Surface treatment method for antibacterial calcium carbonate special for papermaking

An antibacterial calcium carbonate, surface treatment technology, applied in calcium carbonate/strontium/barium, papermaking, textiles and papermaking, etc., can solve problems such as uneven distribution of surface treatment agents, calcium carbonate agglomeration, etc., and achieve good antibacterial and antibacterial effects. The effect of good contact degree, smoothness and gloss improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

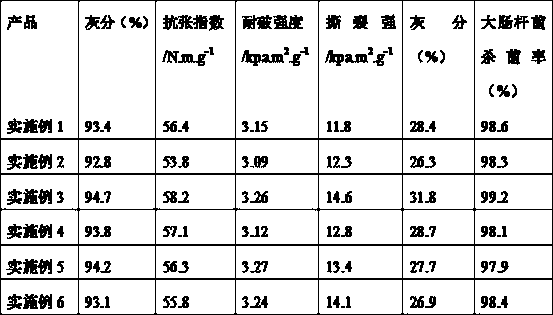

Examples

Embodiment 1

[0026] A surface treatment method for special antibacterial calcium carbonate for papermaking includes the following steps:

[0027] S1: Add limestone to the pulverizer and pulverize to a particle size ≤0.4mm to obtain coarse calcium carbonate powder:

[0028] S2: Add the coarse calcium carbonate powder to the grinder, and add the first modifier that is 3% of the coarse calcium carbonate powder, and the first modifier is composed of nonylphenol polyoxyethylene with a weight ratio of 2:1 It is composed of ether phosphate monoester sodium salt and trimethylsilyl cage polysilsesquioxane, milled at a speed of 1000r / min for 1.5h to obtain calcium carbonate fine powder with a particle size of 500 mesh;

[0029] S3: Transport the fine calcium carbonate powder to a high-speed mixer, and then add a second modifier that is 2% of the coarse calcium carbonate powder. The second modifier is composed of sapindus saponin with a weight ratio of 2:1:1 , Chitosan and potassium N-propyl-perfluorooctyl...

Embodiment 2

[0031] A surface treatment method for special antibacterial calcium carbonate for papermaking includes the following steps:

[0032] S1: Add limestone to the pulverizer and pulverize to a particle size ≤0.4mm to obtain coarse calcium carbonate powder:

[0033] S2: The coarse calcium carbonate powder is added to the grinder, and 2.5% of the coarse calcium carbonate powder is added as a first modifier composed of nonylphenol polyoxyethylene in a weight ratio of 1:1 It is composed of ether phosphate monoester sodium salt and trimethylsilyl cage polysilsesquioxane, milled at a speed of 1200r / min for 2h to obtain calcium carbonate fine powder with a particle size of 600 mesh;

[0034] S3: Transport the fine calcium carbonate powder to a high-speed mixer, and then add a second modifier 2.5% of the coarse calcium carbonate powder. The second modifier is made up of sapindus saponin with a weight ratio of 1:1:2. , Chitosan and potassium N-propyl-perfluorooctylsulfonamide glutamate, stirred a...

Embodiment 3

[0036] A surface treatment method for special antibacterial calcium carbonate for papermaking includes the following steps:

[0037] S1: Add limestone to the pulverizer and pulverize to a particle size ≤0.4mm to obtain coarse calcium carbonate powder:

[0038] S2: The coarse calcium carbonate powder is added to the grinder, and 3.5% of the coarse calcium carbonate powder is added as the first modifier, which is composed of nonylphenol polyoxyethylene with a weight ratio of 3:1 It is composed of ether phosphate monoester sodium salt and trimethylsilyl cage polysilsesquioxane. It is ground at a speed of 1500r / min for 1h to obtain a fine powder of calcium carbonate with a particle size of 800 mesh;

[0039] S3: Transport the fine calcium carbonate powder to a high-speed mixer, and then add a second modifier that is 2.0% of the coarse calcium carbonate powder, and the second modifier is composed of Sapindus saponin with a weight ratio of 3:1:1 , Chitosan and potassium N-propyl-perfluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com