A kind of glass fiber reinforced halogen-free flame-retardant polycarbonate composite material and preparation method thereof

A technology of flame-retardant polycarbonate and composite materials, applied in the field of composite materials, can solve the problems of increasing the weight and unit cost of plastic products, making plastic products brittle and easy to break, and reducing the toughness index of materials, so as to enhance product competitiveness, Prevent melting and dripping, and the effect of easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

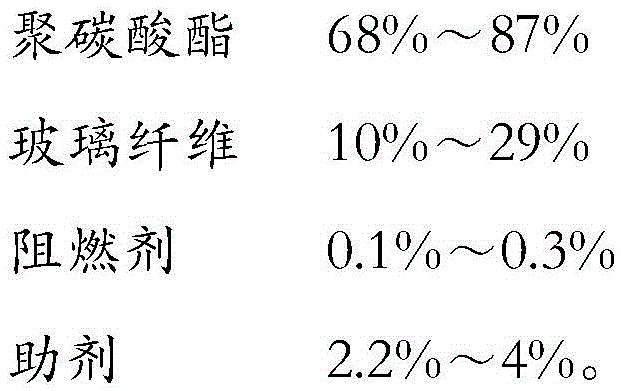

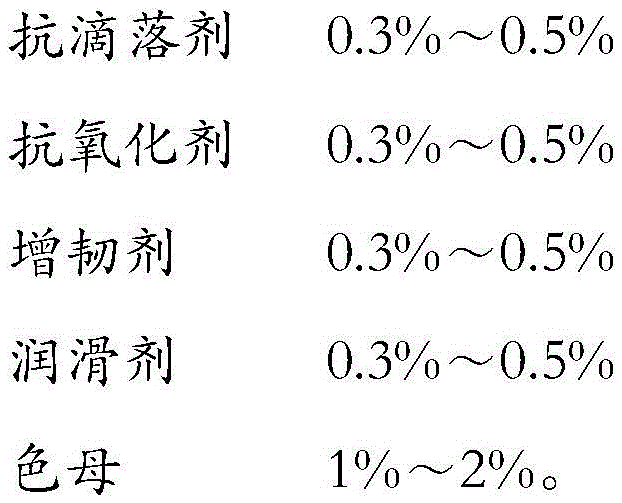

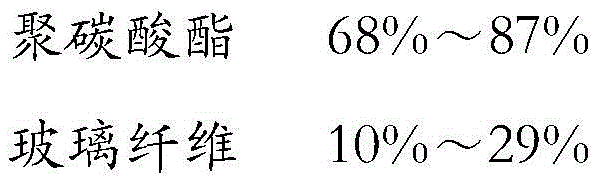

[0054] 1) Take 68.7kg of polycarbonate, 29kg of glass fiber, 0.1kg of flame retardant, 0.3kg of anti-dripping agent, 0.3kg of antioxidant, 0.3kg of toughening agent, 0.3kg of lubricant and 1kg of color masterbatch in a plastic cylinder Mix for 3 minutes, stir to mix well;

[0055] Among them, the diameter of glass fiber is 3mm, the refractive index of polycarbonate is 1.60, and the transmittance is 90%. The pigment in the masterbatch is carbon black.

[0056] 2) Take out the mixed raw materials in the above step 1), pour them into the feed port of the twin-screw extruder, extrude them at a temperature of 180°C and a speed of 300 rpm, and extrude them into strip-shaped raw materials ;

[0057] 3) Cool the primary material obtained in step 2) in a water tank and in the air, and then cut it into plastic particles by a pelletizer to obtain a glass fiber-reinforced halogen-free flame-retardant polycarbonate composite material, and the color is black .

Embodiment 2

[0059] 1) Take 87kg of polycarbonate, 10kg of glass fiber, 0.3kg of flame retardant, 0.3kg of anti-dripping agent, 0.3kg of antioxidant, 0.3kg of toughening agent, 0.3kg of lubricant and 1.5kg of color masterbatch in a plastic cylinder Mix for 10 minutes, stir to mix well;

[0060] Among them, the diameter of glass fiber is 4mm, the refractive index of polycarbonate is 1.68, and the transmittance is 94%. The pigment in the masterbatch is cadmium red.

[0061] 2) Take out the raw material mixed in the above step 1), pour it into the feed port of the twin-screw extruder, extrude it at a temperature of 190°C and a speed of 320 rpm, and extrude it into a strip-shaped raw material ;

[0062] 3) Cool the primary material obtained in step 2) in a water tank and in the air, and then cut it into plastic particles by a pelletizer to obtain a glass fiber-reinforced halogen-free flame-retardant polycarbonate composite material, and the color is red .

Embodiment 3

[0064] 1) Take 80.7kg of polycarbonate, 15kg of glass fiber, 0.3kg of flame retardant, 0.5kg of anti-dripping agent, 0.5kg of antioxidant, 0.5kg of toughening agent, 0.5kg of lubricant and 2kg of color masterbatch in a plastic cylinder Mix for 7 minutes, stir to mix well;

[0065] Among them, the diameter of glass fiber is 5mm, the refractive index of polycarbonate is 1.62, and the transmittance is 91%. The pigment in the color masterbatch is permanent yellow.

[0066]2) Take out the raw materials mixed in the above step 1), pour them into the feed port of the twin-screw extruder, extrude them at a temperature of 200°C and a speed of 340 rpm, and extrude them into strip-shaped raw materials ;

[0067] 3) Cool the primary material obtained in step 2) in a water tank and in the air, and then cut it into plastic particles by a pelletizer to obtain a glass fiber-reinforced halogen-free flame-retardant polycarbonate composite material, and the color is yellow .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com