Calcium phosphate polymer composite and method

a calcium phosphate and composite technology, applied in the field of mineral polymer composites, can solve the problems of unidirectional or multidirectional bone-repair composites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

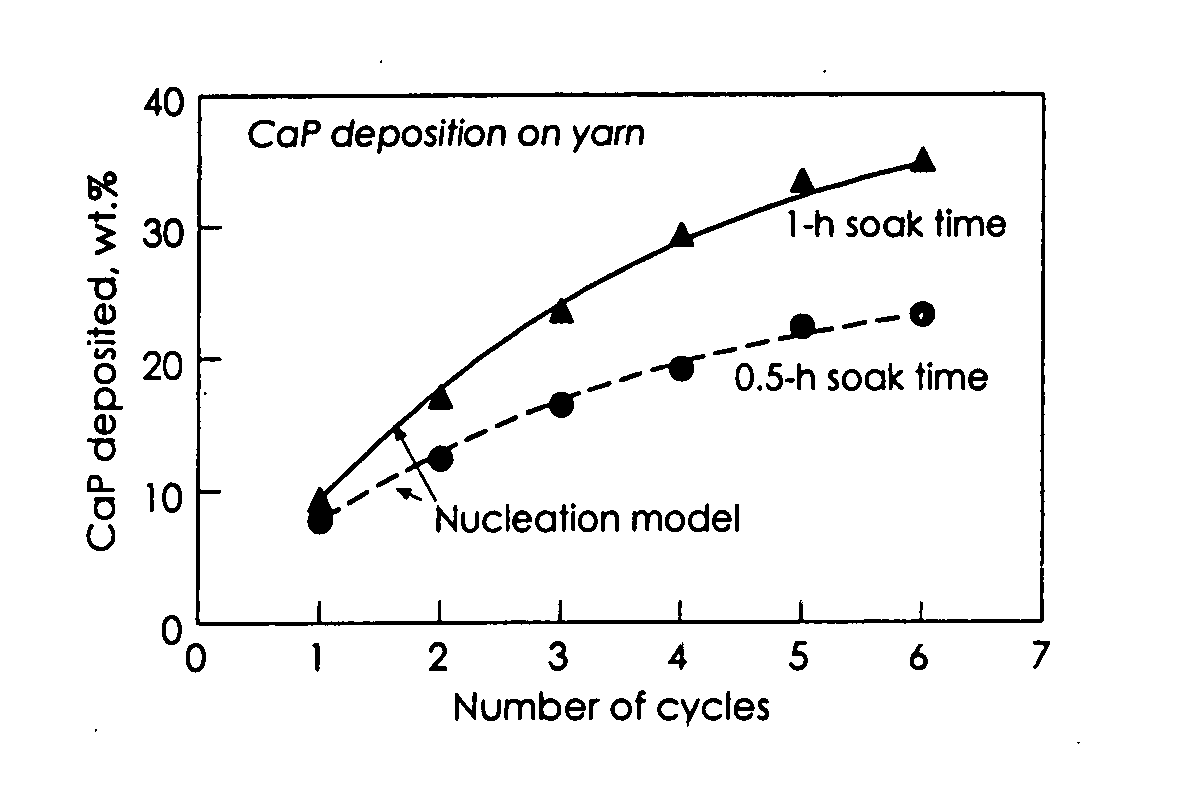

[0053] CaP Coating on Fully Drawn PLA Yarn

[0054] Commercially available poly-lactic acid (PLA) yarn (Mw˜121 kDa, Tg˜55° C., Tm˜175° C.) was obtained from Teleflex Medical Incorporated. Each yarn contained about 30 filaments, with the filaments having an average diameter of 24.5 μm. The PLA yarn was wound around a rectangular, using a custom-built winding machine that allowed for the control of winding speed and tension. During this stage, care was taken to avoid overlapping of the yarn on the frame. A linear spinning rate of 20 cm / min and a tension of approximately 6 N were used for all the experiments. The yarn was then soaked in 1 N NaOH for 1 min. at 25° C. to saponify the surfaces of fibers. The soaked yarn was rinsed in distilled water and air-dried.

[0055] The saponification process was checked in several ways. In one test, water contact angles of the treated PLA films were measured by the sessile drop technique (advancing angles) using a contact angle measurement apparatus (...

example 1

[0137] Drawn PLA fiber yarn (30 filament, 120 denier) was wound around open plastic frames (21 / 4×11 / 8 in.). The amount of fiber on each frame varied since the process was done by hand. The fiber and frame were then weighed. The samples were then soaked in simulated body fluid solution (3× concentration) for 12 h to generate a layer of hydroxyapatite (HA) coating on the surface of the PLA fibers. The samples were left to dry overnight. After drying the weight was recorded and was used to calculate the percentage of HA by weight of each sample. The samples were then hot compacted into bars with dimensions around (4×0.5×0.2) cm at a temperature of 175° C. for 30 min. Afterwards, each sample was subjected to a three-point bend test to determine flexural modulus and flexural strength. This was done at a strain rate of 1 mm / min. It is noted that etching is not used in this example. Nonetheless, etching can be used prior to biomimetic coating. Also, a low temperature binding sheath was not...

example 2

[0145] Direct Coating of Calcium Phosphate Precursors

[0146] Pre-formed or calcium phosphate precurors can be directly coated onto PLA fibers. A hydrothermal method is used to make the HA, then the particles are used with PCL to coat over the fibers. In addition, other calcium phosphates can be used.

[0147] The HA particles used in the composite were prepared by reacting of 200 mL calcium nitrate solution (2 g / dL) and 600 mL ammonium phosphate solution (2 g / dL). After drying, the precipitate was ground into powder, which has an average particle size of 120 nm and is shown in FIG. 19. Ten mg of ground HA powder was then added into 10 mL PCL (Dow, MW 80,000) acetone solution (1% wt / wt), which was used to dip-coat the PLA fiber strand composed of 30 fibers with a 22-μm diameter for each fiber. Sixty meters of PCL-HA coated PLA fibers were then aligned and hot-pressed in a 40-mm×5-mm×2-mm mold at 80° C. for 4 min. The resulting composite was taken out after cooling and its composition w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com