Waterborne epoxy graphene low-zinc antirust primer

A water-based graphene and water-based epoxy technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of low concentration and poor stability of graphene dispersions, and achieve good anchoring effect, low surface tension, Volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

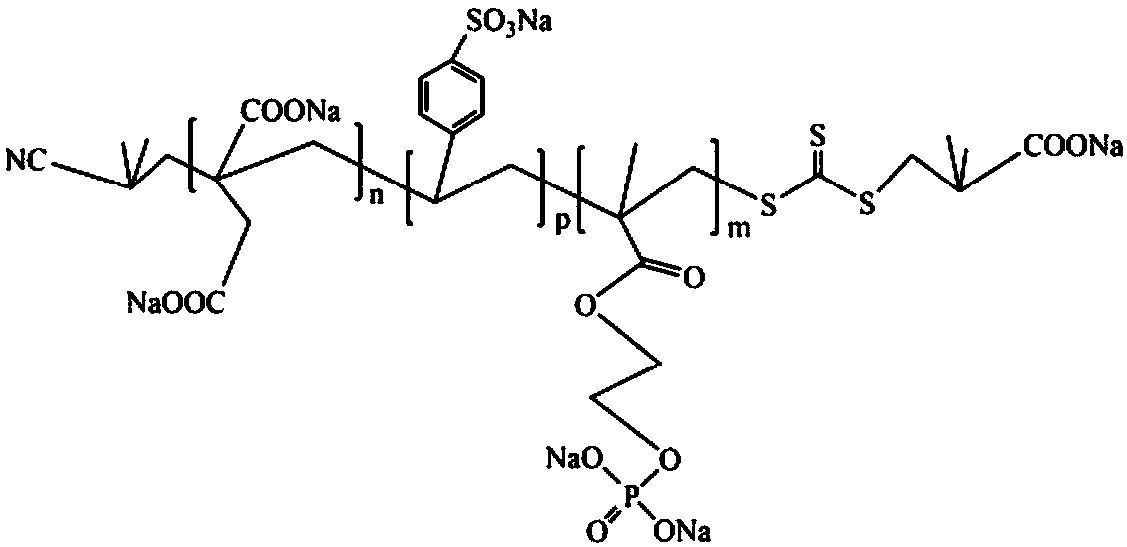

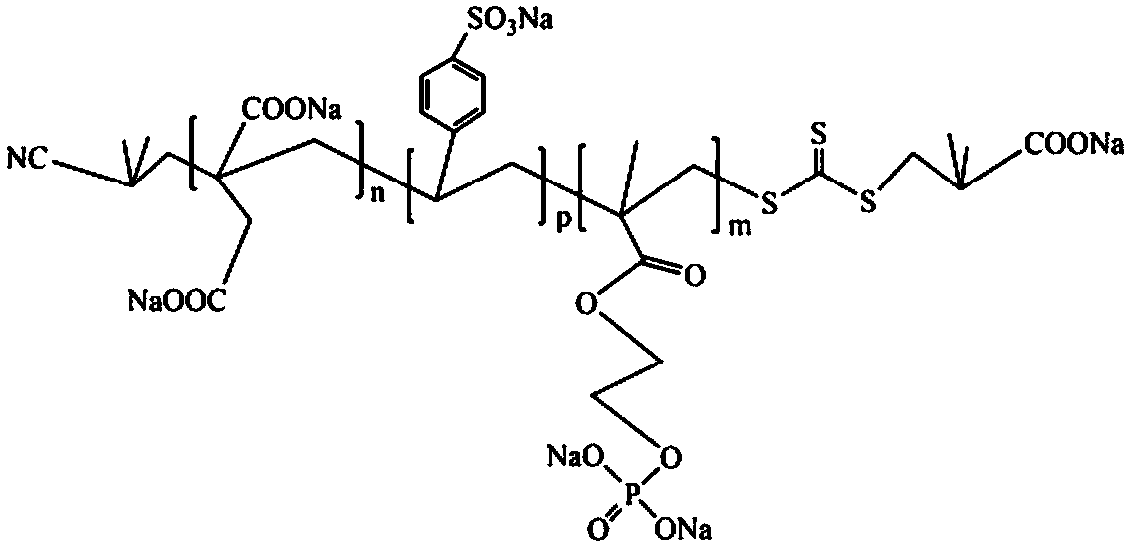

[0034] A kind of ternary block copolymer anionic dispersant A, its steps are as follows:

[0035] In parts by weight, 25.0 parts of itaconic acid, 12.0 parts of sodium p-styrene sulfonate, 19.0 parts of methacryloxybutyl alcohol monophosphate, 1.6 parts of S, S'-bis(α,α' -Dimethyl-α"-acetic acid) trithiocarbonate, 80.0 parts of ethanol are added in the reaction kettle, logical N 2 Protection, start stirring and dissolve evenly, raise the temperature to 75°C, evenly add 10.0 parts of ethanol solution containing 10% azobisisobutyronitrile dropwise, finish dropping within 0.5h, keep at 75°C and continue the reaction for 6h; then slowly add 10 % NaOH solution and deionized water to adjust the pH to 7-8 to obtain the anionic dispersant A of the ternary block copolymer.

Embodiment 2

[0037] A kind of ternary block copolymer anionic dispersant B, its steps are as follows:

[0038] In parts by weight, 22.0 parts of itaconic acid, 13.0 parts of sodium p-styrenesulfonate, 15.0 parts of methacryloyloxyethyl alcohol monophosphate, 3.0 parts of 4,4'-dithiophenylacetic acid, 70.0 parts of Virahol joins in the reactor, logical N 2 Protection, start stirring and dissolve evenly, heat up to 70°C, add 8.0 parts of isopropanol solution containing 10% azobisisobutylamidine hydrochloride dropwise evenly, drop it within 0.5h, keep at 70°C to continue the reaction 6h; then slowly add 10% NaOH solution and deionized water to adjust the pH to 7-8 to obtain the anionic dispersant B of the ternary block copolymer.

[0039] The ternary block copolymer anionic dispersant technical index that makes in the embodiment of the present invention 1,2 is as shown in table 1:

[0040] Table 1 Ternary block copolymer anionic water-based dispersant technical indicators

[0041] ...

Embodiment 3

[0043] A 10% solid-containing aqueous graphene dispersion X, the preparation steps of which are as follows: add 38.5 parts of deionized water, 25.0 parts of ethanol, methyl 3-methoxypropionate to the dispersion tank according to the weight ratio of the formula 8.0 parts, 4.0 parts of wetting agent, 14.0 parts of ternary block copolymer anionic dispersant A, stir evenly, add 10.0 parts of graphene powder, disperse at 1000~1200r / min for 30~45min at high speed, and then move to nano sand The mill circulates and grinds for 6-12 hours until the particle size is D 50 <120nm, transfer to the adjusting tank, add 0.3 parts of pH adjuster and 0.2 parts of defoamer at 300-500r / min, stir for 20-30min, filter with 200 mesh filter, pack to get the water-based graphene Dispersion X.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com