Metal band type stepless speed variator lubricating device

A technology of continuously variable transmissions and lubricating devices, applied in the direction of transmission, transmission parts, gear lubrication/cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Next, embodiments of the present invention will be described based on embodiments of the present invention shown in the drawings.

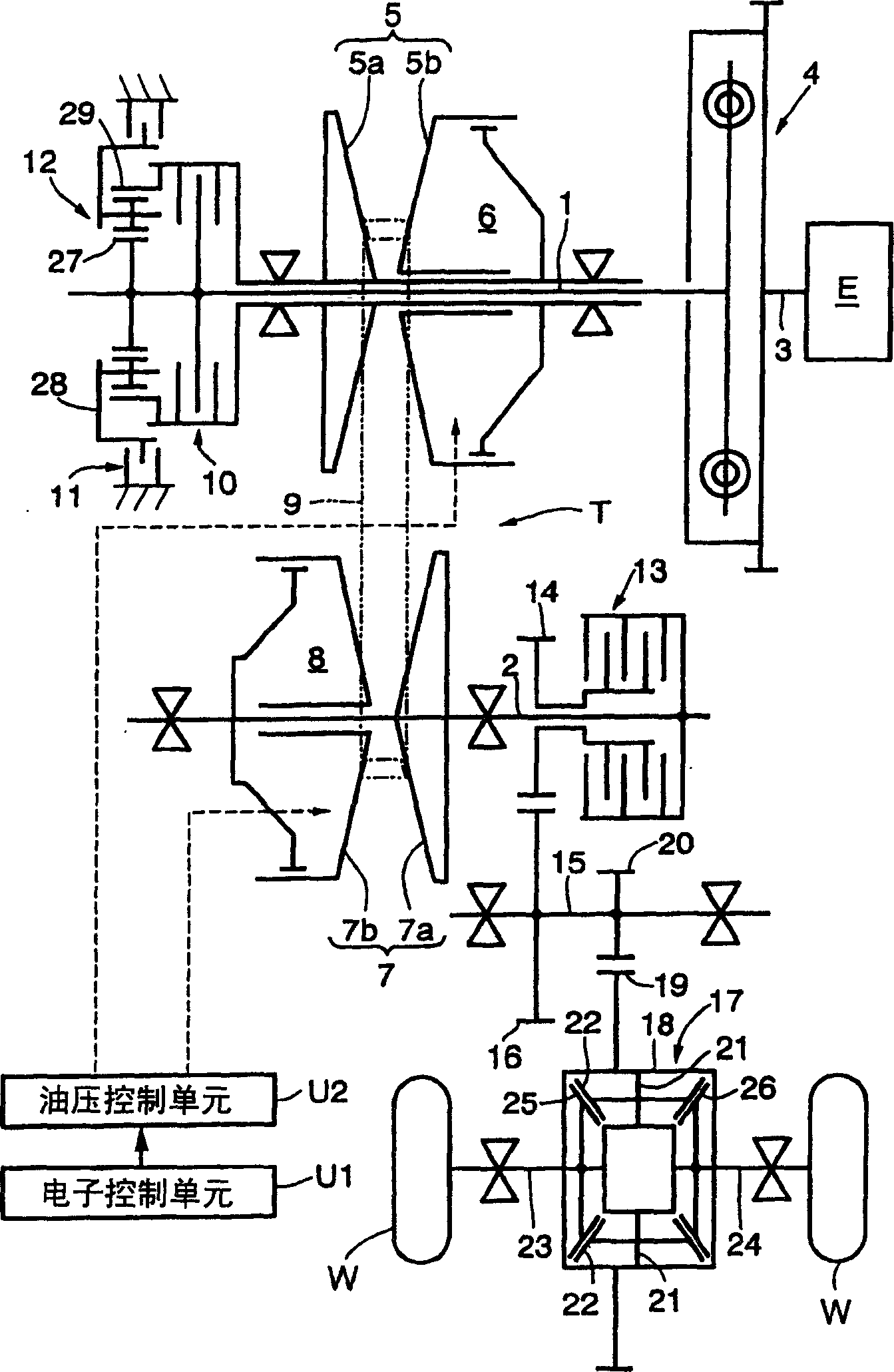

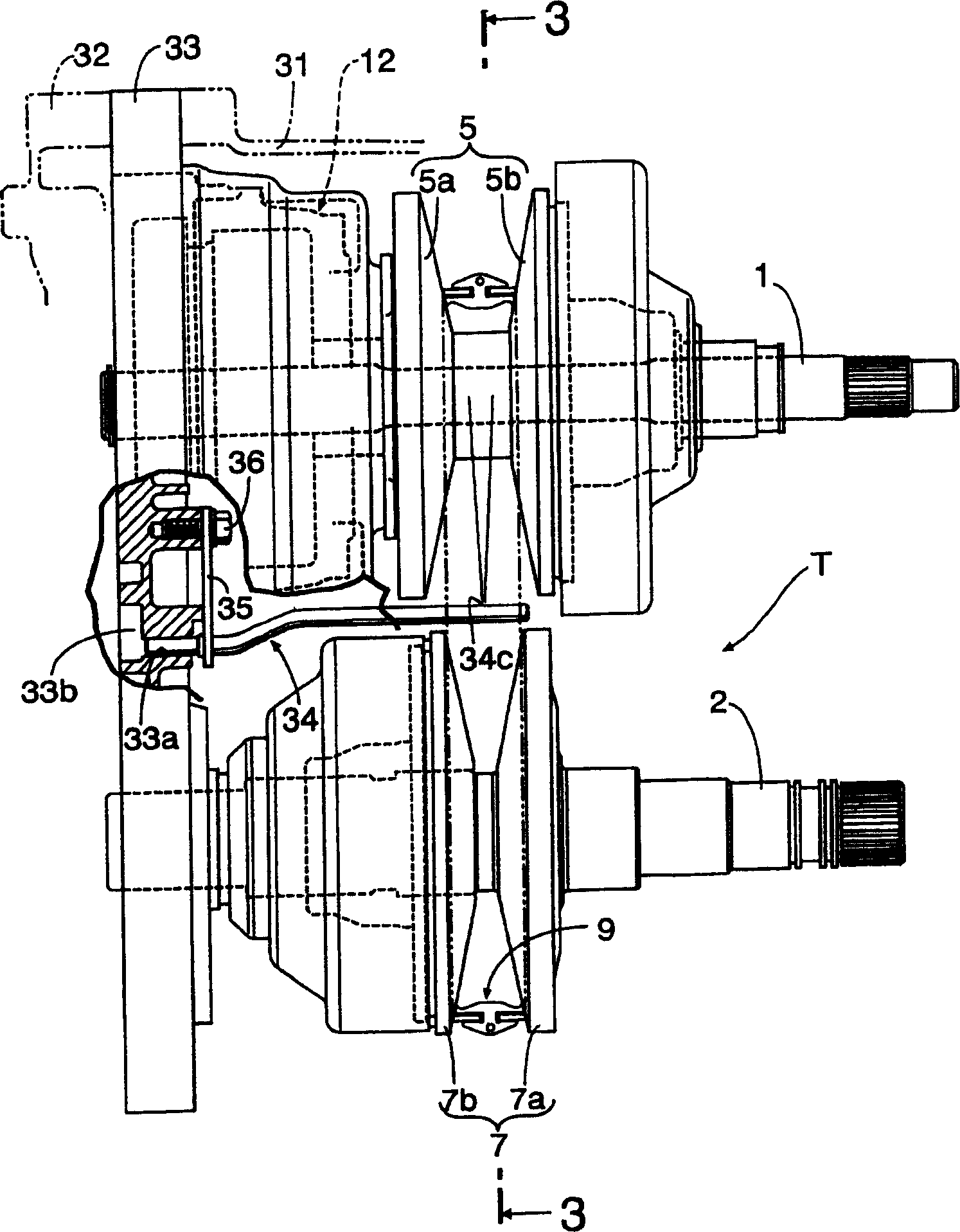

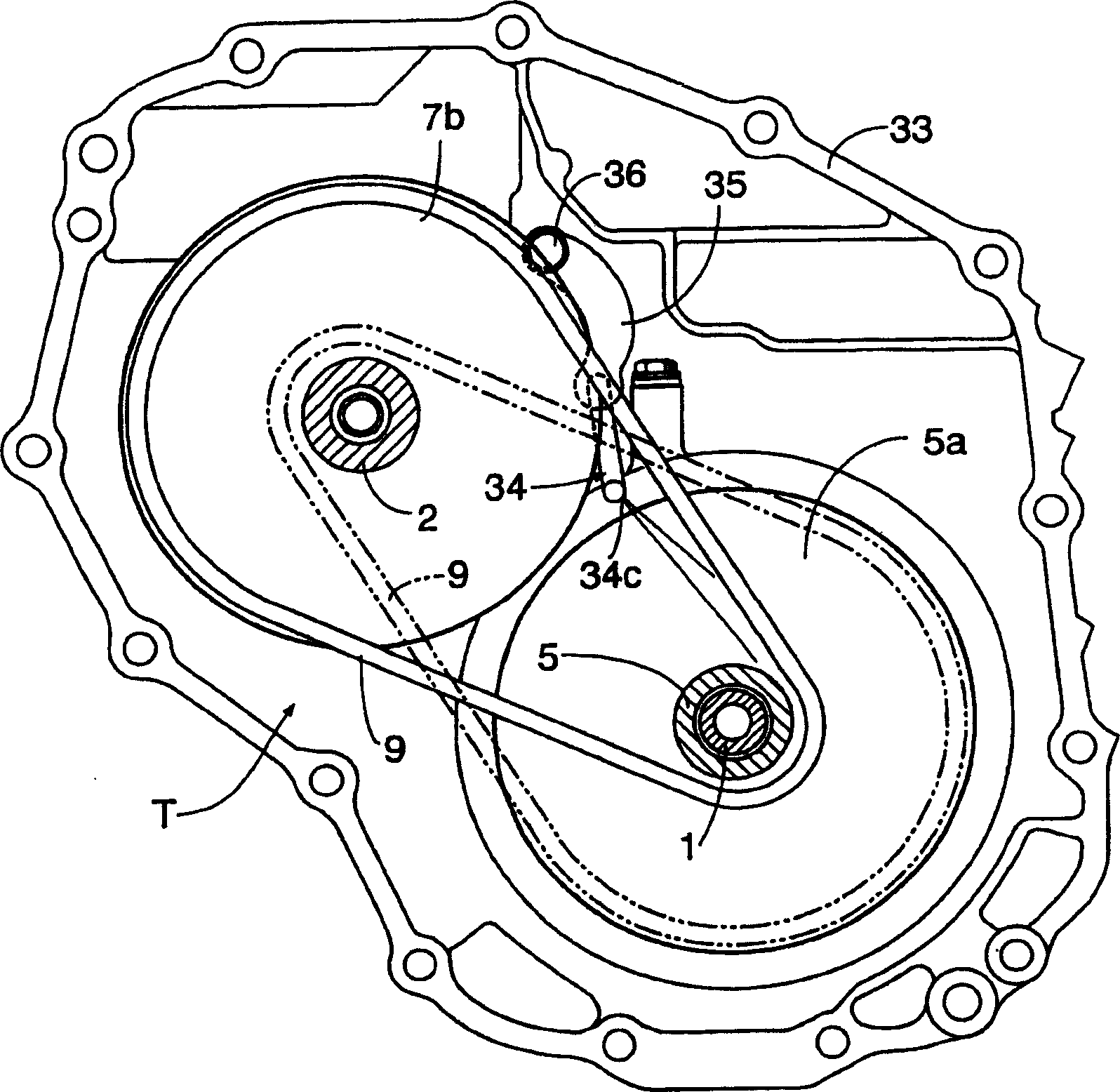

[0022] Figure 1 to Figure 6 represents an embodiment of the invention in which figure 1 It is a schematic diagram of a vehicle power transmission system equipped with a metal belt type continuously variable transmission, figure 2 It is the front view of the main parts of the metal belt continuously variable transmission, image 3 yes figure 2 The 3-3 line profile, Figure 4 It is a perspective view of the main parts of the metal belt continuously variable transmission, Figure 5 yes image 3 Enlarged view of main parts, Image 6 yes Figure 5 6-way view.

[0023] Such as figure 1 As shown, the metal belt continuously variable transmission T for vehicles includes a drive shaft 1 and a driven shaft 2 arranged in parallel, and the left end of the crankshaft 3 of the engine E is connected to the right side of the drive shaft 1 via a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com