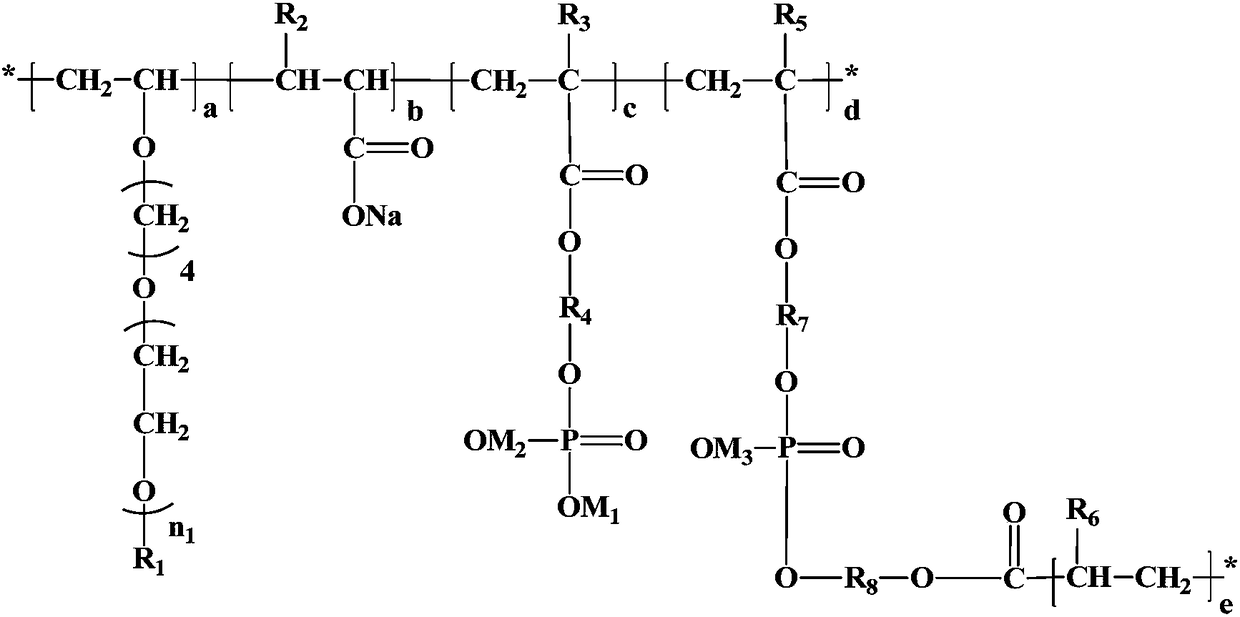

A kind of cross-linked low-sensitivity polycarboxylate water reducer and preparation method thereof

A low-sensitivity, polycarboxylic acid technology, used in the field of building materials, can solve the problems of unimproved dosage sensitivity and water-reducing agent dosage sensitivity, and achieve excellent low-sensitivity performance, good anti-intercalation effect, and improved dispersion. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

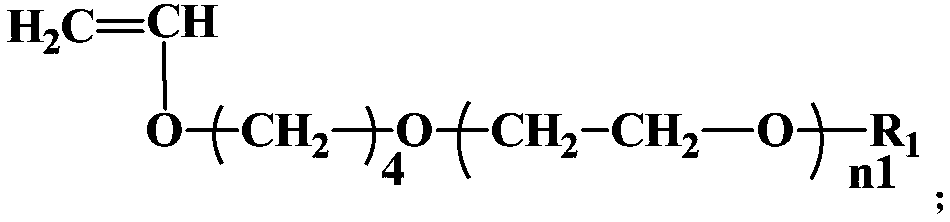

[0043] (1) 180 g of VPEG-type monomer 4-hydroxybutyl vinyl polyoxyethylene ether with a number average molecular weight of 2000 was dissolved in 180 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

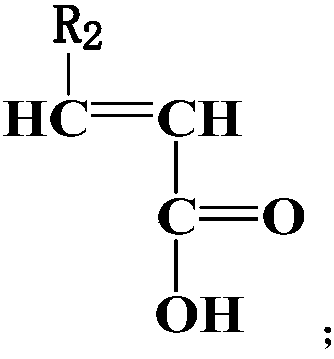

[0044] (2) 26 g of acrylic acid and 1.5 g of mercaptopropionic acid were dissolved in 20 g of deionized water, and then 10 g of 30% potassium hydroxide solution was added for partial neutralization to obtain a second solution;

[0045] (3) 0.6g sodium formaldehyde sulfoxylate is dissolved in 30g deionized water to obtain the third solution;

[0046] (4) Add 22g of the second solution dropwise to the first solution, and keep the temperature at 15°C;

[0047] (5) 3 g of 2-methacryloyloxyethyl phosphate and 1 g of di(hydroxyethyl acrylate) phosphate were added to the remaining second solution;

[0048] (6) 0.05g ferrous sulfate and 2.5g hydrogen peroxide (30%) are joined in the material of step (4) gained successively, then the material ...

Embodiment 2

[0050] (1) 180 g of VPEG-type monomer 4-hydroxybutyl vinyl polyoxyethylene ether with a number average molecular weight of 2400 was dissolved in 180 g of deionized water, and the temperature was adjusted to 15° C. to obtain the first solution;

[0051] (2) 24 g of acrylic acid and 1.4 g of thioglycolic acid were dissolved in 20 g of deionized water, and then 9 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0052] (3) 0.6g FF6 was dissolved in 30g deionized water to obtain the third solution;

[0053] (4) Add 20 g of the second solution dropwise to the first solution, and keep the temperature at 15°C;

[0054] (5) Add 2 g of 2-methacryloyloxypropyl phosphate and 1 g of di(hydroxyethyl acrylate) phosphate into the remaining second solution;

[0055] (6) 0.055g ferrous sulfate and 2.5g hydrogen peroxide (30%) are joined in the material of step (4) gained successively, then the material of step (5) gained and the 3rd solutio...

Embodiment 3

[0057] (1) 180 g of VPEG-type monomer 4-hydroxybutyl vinyl polyoxyethylene ether with a number average molecular weight of 3000 was dissolved in 180 g of deionized water, and the temperature was adjusted to 14° C. to obtain the first solution;

[0058] (2) 20 g of acrylic acid and 1.2 g of mercaptoethanol were dissolved in 20 g of deionized water, and then 8 g of 30% sodium hydroxide solution was added for partial neutralization to obtain a second solution;

[0059] (3) 0.5g sodium hypophosphite is dissolved in 30g deionized water to obtain the third solution;

[0060] (4) Add 15 g of the second solution dropwise to the first solution, and keep the temperature at 14°C;

[0061] (5) 3 g of acryloyloxyethyl phosphate and 1.2 g of di(hydroxyethyl acrylate) phosphate were added to the remaining second solution;

[0062] (6) 0.045g ferrous sulfate and 2.0g sodium persulfate are added to the material obtained in step (4) successively, and then the material obtained in step (5) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com