Preparation method of fatty alcohol polyoxyethylene phosphate ester potassium salt

A technology of alcohol phosphate polyoxyethylene ester potassium salt and fatty alcohol, which is applied in the field of synthesis of anionic surfactants in organic chemistry, can solve the problems of inconvenient use, low solid content of potassium salt, increased transportation cost, etc., and achieves convenient storage. and use, good economic benefits, and the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

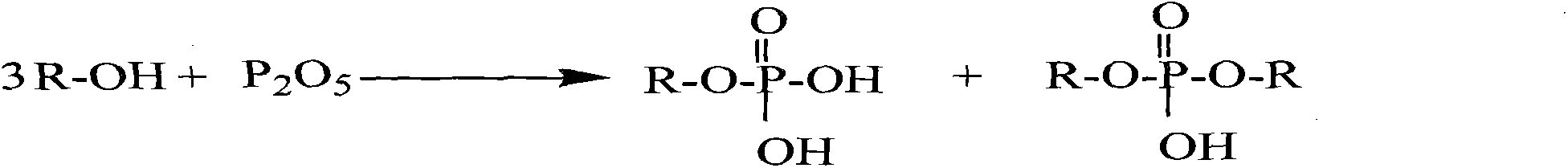

[0020] A preparation method of fatty alcohol polyoxyethylene phosphate potassium salt, comprising the following steps: (1) using fatty alcohol as a raw material to carry out esterification reaction with phosphorus pentoxide; (2) adding deionized water for hydrolysis to obtain A mixture of fatty alcohol phosphate esters based on phosphoric acid monoesters and phosphoric diesters is directly condensed with ethylene oxide under the condition of no catalyst; (3) neutralizing the pH to 6 with 60% potassium hydroxide aqueous solution ~8, the potassium salt of fatty alcohol polyoxyethylene ether phosphate with a solid content of more than 90% was prepared; the main synthetic route is as follows:

[0021] Esterification reaction:

[0022]

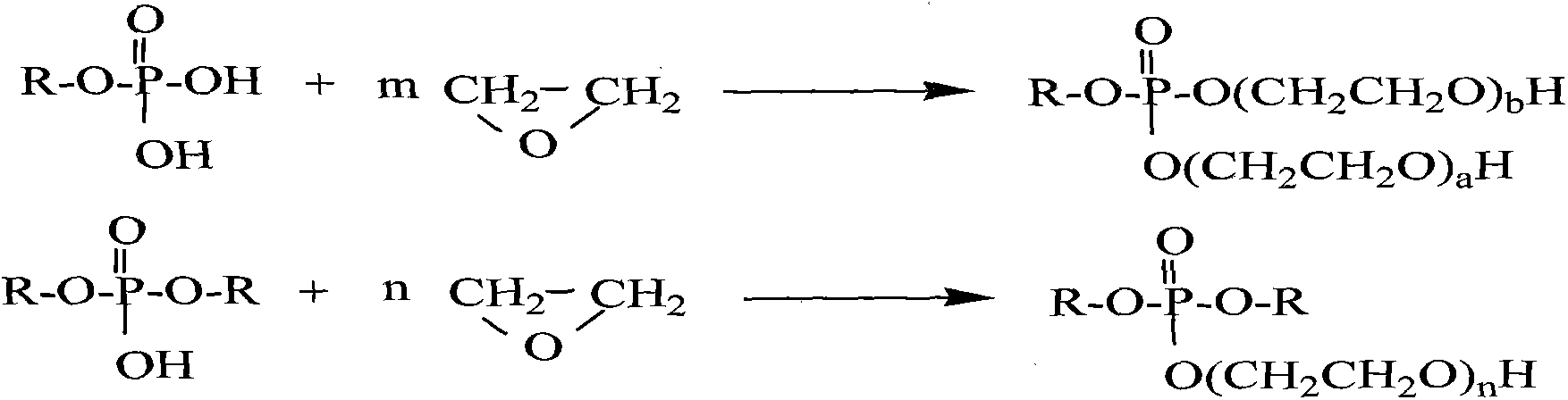

[0023] Condensation reaction:

[0024]

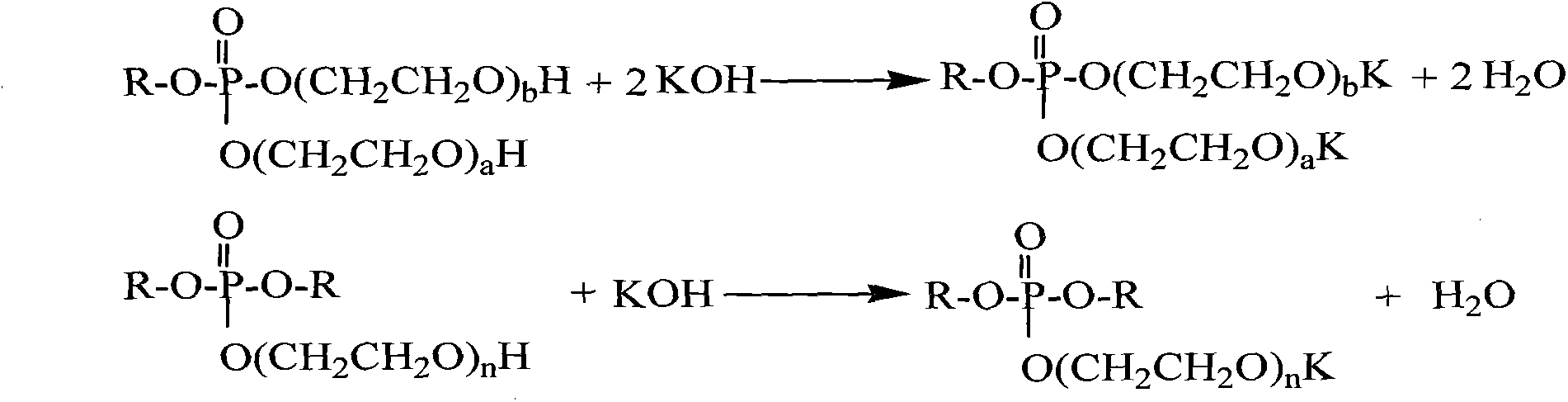

[0025] Neutralization reaction:

[0026]

[0027] R is C in the reaction equation 12~14 or C 18~16 A saturated branched alkyl group, where m=a+b.

[0028] Preferably, the molar ratio of the fa...

Embodiment 1C12

[0041] Example 1C 12~14 Preparation of Potassium Salt of Polyoxyethylene Ether Alcohol Phosphate

[0042] Esterification reaction: In a 500mL four-necked flask, add 0.75mol (144.8g) C 12~14 Alcohol, add 36.0g of phosphorus pentoxide in five batches, react at a temperature of 50-55°C for 8.0 hours, then add 0.9g of deionized water, hydrolyze at a temperature of 75-80°C for 1.0 hour, cool to obtain the esterification product C 12~14 alcohol phosphate.

[0043] Condensation reaction and neutralization reaction: Add the above-mentioned esterification product into a 2.5L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. The air was replaced with nitrogen for 3 times, and when the temperature of the kettle rose to 125-130° C., 198.0 g of ethylene oxide was introduced into the reaction mixture for 2.5 hours, and the reaction was continued for 0.5 hours. After the reaction is complete, cool down and release the pressure. The obtained intermedi...

Embodiment 2C18

[0044] Example 2C 18~16 Preparation of Potassium Salt of Polyoxyethylene Ether Alcohol Phosphate

[0045] Esterification reaction: In a 500mL four-necked flask, add 1.0mol (263.0g) C 18~16 Alcohol, add 72.0g of phosphorus pentoxide in two batches, react at 90-95°C for 3.0 hours, then add 6.7g of deionized water, hydrolyze at 65-70°C for 2.0 hours, cool to obtain the esterification product C 18~16 alcohol phosphate.

[0046] Condensation reaction and neutralization reaction: Add the above-mentioned esterification product into a 2.5L pressure reactor, and connect the ethylene oxide metering tank to the pressure reactor. The air was replaced with nitrogen for 3 times, and when the temperature of the kettle rose to 50-55° C., 396.0 g of ethylene oxide was introduced into the mixture for 5.5 hours, and the reaction was continued for 0.5 hours. After the reaction is complete, cool down and release the pressure. The obtained intermediate product was transferred to a 1000mL four-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com