Engineering plastic with high wearing resistance

An engineering plastic and high wear-resistant technology, which is applied in the field of high wear-resistant engineering plastics and engineering plastics, can solve the problems of coating strength influence, service time influence, equipment operation failure, etc., and achieve excellent mechanical properties and low wear rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

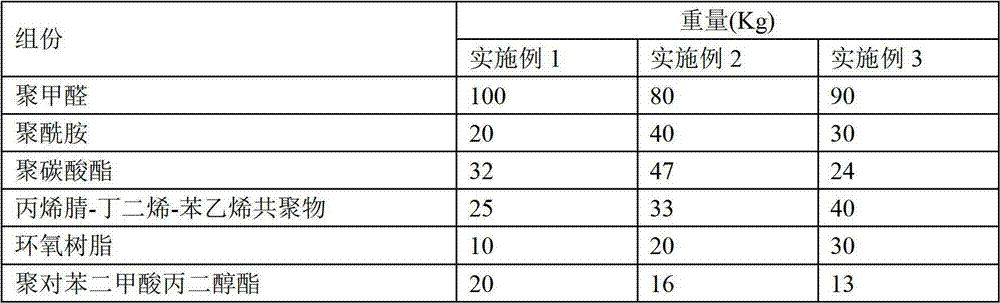

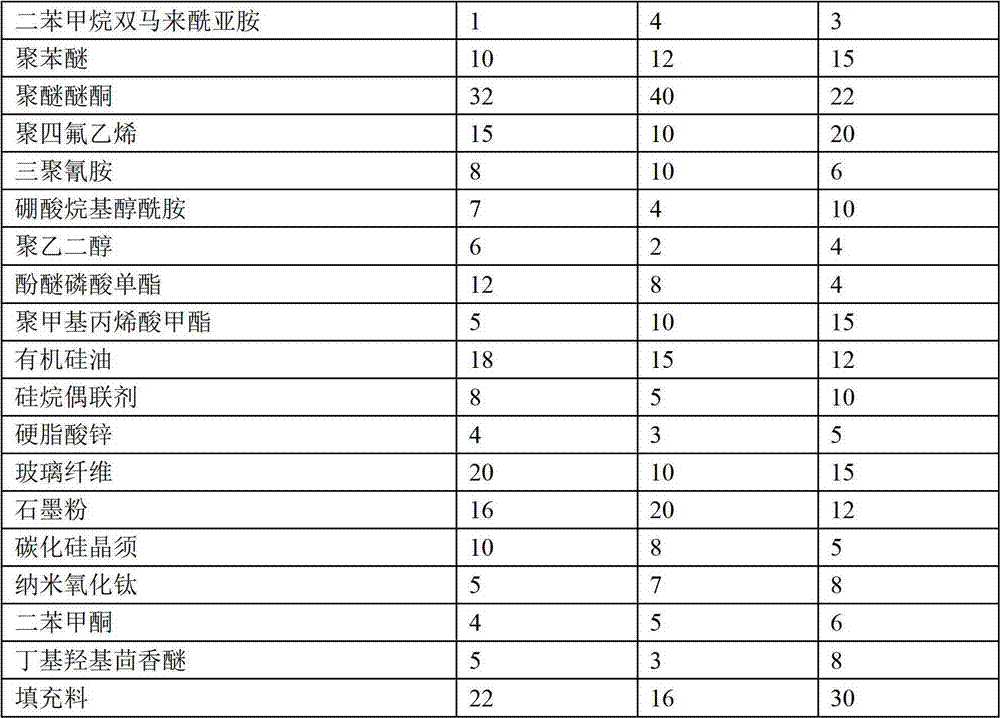

Examples

Embodiment 1

[0024] S1 Put the raw materials of each component into the high mixer and blend for 30 minutes;

[0025] S2 Add the mixture obtained in S1 into a twin-screw extruder, the extrusion processing temperature is 200°C, and the screw speed is 280rpm;

[0026] S3 sends the cooled extrudate to the granulator to obtain high-performance wear-resistant plastic granules. Example 2

Embodiment 2

[0027] The difference from Example 1 is that the temperature in step S2 is 220° C., and the screw speed is 500 rpm. Example 3

Embodiment 3

[0028] The difference from Example 1 is that the temperature in step S2 is 260° C., and the screw speed is 600 rpm. performance test

[0029] The thermoplastic elastomer obtained in the above examples was subjected to thermoplastic molding, and after being made into a sample according to the requirements of relevant standards, a performance test was carried out, and the wear-resistant plastic disclosed in the patent CN01116594 was used as a control. The test data are shown in Table 2.

[0030] The performance test data of table 2 embodiment 1~embodiment 3 and comparative example

[0031]

[0032] It can be seen from the table that the wear-resistant engineering plastic provided by the present invention has excellent mechanical properties, the bending strength can reach more than 140 MPa, the tensile strength can reach more than 130 MPa, and the wear rate is small, below 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com