Method for carrying out surface treatment on pigments by using phosphorous compounds

A surface treatment and compound technology, applied in dyeing low-molecular-weight organic compound treatment, pigment slurry, organic dyes, etc., can solve the problem of unable to meet the requirements of color paste stability and tinting strength, and improve the stability and tinting strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

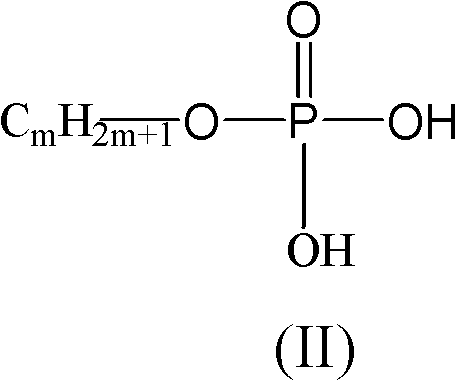

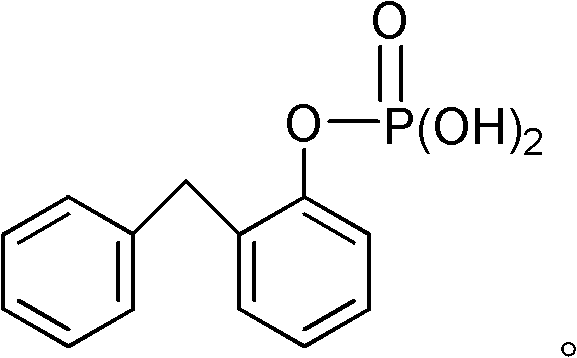

[0031] Mix 0.2kg 2-benzyl phenyl phosphate monoester, 0.2kg octadecyl phosphate monoester and 10kg carbon black in 50kg deionized water and stir into a slurry at room temperature, then adjust with 20wt.% NaOH aqueous solution The pH value of the slurry is 11.0. After stirring the slurry with adjusted pH value at 50 r / min for 2 hours at 85° C., the resulting slurry is filtered to obtain a pigment filter cake. After complete vacuum drying at 0.03MPa pressure and 60°C temperature, the dried pigment filter cake is pulverized into powder by using pulverization equipment with a pulverization fineness of less than 20 mesh.

Embodiment 2

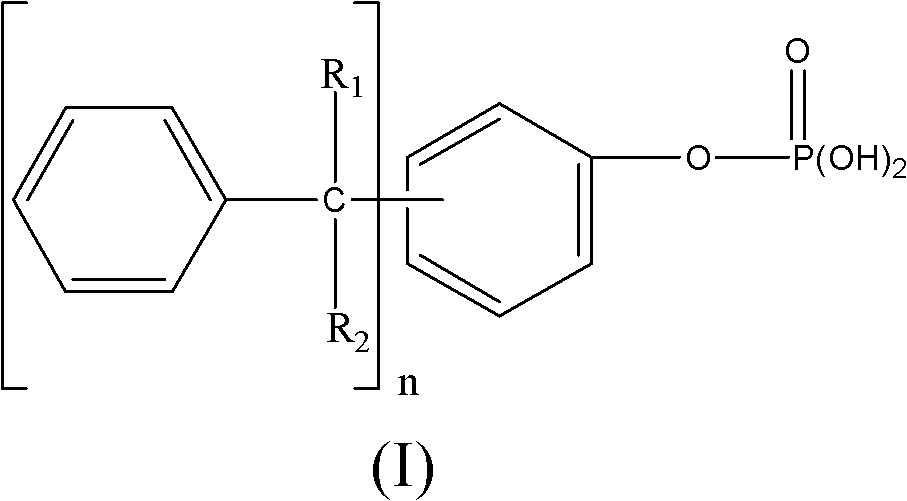

[0033] With 0.2kg 2,4,6-three (1-methyl-1-phenylethyl) phenyl phosphate monoester, 0.3kg hexadecyl phosphate monoester and 10kg iron oxide red are mixed uniformly in 50kg deionized water and After stirring at room temperature to form a slurry, adjust the pH value of the slurry to 9.0 with 15wt.% ammonia solution, and stir the slurry with adjusted pH value at 100r / min for 5 hours at 60°C. The obtained slurry is filtered to obtain a pigment filter cake, and after the obtained pigment filter cake is vacuum-dried at a pressure of 0.06 MPa and a temperature of 85° C., the dried pigment filter cake is pulverized into a powder using a crushing equipment with a grinding fineness of less than 20 mesh.

Embodiment 3

[0035] 0.2kg 2,4,6-tris(1-methyl-1-phenylethyl) phenyl phosphate monoester, 0.3kg octadecyl phosphate monoester and 10kg Pigment Blue 15 (P.B.15) in 50kg deionized After mixing uniformly in water and stirring at room temperature to form a slurry, adjust the pH value of the slurry to 9.0 with 15wt.% ammonia solution, and stir the slurry with adjusted pH value at 60°C at 100r / min for 5 Hours later, the obtained slurry was filtered to obtain a pigment filter cake, and after the obtained pigment filter cake was completely vacuum-dried at a pressure of 0.06MPa and a temperature of 70°C, the dried pigment filter cake powder was crushed using a crushing equipment with a grinding fineness of less than 20 mesh into powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com