Pulverized coal flameless combustion system and method

A flameless combustion, pulverized coal technology, applied in the field of combustion, can solve the problems of easy wear of nozzles, complex system, high energy consumption of high-pressure fans, achieve simple system, reduce fan head and power consumption, and flameless combustion method of pulverized coal reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

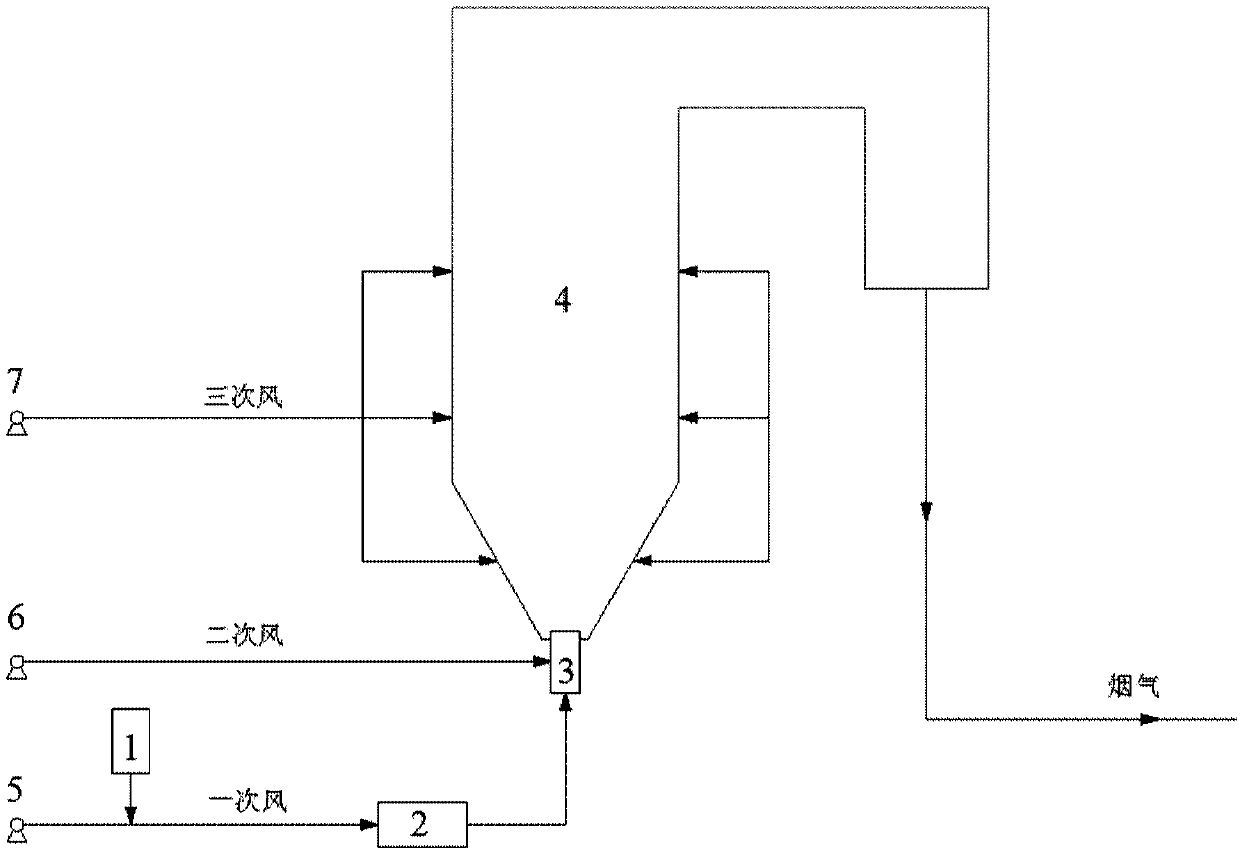

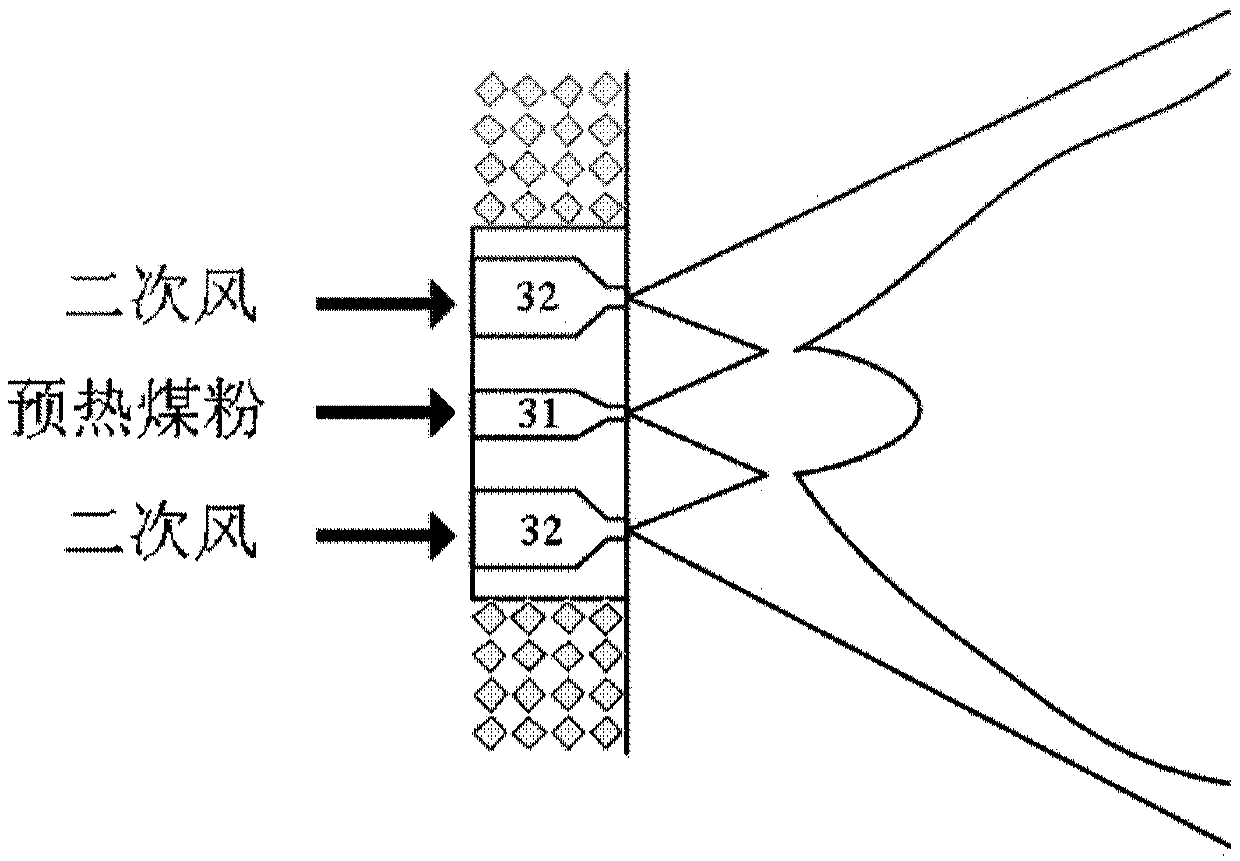

[0039] The disclosure provides a pulverized coal flameless combustion system and method, which adopts the method of preheating fuel and graded air distribution, and disperses the secondary air and tertiary air into the furnace to ensure that the oxygen content in the reaction zone in the furnace is lower than 10 % or lower, after the pulverized coal combustion is stable, the flame front disappears, showing uniform flameless combustion, which can reduce the injection speed of the secondary air, so that the injection speed of the secondary air is between 20 and 50m / s, and the pressure head of the fan can be reduced and power consumption.

[0040] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

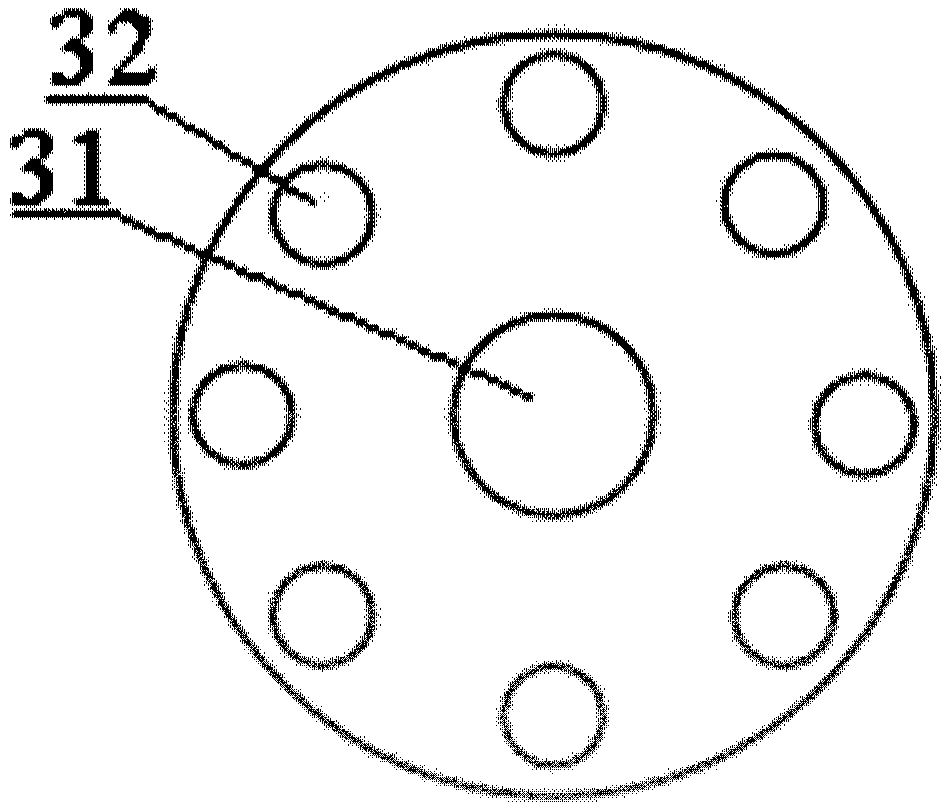

[0041] As an embodiment of the present disclosure, a pulverized coal flameless co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com