Wire coiling type electronic cigarette atomizer and wire coiling manufacturing tool thereof

An electronic cigarette atomizer and manufacturing tool technology, which is applied in the fields of tobacco, smoker supplies, food science, etc., can solve the problems of poor electrical conductivity of resistance wire, unsatisfactory effect of atomizer, complicated structure of atomizer, etc. Simple structure, easy production, and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

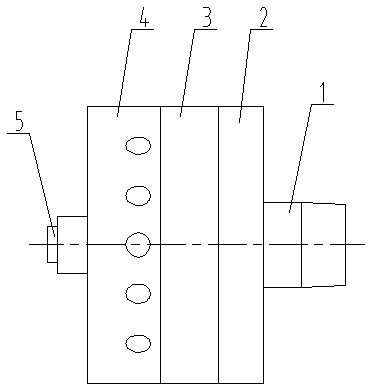

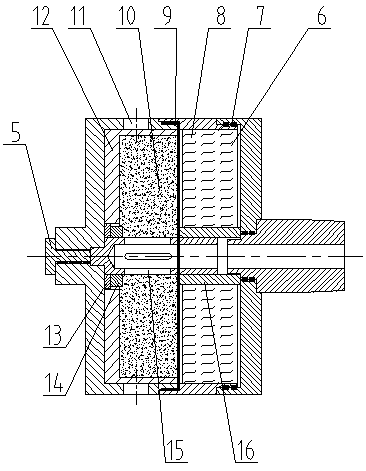

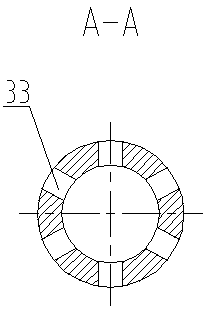

[0058] See attached Figure 1-17 As shown, the electronic cigarette nebulizer of the present invention and its wire making tool include the nebulizer and the making tool of the wire in the nebulizer, the atomizer includes a conductor 5 connected to the battery, and the conductor 5 The other end is connected with an atomizing tube 4, and the other end of the atomizing tube 4 is connected with an oil storage tube 3, a cover 2 and a cigarette holder 1 sequentially from the length direction, and a guide is installed at the center of the atomizing tube 4. Trachea 15, on the outer circumference of described air duct 15 is provided with insulating and high-temperature-resistant top wire gas conduction insulation disk 12 of ceramic material, the top of the top wire gas conduction insulation disk 12 is connected with a winding coil capable of conducting heat. Spiral coil wire 9, the coil wire 9 is a planar spiral double-filament structure, the coil wire 9 includes a positive pole 28 an...

Embodiment 2

[0062] See attached Figure 18 As shown, it includes an atomizer and a production tool for coil wire in the atomizer. The atomizer includes a conductor 5 connected to a battery, and the other end of the conductor 5 is connected to an atomizing cylinder 4. The atomizer The other end of the tube 4 is sequentially connected with the oil storage tube 3, the cover 2 and the mouthpiece 1 from the length direction, and the center of the atomization tube 4 is also equipped with an air guide tube 15, and an air guide tube 15 is installed on the outer circumference of the air guide tube 15. There is a top wire gas-guiding insulating disk 12 of insulating and high-temperature-resistant ceramic material, and the top of the top wire gas-guiding insulating disk 12 is connected with a coil wire 9 that can conduct heat and is wound into a spiral shape. Planar four-wire structure that spirals inward toward the center of the atomizing tube 4 , the coil wire 9 includes a positive pole 28 and fou...

Embodiment 3

[0067] See attached Figure 1-15 As shown, it includes an atomizer and a production tool for coil wire in the atomizer. The atomizer includes a conductor 5 connected to a battery, and the other end of the conductor 5 is connected to an atomizing cylinder 4. The atomizer The other end of the tube 4 is sequentially connected with the oil storage tube 3, the cover 2 and the mouthpiece 1 from the length direction, and the center of the atomization tube 4 is also equipped with an air guide tube 15, and an air guide tube 15 is installed on the outer circumference of the air guide tube 15. There is a top wire gas-conducting insulating disk 12 of insulating and high-temperature-resistant ceramic material, and the top of the top wire gas-conducting insulating disk 12 is connected with a coil wire 9 that can conduct heat and is wound into a spiral shape, and the coil wire 9 is a plane Helical six-wire structure, the coil wire 9 includes a positive pole 28 and six negative poles 29, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com