Preparation method of phosphomonoester

A phosphoric acid monoester and temperature control technology, which is applied in chemical instruments and methods, phosphorus organic compounds, compounds of Group 5/15 elements of the periodic table, etc. problem, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

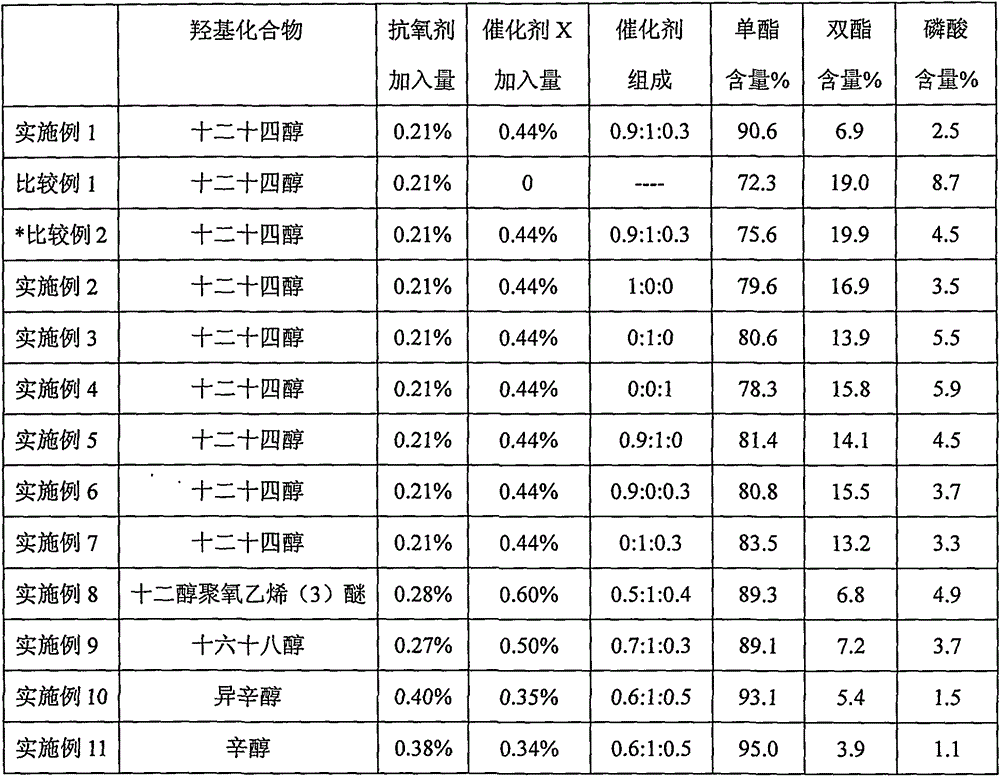

Embodiment 1

[0039] Preparation of dodecyl tetradecyl phosphate monoester: Add 200.00 g of dodecyl alcohol (the mass ratio of dodecanol to tetradecyl alcohol is 70:30), 0.42 g of hypophosphorous acid and pure water in a round bottom flask 14.80g, turn on the stirring and increase the temperature; when the temperature rises 70℃, start to add 74.28g of phosphorus pentoxide, the temperature is controlled at 75±5℃, the feeding time is controlled for 1.5 hours; after the addition, keep the temperature at 85℃ for 4.5 hours , And then add 5.18g of pure water and catalyst (the catalyst is SnCl 4 , MnO 2 And CuSO 4 A mixture with a mass ratio of 0.9:1:0.3) 0.88g, the temperature is controlled to 85°C, and the temperature is kept at this temperature for 2 hours, and then the temperature is lowered to 75°C and filtered to obtain a phosphate product. Analyzed by double indicator titration method, we found that: monoester 90.6%, diester: 6.9%, phosphoric acid 2.5%.

Embodiment 2

[0047] The difference from Example 1 is that the catalyst is SnCl 4 .

[0048] In the round bottom flask, add 200.00 g of dodecatetraol (the mass ratio of dodecanol to tetradecanol is 70:30), 0.42 g of hypophosphorous acid and 14.80 g of pure water, turn on the stirring and increase the temperature; when the temperature rises by 70 Start adding 74.28g of phosphorus pentoxide in stages at ℃, the temperature is controlled at 75±5℃, and the feeding time is controlled to 1.5 hours; after the addition, keep it at 85℃ for 4.5 hours, and then add 5.18g of pure water and SnCl 4 0.88g, control the temperature to 85±2℃, keep it at this temperature for 2 hours and then cool to 75℃ to filter to obtain the phosphate product. Analyzed by double indicator titration method: monoester 79.6%, diester: 16.9%, phosphoric acid 3.5%.

Embodiment 3

[0050] The difference from Example 1 is that the catalyst is MnO 2 .

[0051] In the round bottom flask, add 200.00 g of dodecatetraol (the mass ratio of dodecanol to tetradecanol is 70:30), 0.42 g of hypophosphorous acid and 14.80 g of pure water, turn on the stirring and increase the temperature; when the temperature rises by 70 Begin to add 74.28g of phosphorus pentoxide in stages at ℃, control the temperature at 75±5℃, and control the feeding time to 1.5 hours; after the addition, keep it at 85℃ for 4.5 hours, then add 5.18g of pure water and 20.88g of MnO. Control the temperature to 85±2°C, keep it at this temperature for 2 hours and then lower the temperature to 75°C to filter to obtain the phosphate product. Analyzed by double indicator titration method: monoester 80.6%, diester: 13.9%, phosphoric acid 5.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com