Alcohol-resistant water-based nano color paste

A nano-color paste and ethanol-resistant technology, which is applied in pigment paste, biocide-containing paint, anti-fouling/underwater coating, etc., can solve the problems of poor stability, uneven coloring, poor compatibility, etc. , to achieve the effect of solving the problem of sagging and dark bubbles, good coating effect and high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

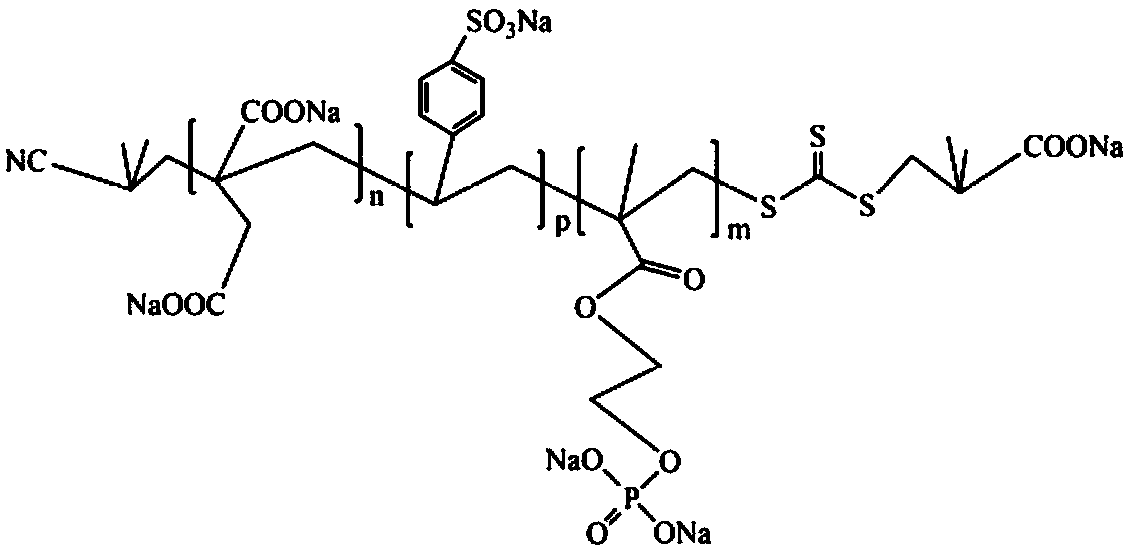

[0026] A kind of ternary block copolymer dispersant A, its steps are as follows:

[0027] In parts by weight, 25.0 parts of itaconic acid, 12.0 parts of sodium p-styrene sulfonate, 19.0 parts of methacryloxybutyl alcohol monophosphate, 1.6 parts of S, S'-bis(α,α' -Dimethyl-α"-acetic acid) trithiocarbonate, 80.0 parts of ethanol are added in the reaction kettle, logical N 2 Protection, start stirring and dissolve evenly, raise the temperature to 75°C, evenly add 10.0 parts of ethanol solution containing 10% azobisisobutyronitrile dropwise, finish dropping within 0.5h, keep at 75°C and continue the reaction for 6h; then slowly add 10 % NaOH solution and deionized water to adjust the pH to 7-8 to obtain the ternary block copolymer dispersant A.

Embodiment 2

[0029] A kind of ternary block copolymer dispersant B, its steps are as follows:

[0030] In parts by weight, 22.0 parts of itaconic acid, 13.0 parts of sodium p-styrenesulfonate, 15.0 parts of methacryloyloxyethyl alcohol monophosphate, 3.0 parts of 4,4'-dithiophenylacetic acid, 70.0 parts of Virahol joins in the reactor, logical N 2 Protection, start stirring and dissolve evenly, heat up to 70°C, add 8.0 parts of isopropanol solution containing 10% azobisisobutylamidine hydrochloride dropwise evenly, drop it within 0.5h, keep at 70°C to continue the reaction 6h; then slowly add 10% NaOH solution and deionized water to adjust the pH to 7-8 to obtain the ternary block copolymer dispersant B.

Embodiment 3

[0032] A kind of ternary block copolymer dispersant C, its steps are as follows:

[0033] In parts by weight, 16.0 parts of itaconic acid, 10.0 parts of sodium p-styrenesulfonate, 12.0 parts of methacryloyloxyalkylpropanol monophosphate, 2.0 parts of diethyldithiocarbamate Type quaternary ammonium salt, 60.0 parts of water are added in the reaction kettle, logical N 2 Protection, start stirring and dissolve evenly, raise the temperature to 85°C, evenly add 12.0 parts of an aqueous solution containing 10% azobisisobutyronitrile dropwise, finish dropping within 0.5h, keep at 85°C and continue the reaction for 6h; then slowly add 10% azobisisobutyronitrile NaOH solution and deionized water are adjusted to pH 7-8 to obtain the ternary block copolymer dispersant C.

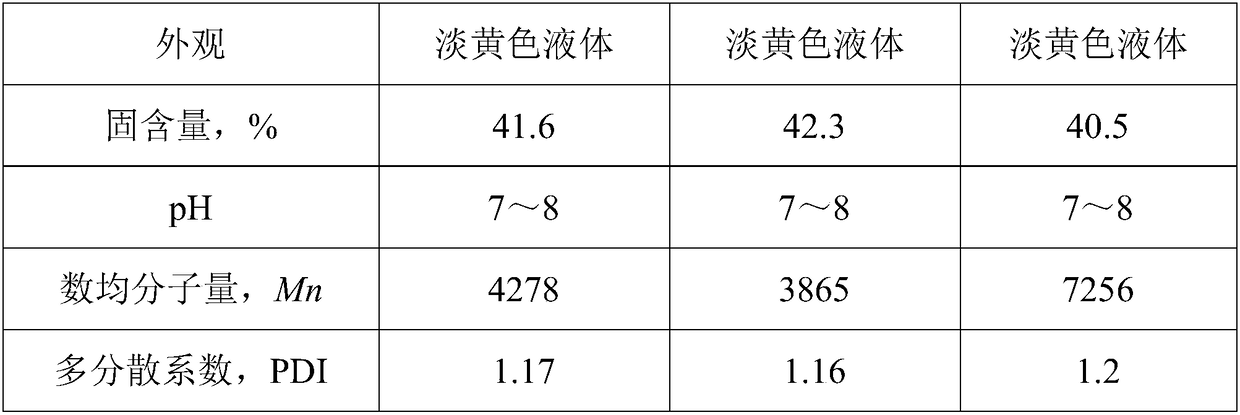

[0034] The ternary block copolymer dispersant technical index that makes in the embodiment of the present invention is as shown in table 1:

[0035] Table 1 Ternary block copolymer water-based dispersant technical in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com