Die bond solder paste for LED packaging and preparing method of die bond solder paste

A technology of LED packaging and solid crystal, which is applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of chip and board surface wear and hardness, and achieve excellent performance, low cost, and good storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

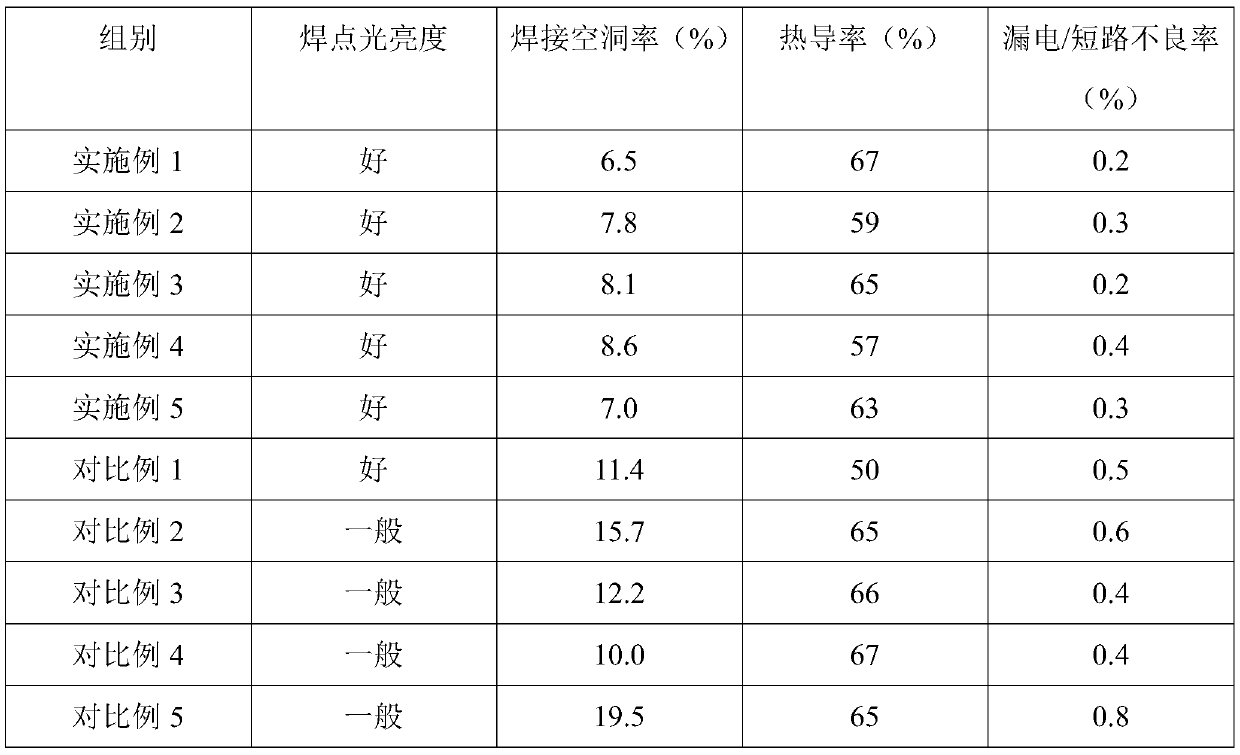

Embodiment 1

[0037] The solid crystal solder paste is composed of Sn96.5Ag3Cu0.5 alloy powder and flux with a mass ratio of 85:15;

[0038] The flux includes the following components in mass percentage: lactic acid-glycolic acid copolymer 10%, sodium bicarbonate 3%, phosphoric acid monoester 4%, water-soluble silicone oil 4%, polyaniline 2%, hydrogenated rosin resin 20%, moisturizing Wetting agent 6%, amide modified hydrogenated castor oil 6% and solvent 45%.

[0039] Wetting agent is composed of isononyl isononanoate and low molecular weight hydrogenated polyisobutylene in a mass ratio of 9:4;

[0040] The solvent is composed of methyl pentynol, N,N-dimethylacetamide, and glycol phenyl ether in a mass ratio of 2:1.5:4.

[0041] The preparation steps of solid crystal solder paste:

[0042] S1: Mix hydrogenated rosin resin, lactic acid-glycolic acid copolymer, phosphoric acid monoester, polyaniline, and solvent, stir evenly, and heat until the materials are completely melted to obtain mixed liquid I...

Embodiment 2

[0047] The solid crystal solder paste is composed of Sn82.5Bi17Cu0.5 alloy powder and flux with a mass ratio of 90:10;

[0048] The flux includes the following components in mass percentage: lactic acid-glycolic acid copolymer 15%, sodium bicarbonate 3%, phosphoric acid monoester 3%, water-soluble silicone oil 5%, polyaniline 3%, disproportionated rosin resin 10%, moisturizing Wetting agent 5%, amide modified hydrogenated castor oil 6% and solvent 50%.

[0049] Wetting agent is composed of isononyl isononanoate and low molecular weight hydrogenated polyisobutylene in a mass ratio of 7:2;

[0050] The solvent is composed of methyl pentynol, N,N-dimethylacetamide, and ethylene glycol phenyl ether in a mass ratio of 4:3:6.

[0051] The preparation steps of solid crystal solder paste:

[0052] S1: Mix the disproportionated rosin resin, lactic acid-glycolic acid copolymer, phosphoric acid monoester, polyaniline, and solvent, stir evenly, and heat until the materials are completely melted to...

Embodiment 3

[0057] The solid crystal solder paste is composed of Sn80.3Ag3Cu1Bi15Sb0.7 alloy powder and flux with a mass ratio of 85:15;

[0058] The flux includes the following components in mass percentage: lactic acid-glycolic acid copolymer 10%, sodium bicarbonate 2%, phosphate monoester 6%, water-soluble silicone oil 3%, polyaniline 1%, polymerized rosin 15%, wetting Agent 8%, hydrogenated castor oil 5% and solvent 50%.

[0059] Wetting agent is composed of isononyl isononanoate and low molecular weight hydrogenated polyisobutylene in a mass ratio of 10:5;

[0060] The solvent is composed of methyl pentynol, N,N-dimethylacetamide, and glycol phenyl ether in a mass ratio of 3:2:5.

[0061] Refer to Example 1 for the preparation steps of solid crystal solder paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com