Dispersant for hydraulic composition

A composition and hydraulic technology, applied in the field of dispersants for hydraulic compositions and hydraulic compositions, can solve the problems of high viscosity of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

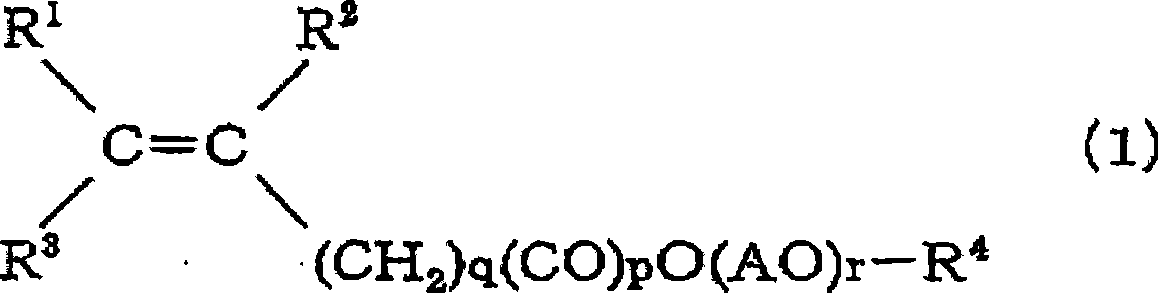

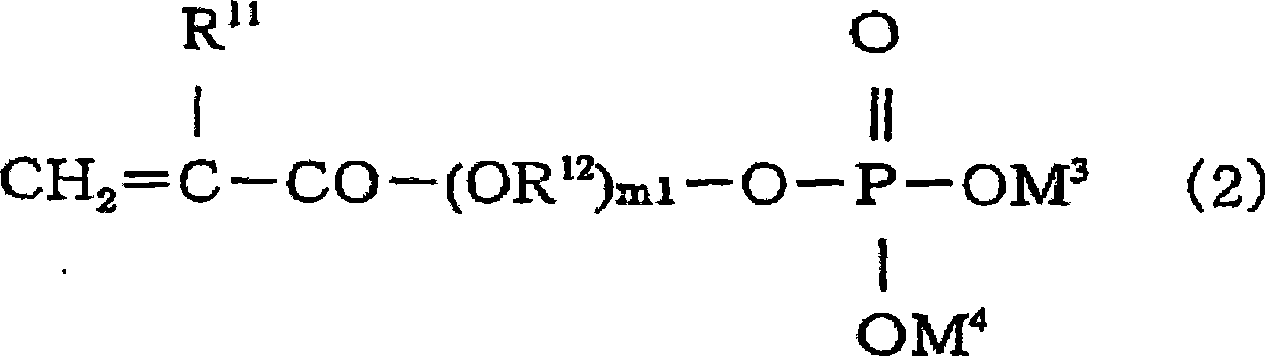

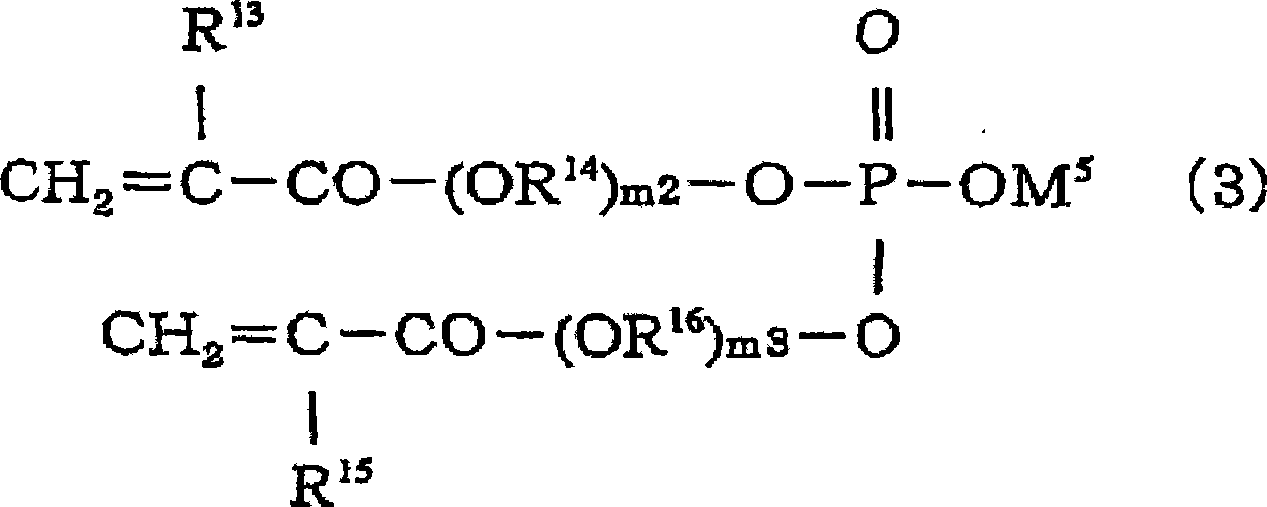

Method used

Image

Examples

Embodiment

[0127] Examples are described below, but the scope of the present invention is not limited to the following examples.

manufacture example (R-1

[0129] 367 g of water was added to a glass-made reaction container (four-neck flask) with a stirrer, nitrogen substitution was performed, stirring, and it heated up to 80 degreeC in nitrogen atmosphere. 426 g of ω-methoxypolyethylene glycol monomethacrylate (the average added mole number of ethylene oxide is 23) (60.8% by weight of active ingredient, 35% by weight of water), 64.2 g of methacrylic acid It was mixed with 3.2 g of 3-mercaptopropionic acid, 85% phosphoric acid was added thereto, the pH was adjusted to 2.0, and the solution obtained by dissolving 11.4 g of ammonium persulfate in 64 g of water was added dropwise over 1.5 hours, respectively. After aging for 1 hour, a solution obtained by dissolving 5.7 g of ammonium persulfate in 32 g of water was added dropwise over 30 minutes, and aging was performed at the same temperature (80° C.) for 1.5 hours thereafter. After aging, 32% sodium hydroxide aqueous solution was added dropwise to neutralize to pH 6.0 to obtain pol...

manufacture example (R-2

[0132] 352 g of water was added to a glass-made reaction container (four-necked flask) with a stirrer, nitrogen substitution was carried out while stirring, and it heated up to 80 degreeC in nitrogen atmosphere. 397 g of omega-methoxy polyethylene glycol monomethacrylate (the average added mole number of ethylene oxide is 23) (the active ingredient is 60.8% by weight, and the moisture is 35% by weight), phosphoric acid mono-[( 123.4 g of phosphoric acid ester (A), which is a mixture of 2-hydroxyethyl) methacrylate and phosphate di-[(2-hydroxyethyl) methacrylate], and 6.1 g of 3-mercaptopropionic acid are mixed , Both of the solution obtained by dissolving 11.9 g of ammonium persulfate in 67 g of water were dripped over 1.5 hours, respectively. After aging for 1 hour, a solution obtained by dissolving 2.6 g of ammonium persulfate in 15 g of water was added dropwise over 30 minutes, and then aging was performed at the same temperature (80° C.) for 1.5 hours. After aging, 32% so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com