Preparation method of ethylene glycol monophenyl ether phosphomonoester surfactant

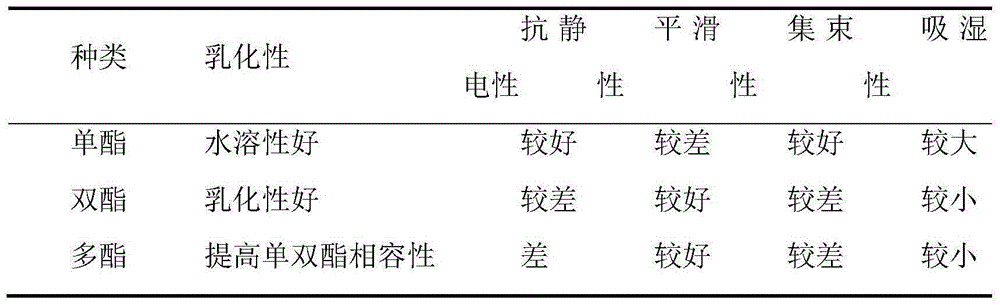

A technology of surfactant and ethylene glycol phenyl ether, which is applied in the field of preparation of ethylene glycol phenyl ether phosphate monoester surfactant, can solve the problems of weak alkali resistance and unsuitability for high alkali environment, and achieve equipment corrosion resistance Small size, easy mass production, alkali resistance and permeability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

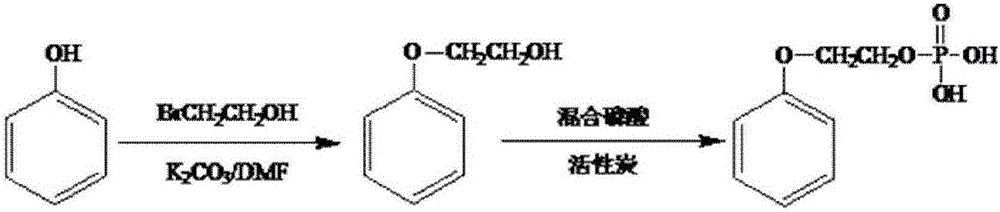

[0029] A kind of preparation method of ethylene glycol phenyl ether phosphoric acid monoester surfactant of the present embodiment, its steps are:

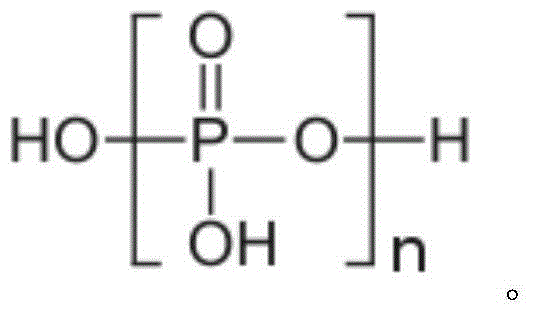

[0030] First mix 1 mol of phenol and 1.05 mol of 2-bromoethanol and dissolve in 150 mL of dimethylformamide, then add 1.5 mol of potassium carbonate and stir evenly, heat the solution to 60°C, and react for 5 hours; after the reaction is completed, add 600 mL of distilled water and stir evenly, Then separate the solution to remove the lower layer, and the separated lower layer solution is heated up to 180°C to evaporate the residual dimethylformamide in the solution; then the solution is cooled to 40°C, and 0.33mol polyphosphoric acid (wherein n is 3 ), heated to 60°C under stirring, then added 1.65g zeolite molecular sieve, reacted for 0.5h; continued to add 0.033molP 2 o 5 Stir evenly and react for another 2 hours; after the above reaction is completed, add distilled water with 3% of the total volume of the solution and hydroly...

Embodiment 2

[0032] A kind of preparation method of ethylene glycol phenyl ether phosphoric acid monoester surfactant of the present embodiment, its steps are:

[0033] First mix 1 mol of phenol and 1.15 mol of 2-bromoethanol and dissolve in 250 mL of dimethylformamide, then add 1.2 mol of potassium carbonate and stir evenly, raise the temperature of the solution to 80°C, and react for 7 hours; after the reaction is completed, add 600 mL of distilled water and stir evenly, Then separate the solution to remove the lower layer, and the separated lower layer solution is heated to 180° C. to evaporate the residual dimethylformamide in the solution; the temperature is lowered to 40° C., and 0.50 mol of polyphosphoric acid (wherein n is 5) is added to the solution, and stirred Lower the temperature to 80°C, then add 5g of activated carbon, react for 2h; continue to add 0.1molP to the solution 2 o 5 Stir evenly and react for another 4 hours; after the above reaction is completed, add distilled w...

Embodiment 3

[0035] A kind of preparation method of ethylene glycol phenyl ether phosphoric acid monoester surfactant of the present embodiment, its steps are:

[0036] First mix 1 mol of phenol and 1.1 mol of 2-bromoethanol and dissolve in 200 mL of dimethylformamide, then add 1.5 mol of potassium carbonate and stir evenly, raise the temperature of the solution to 80°C, and react for 6 hours; after the reaction is completed, add 600 mL of distilled water and stir evenly, Then separate the solution to remove the lower layer, and the separated lower layer solution is heated to 180° C. to evaporate the residual dimethylformamide in the solution; the temperature is lowered to 40° C., and 0.5 mol of polyphosphoric acid (wherein n is 5) is added to the solution, and stirred Lower the temperature to 80°C, then add 5g of activated carbon, react for 2h; continue to add 0.08molP to the solution 2 o 5 Stir evenly and react for another 4 hours; after the above reaction is completed, add distilled wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com