High-efficiency dephosphorization method and high-efficiency dephosphorization device

A high-efficiency and protective device technology, applied in the direction of metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problem of low flow efficiency and achieve the effects of reduced spray speed, broad market and economic benefits, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

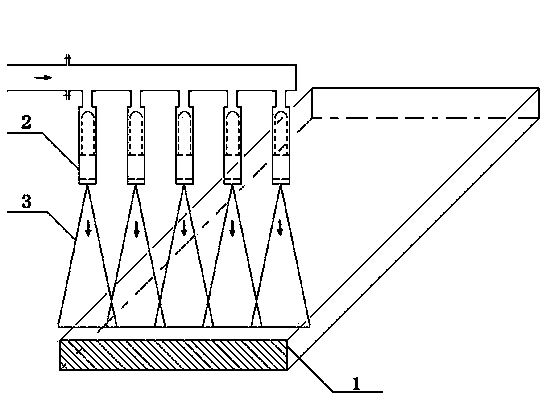

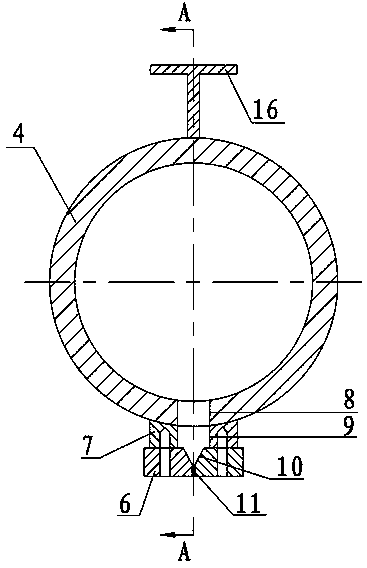

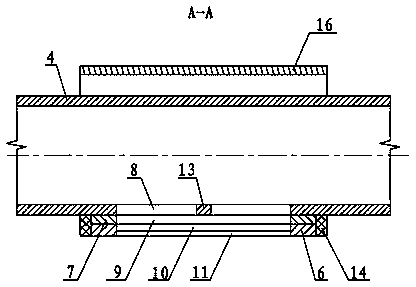

[0037] Embodiment one: if Figure 2~4 As shown, an integrated high-efficiency dephosphorization device includes an integral pressure-bearing chamber 4 for circulating a dephosphorization medium and an injection section 5 for spraying a dephosphorization medium, and the pressure-receiving chamber 4 is provided with a dephosphorization medium Inlet, the lower side wall of the pressure chamber 4 is provided with an outlet channel 8 for the dephosphorization medium, and the outlet part 12 of the injection section is a long and narrow slit, so that the flow jet sprayed on the surface of the metal blank is non-destructive. Diffused flake shape, the injection section 5 is fixed at the outlet channel 8 of the pressure chamber through the joint section 7, the two ends of the injection section 5 are provided with sealing plates 14, and the pressure chamber is provided with Rib 16.

[0038] In this embodiment, the pressure-receiving chamber 4 is a pipe with a circular axial cross-sectio...

Embodiment 2

[0042] Embodiment two: if Figure 5 As shown, a split-type high-efficiency phosphorus removal device, the split-type pressure-bearing chamber 15 is spliced by two semicircular grooves on the left and right, and the spray block can be integrated with the semicircular groove, or can be independent After it is made, it is connected to the semi-circular groove.

Embodiment 3

[0043] Embodiment three: as Image 6 As shown, a split-type high-efficiency dephosphorization device with a partition, a partition 17 is arranged in the middle of the two semicircular grooves, and the partition forms two disconnected partitions inside the pressure chamber. The compartments are all provided with independent phosphorus removal medium inlets and spray outlet channels.

[0044] When using gas, liquid (or solid) as the phosphorus removal medium, when the gas medium is sprayed out, a negative pressure will be generated near the outlet section, and the liquid (or solid) phosphorus removal medium will be sucked out to complete the descaling together. By setting the guide mechanism (For example: using the Coanda Effect——Coanda Effect) and other measures can reduce the distance between the outlet sections of the two injection sections and improve the utilization rate of negative pressure (the specific implementation method is not shown in the drawings).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com