Gemini phosphate surfactant and preparation method thereof

A surfactant and phosphoric acid ester technology, applied in the chemical industry, can solve the problems of complex preparation process, and achieve the effect of reducing cost and strong atomic economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

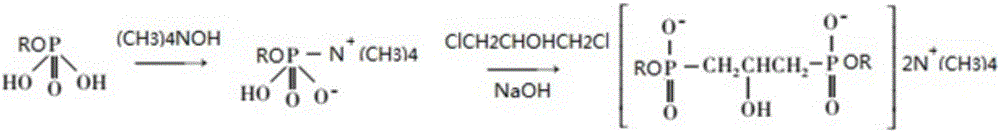

Method used

Image

Examples

Embodiment 1

[0036] (1) 1molPOCl has been added in advance 3 In the reactor 1#, slowly add 1mol C8-C10 fatty alcohol dropwise, control the drop rate to maintain the reaction at 15°C, after the dropwise addition, start the 4kPa decompression condition, and slowly raise the temperature to 25°C to continue the reaction for 3h, then add 2mol water dropwise , maintained at 25°C for 1h hydrolysis reaction to obtain alkyl phosphate monoester.

[0037] (2) The hydrogen chloride gas by-product of step (1) is pumped into the reactor 2# under reduced pressure conditions, and the 1mol glycerol added in advance is carried out chlorination reaction at 115° C. for 4 hours under the action of the Sokalan DCS catalyst accounting for 6% of glycerol weight. After the chlorination is completed, start the vacuum distillation column, control the temperature of the kettle to 130°C, and the temperature of the tower top to 95°C, and collect the distillate to obtain dichloroglycerin.

[0038](3) Add the alkyl phos...

Embodiment 2

[0041] Alkyl phosphate monoester and dichloroglycerin are prepared in the same manner as in Example 1, the difference is that (3) the alkyl phosphate monoester obtained in step (1) is added to reactor 3#, and 1mol tetraethyl Ammonium hydroxide was used for neutralization reaction, followed by adding 0.5 mol of dichloroglycerol obtained in step (2) to react as a linking group to generate Gemini phosphate surfactant with a yield of 87.4%.

Embodiment 3

[0043] (1) 1molPOCl has been added in advance 3 In the reactor 1#, slowly add 1mol C12-C14 fatty alcohol dropwise, control the drop rate to maintain the reaction at 15°C, after the dropwise addition, start the 4kPa decompression condition, and slowly raise the temperature to 30°C to continue the reaction for 2h, then add 2mol water dropwise , maintained at 40 ° C for 2h hydrolysis to obtain alkyl phosphate monoester.

[0044] (2) The hydrogen chloride gas by-product of step (1) is pumped into the reactor 2# under reduced pressure, and the 1mol glycerol added in advance is carried out chlorination reaction at 100° C. for 5 h under the action of the Sokalan DCS catalyst accounting for 10% of glycerol weight. After the chlorination is completed, start the vacuum distillation column, control the temperature of the kettle to 135°C, and the temperature of the tower top to 100°C, and collect the distillate to obtain dichloroglycerin.

[0045] (3) Add the alkyl phosphate monoester ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com