monoester monomer 2, a phosphate diester monomer 3 and an unsaturated carboxylic acid monomer 4 at a pH of 7 or less.

Owner:KAO CORP

Compositions and methods for detecting phosphomonoester

The invention provides a method of modifying a phosphomonoester moiety of a target compound. The method can include the steps of (a) providing a target compound having an electrophilic moiety and a phosphomonoester moiety; (b) contacting the target compound with a first carbodiimide compound under conditions for preferential addition of the first carbodiimide compound to the electrophilic moiety over the phosphomonoester moiety, thereby forming an electrophile-protected target compound; and (c) contacting the electrophile-protected target compound with a second carbodiimide compound and a nucleophilic compound under conditions for addition of the nucleophilic compound to the phosphomonoester.

Owner:ILLUMINA INC

Lubricant composition and continuously variable transmission

ActiveUS20110053816A1High metal to metal friction coefficientImprove wear resistanceAdditivesPhosphorous acidPhosphoric acid

Provided is a lubricating oil composition containing a base oil which includes a mineral oil and / or a synthetic oil, and compounded therein, (A) at least one phosphorus-containing compound selected from phosphoric acid monoesters, phosphoric acid diesters and phosphorous acid monoesters, each having a C1 to C8 hydrocarbon group or groups and (B) a tertiary amine compound having C6 to C10 hydrocarbon groups as substituents thereof. The lubricating oil composition provides both a high metal to metal friction coefficient and an excellent wear resistance and is suitably used in a continuously variable transmission.

Owner:IDEMITSU KOSAN CO LTD

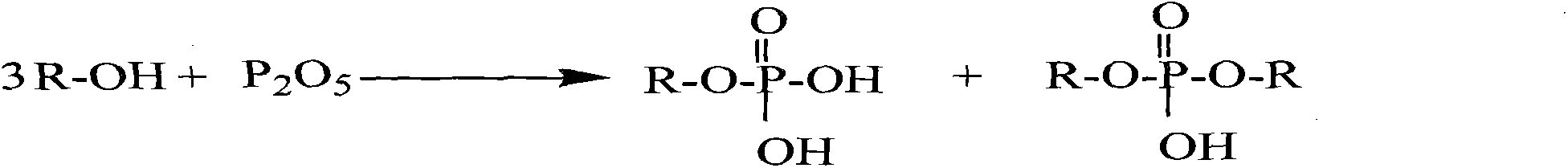

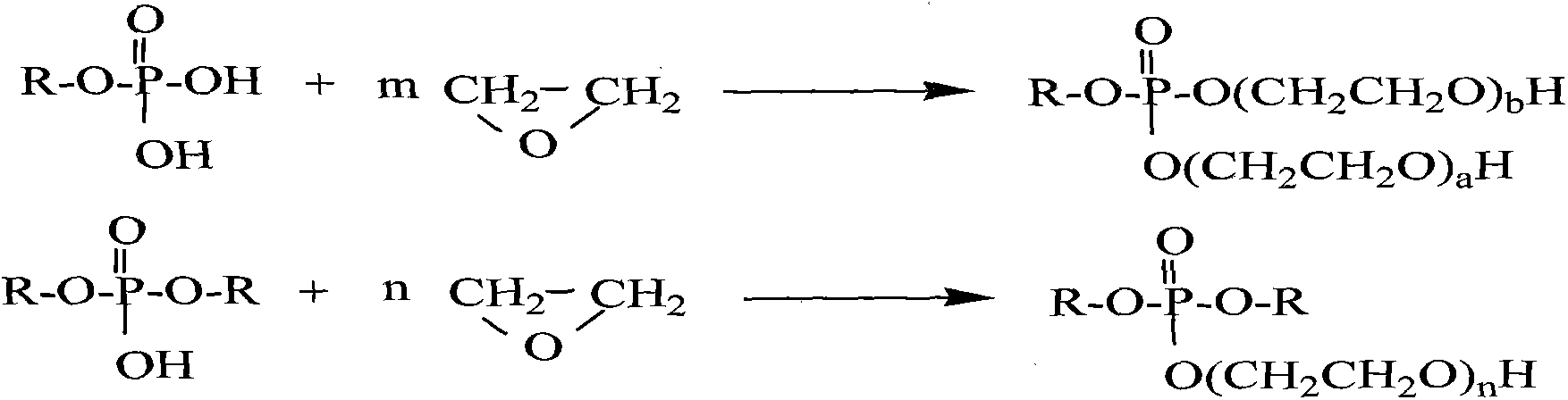

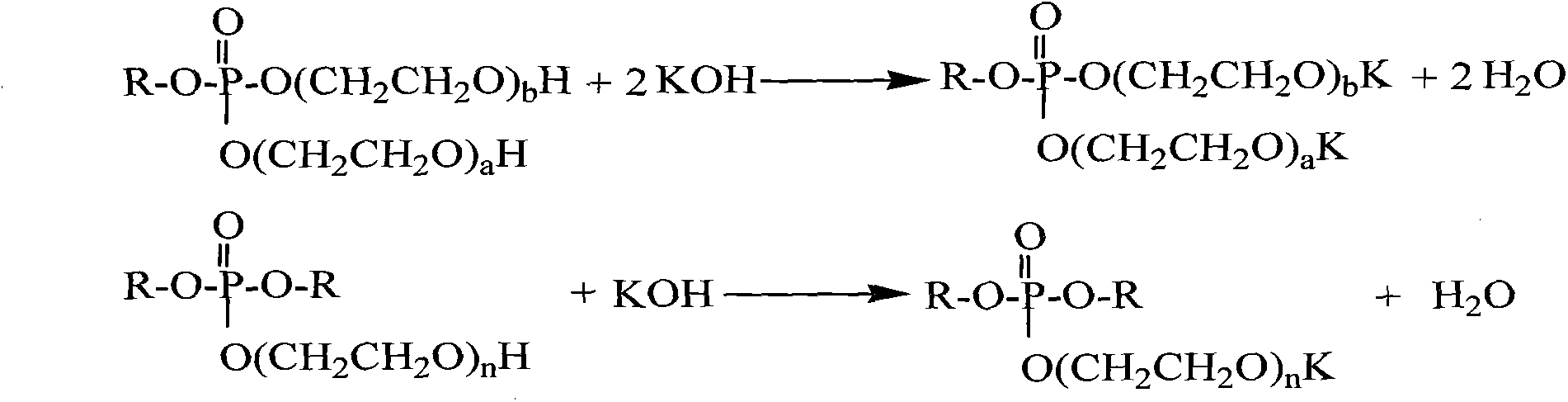

Preparation method of fatty alcohol polyoxyethylene phosphate ester potassium salt

InactiveCN103374029AHigh solid contentEasy to storeGroup 5/15 element organic compoundsPotassium hydroxideFatty alcohol

The invention discloses a preparation method of fatty alcohol polyoxyethylene phosphate ester potassium salt, which comprises the following steps: (1) performing esterification reaction on fatty alcohol used as a raw material and phosphorus pentoxide; (2) adding deionized water, hydrolyzing to obtain a fatty alcohol phosphate ester mixture mainly containing phosphate monoester and phosphate diester, and directly performing condensation reaction with epoxyethane in the absence of a catalyst; and (3) neutralizing with a 60% potassium hydroxide water solution until the pH value is 6-8, thus preparing to obtain fatty alcohol polyoxyethylene ether phosphate ester potassium salt of which the solid content is 90% or above. In the above mode, in comparison with the fatty alcohol polyoxyethylene ether phosphate ester potassium salt, the fatty alcohol polyoxyethylene phosphate ester potassium salt synthesized by the invention has the advantages of high solid content and liquid flow, reduces the transportation cost, and facilitates storage and use by users, thus having better economic benefits.

Owner:NINGBO LIANKAI CHEM

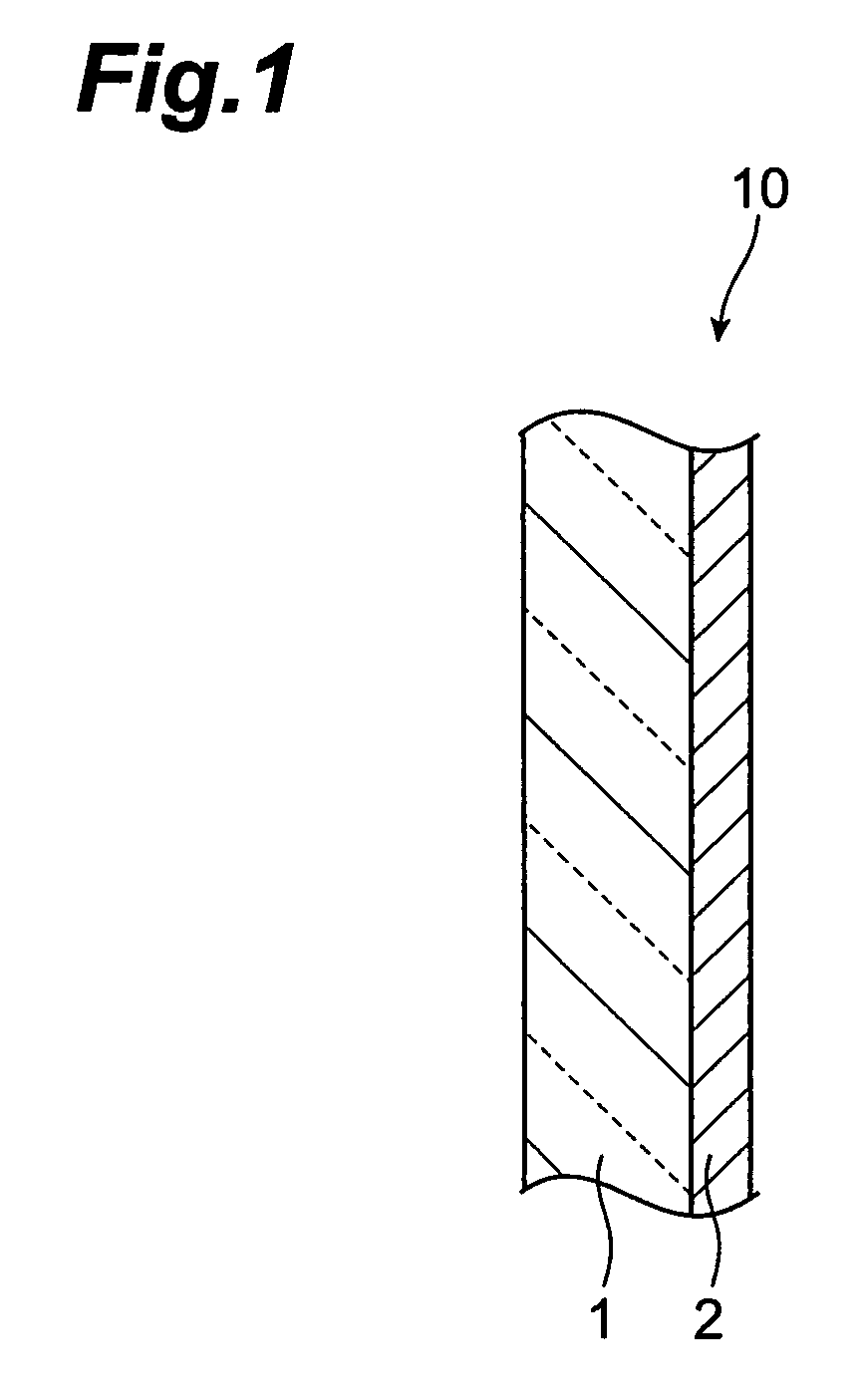

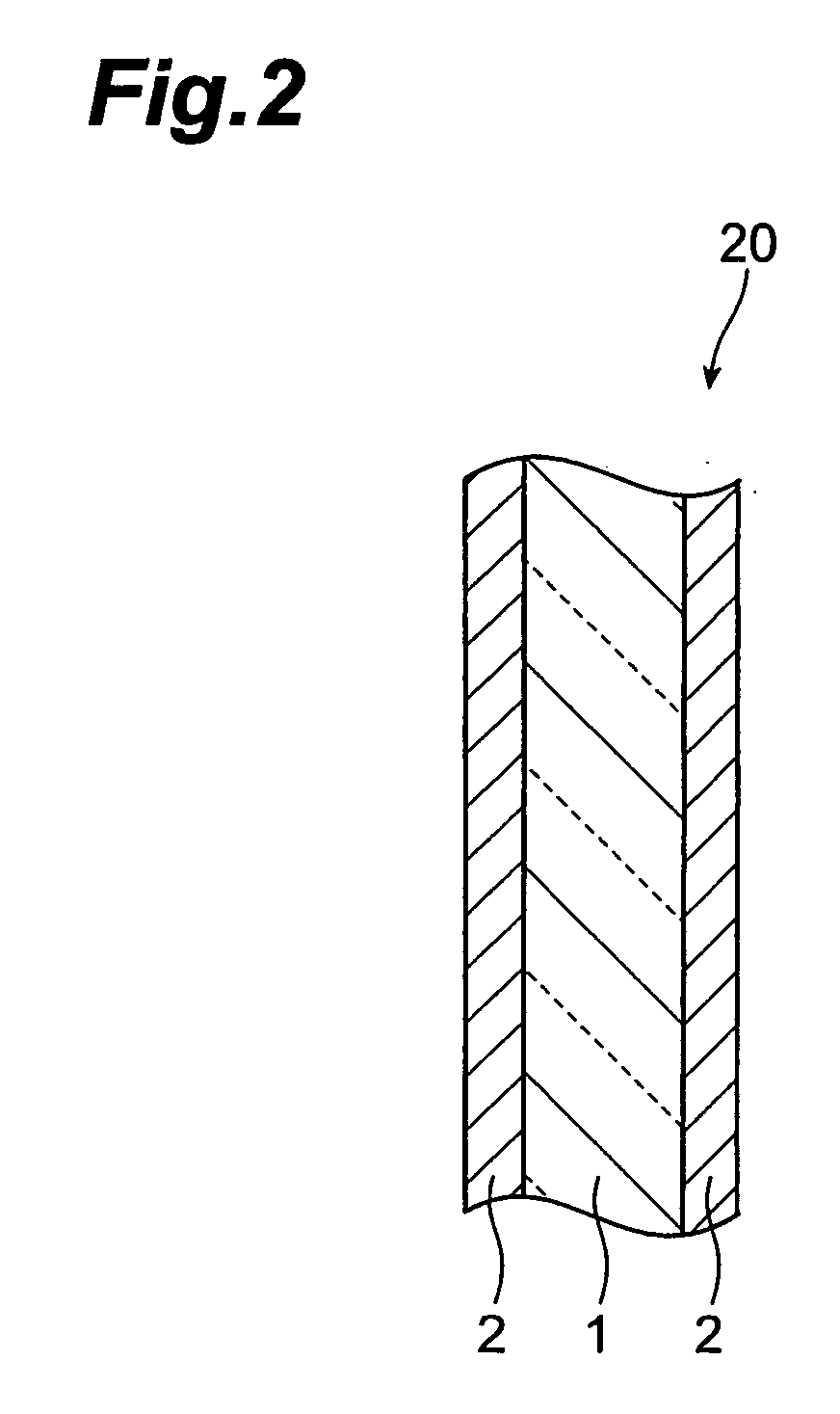

Infrared absorbing composition, resin composition, interlayer for laminated glass, laminated body, laminated glass and building material

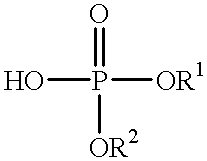

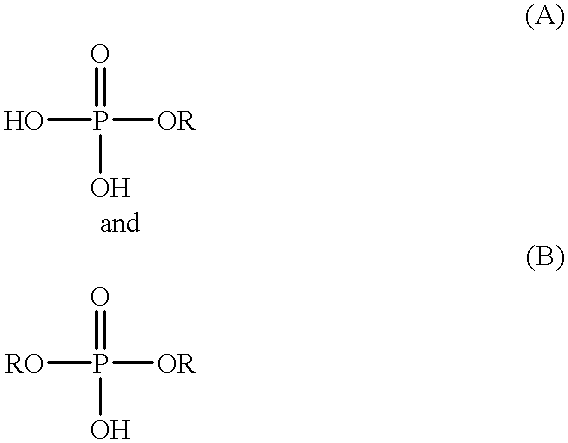

InactiveUS20070042194A1Avoid low lightImprove visibilityGlass/slag layered productsCoatingsPhosphoric Acid EstersO-Phosphoric Acid

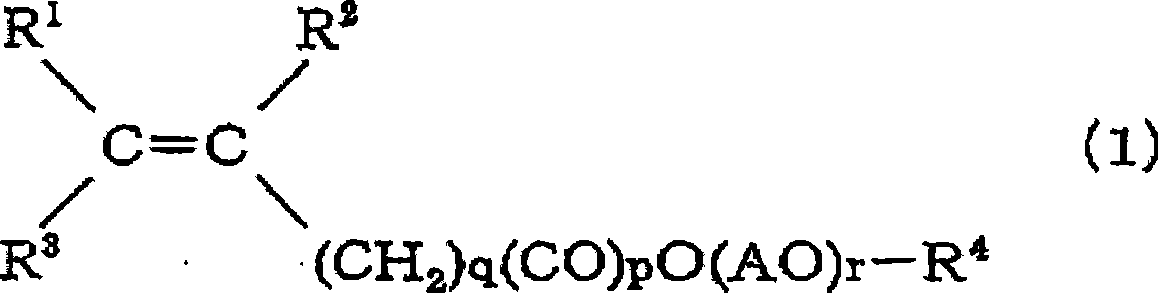

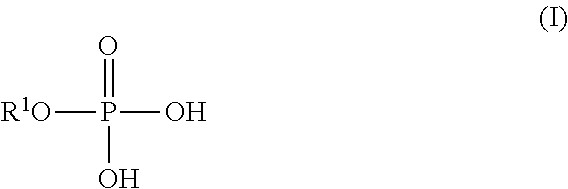

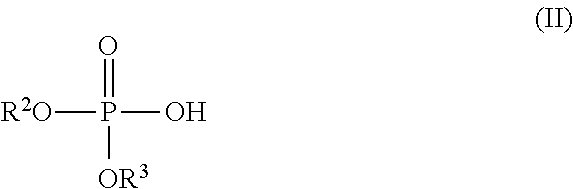

An infrared-absorbing composition comprising a phosphoric acid ester compound including a phosphoric acid monoester represented by formula (1) below and a phosphoric acid diester represented by formula (2) below, and copper ion, wherein the ratio of the phosphoric acid monoester and the phosphoric acid diester is 30:70 to 74:26 as the molar ratio. wherein R1 and R2 each independently represent an ester bond-containing C4-18 group, a C4-18 alkyl group, a C4-18 alkenyl group or a C4-18 alkynyl group, with the proviso that the multiple R2 groups may be the same or different.

Owner:KUREHA KAGAKU KOGYO KK

Waterborne epoxy graphene low-zinc antirust primer

ActiveCN108250900AEvenly dispersedEvenly distributedAnti-corrosive paintsEpoxy resin coatingsEpoxyRust

The invention relates to a waterborne epoxy graphene low-zinc antirust primer. The waterborne epoxy graphene low-zinc antirust primer comprises a component A and a component B, wherein the component Ais composed of a waterborne epoxy curing agent, zinc powder, ferrophosphorus powder, a block copolymer dispersant, MMP, a graphene dispersion and an auxiliary agent; the component B is waterborne epoxy resin; the graphene dispersion is composed of MMP, ethanol, graphene, a block copolymer dispersant, etc.; and the block coplymer dispersant is prepared from itaconic acid, vinylbenzenesulfinic acidsodium salt, methacryloyloxy alkylol phosphomonoester, a RAFT reagent and an initiator through a reaction. The waterborne epoxy graphene low-zinc primer prepared by using the preparation method provided by the invention has excellent adhesion force, flash-rust resistance, corrosion resistance, oil resistance, water resistance, salt fog resistance and storage stability, is a low-VOC, low-zinc, environment-friendly and anticorrosive coating, and is extensively used as an anticorrosive primer for a steel structure in chemical atmosphere and marine environments and used as a primer for rust prevention and corrosion prevention of bridges, storage tanks, containers, ships, steel structure facilities and the like and for protection of steel plates in workshops.

Owner:明光科迪新材料有限公司 +2

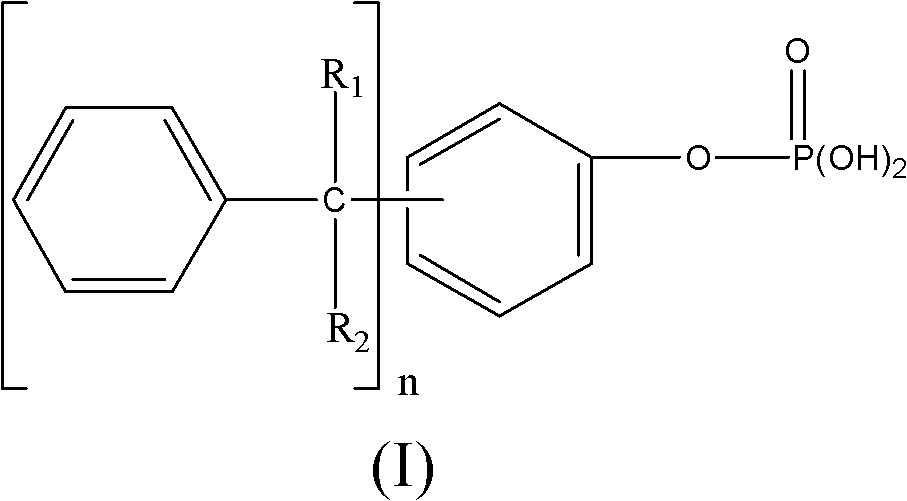

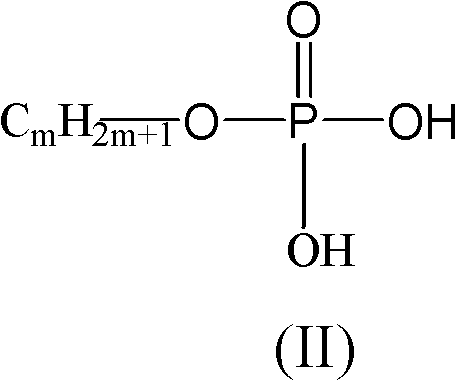

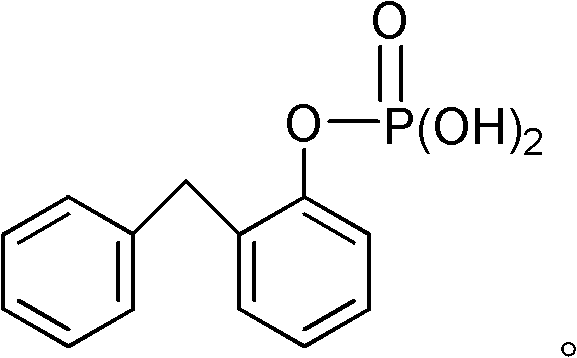

Method for carrying out surface treatment on pigments by using phosphorous compounds

ActiveCN102604447AImprove stabilityHigh tinting strengthOrganic dyesPigment pastesWater basedAlkylphosphate

The invention discloses a method for carrying out surface treatment on pigments by using phosphorous compounds. The method comprises the following steps that mixing aromatic phosphorous compound and alkyl phosphorous compound and then carrying out surface treatment on a pigment, wherein one of 2-benzyl phenol phosphomonoester and 2,4,6-tris(1-methyl-1-phenylethyl)phenol phosphomonoester is preferably chosen as the aromatic phosphorous compound, and alkyl phosphate containing 12 to 18 carbon atoms is preferably chosen as the alkyl phosphorous compound. When the pigment treated by the method is used in the preparation of water-based color paste, the stability and tinctorial strength of the water-based color paste are remarkably enhanced.

Owner:SUZHOU SUNMUN TECH CO LTD

Environment-friendly antibacterial fresh-keeping bag

InactiveCN104788785AEnhanced inhibitory effectGood killing effectTrichlorovinylsilanePotassium iodine

Environment-friendly antibacterial fresh-keeping bag comprises the following components in parts by weight: 90-99 parts of polyethylene, 0.1-10 parts of a breathable and water-tight supporting body, 0.1-10 parts of an antibacterial agent, 0.01-5 parts of an ethylene absorbing and decomposing agent and 0.01-5 parts of a coupling agent, wherein the breathable and water-tight supporting body is one of ultrafine inorganic powder organic montmorillonite and active clay; the ethylene absorbing and decomposing agent is one of pPotassium permanganate, potassium dichromate, potassium iodide and calcium peroxide; the antibacterial agent is an inorganic silver ion glass carrier antibacterial agent, a glass carrier silver ion antibacterial agent or a nanosilver-containing antibacterial fine grain; the coupling agent is one of chelated lactic titanate, isopropyltri(polyether isooctyl pyrophosphato)titanate, phosphomonoester, triisopropyl borate, gamma-chloropropyltrichlorosilane, gamma -hexyldiamino propyl triethoxysilane, vinylsilane and trichlorovinylsilane.

Owner:ZHEJIANG YIFAN COMMODITY

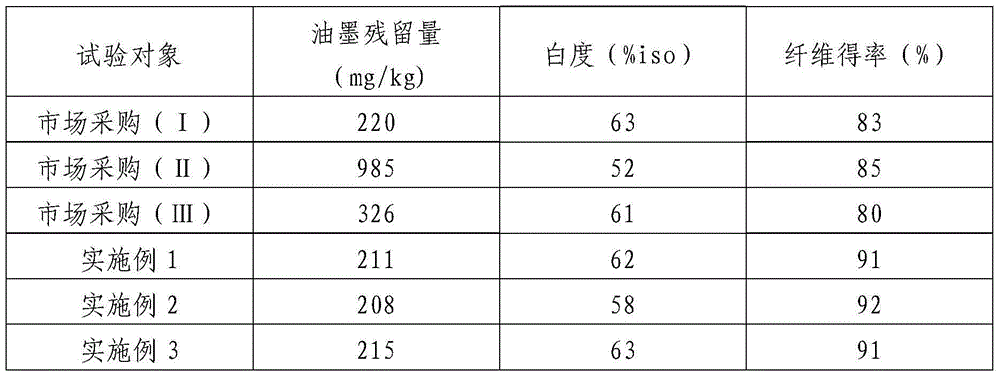

Method for removing ink of waste paper

InactiveCN104631179AReduce remaining amountImprove protectionPaper recyclingWaste paper working-upFiberSodium stearate

The invention discloses a method for removing ink of waste paper, which comprises the following steps: removing ink of waste paper through repulping; removing slag and concentrating; and floating to remove ink. An ink removal agent is added in the process of removing ink through waste paper repulping, the ink removal agent is prepared through the following steps: weighing the following components according to weight percentage: 10-15% of fatty alcohol polyoxyethylene ether, 43-46% of sodium dodecyl benzene sulfonate, 2-5% of tween 80 and balance of water. In the process of floating to remove ink, a trapping agent is added, a method for preparing the trapping agent comprises the following steps: weighing the following components according to weight percentage: 20-30% of sodium stearate, 5-8% of polyoxyethylene ether phosphomonoester, and 65-70% of water. According to the method, under whiteness guarantee condition, the residual amount of ink on the recycled paper is little, and secondary fiber yield is high.

Owner:SICHUAN MINGMING CHEM

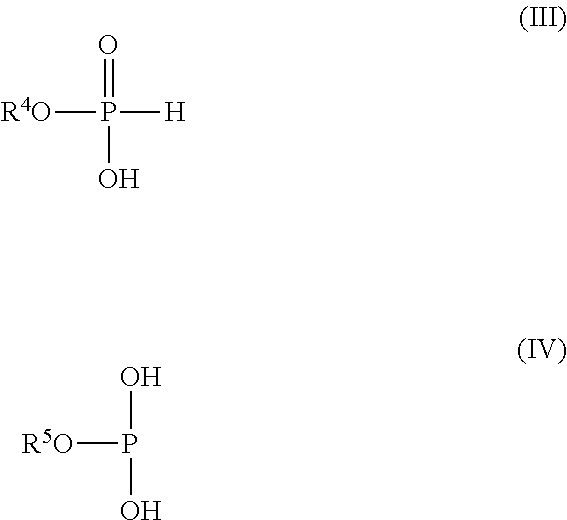

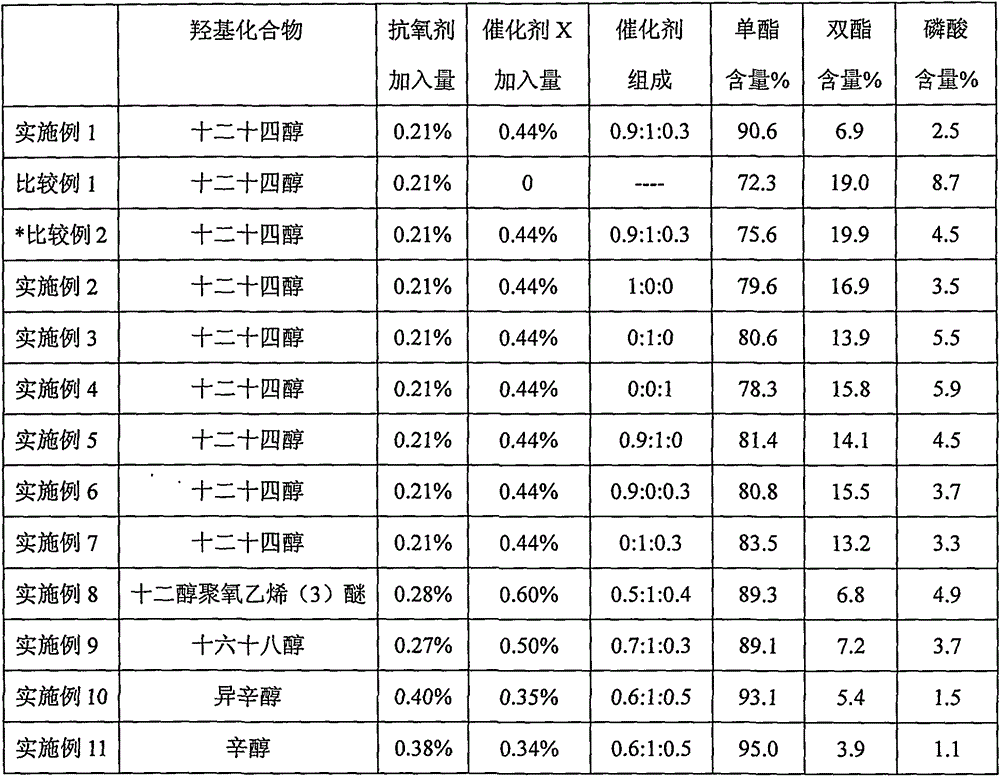

Preparation method of phosphomonoester

ActiveCN105524105AImprove technical effectHigh in Phosphate MonoestersPhosphorus organic compoundsThermal insulationPhosphomonoesters

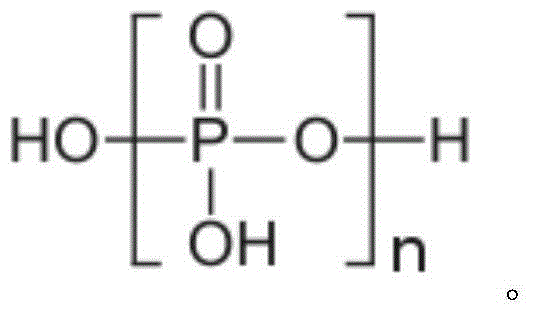

The invention relates to a preparation method of phosphomonoester and mainly solves problems of complex preparation technology of phosphomonoester and low content of phosphomonoester existing in the prior art. The preparation method of the invention comprises the following steps: (1) adding a hydroxy compound and water into a reactor, and heating to 55-80 DEG C; (2) slowly pouring P2O5, controlling temperature of materials in the reactor to 55-95 DEG C, and controlling pouring time within 1-2 h; (3) carrying out thermal insulation at 75-95 DEG C for 3-6 h so as to obtain a material A; and (4) adding water and a catalyst X into the material A, controlling temperature to 70-90 DEG C, and carrying out thermal insulation at the temperature for 2-3 h so as to obtain phosphomonoester. The hydroxy compound accords with the following general formula: RO(EO)m(PO)nH. The catalyst X is at least one compound selected from SnCl4, MnO2 and CuSO4. The preparation method can be used in preparation of phosphomonoester.

Owner:SHANGHAI DUOLUN CHEM

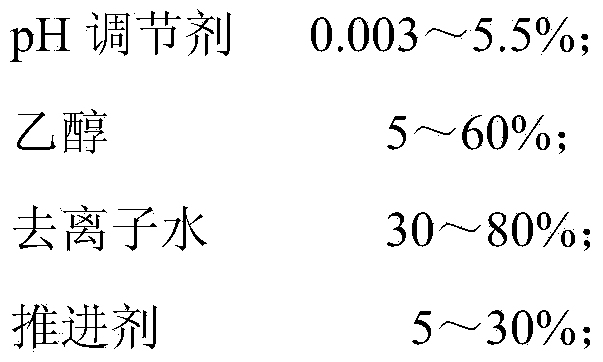

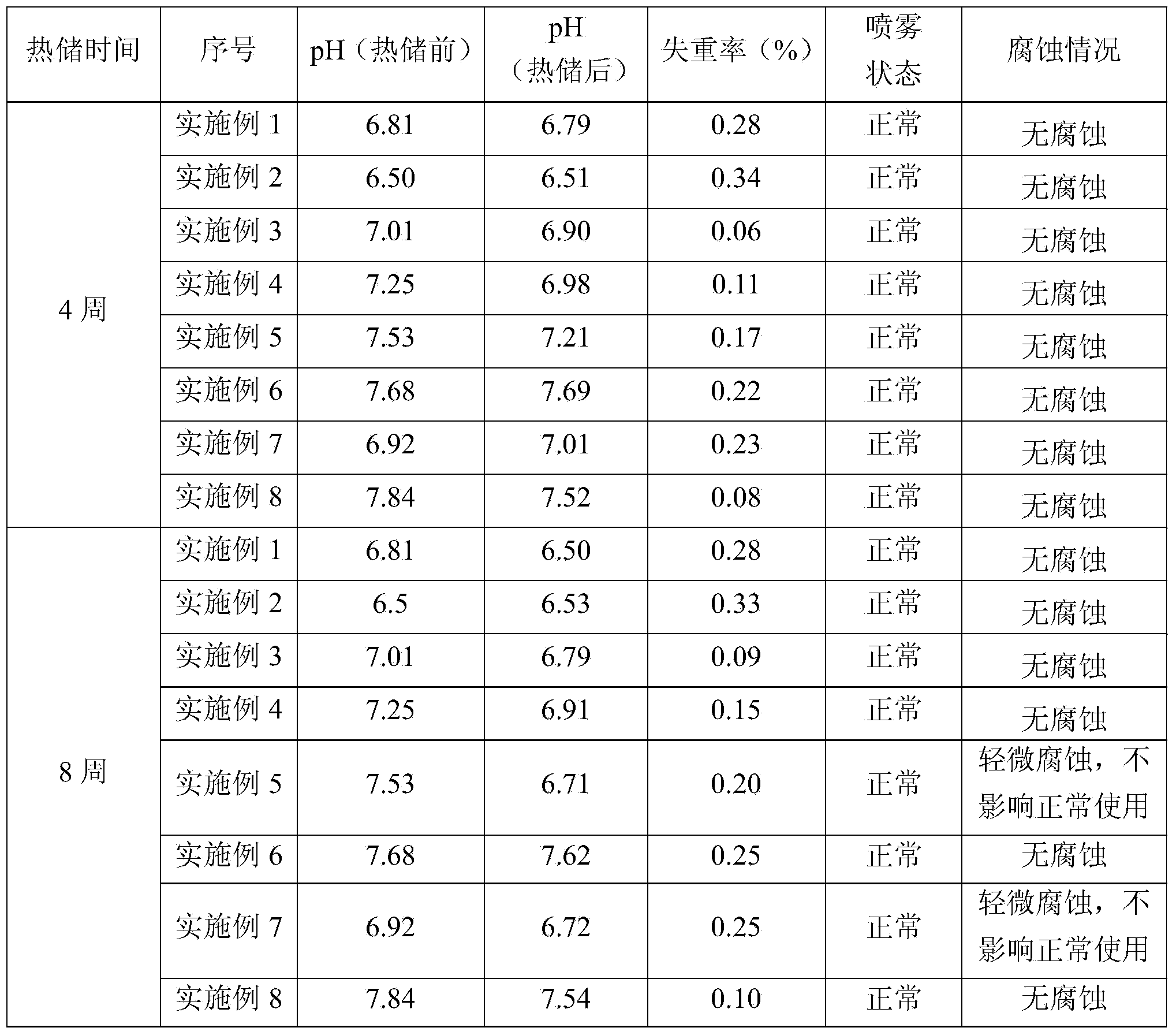

Water-based insect expelling aerosol composition

ActiveCN104027255ANo pollution in the processEasy to useCosmetic preparationsToilet preparationsChemical structureWater based

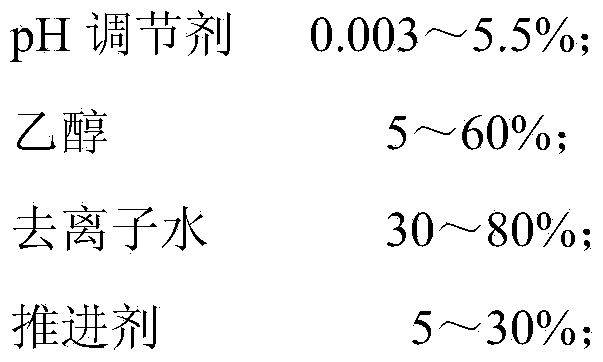

The invention discloses a water-based insect expelling aerosol composition which comprises the following components in percentage by weight: 0.2%-20% of insect expelling active component, 0.01%-5% of phosphate surface active agent, 0.003%-5.5% of pH regulating agent, 5%-60% of ethanol, 30%-80% of deionized water and 5%-30% of propelling agent, wherein the phosphate surface active agent is phosphomonoester or phosphodiester or a mixture of the phosphomonoester and the phosphodiester, and the phosphomonoester or the phosphodiester or the mixture of the phosphomonoester and the phosphodiester is in a chemical structure which contains more than 12 carbon atoms; the pH range of the water-based insect expelling aerosol composition is 6-8. The water-based insect expelling aerosol composition disclosed by the invention can effectively prevent the mosquito bite. According to the water-based insect expelling aerosol composition, the pH value of an aerosol content system is neutral, so that the degradation of active component and the corrosion to a tank body can be well prevented.

Owner:安福超威日化有限公司

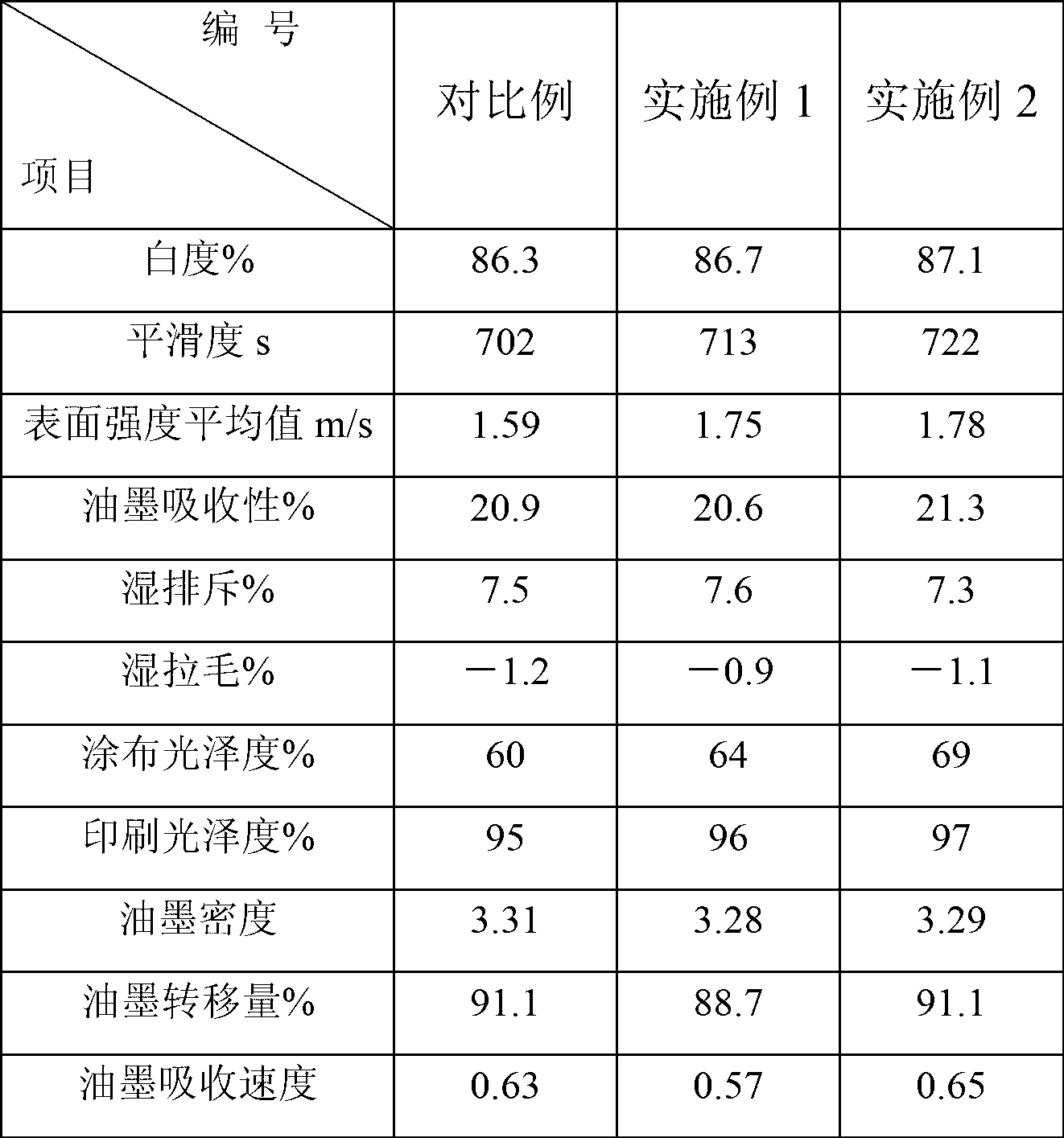

Surface treatment method for antibacterial calcium carbonate special for papermaking

ActiveCN108516572AGood dispersionGood hydrophilic and lipophilicCalcium/strontium/barium carbonatesInorganic compound additionDispersityPapermaking

The invention discloses a surface treatment method for antibacterial calcium carbonate special for papermaking. The surface treatment method includes the steps that limestone is added into a smashingmachine, smashing is carried out, and calcium-carbonate coarse powder is obtained; the calcium-carbonate coarse powder is added into a grinding machine, first modifying agent is added, grinding is carried out, and calcium-carbonate fine powder is obtained; the calcium-carbonate fine powder is delivered to a high-speed stirring machine, second modifying agent is added, the mixture is stirred at high speed and mixed to be even, drying is carried out, and modified calcium carbonate for papermaking is obtained, wherein the first modifying agent is prepared from nonylphenol polyoxyethylene ether phosphomonoester sodium salt and octakis(trimethylsiloxy)silsesquioxane; the second modifying agent is prepared from sapindus-saponin, chitosan and N-propyl-perfluor octyl sulfamide potassium glutamate.The calcium carbonate obtained through surface modification has good dispersity, hydrophilic oleophylic performance, thixotropy, processing fluidity and bonding adhesive force, and also has good antibacterial bacteriostasis effect, ageing resistance and yellowing resistance, and the antibacterial calcium carbonate can serves as an excellent papermaking filler.

Owner:贺州钟山县双文碳酸钙新材料有限公司

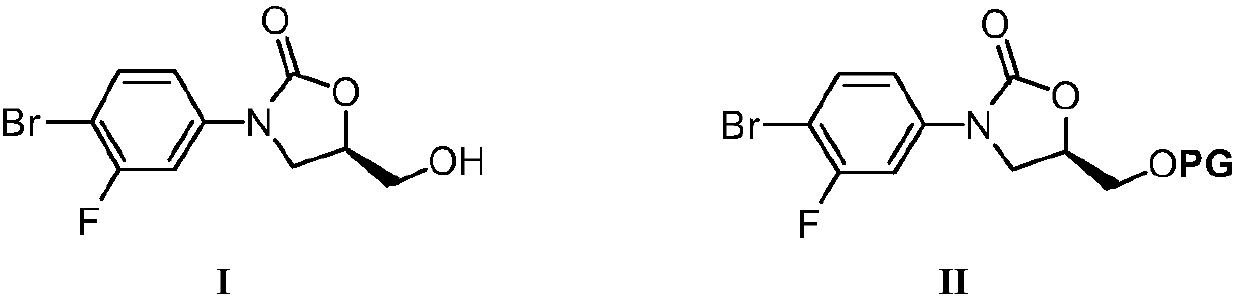

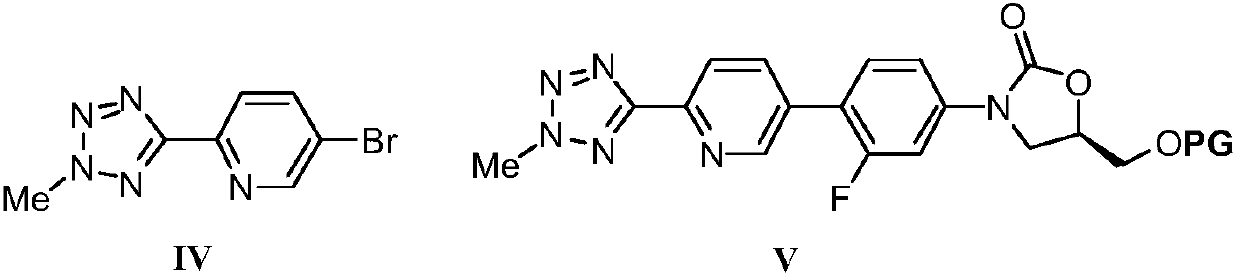

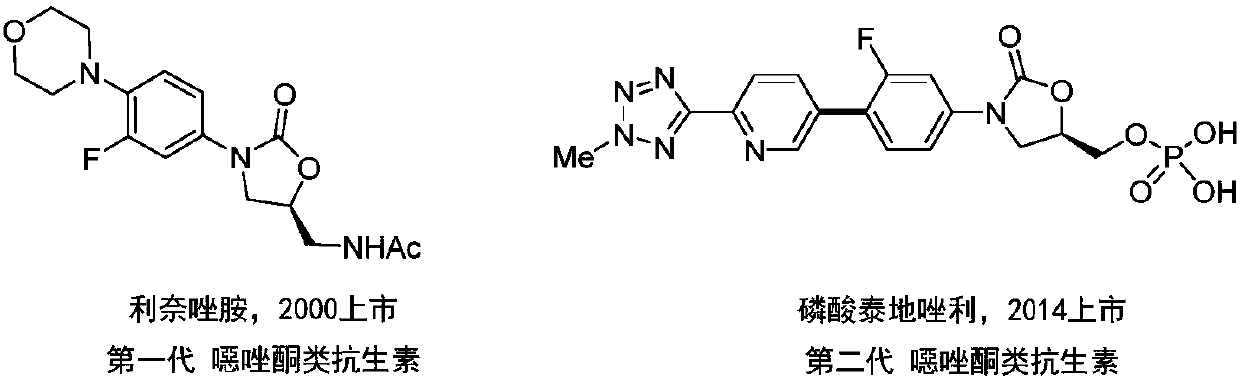

Nickel catalyzed tedizolid phosphate synthesis method

ActiveCN107827927ALow priceGuaranteed yieldGroup 5/15 element organic compoundsBulk chemical productionSynthesis methodsPhosphoric acid

The invention discloses a nickel catalyzed tedizolid phosphate synthesis method. The method includes that methyl tetrazolium bromopyridine serving as an electrophilic reagent and N-oxazolidinone phenyl zinc halide serving as a nucleophilic reagent are subjected to nickel catalyzed Negishi coupling reaction and in-situ deprotection to obtain pharmaceutically active molecular tedizolid through a two-step one-pot process, and tedizolid is subjected to phosphoric acid esterification to obtain tedizolid phosphate. The method has advantages that 1) by in-situ synthesis and utilization of the organiczinc reagent, a complex step of metal reagent separation is avoided; 2) a cheap nickel catalyzing system is applied to establishment of a tedizolid phosphate core framework for the first time, and efficiency of nickel catalyzed Negishi coupling reaction is equivalent to that of palladium catalyzed Suzuki coupling reaction in current industrial synthesis of tedizolid phosphate. The remarkable advantages are beneficial to improvement of efficiency in tedizolid phosphate synthesis and production cost reduction, and the nickel catalyzed tedizolid phosphate synthesis method has a promising industrial application prospect.

Owner:陕西思尔生物科技有限公司 +1

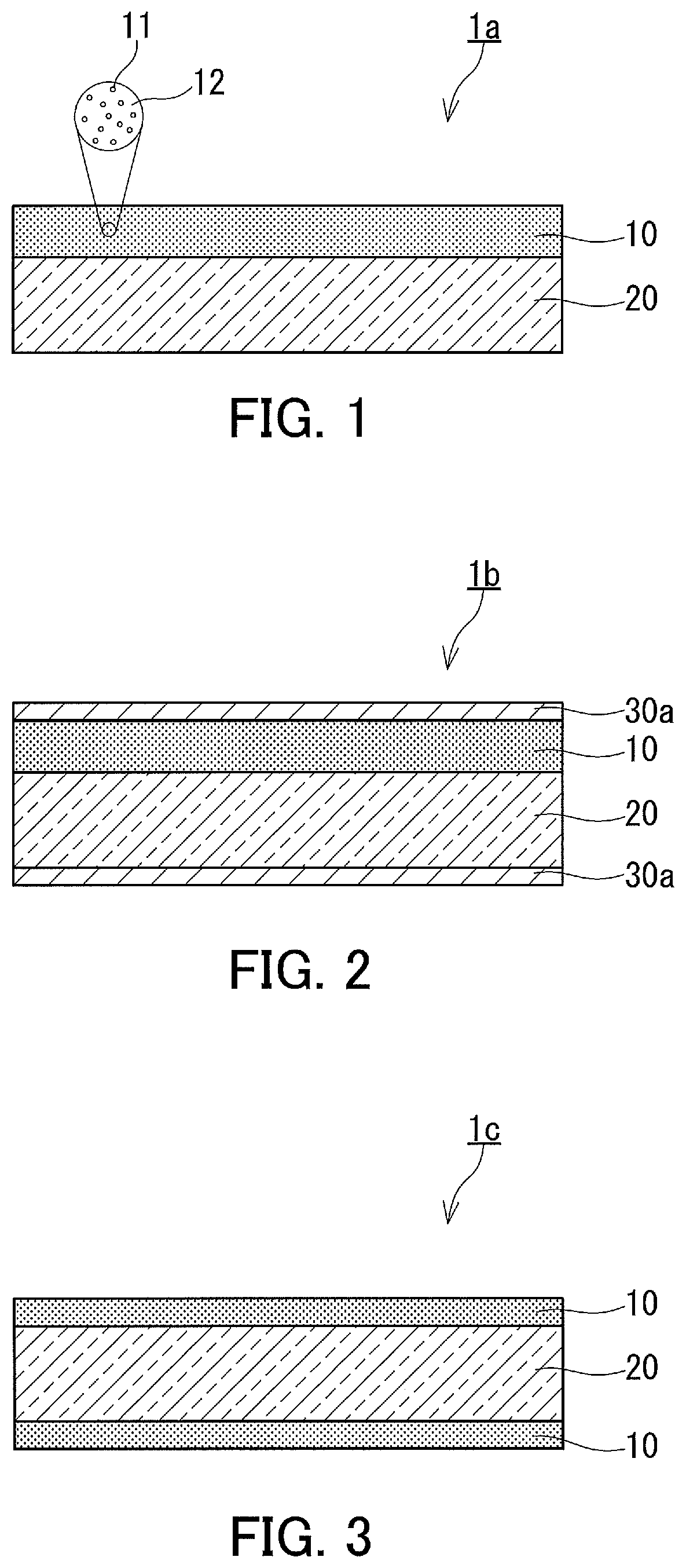

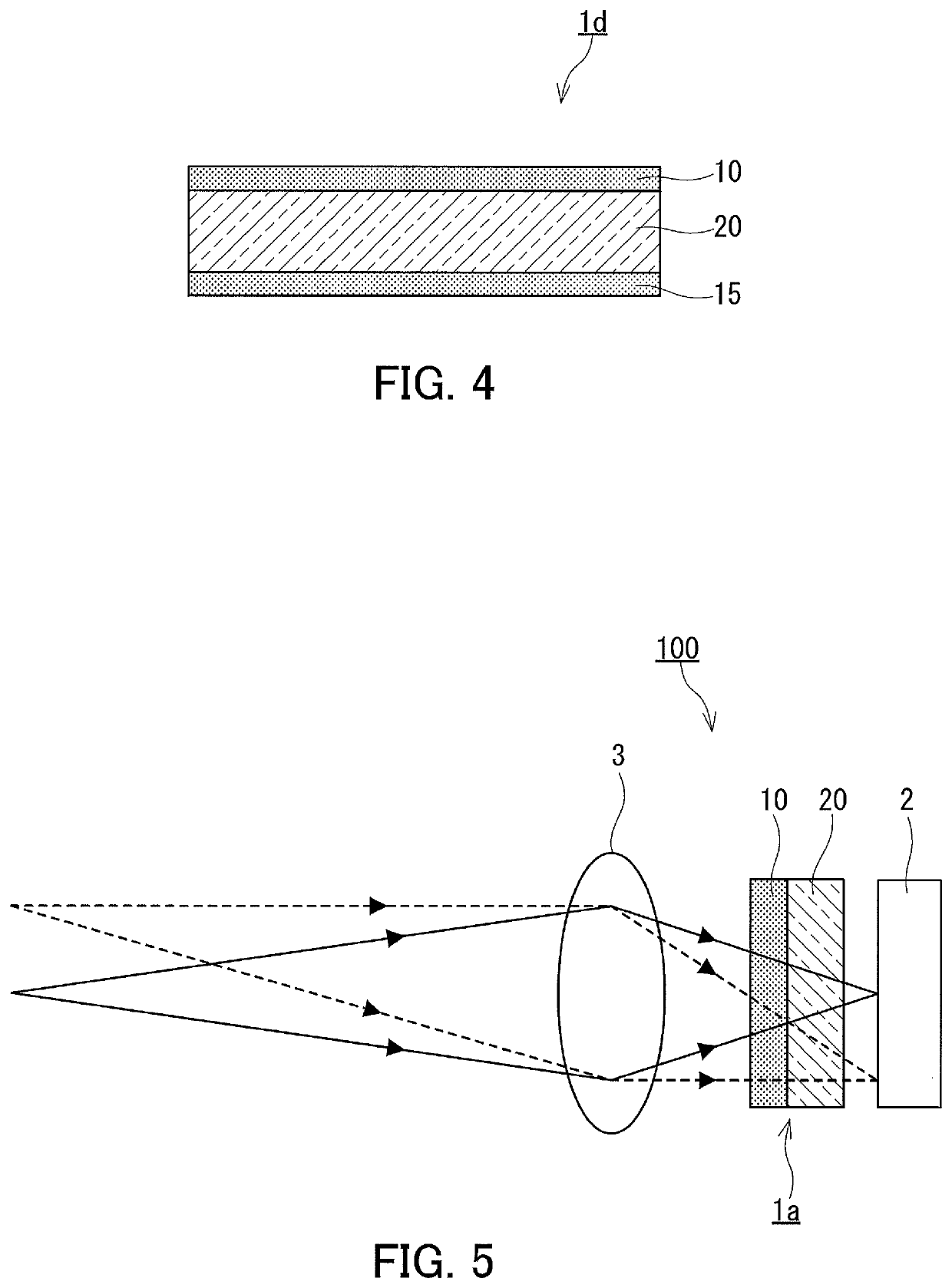

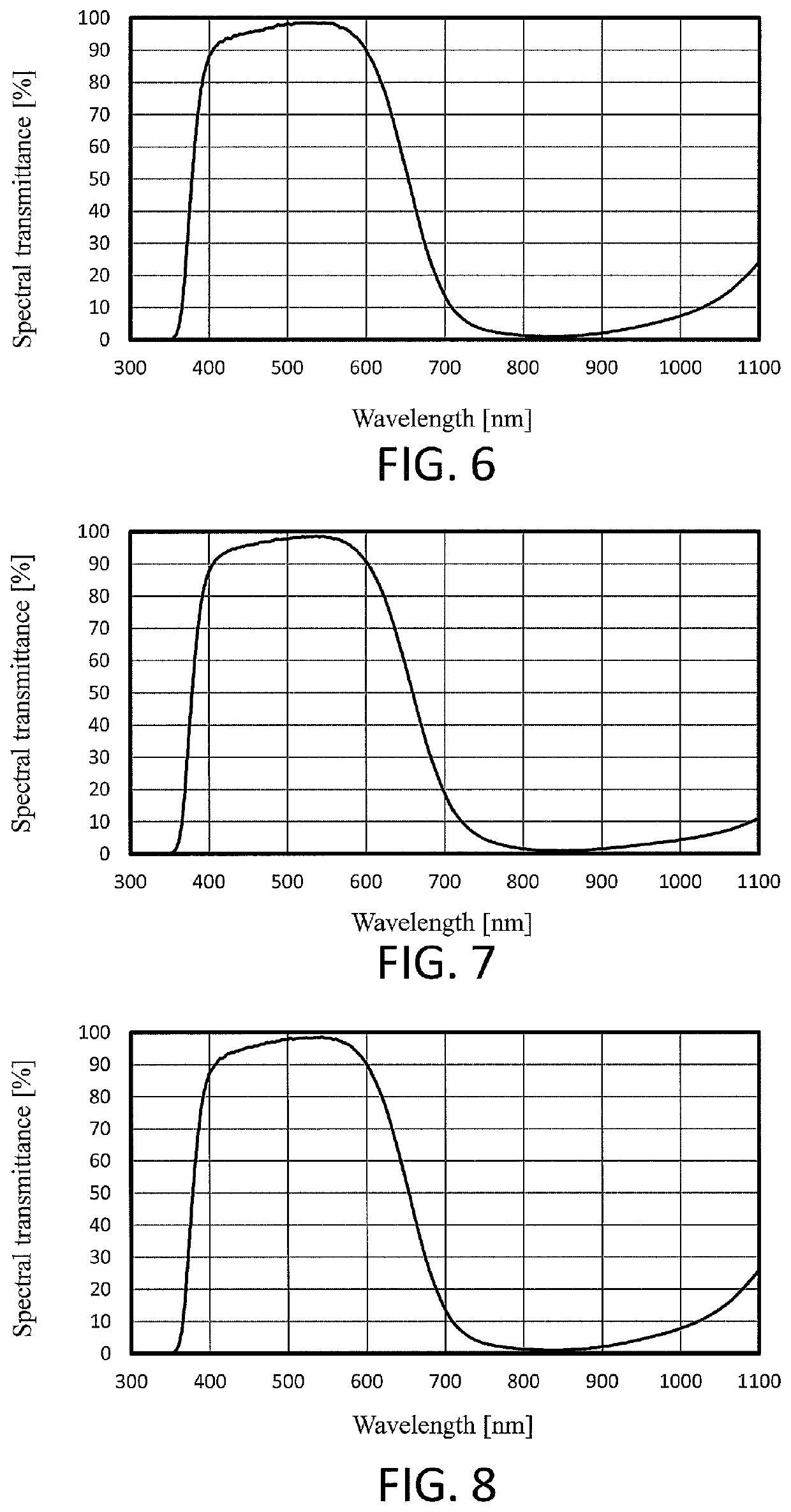

Infrared-absorbing composition, infrared-cut filter, and imaging optical system

ActiveUS10809427B2High light transmittanceShortening the infrared-side cut-off wavelengthOther chemical processesOptical filtersPhosphoric Acid EstersInfrared

An infrared-absorbing composition according to the present invention includes: an infrared absorber formed by a phosphonic acid represented by the following formula (a) and copper ion; and a phosphoric acid ester allowing the infrared absorber to be dispersed. The phosphoric acid ester includes at least one of a phosphoric acid diester and a phosphoric acid monoester. R1 is a phenyl group or a phenyl group in which at least one hydrogen atom is substituted by a halogen atom. When molar contents of the phosphonic acid, the copper ion, and the phosphoric acid ester are respectively defined as CA mol, CC mol, and CE mol and a total molar content of reactive hydroxy groups is defined as CH mol, the relations CA / CE<1 and CH / CC>1.95 are satisfied.

Owner:NIPPON SHEET GLASS CO LTD

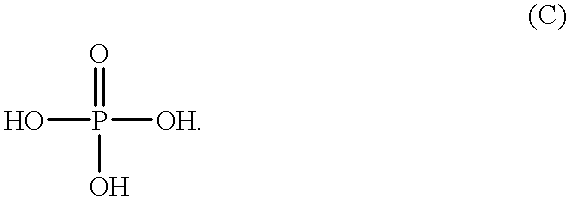

Process for the preparation of phosphoric monoester

InactiveUS6407277B1Reduce the amount requiredIncrease productionPhosphorus organic compoundsPhosphoric Acid EstersPhosphomonoesters

An organic hydroxyl compound is reacted with a phosphorylating agent comprising phosphorus pentaoxide and at least one compound selected from the group consisting of water, phosphoric acid and polyphosphoric acid and having a value represented by formula (I) of from 0.5 to 1.0, under such a condition that the ratio as defined by formula (II) has a value in the range of from 2.8 to 3.2; or alternatively, an organic hydroxyl compound is reacted with the above phosphorylating agent under such a condition that the ratio as defined by formula (II) has a value in the range of from exceeding 3.2 up to 6.4 and then phosphorus pentaoxide is added to the reaction product in such an amount that the ratio as defined by formula (II) has a value in the range of from 2.8 to 3.2 with respect to the total feeds of the starting materials to conduct further reaction. Said process enables the preparation of a phosphoric ester mixture which is excellent in hue and odor, is reduced in the amount of orthophosphoric acid formed as a by-product and contains a phosphoric monoester useful as the component of detergent in an increased amount.

Owner:KAO CORP

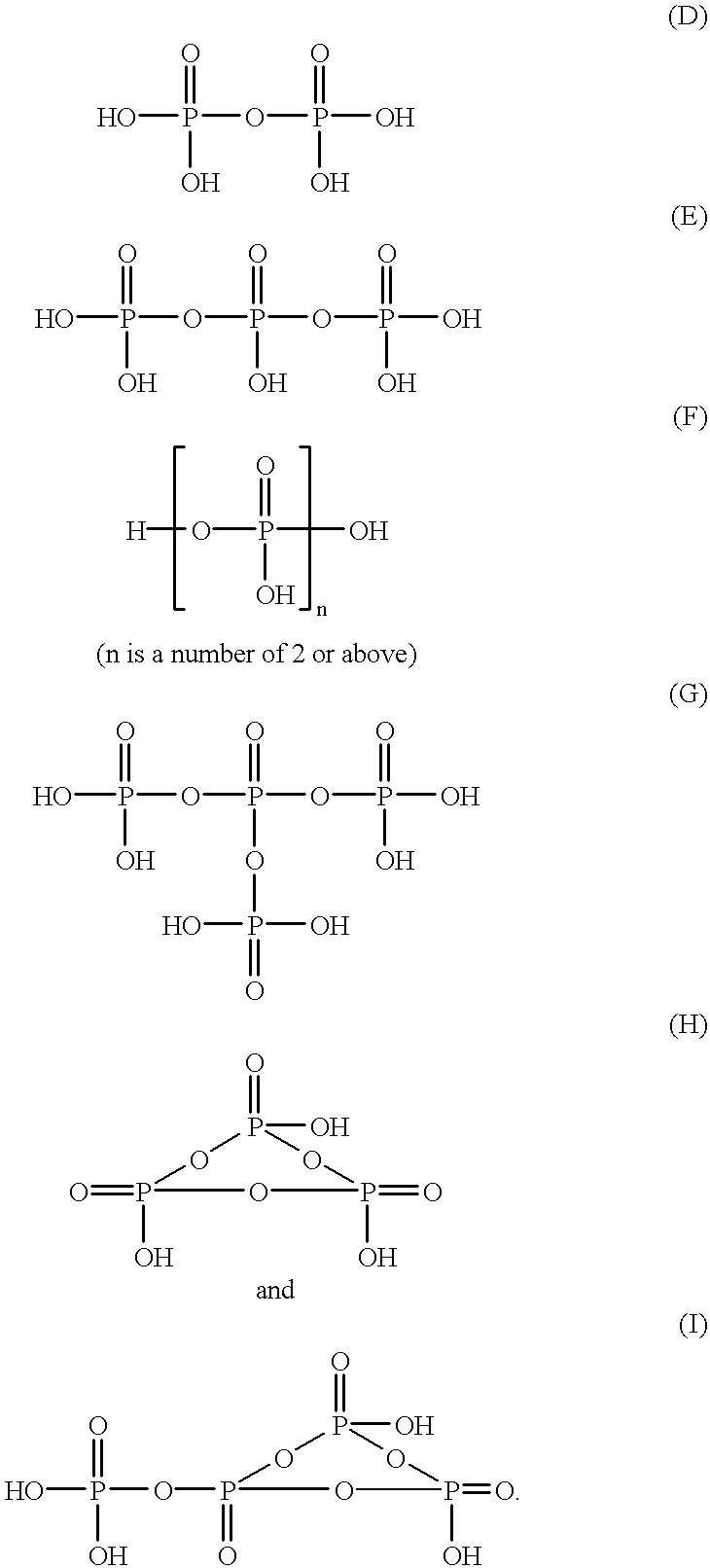

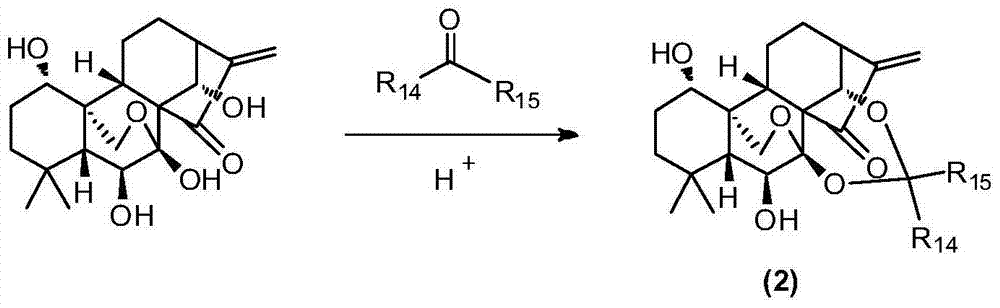

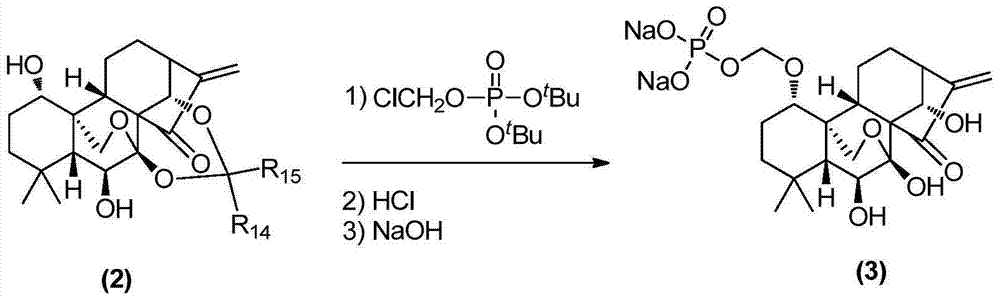

Water-soluble rubescensin a derivative and preparation method thereof

InactiveCN104327089AGood water solubilityEnhance drug propertiesOrganic chemistryAntineoplastic agentsSolubilityPhosphomonoesters

The invention relates to a water-soluble rubescensin a derivative and a preparation method thereof. Specifically, the structure of rubescensin a derivative is modified, and on the basis of reaction of hydroxyl groups in the structure, phosphomonoester, carbamic acid ester or salt and other water soluble groups are introduced, so that water solubility and drug characteristics are significantly improved.

Owner:SHENZHEN JYMED TECH

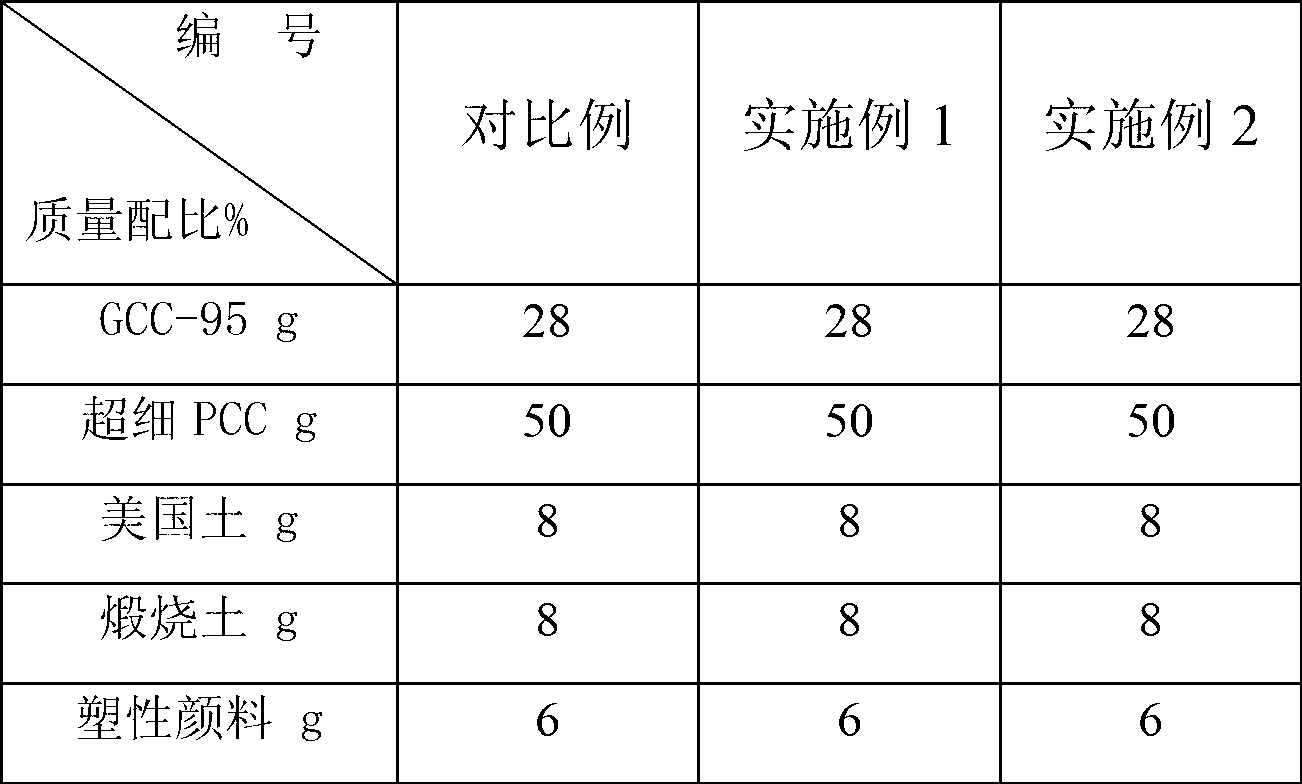

Preparation method of ultrafine coating light calcium carbonate

InactiveCN103011228AQuality improvementAvoid clumpingCalcium/strontium/barium carbonatesCoatings with pigmentsCalcium hydroxideFlocculation

The invention provides a preparation method of ultrafine coating light calcium carbonate. The preparation method comprises the following steps of: adding a compound dispersant to calcium hydroxide water slurry, then sending the slurry to grinding equipment to be ground and simultaneously filling carbon dioxide gas to carry out carbonization, and carbonizing the slurry until the pH value of the calcium hydroxide slurry is 6.5-7.5, thus obtaining the slurry containing ultrafine light calcium carbonate, wherein the compound dispersant comprises mixed phosphate salt, sodium polyacrylate and citrate; and the mixed phosphate salt is a mixture of dodecanol phosphomonoester and heptadecanol phosphodiester. The preparation method has the advantages that the prepared ultrafine light calcium carbonate slurry is directly used for coating without drying, thus not only saving the cost but also avoiding the problem of flocculation of ultrafine grains in the drying process; the ultrafine light calcium carbonate produced by the method has a small grain size; the slurry prepared from the ultrafine light calcium carbonate has low viscosity; and used for coating paper, the ultrafine light calcium carbonate can improve the quality of paper and reduce the production cost.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

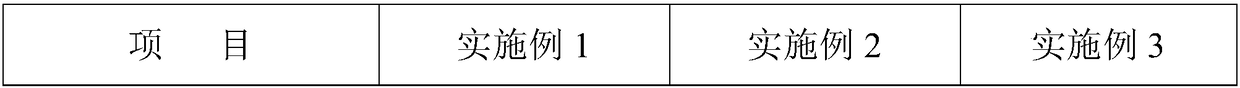

Alcohol-resistant water-based nano color paste

InactiveCN108276834AStrong coloring powerHigh transparencyFireproof paintsAntifouling/underwater paintsHigh resistanceWater based

The invention relates to an alcohol-resistant water-based nano color paste. The nano color paste consists of methyl 3-methoxypropionate (MMP), ethanol, a wetting agent, a toner, a ternary block copolymer dispersing agent, other auxiliary agents and water, wherein the ternary block copolymer dispersing agent is synthesized by using itaconic acid, sodium vinyl benzene sulfonate, methyl acryloyloxy alkyl alcohol phosphomonoester, a reversible addition-fragmentation chain-transfer polymerization (RAFT) chain transfer agent and an azo initiator through an RAFT technology, the number-average molar mass (Mn) of the ternary block copolymer dispersing agent is 3000-8000 and the polydispersity index (PDI) is less than or equal to 1.2. The alcohol-resistant water-based nano color paste prepared by the invention has excellent tinctorial strength, transparency, compatibility, alcohol resistance, storage stability, excellent corrosion resistance, high resistance to temperature of more than 200 DEG C, aging resistance, stain resistance, transference resistance, water resistance and salt fog resistance. The alcohol-resistant water-based nano color paste is widely used in the fields of woodware staining, water-based wood paint, water-based automobile paint, water-based plastic paint, water-based industrial paint, water-based glass stoving varnish, water-based metal stoving varnish, water-basedUV coatings, water surface printing ink and the like.

Owner:英德科迪颜料技术有限公司 +1

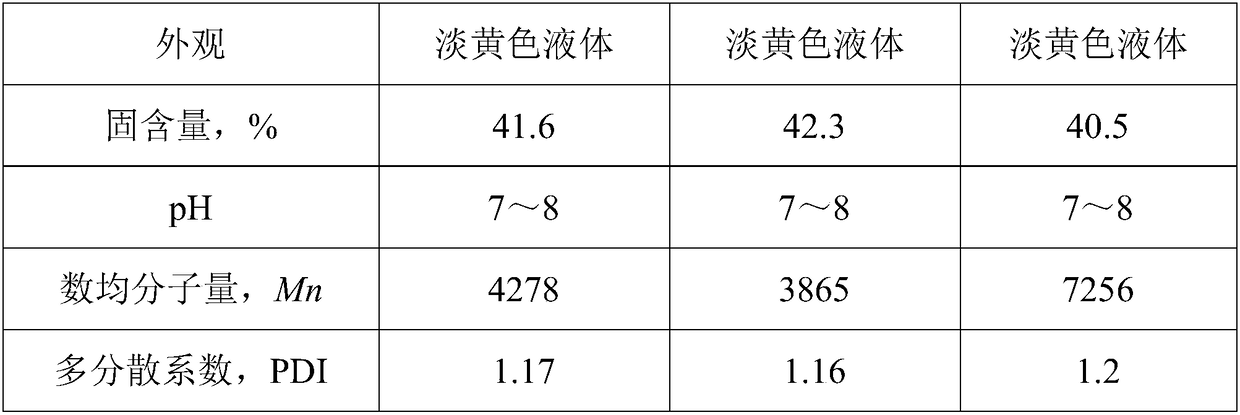

Preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant

ActiveCN105080421AGood alkali resistanceImprove permeabilityTransportation and packagingMixingEthylene glycol monophenyl etherPolymer science

The invention discloses a preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant and belongs to the technical field of surfactant. The preparation method disclosed by the invention comprises the steps of mixing phenol with 2-bromoethanol, dissolving the mixture in dimethylformamide, then adding and uniformly agitating potassium carbonate for reaction, adding distilled water to separate liquid, and increasing the temperature of solution at a lower layer to 160 to 180 DEG C to remove residual dimethylformamide in the solution; then adding polyphosphoric acid into the solution, agitating the solution and increasing the temperature to 60 to 80 DEG C, then adding 1.65 to 5g of catalyst for reaction, adding and uniformly agitating P2O5 for reaction, and adding distilled water with volume of 3 to 5 percent of total volume of the solution to perform hydrolysis for 1 to 3h at 60 to 80 DEG C to obtain the ethylene glycol monophenyl ether phosphomonoester surfactant. The preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant has the advantages that the conversion rate of the prepared ethylene glycol monophenyl ether phosphomonoester is high, the monoester content highly reaches 86 to 86 percent, the alkali resistance of the surfactant is extremely high and the permeability is excellent.

Owner:马鞍山市恺鸾鑫实业有限责任公司

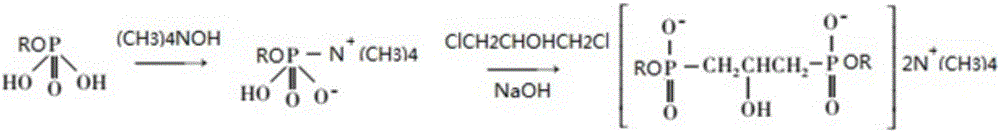

Gemini phosphate surfactant and preparation method thereof

InactiveCN106831860ASolve environmental problemsSolving Recycling ProblemsGroup 5/15 element organic compoundsTransportation and packagingGlycerolPhosphomonoesters

The invention discloses a preparation method of a Gemini phosphate surfactant. The method comprises the following steps: (1) obtaining alkyl phosphomonoester and a hydrogen chloride gas from fatty alcohol and POCl3; (2) carrying out catalytic chlorination on the hydrogen chloride gas obtained in the step (1) and glycerin to obtain glycerin dichlorohydrin; and (3) carrying out neutralization reaction on the alkyl phosphomonoester obtained in the step (1) and a quaternary ammonium base and then adding the glycerin dichlorohydrin obtained in the step (2) to obtain the Gemini phosphate surfactant. The preparation method of the Gemini phosphate surfactant, disclosed by the invention, is high in yield and simple in preparation flow. Meanwhile, the invention further provides the Gemini phosphate surfactant.

Owner:肇庆市稳固化工有限公司

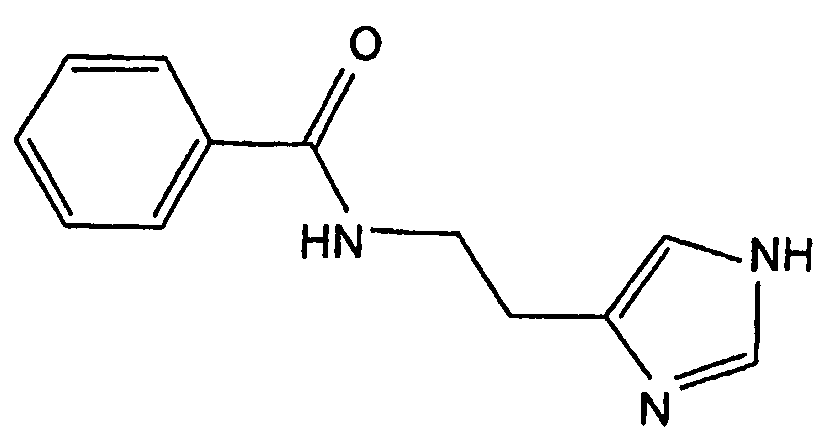

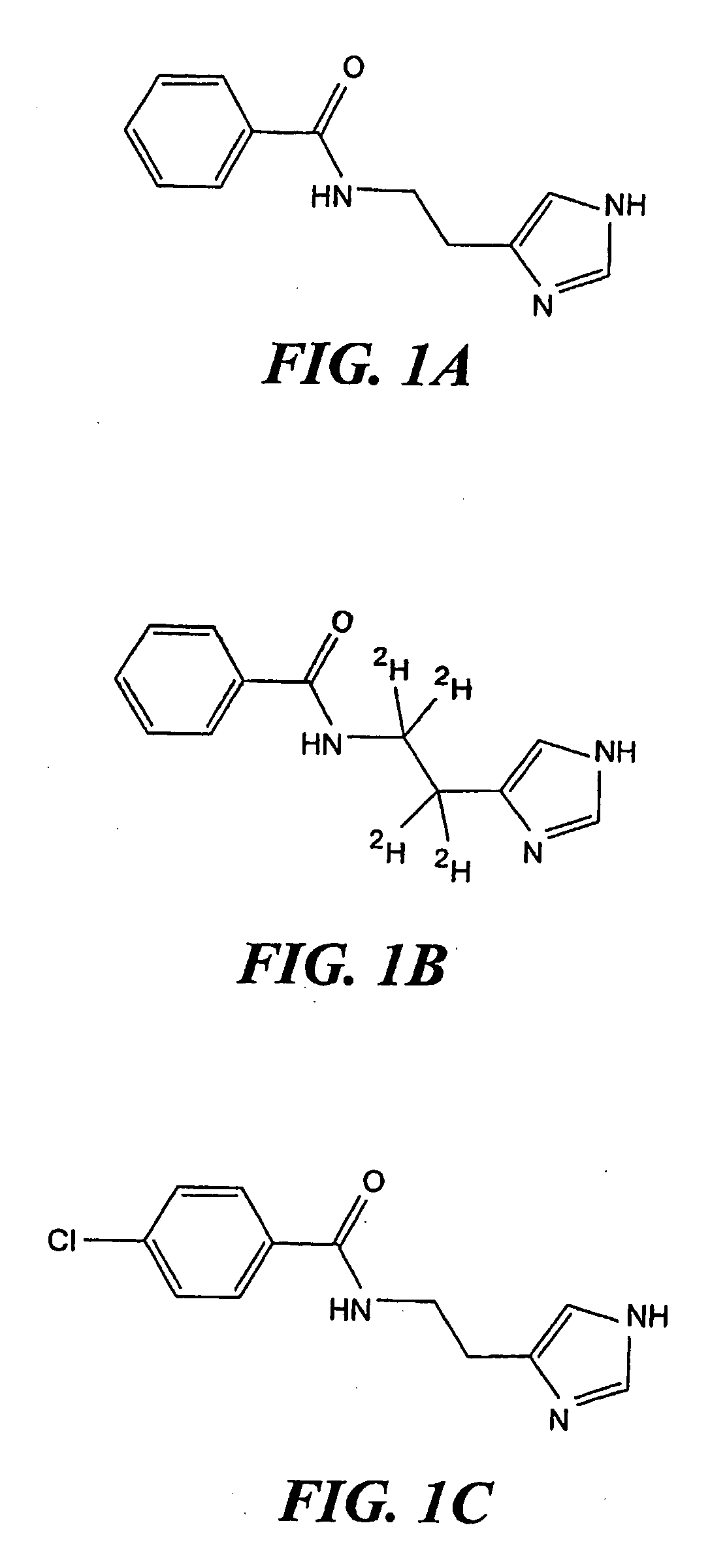

Non-signal Imidazole Reagents for Mass Spectrometry Analysis of Phosphomonoesters

InactiveUS20090215185A1High sensitivityStrong specificityGroup 5/15 element organic compoundsMicrobiological testing/measurementMulti analyteMass Spectrometry-Mass Spectrometry

Analytical chemical reagents termed non-signal imidazoles and a method for their use that provide a host of advantages for analysis of phosphomonoesters are described. The method and compounds of the invention provide a host of advantages for the analysis of phosphomonoester-containing compounds, namely characteristic, multi-analyte detection with high sensitivity and specificity of known and unknown phosphomonoester-compounds simultaneously.

Owner:TRACE BIO ANALYTICS

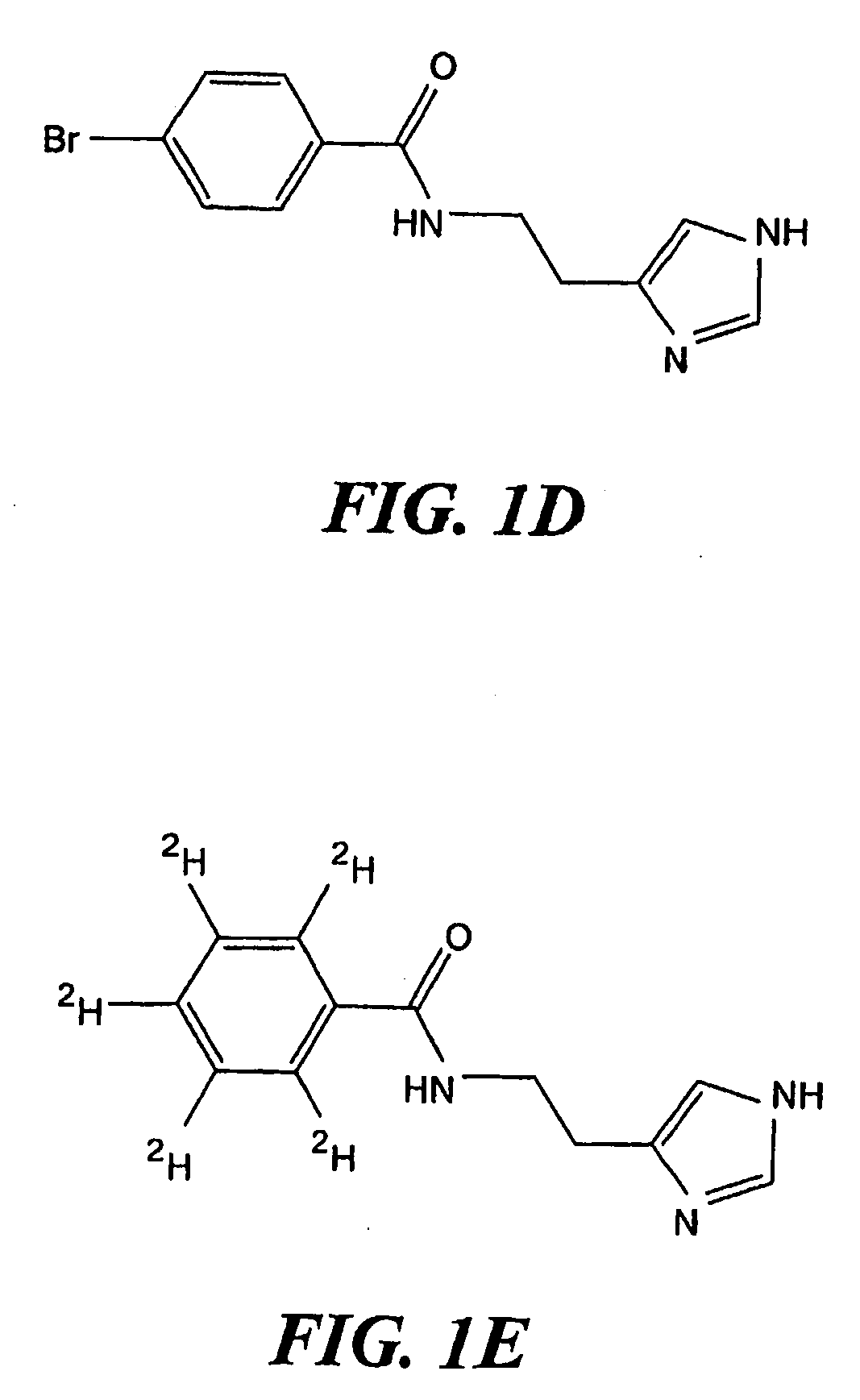

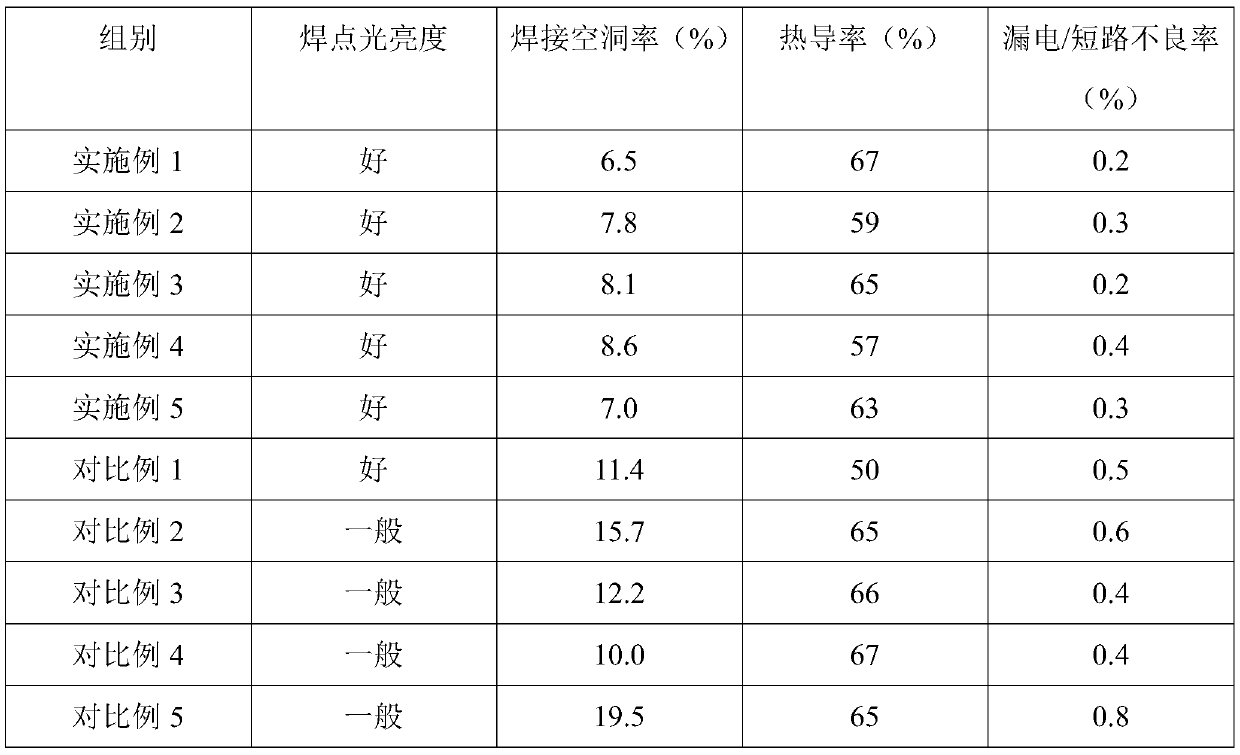

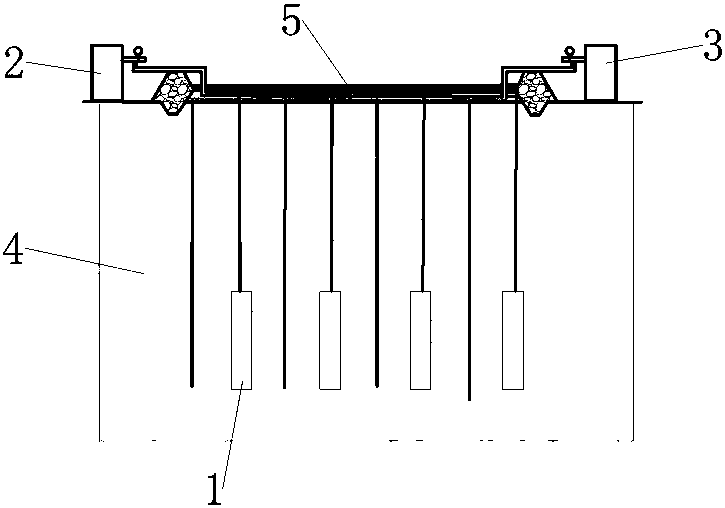

Die bond solder paste for LED packaging and preparing method of die bond solder paste

ActiveCN110202292APrevent bridging, etc.Improve liquidityWelding/cutting media/materialsSoldering mediaSodium bicarbonateSolvent

The invention discloses die bond solder paste for LED packaging and a preparing method of the die bond solder paste. The die bond solder paste is composed of tin-based alloy powder and scaling powderwith the mass ratio of (85-90): (10-15), and the tin-based alloy powder is one of a Sn96.5Ag3Cu0.5 alloy, a Sn82.5Bi17Cu0.5 alloy, a Sn80.3Ag3Cu1Bi15Sb0.7 alloy and a Sn96.5Ag3.5 alloy. The scaling powder comprises following components including lactic acid-glycollic acid copolymer, sodium bicarbonate, phosphomonoester, water soluble silicone oil, polyaniline, resin, a wetting agent, a thixotropicagent and a solvent. The die bond solder paste has good printing performance, excellent weldability, low postwelding residues and corrosion resistance, high heat conductivity and good storage performance, and the LED packaging reliability is obviously improved.

Owner:江苏博蓝锡威金属科技有限公司

Preparation method of phosphomonoester

InactiveCN109748933AImprove technical effectHigh in Phosphate MonoestersPhosphorus organic compoundsPhosphomonoestersOrganic chemistry

Owner:吕志敏

Method used for carbonate bacterium and phosphate bacterium compound passivating heavy metal and solidifying pollution electroplating sludge

InactiveCN108675586AEfficient depositionSludge treatment by de-watering/drying/thickeningWater contaminantsFlocculationSludge

The invention discloses a method used for carbonate bacterium and phosphate bacterium compound passivating heavy metal and solidifying pollution electroplating sludge. The method comprises following steps: 1, a solution A is prepared, a solution B is prepared, and the solution A and the solution B are blended so as to obtain a composite bacterium solution, wherein the solution A is prepared through hydrolysis of urea with Bacillus pasteurii into carbonate ions, and the solution B is prepared through hydrolysis of an organic phosphomonoester into phosphate ions; 2, the composite bacterium solution and heavy metal ion-containing electroplating sludge are subjected to mechanical uniform stirring; 3, Bacillus subtilis is adopted for flocculation of electroplating sludge, vacuum dehydration iscarried out, the composite bacterium solution is adopted for passivation of free heavy metal ions in the electroplating sludge, and electroplating sludge solidifying is carried out. The method is capable of realizing high efficiency passivation of free heavy metal ions in electroplating sludge, solidifying electroplating sludge, and realizing environment-friendly discharge of water in sludge, andthe solidified electroplating sludge can be treated through deep landfilling.

Owner:WENZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com