Method for preparing magnetic biological carbon adsorbing material and usage thereof

An adsorption material and bio-carbon technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of unstable structure, easy detachment of magnetic medium, increased cost, etc., and achieve the effect of stable existence, special structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

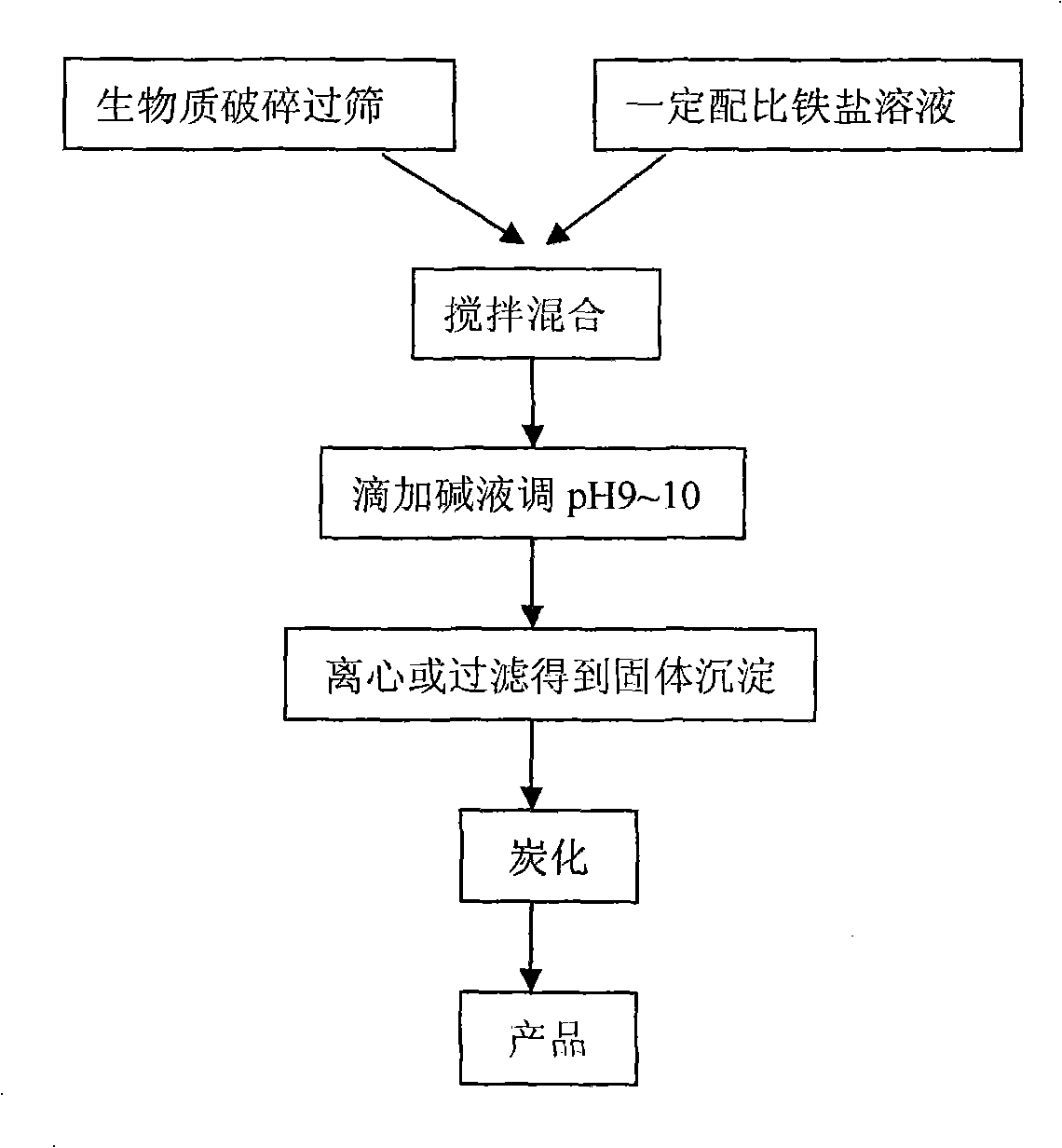

Method used

Image

Examples

Embodiment 1

[0018] Dry and pulverize orange peel biomass, sieve 20 mesh; add sieved biomass to 0.1mol / L Fe 2+ : Fe 3+ =1:1 in the iron salt solution, the weight percentage of biomass is 1%, under stirring, add dropwise 3mol / L NaOH solution to solution pH to 9-10; After solid precipitation is filtered, dried, compacted, in The magnetic biochar adsorbent MBO-1 was obtained by oxygen-limited carbonization at 700 °C for 1 h.

Embodiment 2

[0020] Dry and pulverize orange peel biomass, sieve 100 mesh; add sieved biomass to 0.5mol / L Fe 2+ : Fe 3+ =1:2 in the iron salt solution, the weight percent of biomass is 10%, under stirring, add dropwise 5mol / LNaOH solution to solution pH to 9-10; The magnetic biochar adsorbent MBO-2 was obtained by oxygen-limited carbonization at ℃ for 4 hours.

Embodiment 3

[0022] Dry and pulverize orange peel biomass, sieve 100 mesh; add sieved biomass to 0.3mol / L Fe 2+ : Fe 3+ =2: In the iron salt solution of 1, the weight percent of biomass is 5%, and 6mol / LNaOH solution is added dropwise to solution pH to 9-10 under stirring; The magnetic biochar adsorbent MBO-3 was obtained by oxygen-limited carbonization at ℃ for 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com