A kind of non-phthalic PVC pellets and preparation method thereof

A non-phthalate and pellet technology, which is applied in the field of non-phthalate PVC pellets, can solve the problems of affecting the mechanical properties and chemical stability of PVC, the lack of matting effect and matte effect, and the increase in the proportion of PVC pellets. Does not affect product characteristics, great promotion value, and does not affect the effect of processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

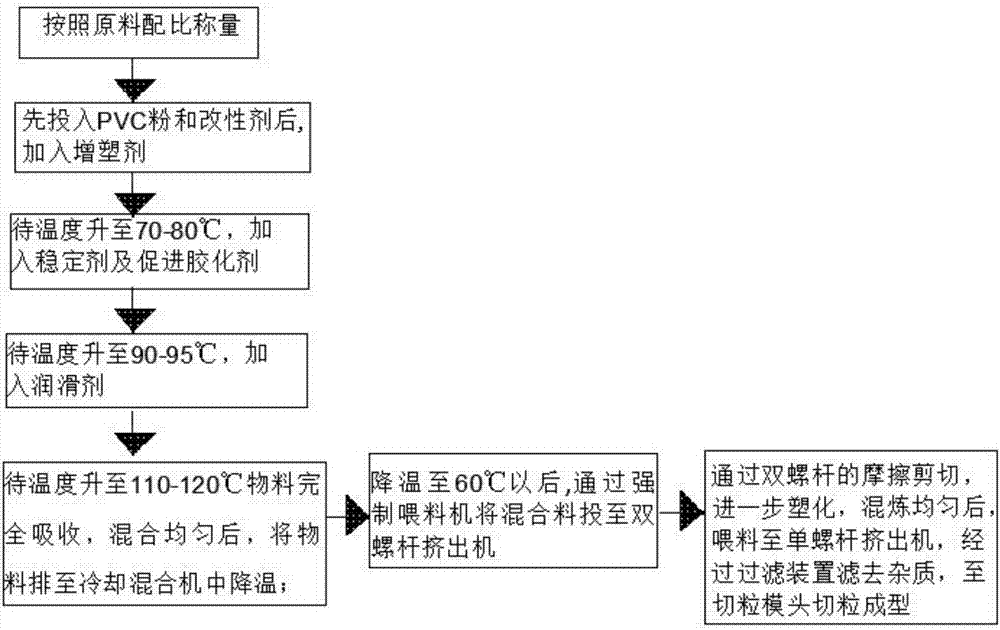

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

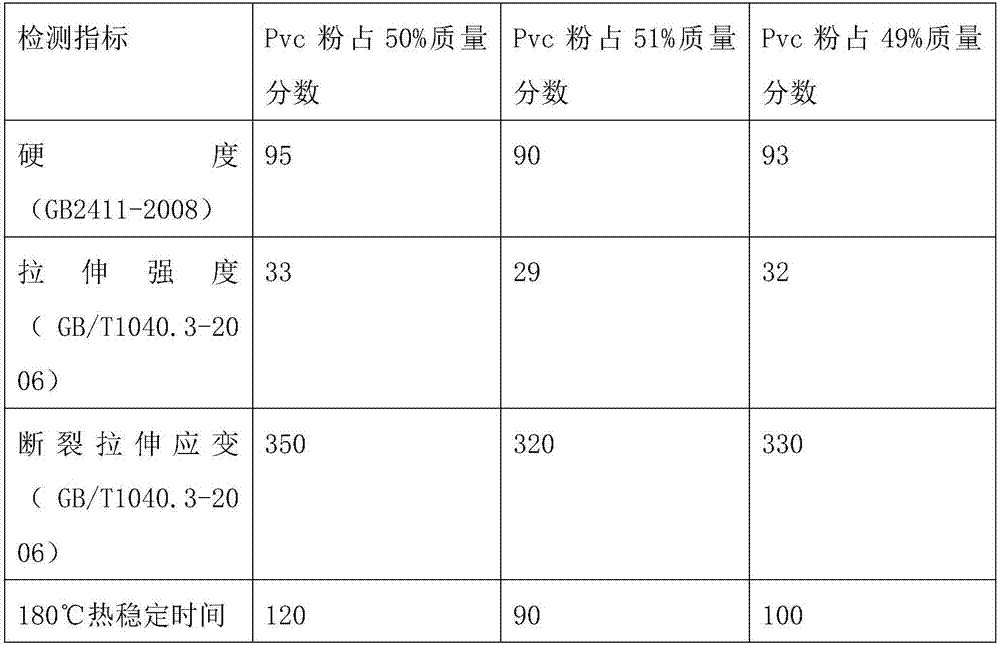

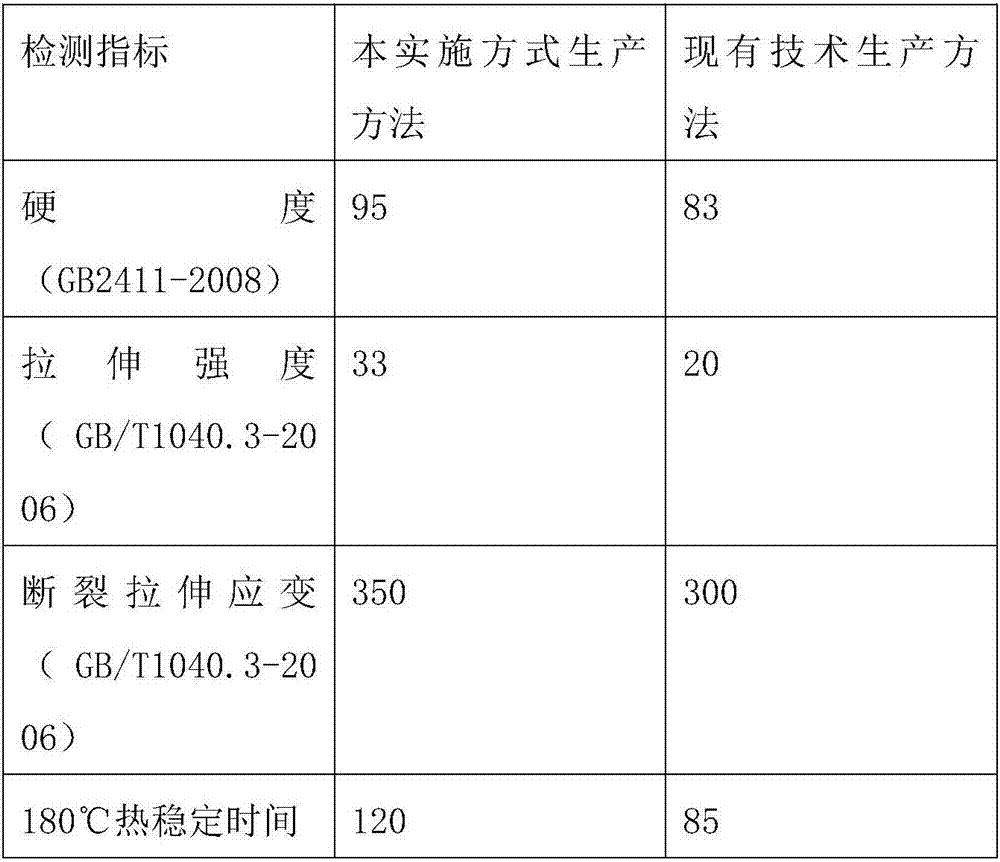

[0034] The invention discloses a non-phthalic PVC granule, which comprises PVC powder, a modifier and a regulator; the PVC powder accounts for 49-51% of the PVC granule; the modifier accounts for the PVC granule 19-21% mass fraction, the balance is regulator. In this embodiment, the modifier can be a matting resin, without adding calcium carbonate, without increasing the specific gravity of the product, the formula is simple, and non-phthalic PVC pellets with a suitable ratio can also ensure the hardness, tensile strength, etc. Performance. Preferably, the PVC powder accounts for 50% of the mass fraction of the PVC pellets; the modifier accounts for 20% of the mass fraction of the PVC pellet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com