Double-hole immersed waterslot for flexible thin slab casting (FTSC) crystallizer

A thin slab continuous casting and mold technology, which is used in casting melt containers, casting equipment, metal processing equipment, etc. More serious problems, to achieve the effect of increasing the distance and reducing the jet velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

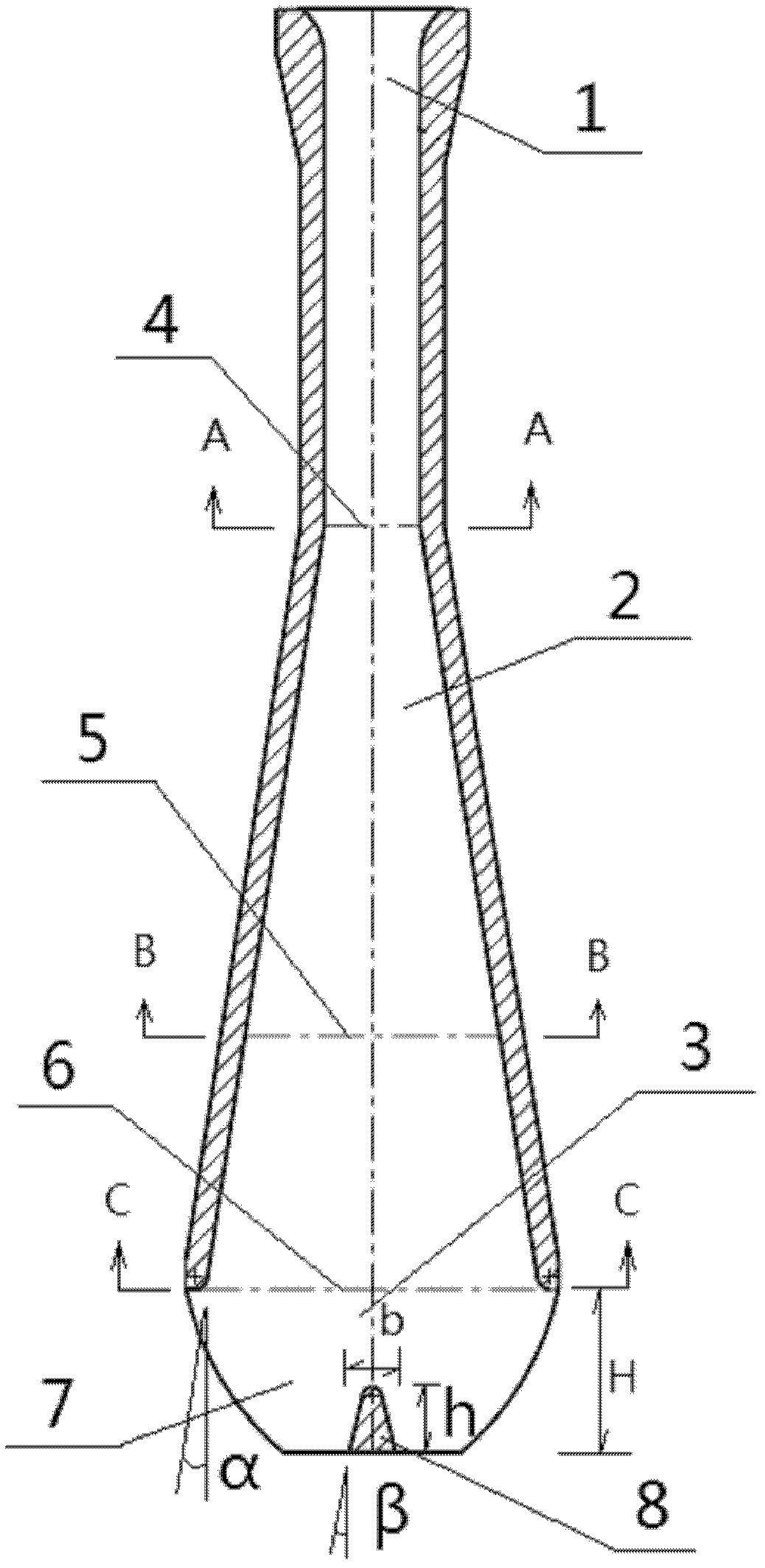

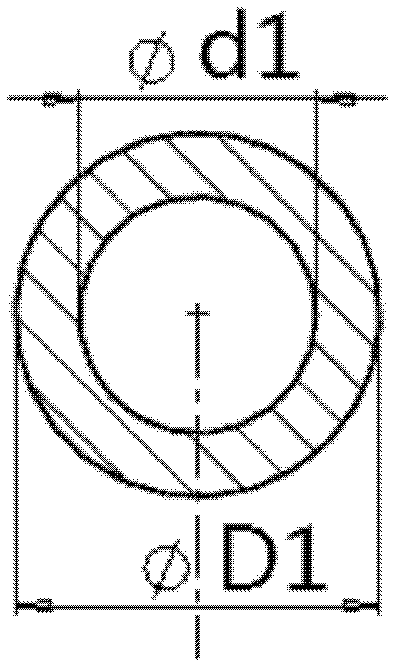

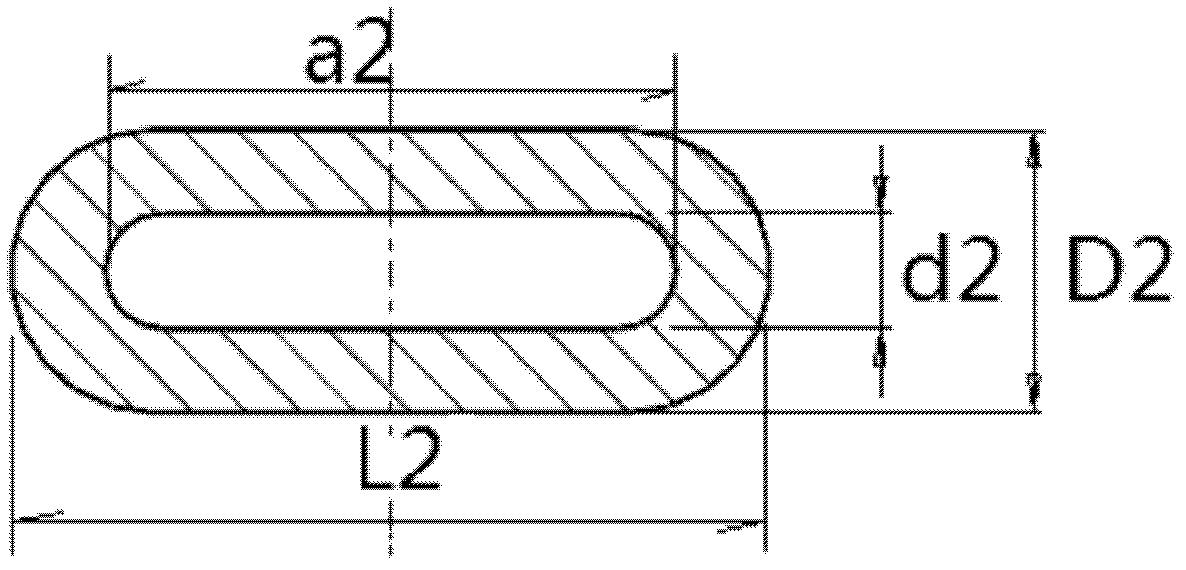

[0026] See Figure 1 to Figure 5 , is a structural schematic diagram of an embodiment of a two-hole submerged nozzle for FTSC thin slab continuous casting crystallizer of the present invention, including an upper circular tubular molten steel inflow end 1, a middle flow channel 2, and a lower outflow end 3 connected in sequence, and the cross section of the middle flow channel 2 From the upper inlet to the lower outlet, it becomes flatter and wider, and the lower outflow end 3 is provided with bilaterally symmetrical discharge holes 7, and there are two discharge holes 7, which changes the current FTSC thin slab continuous casting mold. The four-hole structure enables the present invention to form a more reasonable molten steel flow field and temperature field characterized by two main swirling flows in the FTSC thin slab continuous casting mold. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com