Patents

Literature

68results about How to "Produced fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

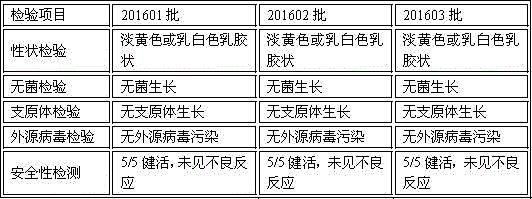

New castle disease and H9 subtype bird flu bivalent vaccine

ActiveCN104922663AImproving immunogenicitySmall dose of immunizationViral antigen ingredientsAntiviralsDiseaseOil adjuvant

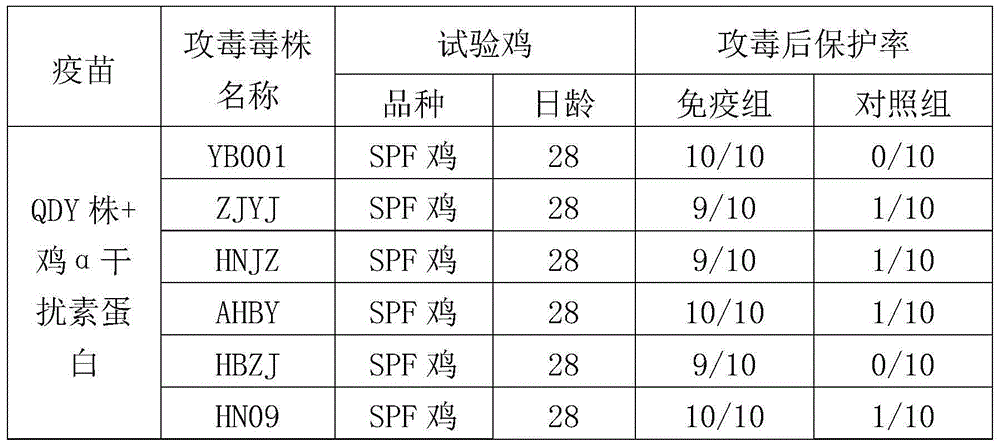

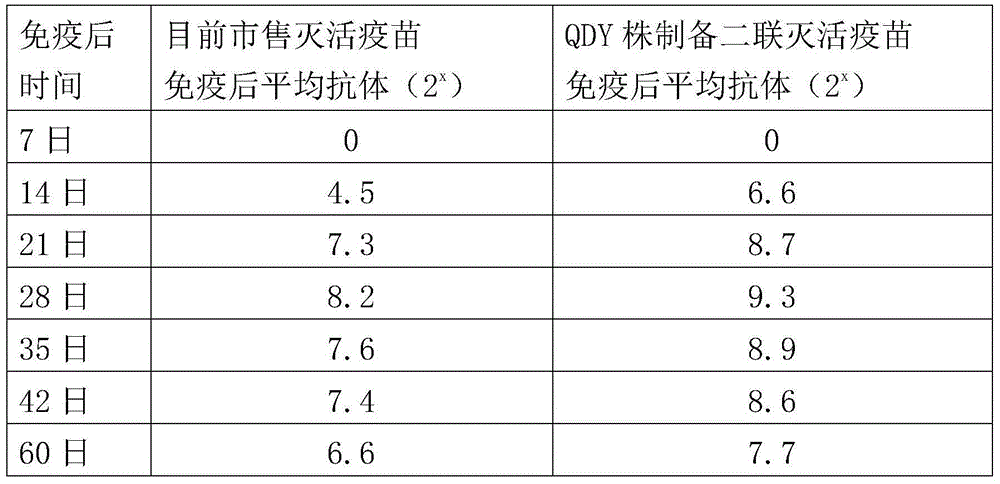

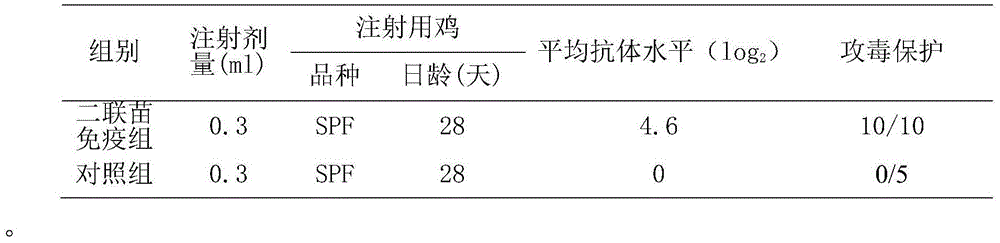

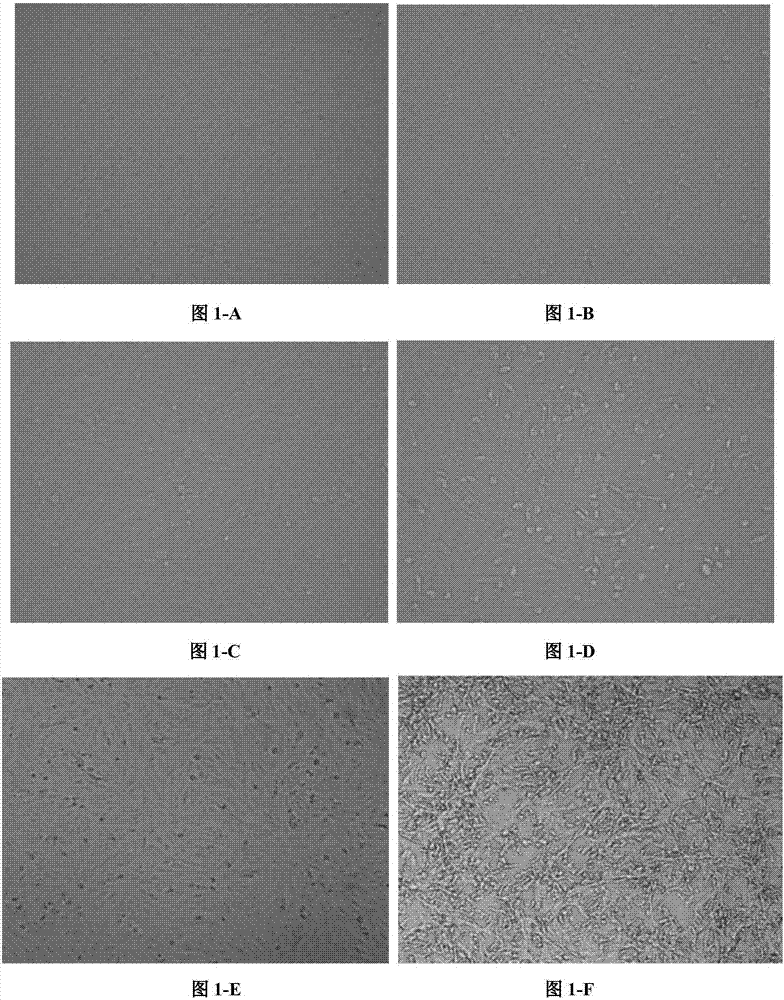

The invention aims at providing a new castle disease and H9 subtype bird flu bivalent vaccine. The new castle disease and H9 subtype bird flu bivalent vaccine contains antigens and adjuvant. The antigens are inactivated H9 subtype bird flu viruses and new castle disease viruses. The H9 subtype bird flu viruses are QDY strains, and the preservation number of the H9 subtype bird flu viruses is CCTCC v201517. The QDY strains of the H9 subtype bird flu viruses and a Lasota strain of the new castle disease viruses are inoculated to chick embryos respectively, and then virus liquid is collected; the virus liquid and the oil adjuvant are mixed and emulsified into the vaccine after the virus liquid is inactivated through a formaldehyde solution. The new castle disease and bird flu bivalent inactivated vaccine is good in immunogenicity, antibody production is fast after immunity, the produced antibody titer is high, the produced antibody holding time is long, the retention period is long, the immunizing dose is small, the selected adjuvant is easy to inject, and two kinds of diseases can be prevented through one-time injection. The vaccine has the advantages of being efficient and good in safety.

Owner:YEBIO BIOENG OF QINGDAO

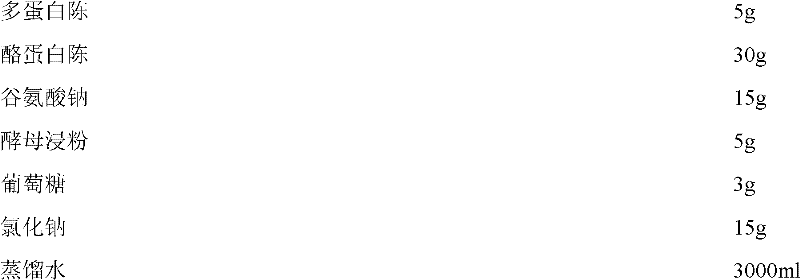

Porcine epidemic diarrhea virus inactivated vaccine and preparation method thereof

ActiveCN107050447AImproving immunogenicityPassive immunity is goodSsRNA viruses positive-sensePeptide/protein ingredientsEpidemic diarrheaMicroorganism

The invention provides a porcine epidemic diarrhea virus inactivated vaccine. The porcine epidemic diarrhea virus inactivated vaccine contains the inactivated porcine epidemic diarrhea virus and an adjuvant, wherein the adjuvant is prepared from the following components in percentage by weight: 5% of squalane, 1% of oleic acid, 1% of Tween 80, 92% of 0.005M sodium citrate buffer solution, and 1% of beta-glucan, the porcine epidemic diarrhea virus is prepared by inactivating the porcine epidemic diarrhea virus strain PEDV-KB2013-4, is assigned with the microbial accession number of CGMCC No.12663, has the classification name of Porcine Epidemic Diarrhea Virus (PEDV), and is preserved in the China General Microbiological Culture Collection Center (CGMCC) on Aug 23, 2016, and the preservation address is the Institute of Microbiology of Chinese Academy of Sciences located in 3, Courtyard 1, West Beichen Road, Chaoyang District, Beijing.

Owner:陕西诺威利华生物科技有限公司 +1

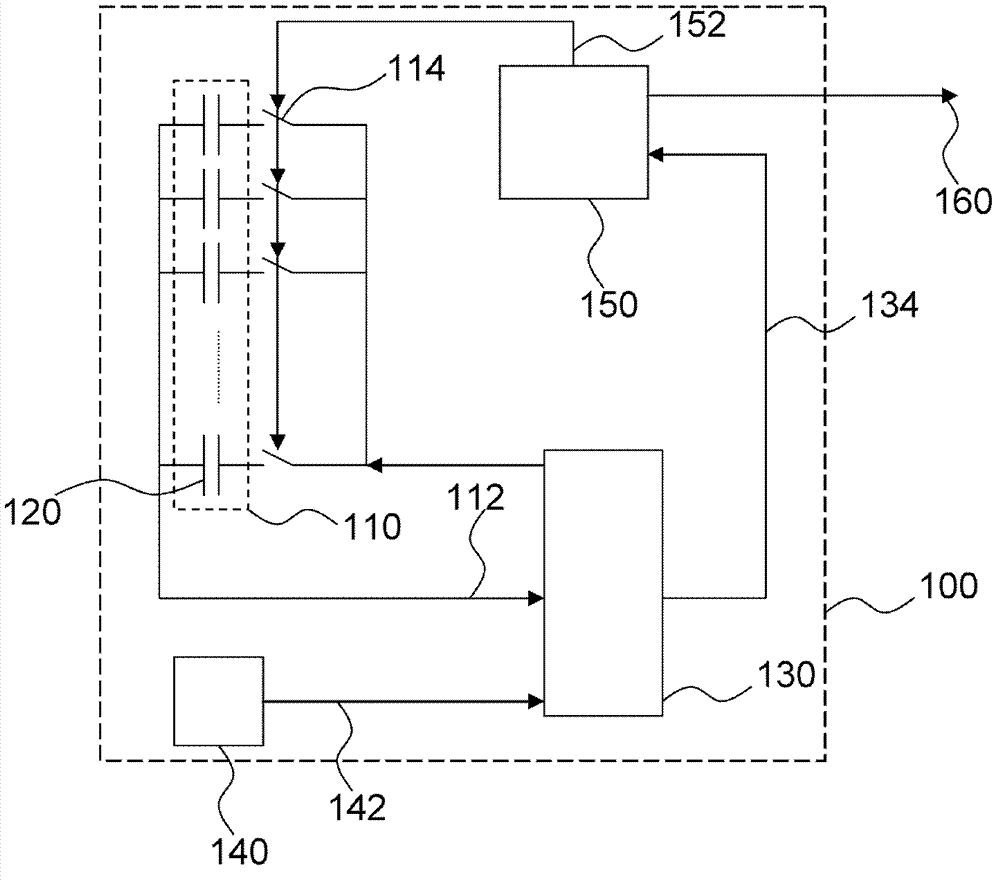

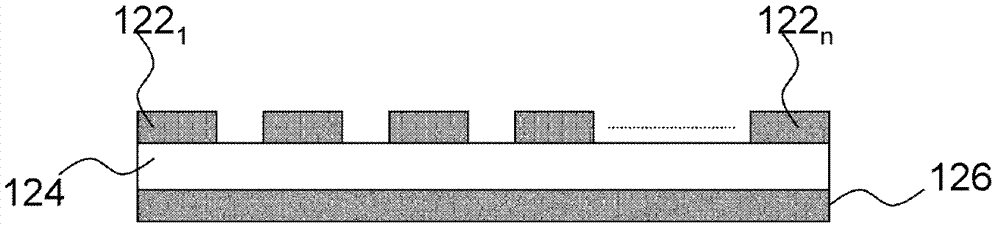

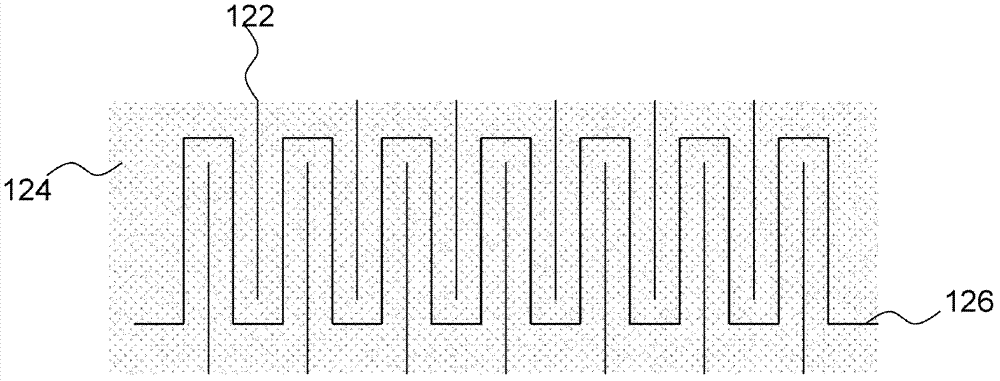

Capacitive sensor, integrated circuit, electronic device and method

Disclosed is a sensor (100, 200) for sensing an analyte of interest, the sensor comprising a plurality of capacitive elements (120), each capacitive element comprising a pair of electrodes (122, 126) separated by a dielectric medium (124) wherein the dielectric constant of the dielectric medium of at least one of the capacitive elements is sensitive to the analyte of interest, the sensor further comprising a comparator (130, 230) adapted to compare a selected set of said capacitive elements against a reference signal and to generate a comparison result signal, and a controller (150, 250) for iteratively selecting said set in response to said comparison result signal, wherein the sensor is arranged to produce a digitized output signal indicative of the sensed level of the analyte of interest. An IC comprising such a sensor, an electronic device comprising such an IC and a method of determining a level of an analyte of interest using such a sensor are also disclosed.

Owner:XIAO TESTING CO LTD

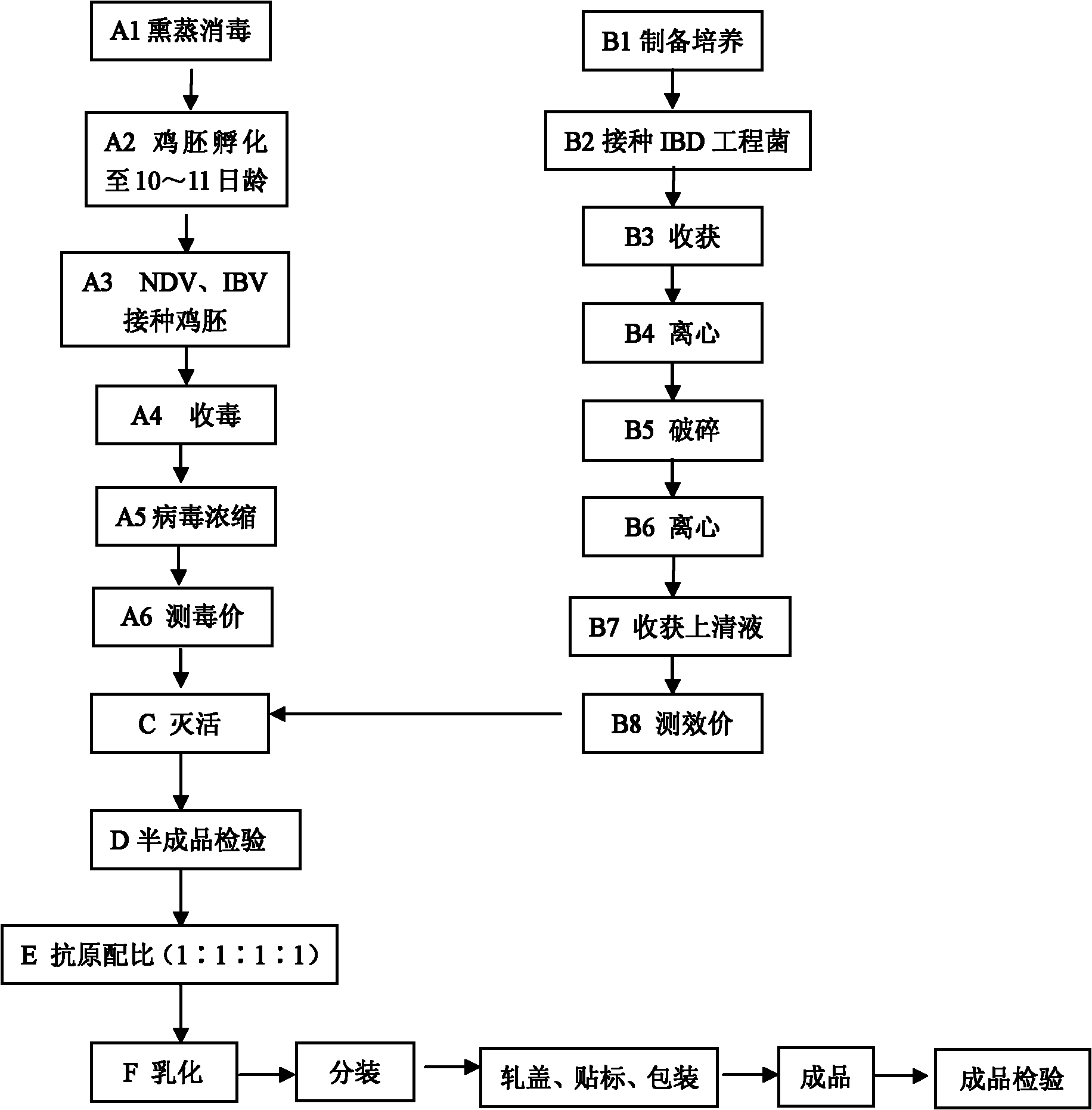

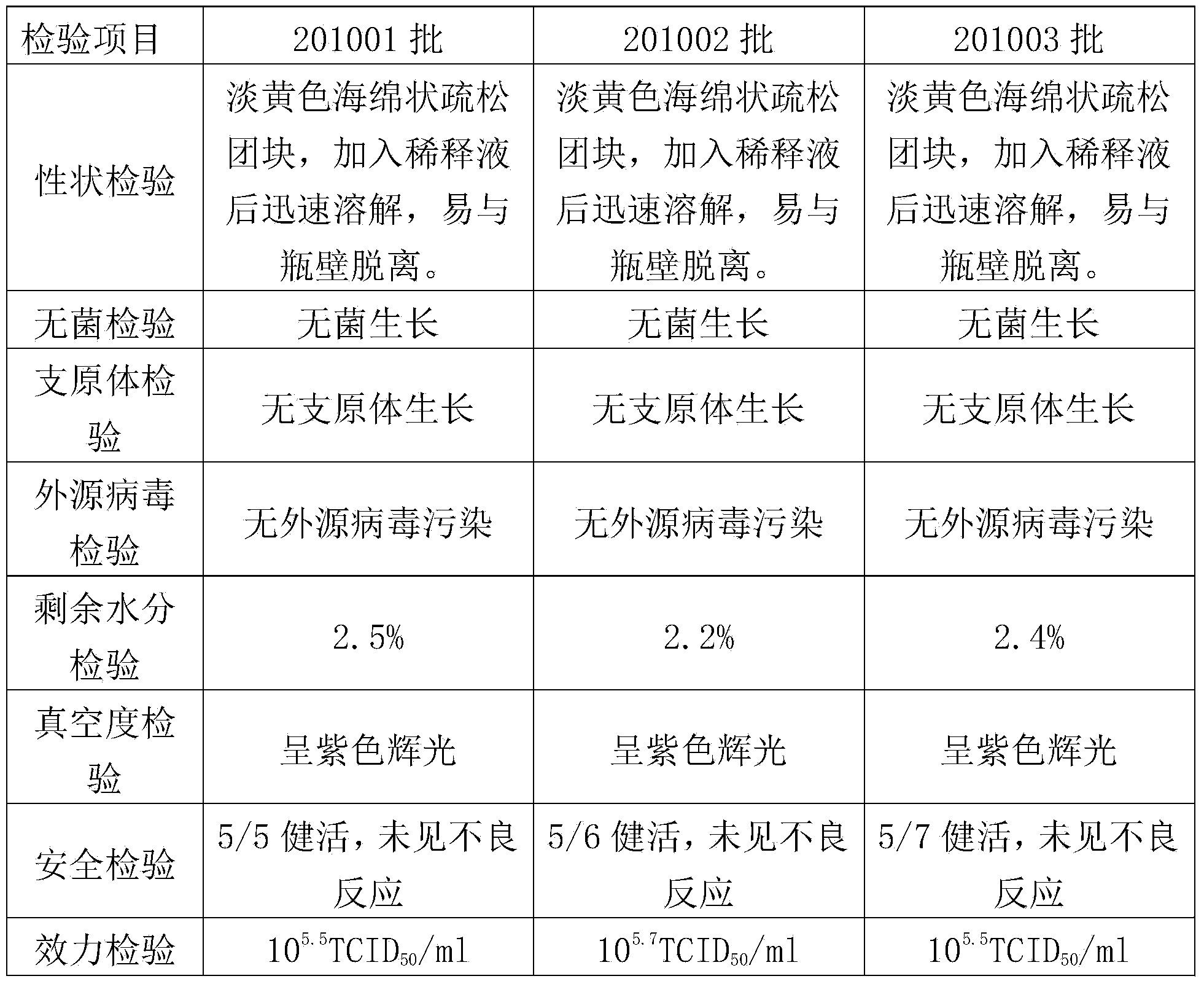

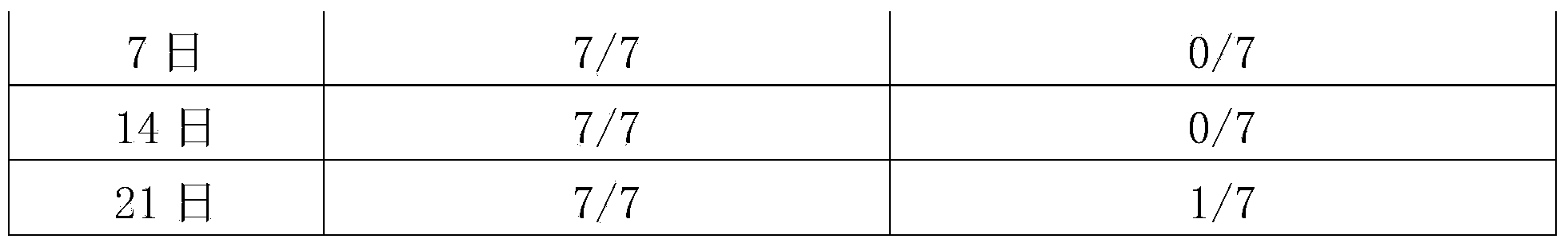

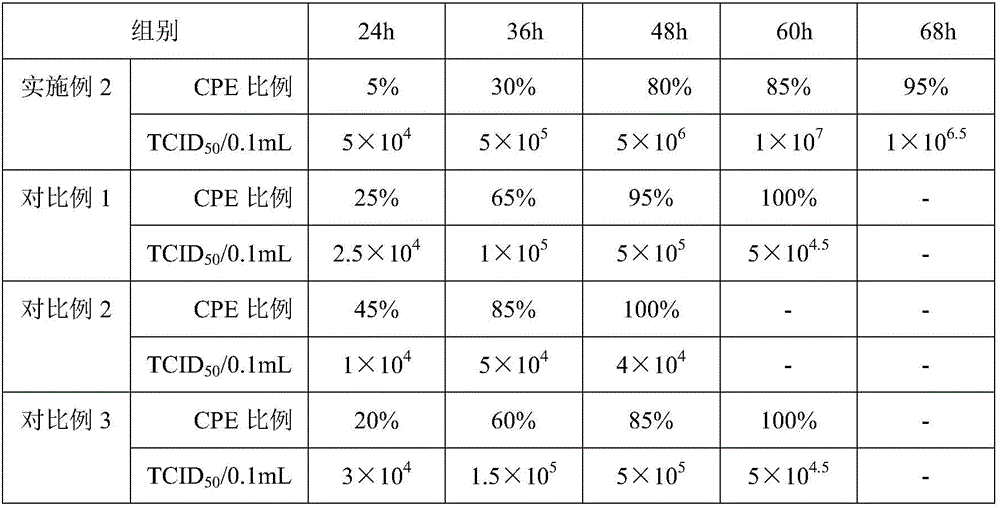

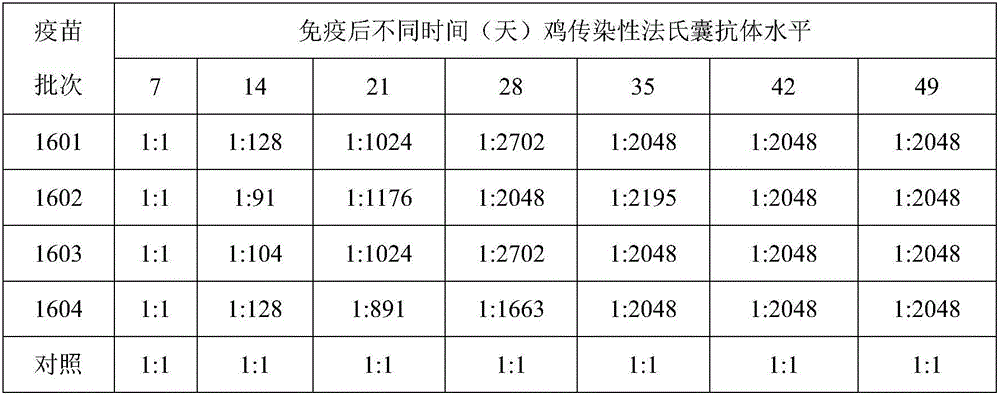

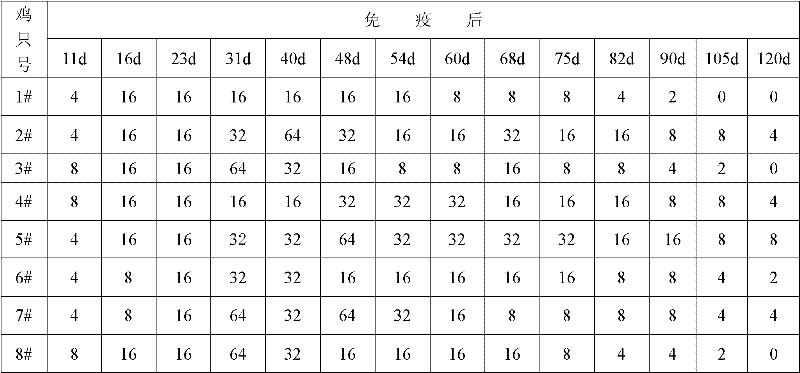

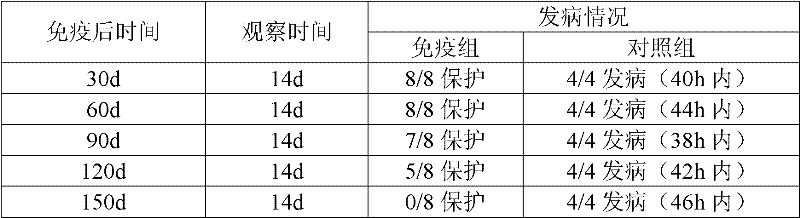

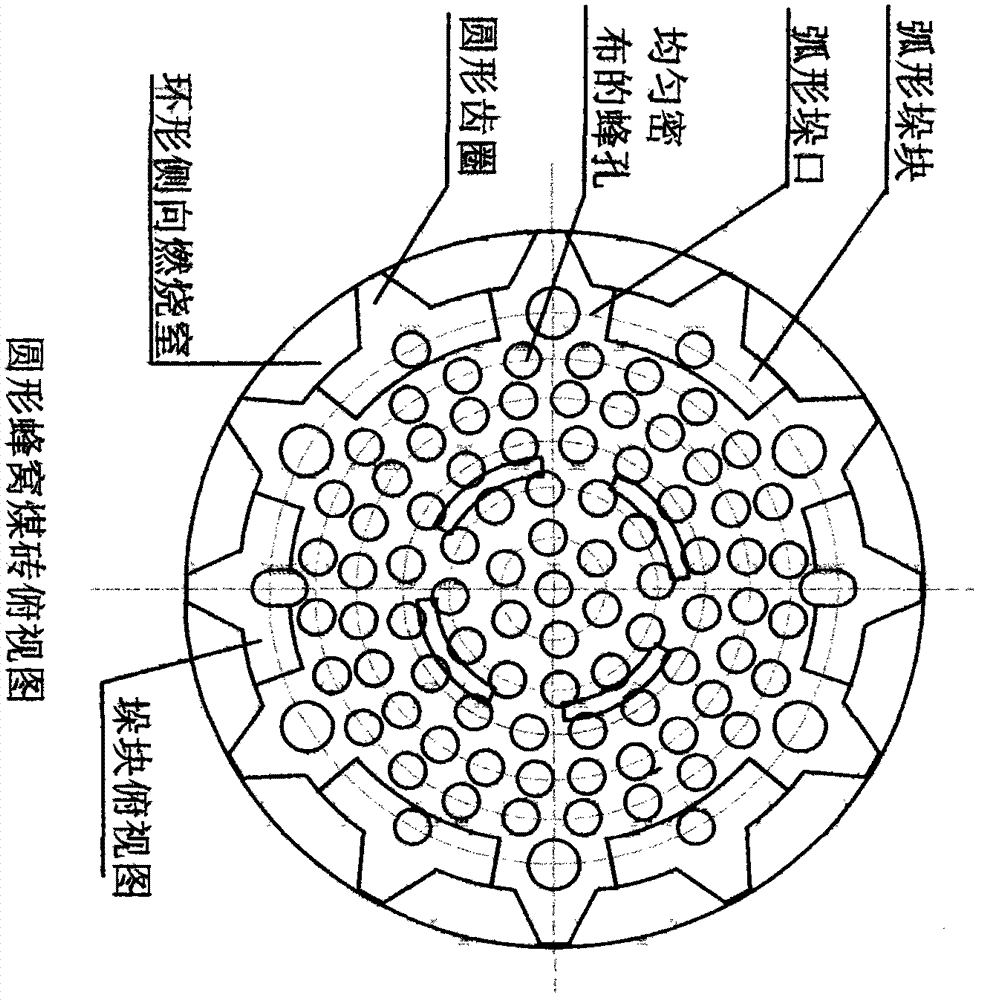

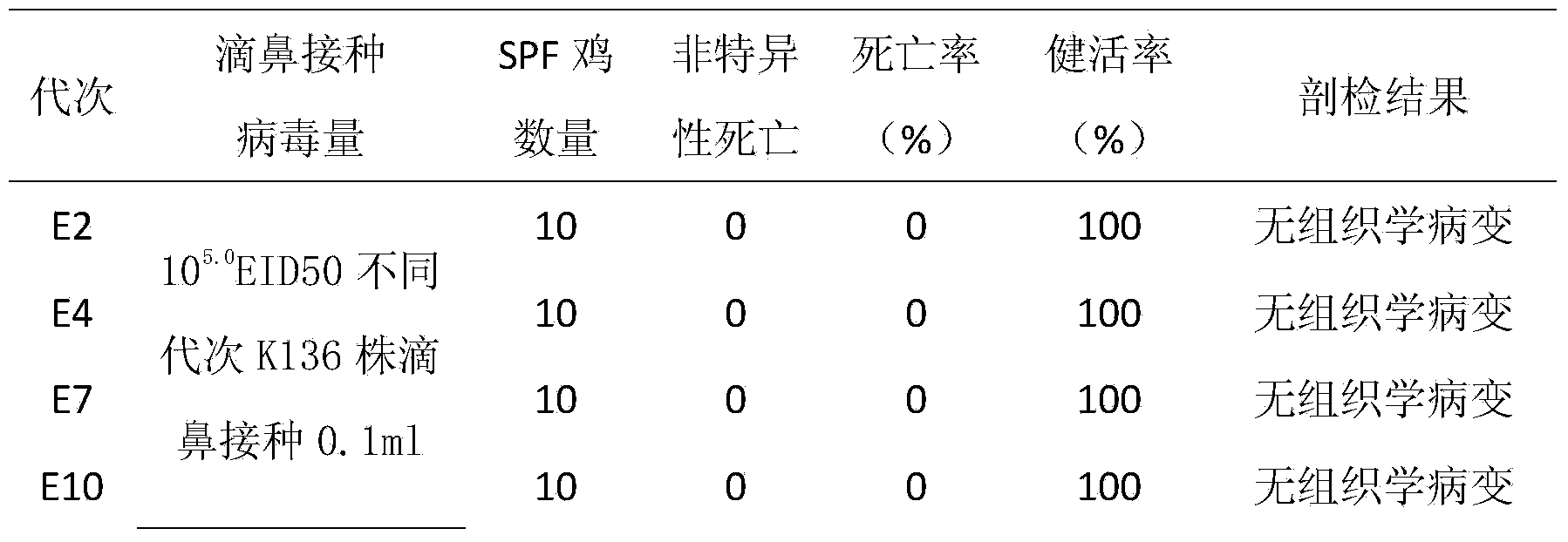

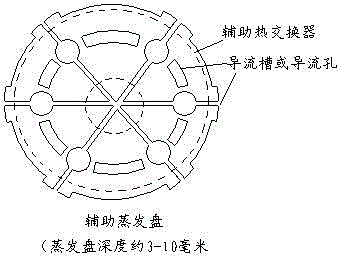

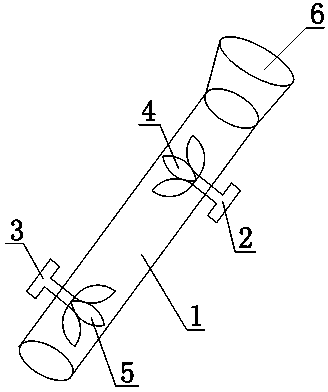

Method for producing triple inactivated vaccine for newcastle disease, infectious bronchitis and infectious bursal disease

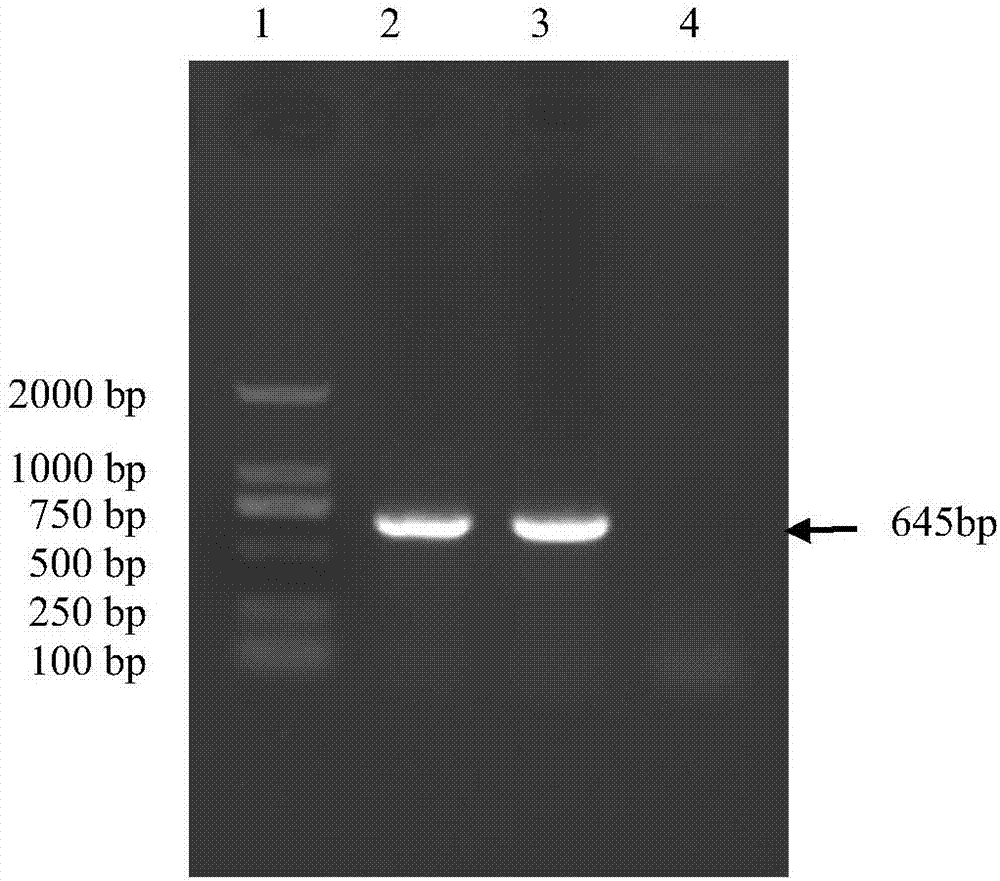

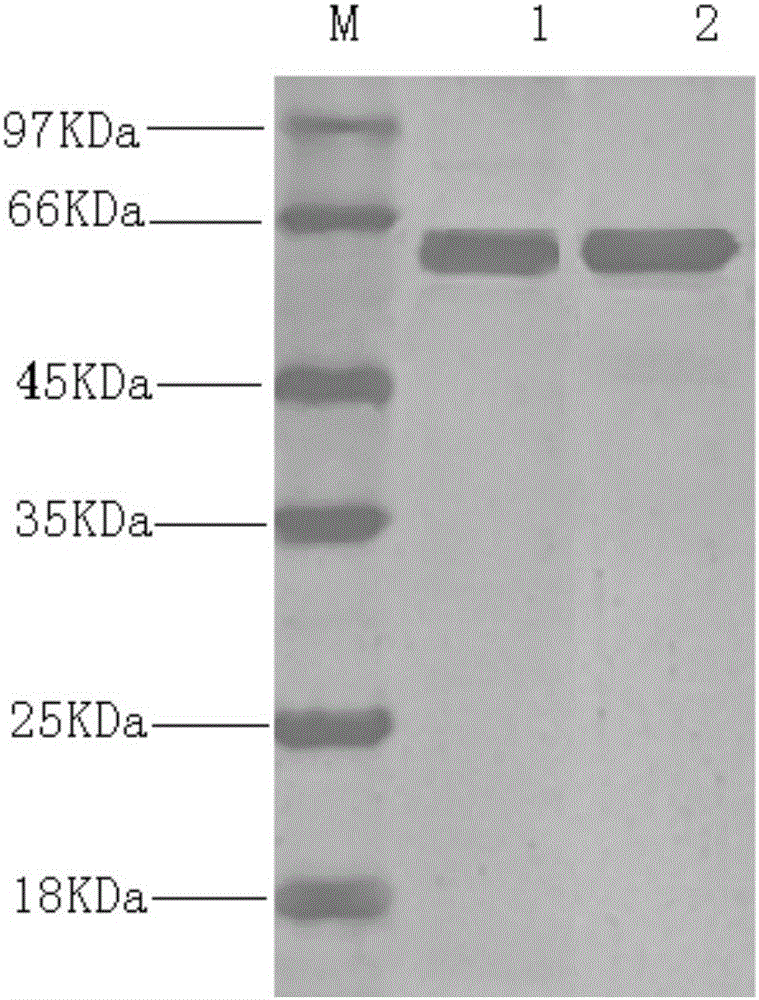

InactiveCN102068694AProduced fastHigh potencyViral antigen ingredientsAntiviralsEscherichia coliAdjuvant

The invention relates to a method for producing a triple inactivated vaccine for newcastle disease, infectious bronchitis and infectious bursal disease. In the method, the inactivated vaccine is prepared by adopting a newcastle disease virus La Sota strain, an infectious bronchitis virus M41 strain, and an Escherichia coli genetic engineering bacteria E. coil BL21 / pET28a-VP2 strain which expresses an infectious bursal disease virus VP2 protein serving as production bacteria toxic species, a super concentration process and a high-quality adjuvant. After immunizing animals, antibodies are produced rapidly; the potency is high; the protection period is long; and the outbreak and the spreading of epidemic diseases are reduced.

Owner:YEBIO BIOENG OF QINGDAO

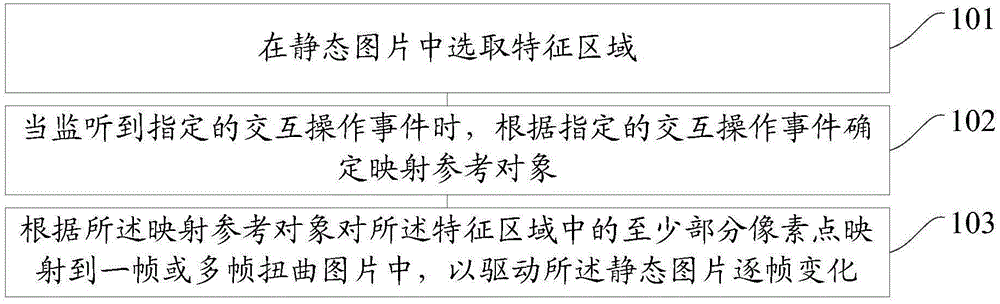

Static picture based dynamic interaction method and device

ActiveCN104571887ALower technical barriersImprove simplicityExecution for user interfacesInput/output processes for data processingMultiple frameHuman–computer interaction

The embodiment of the invention provides a static picture based dynamic interaction method and device. The static picture based dynamic interaction method and device comprises the steps of selecting a feature area in a static picture, determining a mapping reference object according to a specific interaction operation event when monitoring the specific interaction operation event, and mapping at least a part of pixel points in the feature area to a one-frame or multi-frame distorted picture so as to drive the static picture to change frame by frame according to the mapping reference object. By means of the static picture based dynamic interaction method and device, the dynamic effect is played without a special application, the technical threshold is reduced, and operation simplicity is improved. In addition, static picture based dynamic interaction is achieved by making feedback on interaction operation of a user, and a dynamic effect mode is enriched.

Owner:BEIJING QIHOO TECH CO LTD

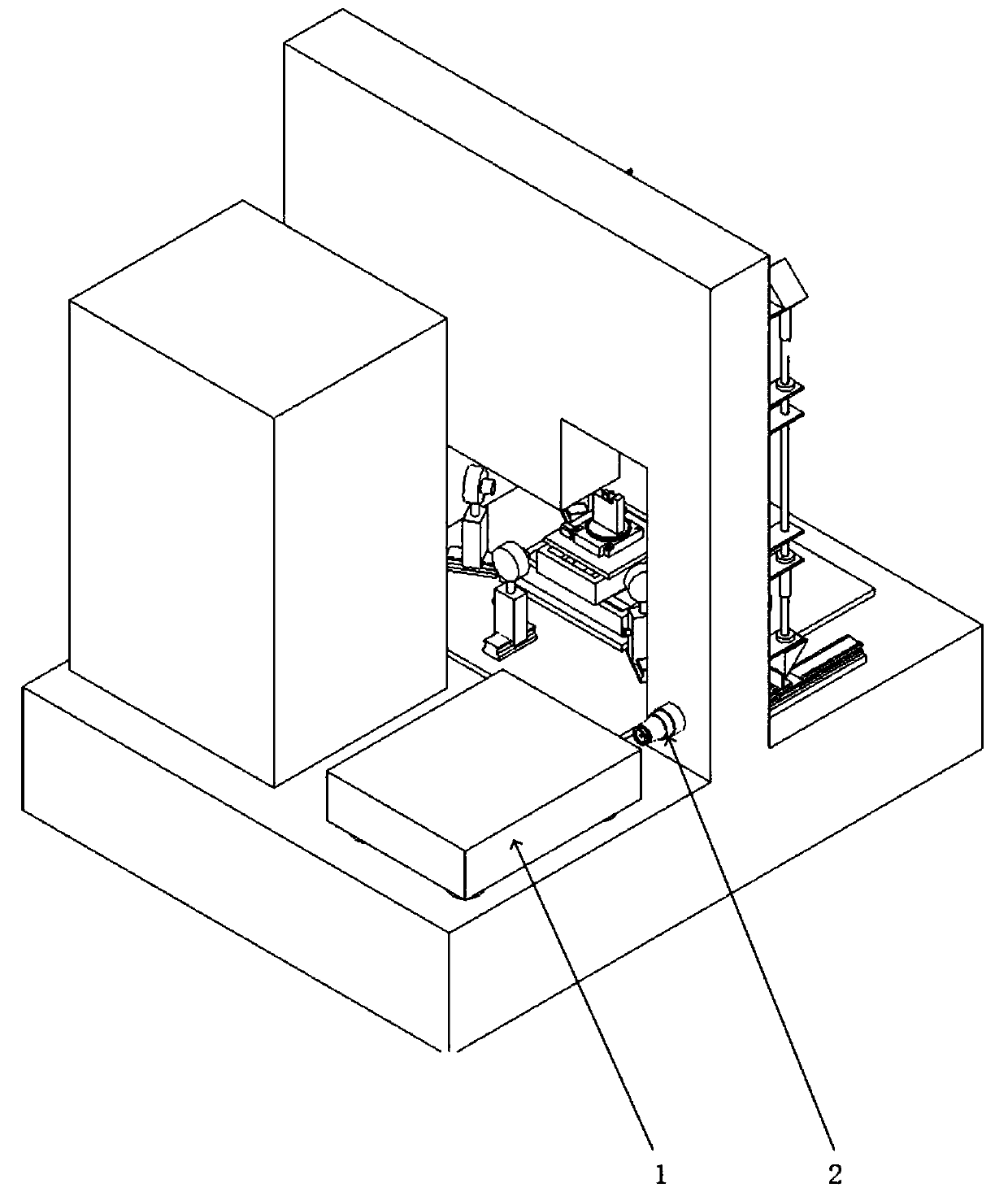

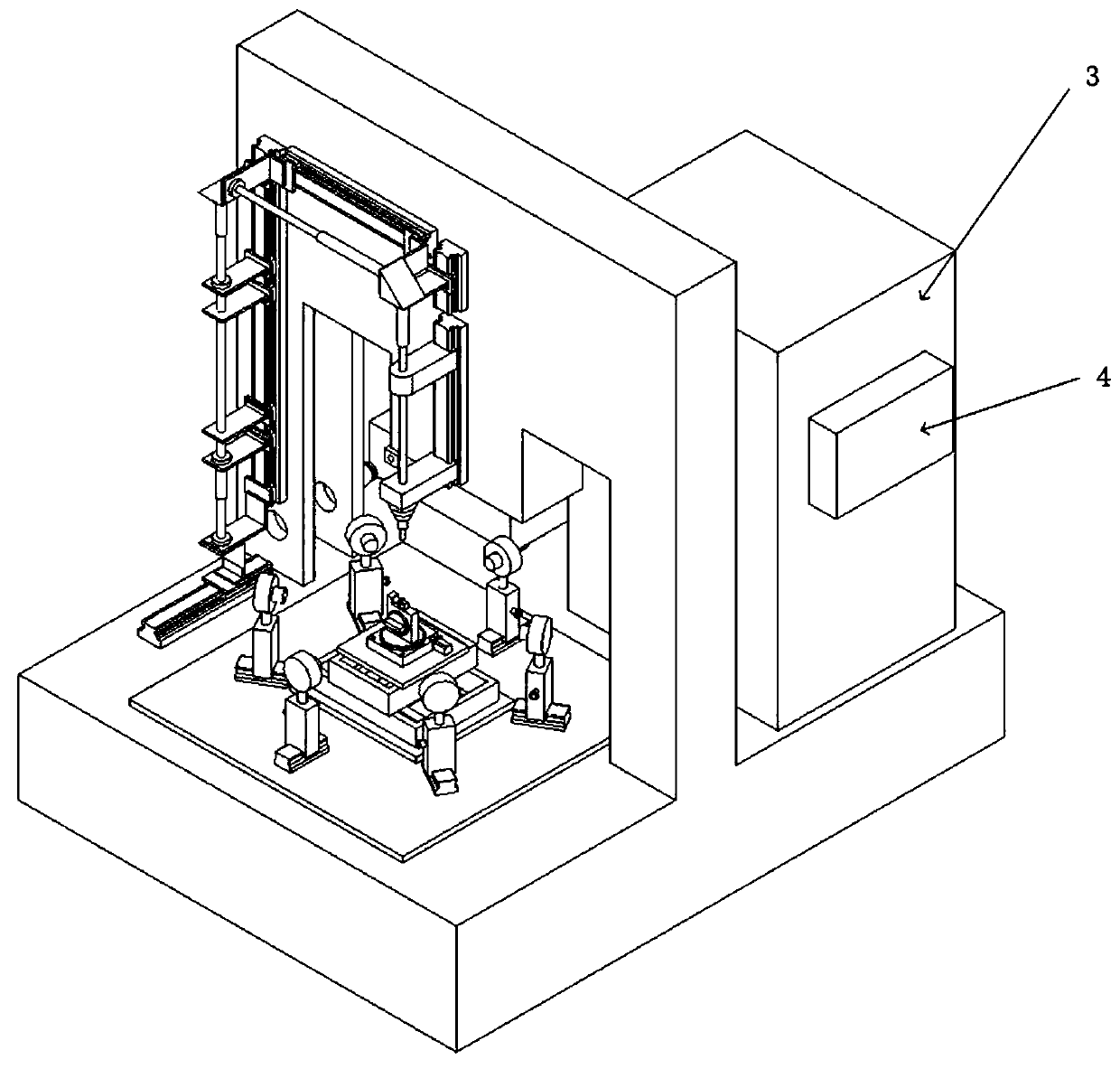

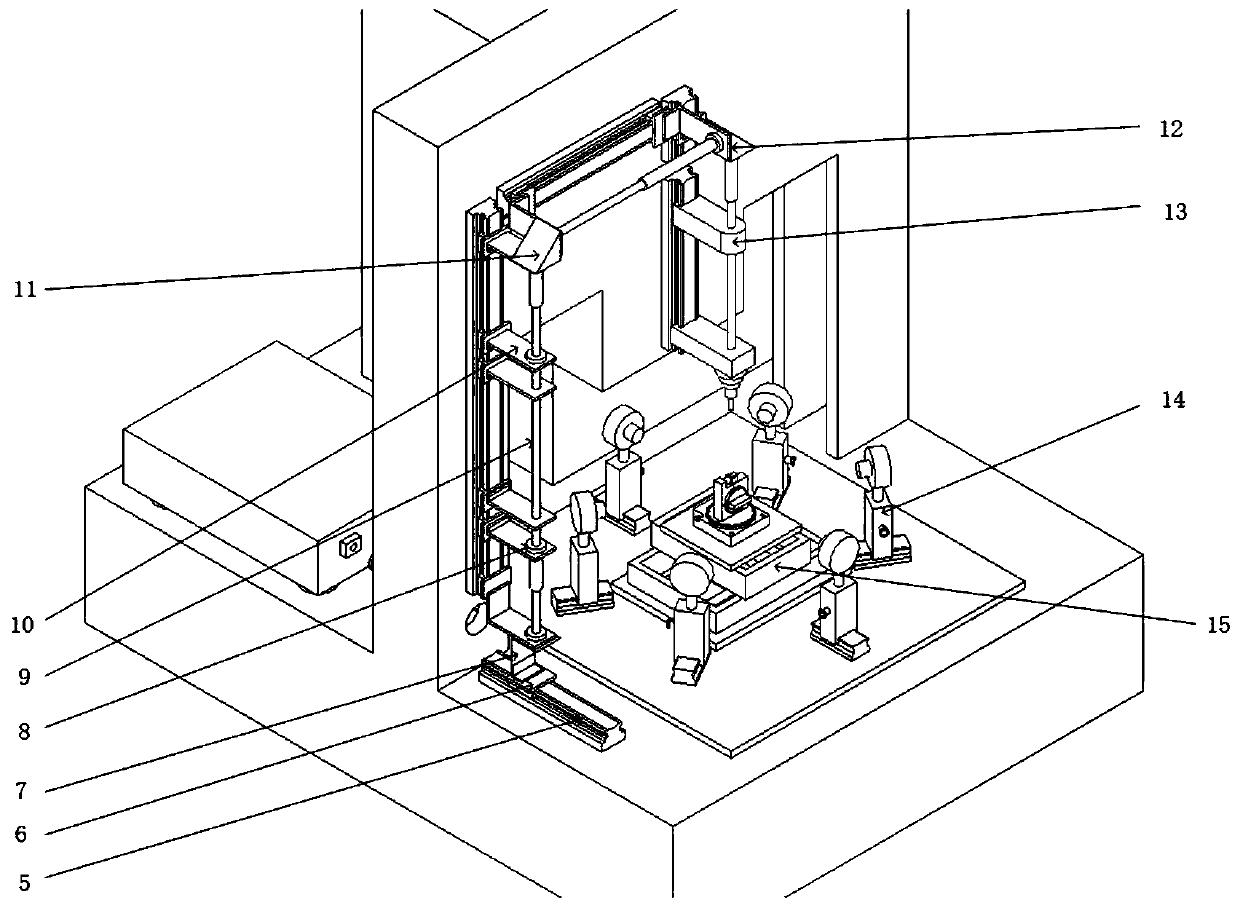

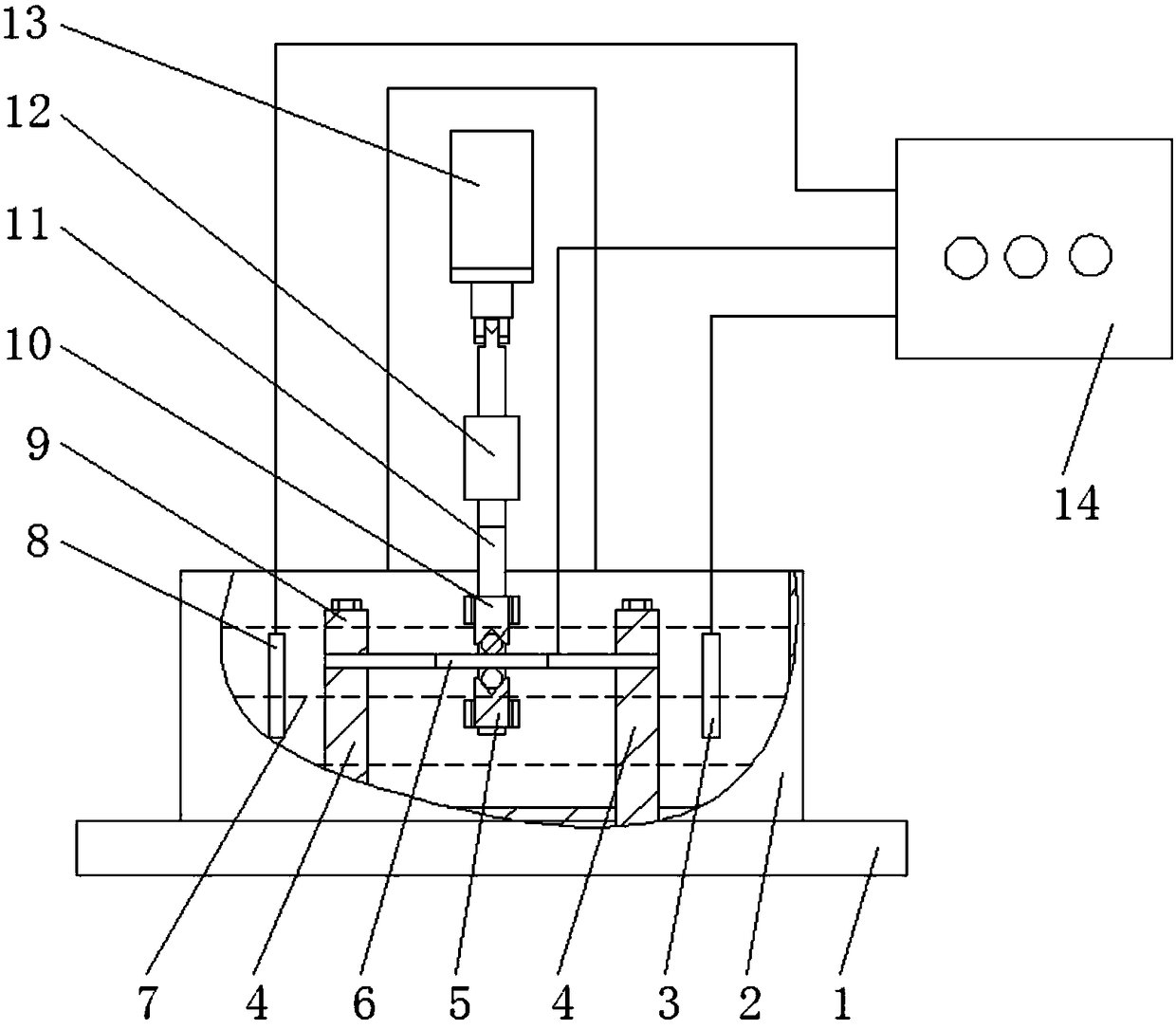

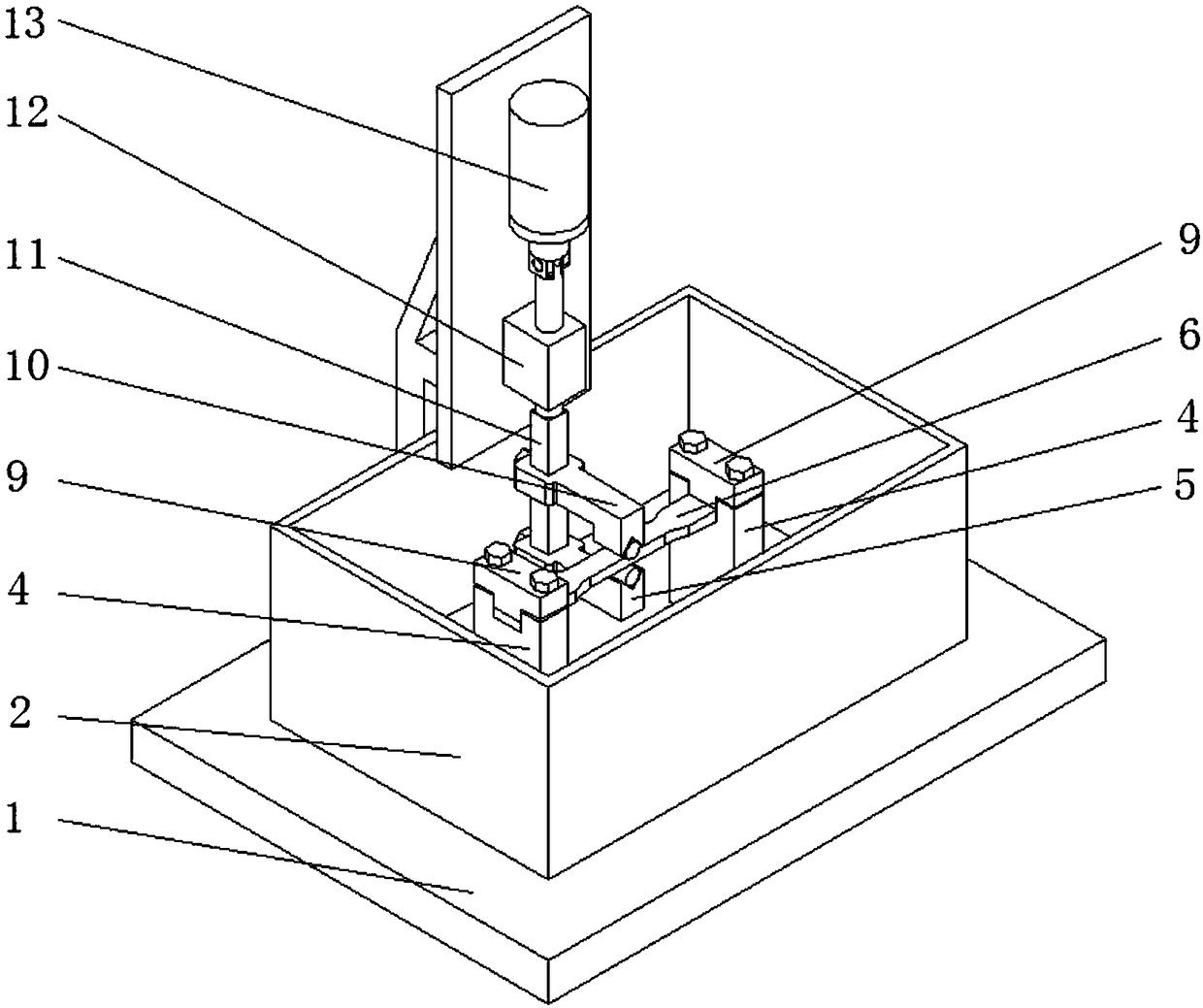

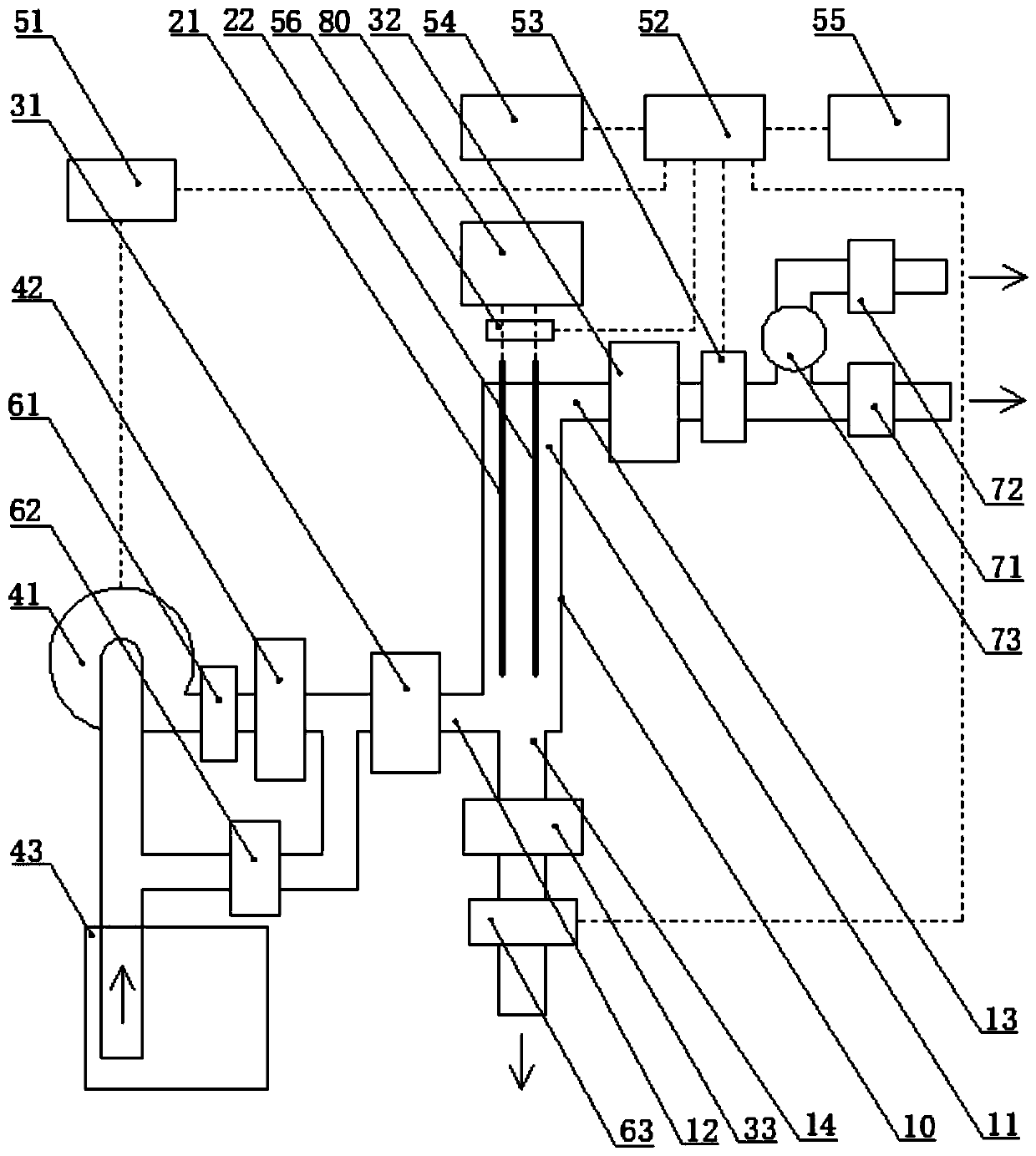

Laser induced plasma assisted electric spark compound processing device and laser induced plasma assisted electric spark compound processing method under action of magnetic field

ActiveCN110340471APromote generationMeet the needs of processing different sizesElectrical-based auxillary apparatusElectricityCompound a

The invention discloses an ultrashort pulse laser induced plasma assisted electric spark compound processing device and an ultrashort pulse laser induced plasma assisted electric spark compound processing method under action of a magnetic field and belongs to the field of laser processing and electric spark compound processing of special processing. The device compounds a laser induced plasma processing unit, an electric spark processing unit and a compound magnetic field unit together organically. The laser induced plasma processing unit comprises an ultrashort pulse laser, a laser power supply, a water cooler and a light path conversion assembly. The compound magnetic field comprises a direct current excitation power supply and an annular electromagnet. The electric spark processing unitcomprises a five-degree-of-freedom precision platform for controlling a workpiece to move expectedly. The device and the method provided by the invention sole the problem that it is hard to process alow conductivity material and achieve cross-dimension processing and the processed surface is not enough high in quality in the electric spark processing technology, and have a very wide applicationprospect.

Owner:HUAZHONG UNIV OF SCI & TECH

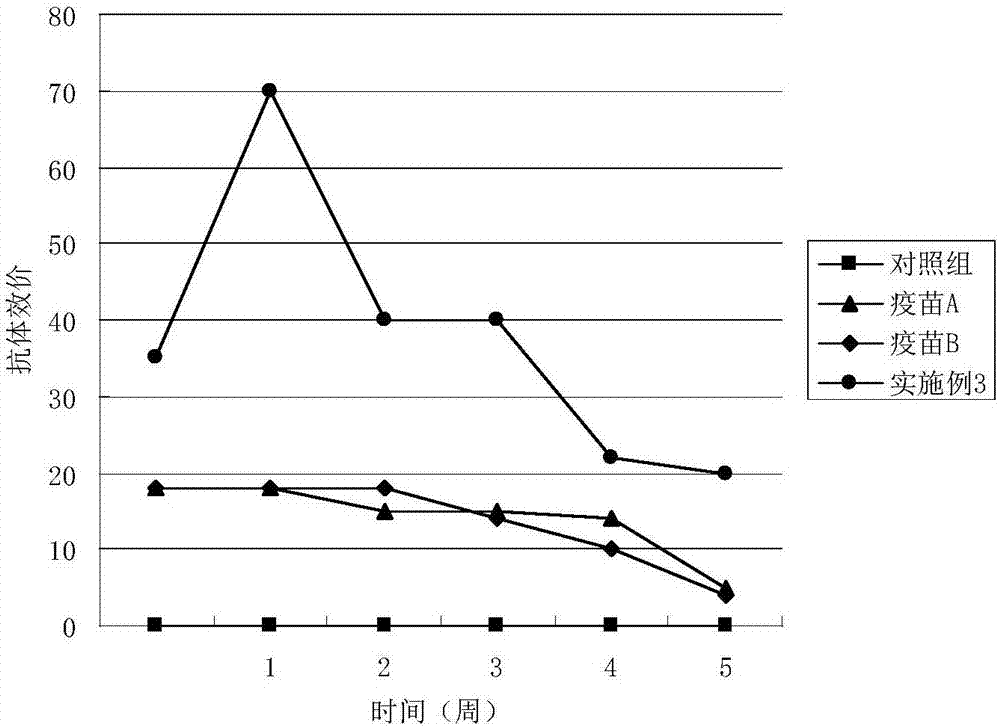

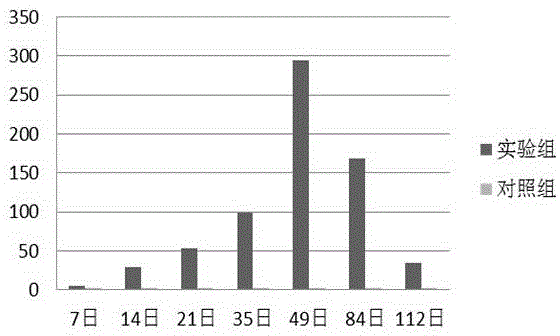

Porcine epidemic diarrhea virus and application thereof

ActiveCN103820399APassive immunity is goodProduced fastInactivation/attenuationImmunoglobulins against virusesMicroorganismMating

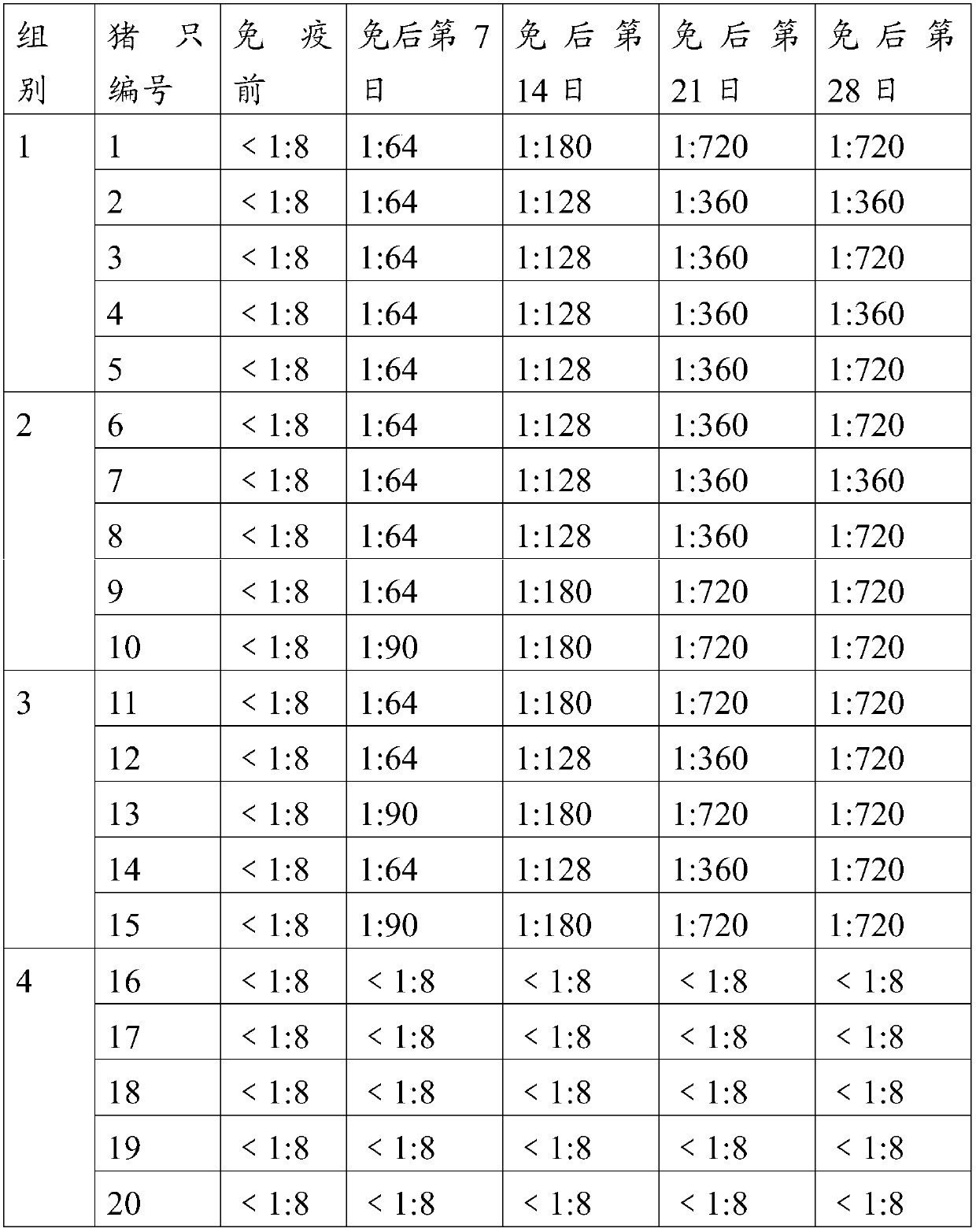

The invention provides a porcine epidemic diarrhea virus strain SD10 which is preserved in General Microbiology Center of China Committee for Culture Collection of Microorganisms, School of Chinese Academy of Sciences Committee, at Beichen West Road, No. 1 yard, No. 3, Chaoyang District, Beijing, on November 8, 2013, and the preservation number is CGMCC No. 8503. Compared with the conventional viruses, the porcine epidemic diarrhea virus strain SD10 screened by the invention is low in toxicity, and good in immunogenicity; the prepared vaccine can quick generate antibodies after immunizing; the generated antibodies are high in titer and long in duration; the vaccine is long in storage life, and small in immunity dose, and can enable piglets of a pregnant sow to get better ectophylaxination if being injected to the pregnant sow before mating, so that the piglets can generate strong immune and can resist virulent attacks, and the piglet survival is improved.

Owner:YEBIO BIOENG OF QINGDAO

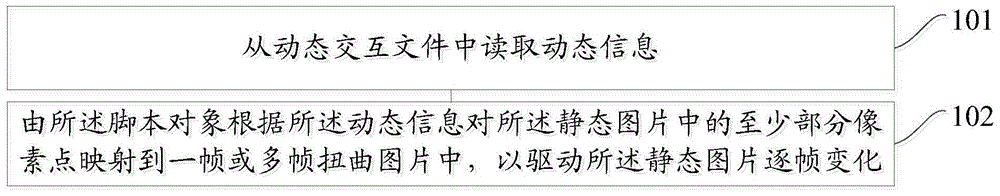

Method and device for generating customizable dynamic graphs

InactiveCN104574483ARich dynamic effectsGuaranteed sizeTexturing/coloringAnimationMultiple frameComputer graphics (images)

The embodiment of the invention provides a method and device for generating customizable dynamic graphs. The method includes the steps that dynamic information is read from dynamic interaction files; the dynamic interaction files comprise script objects and static images; at least part of pixel points in the static images are mapped to distorted images of one frame or multiple frames through the script objects according to the dynamic information so as to drive the dynamic images to change frame by frame. According to the method and device, the customizable dynamic graphs are achieved through the dynamic information, the dynamic effect can be assigned by users, and the dynamic effect mode is richened; due to the fact that the static images are small in size change, only information, such as the dynamic information and the scrip objects with the size being smaller is added, and the size is reduced greatly while the dynamic effect is guaranteed.

Owner:BEIJING QIHOO TECH CO LTD +1

Porcine epidemic diarrhea virus variant inactivated vaccine and application thereof

InactiveCN106729691AImproving immunogenicityPassive immunity is goodSsRNA viruses positive-senseViral antigen ingredientsEpidemic diarrheaNeutralizing antibody

The invention provides a porcine epidemic diarrhea virus variant inactivated vaccine which is prepared after inactivating a diarrhea virus variant PEDV / CH / BJ / 2014. The vaccine is excellent in immunogenicity; after a sow is inoculated with the vaccine before parturition, a neutralizing antibody is rapidly produced, the antibody titer is high, the maintenance time is long, a piglet of the inoculated sow litter acquires better passive immunity, the piglet is effectively protected against the attack of the epidemic diarrhea virus, and the survival rate of the piglet is increased.

Owner:BEIJING DAWEIJIA BIOTECH SHARE CO LTD

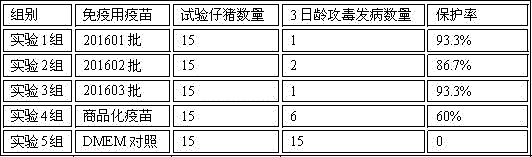

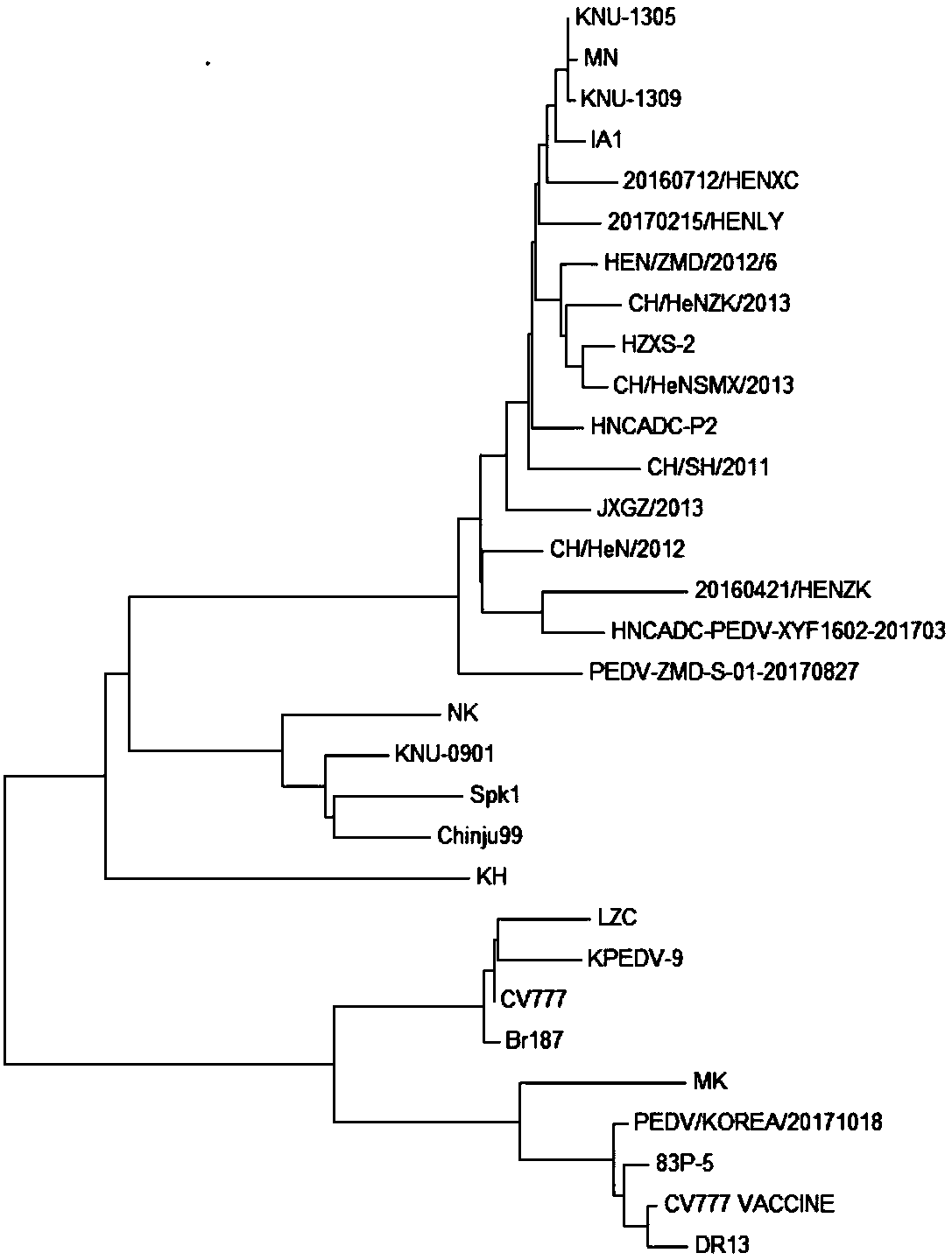

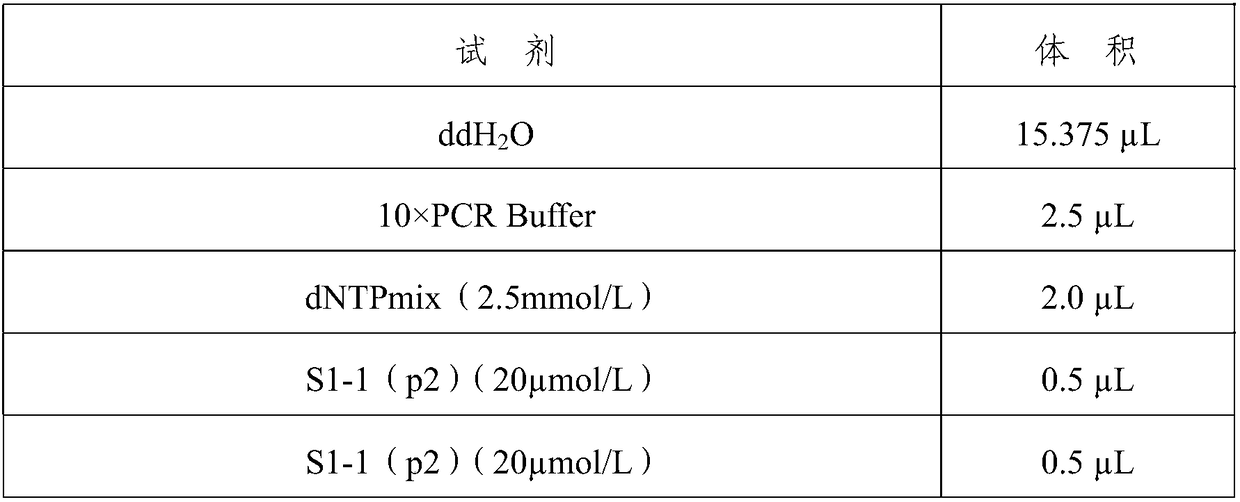

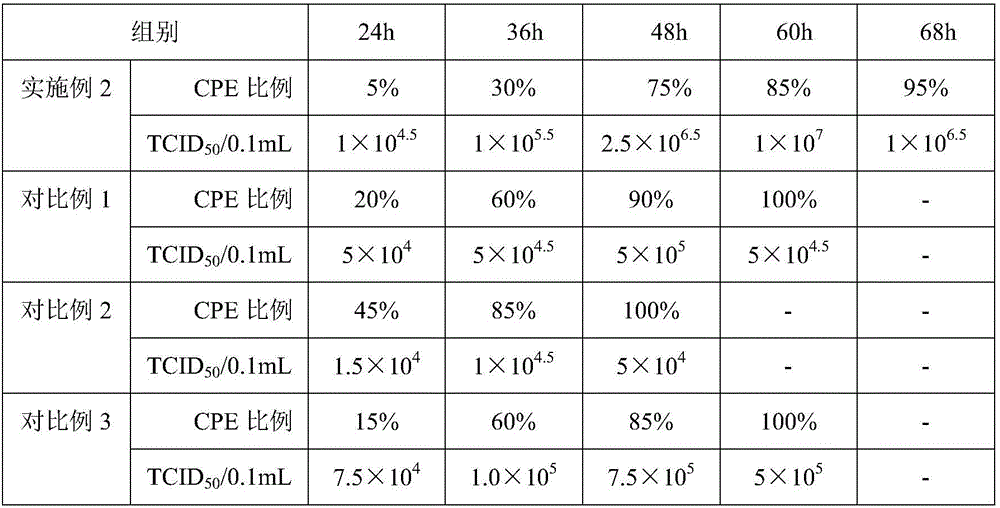

Porcine epizootic diarrhea virus variant strain and application thereof

ActiveCN108517318AProduced fastImprove securitySsRNA viruses positive-senseViral antigen ingredientsBALB/cDisease

The invention belongs to the technical field of microbes, and particularly relates to a porcine epizootic diarrhea virus variant strain (PEDV-HNCADC-2017, preservation number: CCTCC NO:V201766) and application thereof. The variant strain provided by the invention realizes the generation passage to 156th generation in VERO cells of 10-percent blood serum medium; the TCID50 of the VERO cells can reach 107.7 / 0.1mL; the toxic valence is high; the reaction can be performed with porcine positive blood serum and Balb / c mouse positive blood serum; the immunofluorescence reaction is stronger. The prepared weak toxicity live vaccine can be used for preventing the porcine epizootic diarrhea diseases; the antibody generation is fast; the high antibody level can be generated after the immunization for2 weeks. The prepared inactivated vaccine has high safety; toxin expelling is avoided after the immunization; the strain can be used for preventing and controlling the porcine epizootic diarrhea diseases of sows and one-day-old piglets. When the combined immunization is used, the immunization effect can be obviously improved.

Owner:HENAN CENT FOR ANIMAL DISEASE CONTROL & PREVENTION

Triple inactivated vaccine for rabbit viral hemorrhagic disease, pasteurellosis and bordetella disease and preparation method of vaccine

ActiveCN110201153AProduced fastHigh immune attack protection rateAntibacterial agentsBacterial antigen ingredientsDiseaseBordetella

The invention relates to a triple inactivated vaccine for rabbit viral hemorrhagic disease, pasteurellosis and bordetella disease and a preparation method of the vaccine. The effective components of the vaccine comprise VP60 protein antigen of rabbit viral hemorrhagic disease virus, inactivated pasteurella multocida QLT-1 strain and bordetella bronchiseptica JN01 strain antigen. The triple inactivated vaccine has fast generation of protective antibody after immunization and high immune attack protection rate, with the attack protection rate for rabbit viral hemorrhagic disease virus AV-34 strain, pasteurella multocida QLT-1 strain and bordetella bronchiseptica JN01 strain all reaching above 80%. The results show that the vaccine is safe and reliable, and can be used for preventing the occurrence of rabbit viral hemorrhagic disease (rabbit plague), rabbit pasteurella multocida disease (type A) and rabbit bronchisepticaemia Bordetella disease.

Owner:QILU ANIMAL HEALTH PROD

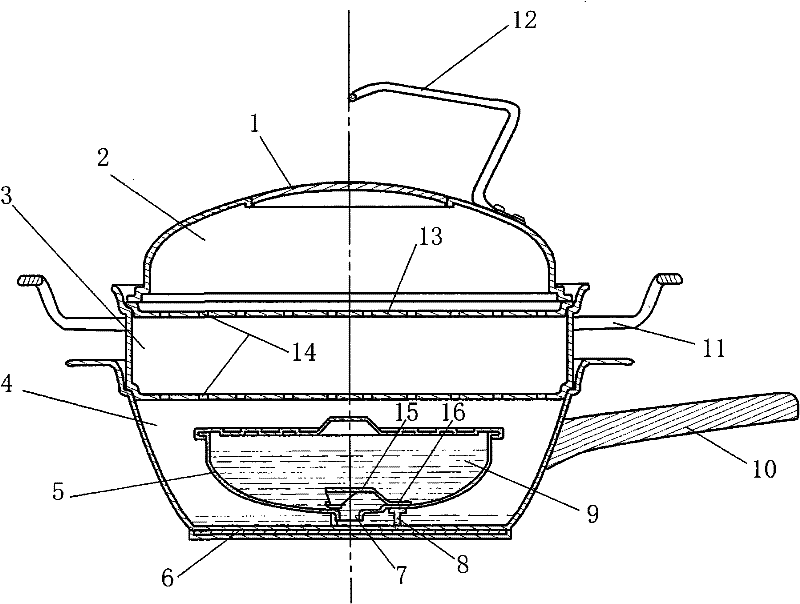

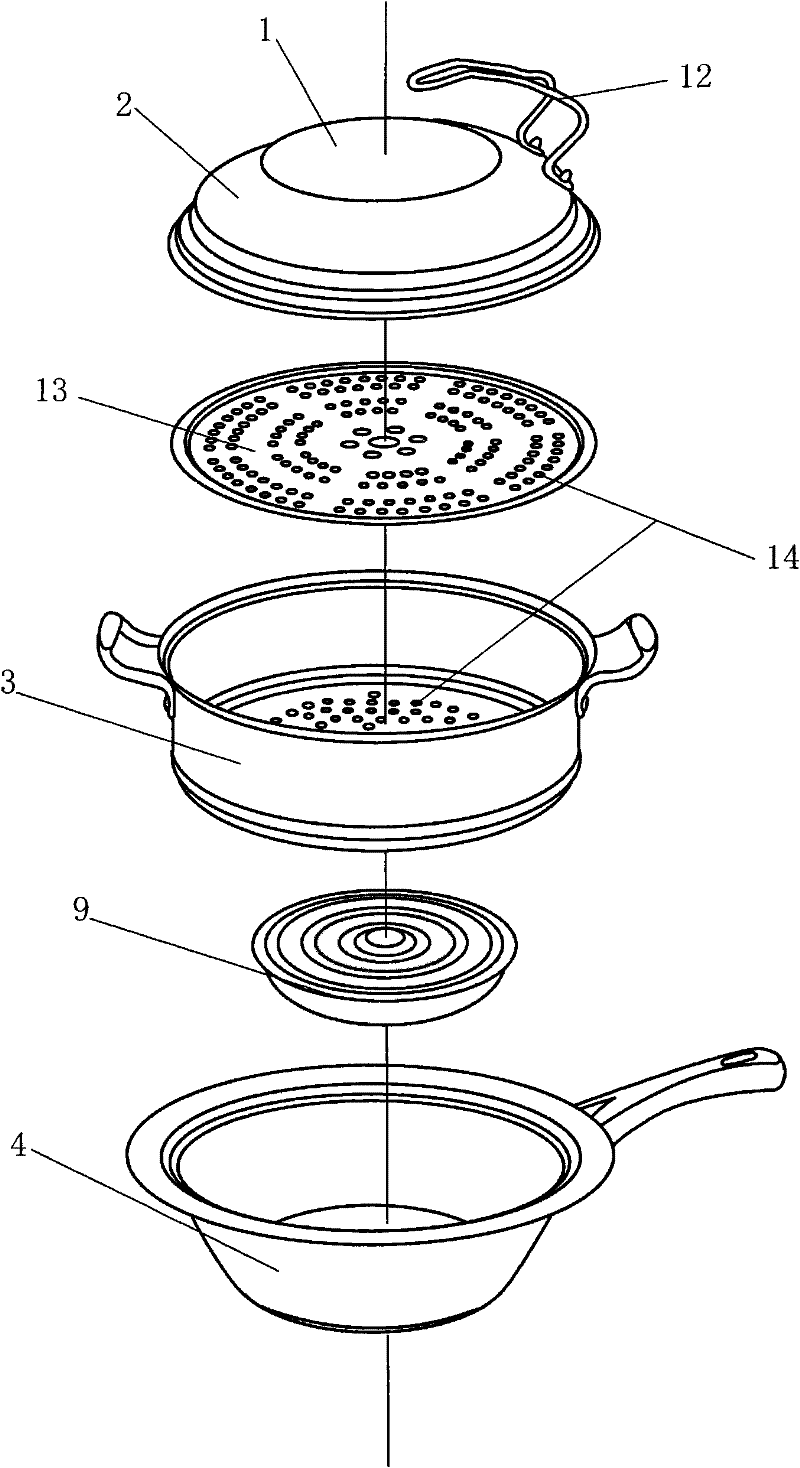

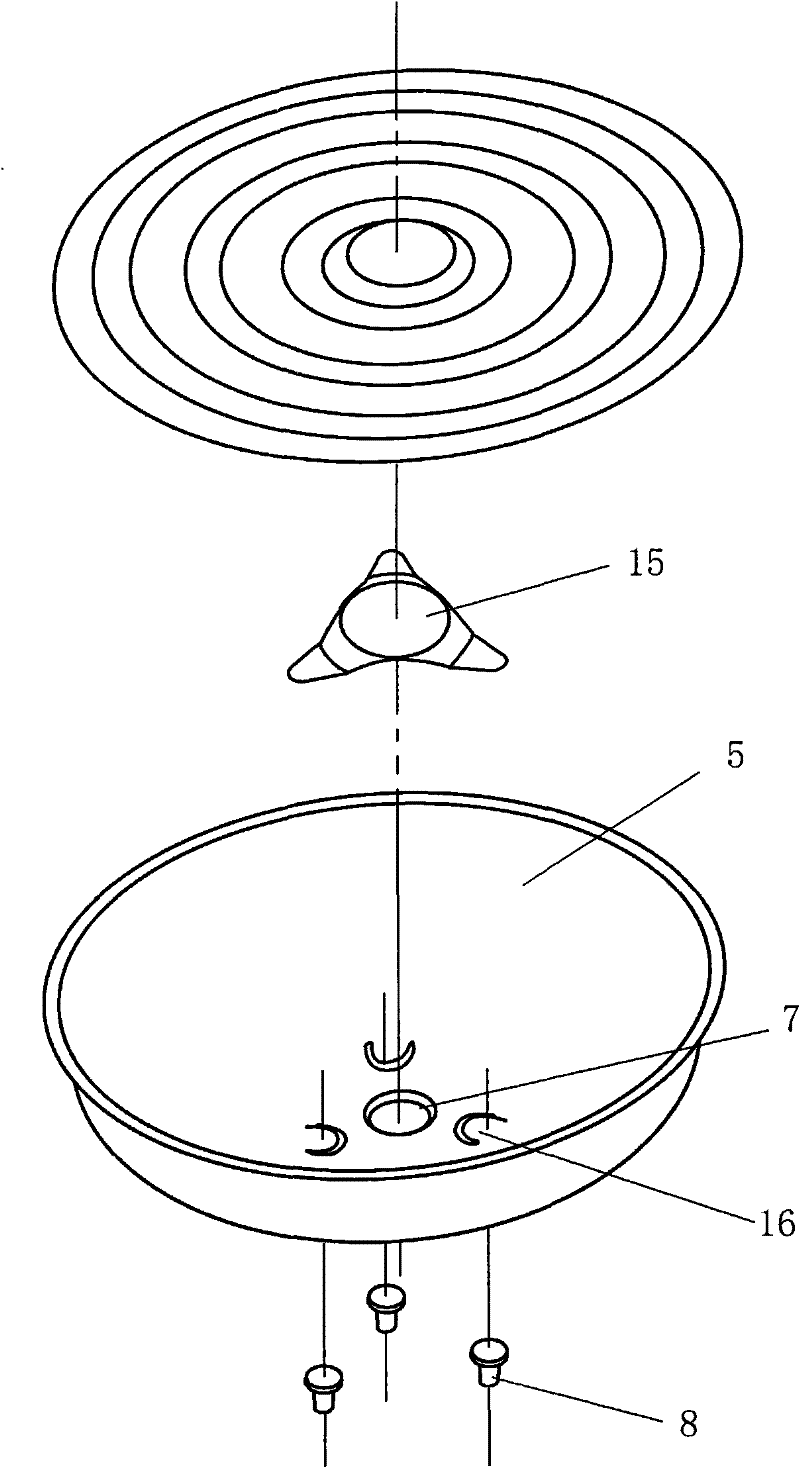

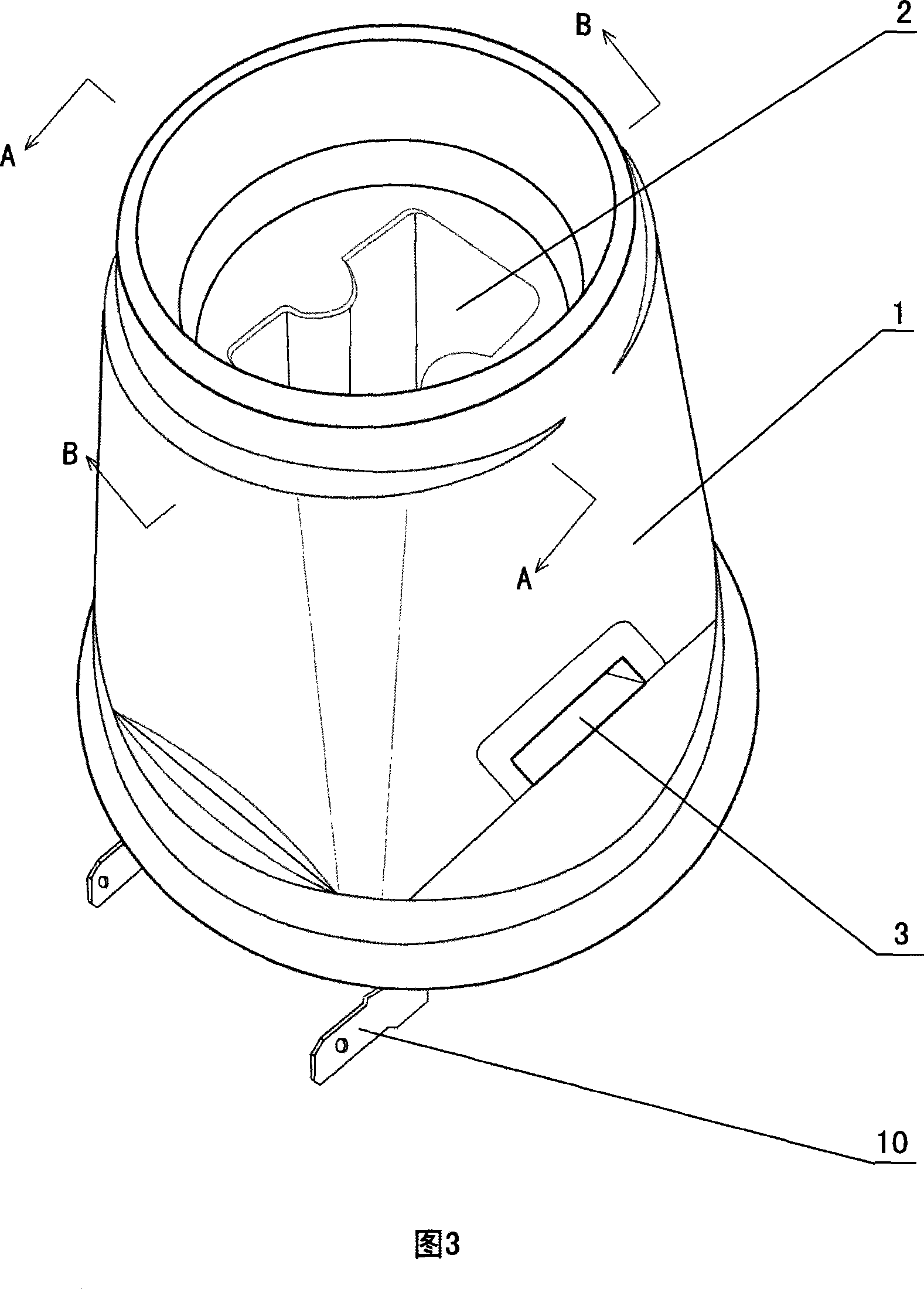

Multi-functional energy-saving boiler

The invention relates to a multi-functional energy-saving boiler. The boiler comprises a bottom pot, a steaming pot and a pot cover which can be overlapped and combined for use, wherein the an automatic water supplier is arranged in the bottom pot, the automatic water supplier is provided with a bowl-shaped shell seat; the upper opening of the bowl-shaped shell seat is closed and the lower opening of the bowl-shaped shell seat is provided with a water outlet tube hole, the inner bottom part of the shell seat is provided with a liquid blocking plate above the water outlet tube hole, the outer bottom part of the shell seat is provided with support legs, and with the support legs, a gap is formed between the water outlet tube hole and the bottom pot. Therefore, the bottom pot only keeps a small amount of water, the heating, boiling and gas generation are extremely quick, and the advantages of one-pot multipurpose and energy conservation are achieved.

Owner:吴加钿

O-type foot-and-mouth disease virus-like particle antigen, vaccine composition containing O-type foot-and-mouth disease virus-like particle antigen, and preparation method and application of vaccine composition

ActiveCN111233984AImproving immunogenicityImprove stabilitySsRNA viruses positive-senseViral antigen ingredientsDiseaseParticulate antigen

The invention provides a foot-and-mouth disease virus-like particle antigen. The foot-and-mouth disease virus-like particle antigen consists of a VP0 antigen protein, a VP1 antigen protein and a VP3 antigen protein through assembling, wherein the VP0 antigen protein is coded by a nucleotide sequence as shown in Seq ID No.1 or coded by a degenerate sequence of the nucleotide sequence as shown in Seq ID No.1, the VP1 antigen protein is coded by a nucleotide sequence as shown in Seq ID No.3 or coded by a degenerate sequence of the nucleotide sequence as shown in Seq ID No.3, and the VP3 antigen protein is coded by a nucleotide sequence as shown in Seq ID No.2 or coded by a degenerate sequence of the nucleotide sequence as shown in Seq ID No.2. The foot-and-mouth disease virus-like particle antigen has favorable immunogenicity, a vaccine composition prepared from the foot-and-mouth disease virus-like particle antigen can protect current epidemic O-type Ind strains through one-time immunization, and the immunoprotection period is long. The invention further provides the vaccine composition prepared from the foot-and-mouth disease virus-like particle antigen, and a preparation method andan application of the vaccine.

Owner:PU LIKE BIO ENG

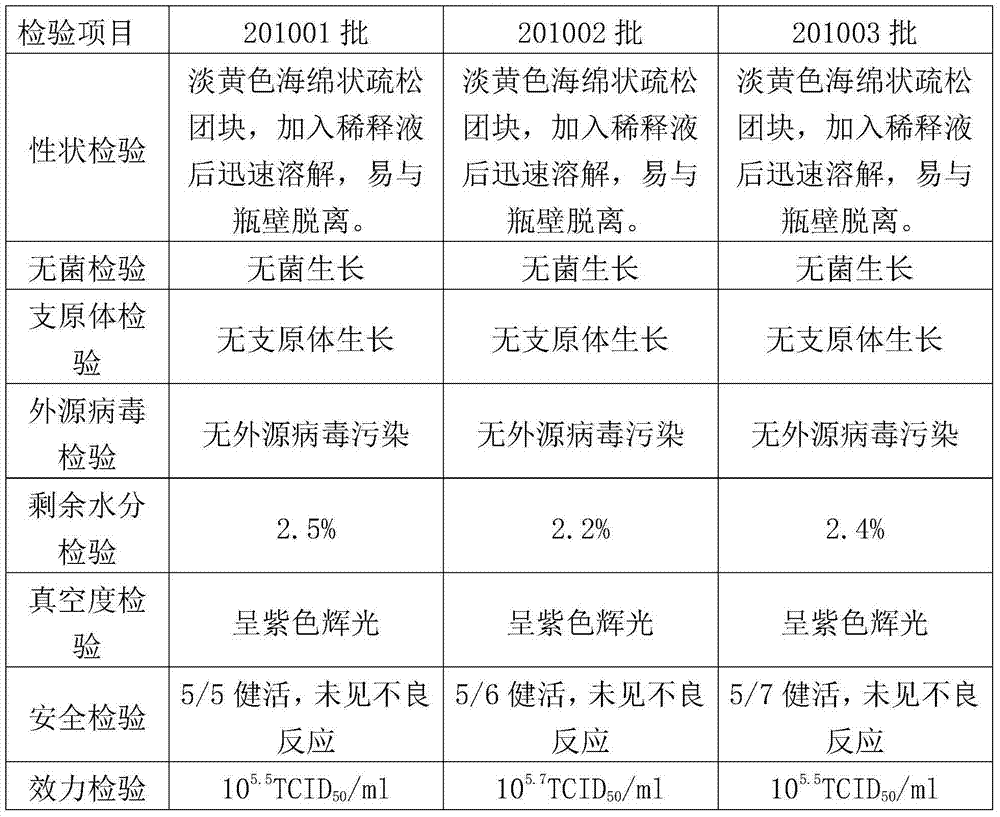

Preparation method of chicken infectious bursal disease virus and aviadenovirus IV combined inactivate vaccine

InactiveCN106822886AImprove concentrationProduced fastViral antigen ingredientsMicroorganism based processesFreeze thawingEmulsion

The invention relates to a method for producing chicken infectious bursal and avian adenovirus type 4 inactivated vaccines with LMH cell lines, which comprises the following steps: separately injecting chicken infectious bursal and avian adenovirus type 4 viruses Inoculate in LMH cells, obtain chicken infectious bursa seedling virus liquid and avian adenovirus type 4 seedling virus liquid by culturing, freezing and thawing, centrifuging, concentrating and other steps, and then sterilize the seedling virus liquid of the two viruses After inactivation, equal volumes are mixed and emulsified to make an emulsion-type inactivated vaccine. The dual vaccine provided by the invention has high potency, has complete immune protection against chicken infectious bursal virus and avian adenovirus type 4, has good safety, is stable and effective, and has a long protection period.

Owner:广州博恒生物科技有限公司

Porcine epidemic diarrhea live vaccine

ActiveCN103933561ALow toxicityImproving immunogenicityDigestive systemAntiviralsAntigenEpidemic diarrhea

The present invention provides a porcine epidemic diarrhea (PED) live vaccine, which contains an antigen and a protection agent, wherein the antigen is a PED virus SD10 strain having the preservation number of CGMCC No.8503. According to the present invention, the used antigen PED virus SD10 strain has characteristics of low toxicity and good immunogenicity, the antibody is rapidly produced after the prepared vaccine is adopted to immunize, the produced antibody has characteristics of high titer, long maintaining time, long storage time and low immune dose, and piglets produced by pregnant sows can achieve good passive immunity through immunization injection before mating, such that the piglets can produce strong immunity and can resist virulent virus attacks so as to improve the piglet survival rate.

Owner:YEBIO BIOENG OF QINGDAO

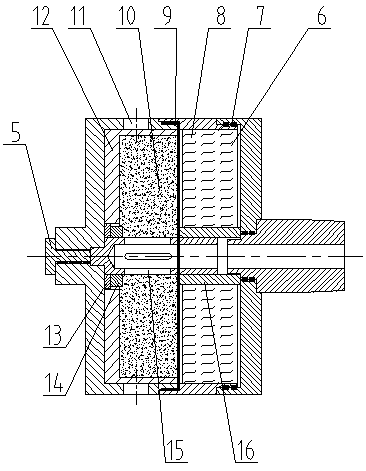

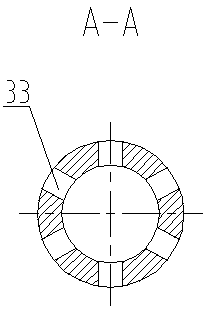

Device and method for detecting hydrogen embrittlement resistance of metal material under dynamic bending condition

ActiveCN108489802AEvaluation of hydrogen embrittlement resistanceConstant hydrogen contentMaterial strength using repeated/pulsating forcesElectricityTest sample

The invention discloses a device for detecting hydrogen embrittlement resistance of a metal material under a dynamic bending condition. The device comprises a loading device and an electrochemical group; both a reference electrode and a auxiliary electrode of the electrochemical group are disposed in a medium solution located in a medium container; both the reference electrode and the auxiliary electrode are connected with a potentiostat; the loading device comprises lower supporting seats; the lower supporting seats are disposed on a bottom plate; upper pressing blocks are disposed on the tops of the upper supporting seats; two ends of a test sample are fixedly mounted between the lower supporting seats and the upper pressing blocks; a upper chuck and a lower chuck are mounted on a connecting rod, respectively contact with the upper surface and the lower surface of the test sample, and are used for applying a bending load to the test sample; and the connecting rod passes through a guiding block and is connected with a piston rod of an oil cylinder. The invention further provides a method for detecting the hydrogen embrittlement resistance of the metal material under the dynamic bending condition. According to the device and the method of the invention, a material is loaded with a dynamic load during a test process; a loading condition reflects the service environment of the material more realistically, and can more objectively evaluate the hydrogen embrittlement resistance of the material; the hydrogen content is constant; and the test period is short.

Owner:武汉钢铁有限公司

Chicken infectious coryza inactivated vaccine adjuvant

InactiveCN102406936AImprove securityHigh protection rateAntibacterial agentsAntibody medical ingredientsToxinVirology

The invention relates to a chicken infectious coryza inactivated vaccine adjuvant. The adjuvant prepared in the invention is used as a chicken infectious coryza inactivated vaccine adjuvant to prepare a chicken infectious coryza inactivated vaccine and has the advantages of high antibody titer produced by inoculated chicken, long antibody protection period, high toxin expelling protection rate and the like.

Owner:YEBIO BIOENG OF QINGDAO

A honeycomb briquette brick

The invention relates to a honeycomb briquette brick and belongs to solid fuel. Compared with honeycomb briquette, the honeycomb briquette brick has innovative combustion chambers so as to generate an epoch-making combustion method that is an internal combustion method. By the internal combustion method, the heat efficiency generated by the honeycomb briquette brick is extremely high, the combustion strength is high, and fault coal even coal gangue can be adopted as a combustion material. The honeycomb briquette brick can be combusted continuously, no black smoke generates when a new honeycomb briquette brick is added, and the flame combustion is not influenced. Coal gas is combusted when the honeycomb briquette brick is combusted, thus achieving zero emission. A brick which is a building material is discharged after the honeycomb briquette brick is combusted. The honeycomb briquette brick is free of dust discharge and coal cinder discharge. The honeycomb briquette brick fundamentally improves the environment. The honeycomb briquette brick allows a tube furnace to be compact in structure and simplified and to have characteristics of small size, light weight, small floor space, easy manufacturing and low total cost. The upper and lower parts of the honeycomb briquette brick are provided with end-surface combustion chambers. The external side surface of the honeycomb briquette brick is an annular side combustion chamber. The honeycomb briquette brick is covered by the combustion chambers, namely, the honeycomb briquette brick is combusted while being covered by flame. The honeycomb briquette brick is widely used for various coal furnace appliances.

Owner:张启凤

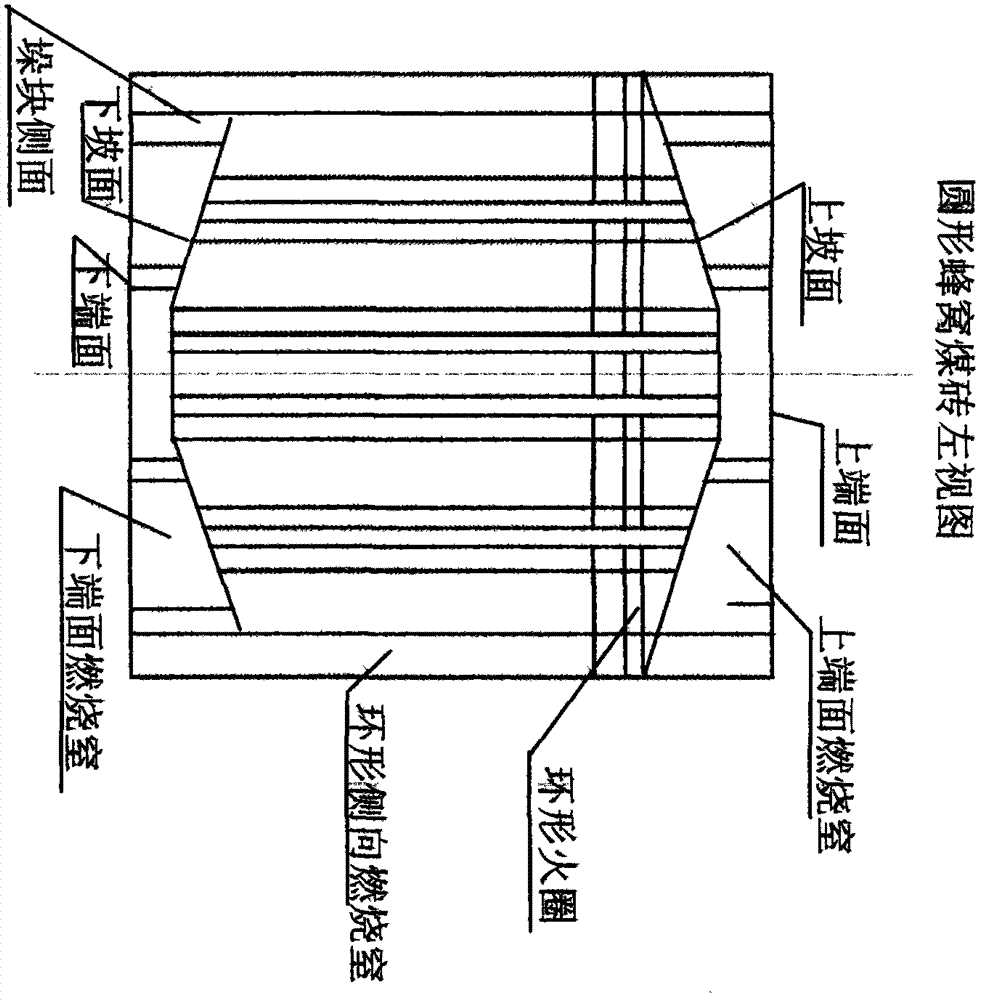

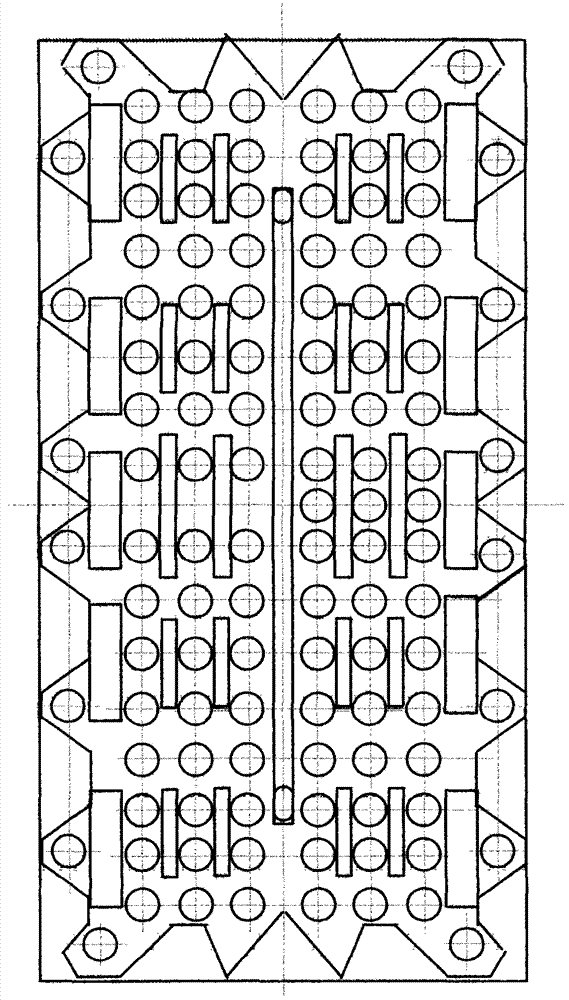

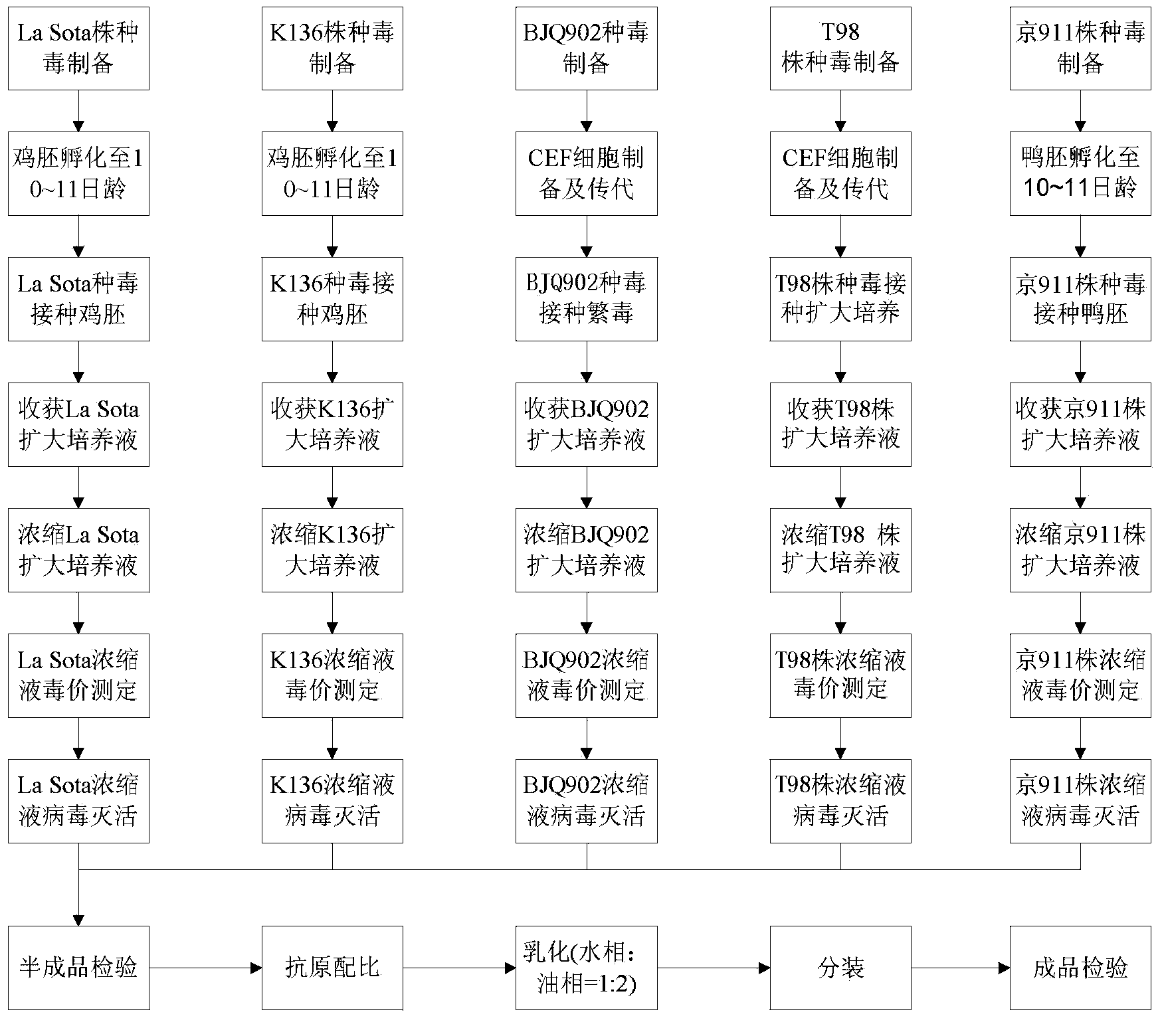

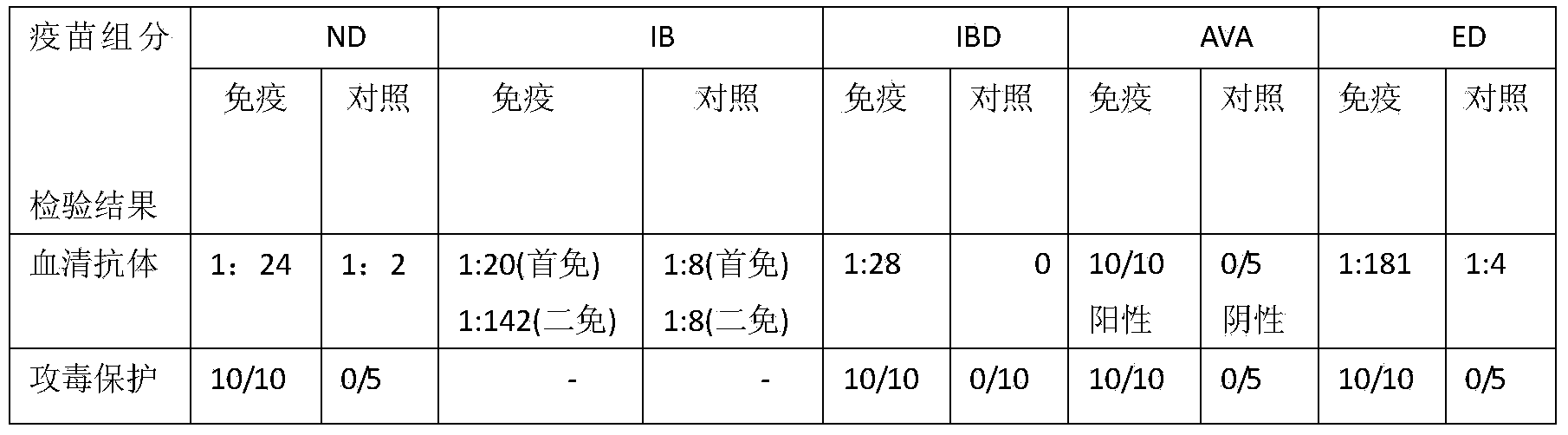

Avian pentavalent vaccine and preparation method thereof

InactiveCN103611156AProduced fastReduce generationViral antigen ingredientsAntiviralsAntigenInfectious bursal disease

The present invention discloses a Newcastle disease, infectious bronchitis, infectious bursal disease, viral arthritis and egg drop syndrome inactivated pentavalent vaccine, and a production method thereof. The antigens of the pentavalent vaccine comprise a Newcastle disease virus La Sota strain, an infectious bronchitis virus K136 strain, an infectious bursal disease virus BJQ902 strain, a viral arthritis T98 strain and an egg drop syndrome virus Jing 911 strain. According to the present invention, the multi-stage continuous concentration process and the homogenizer emulsification process are adopted during the preparation process, the inactivated vaccine for concurrently preventing and treating the five chicken epidemic diseases is firstly prepared, characteristics of rapid antibody generation, high titer and long protection period are provided after immunizing animals, and epidemic disease occurrence and spread are reduced.

Owner:TIANJIN RINGPU BIO TECH

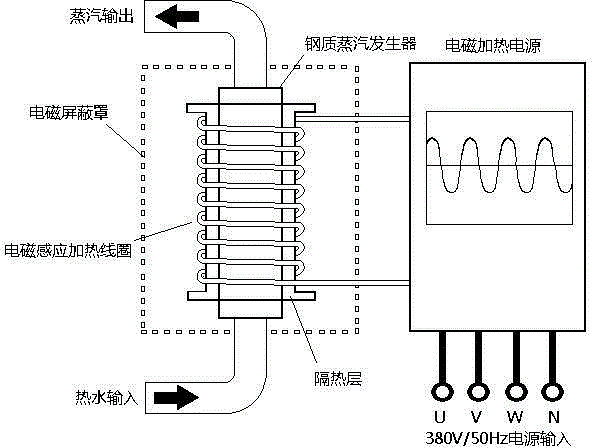

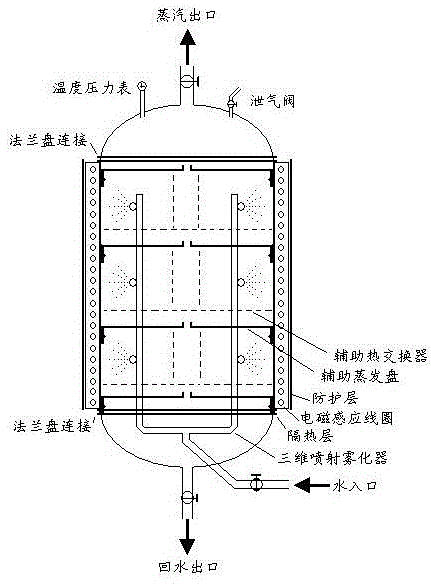

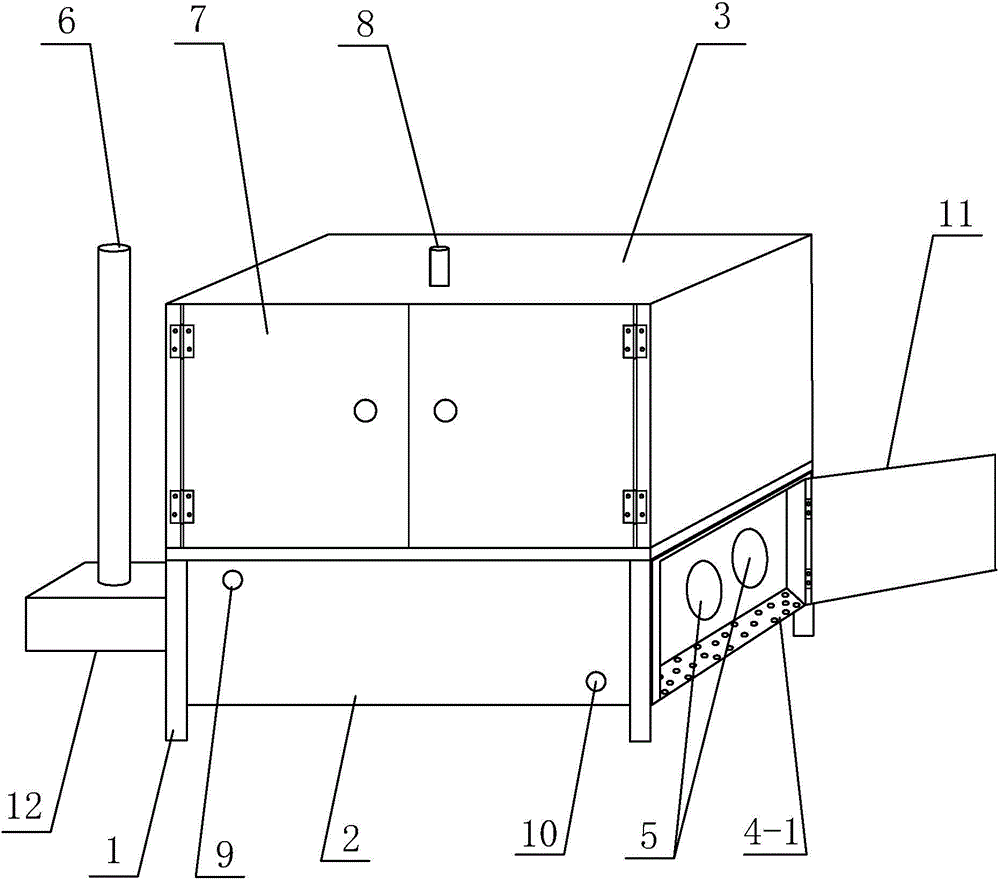

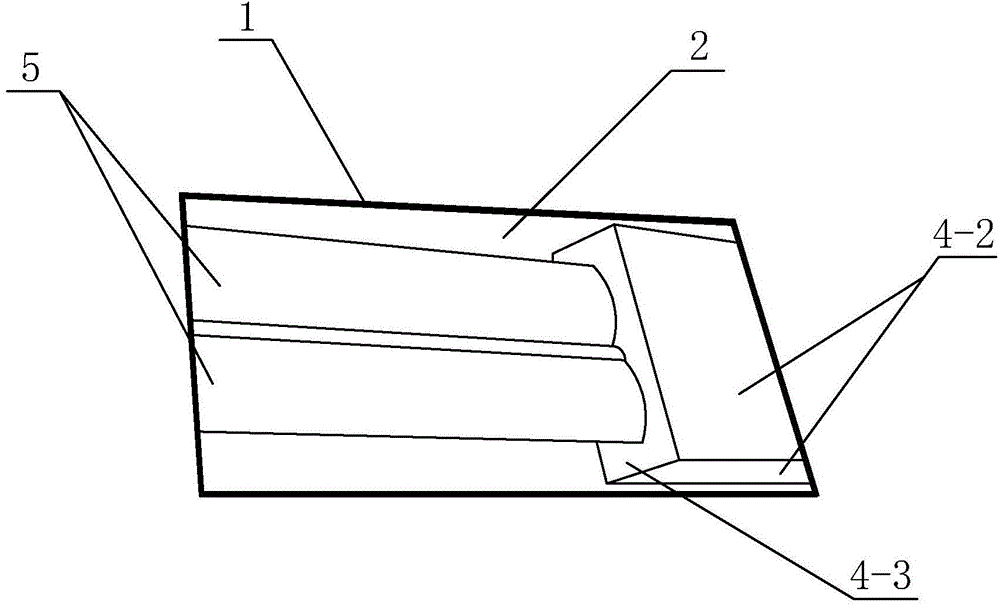

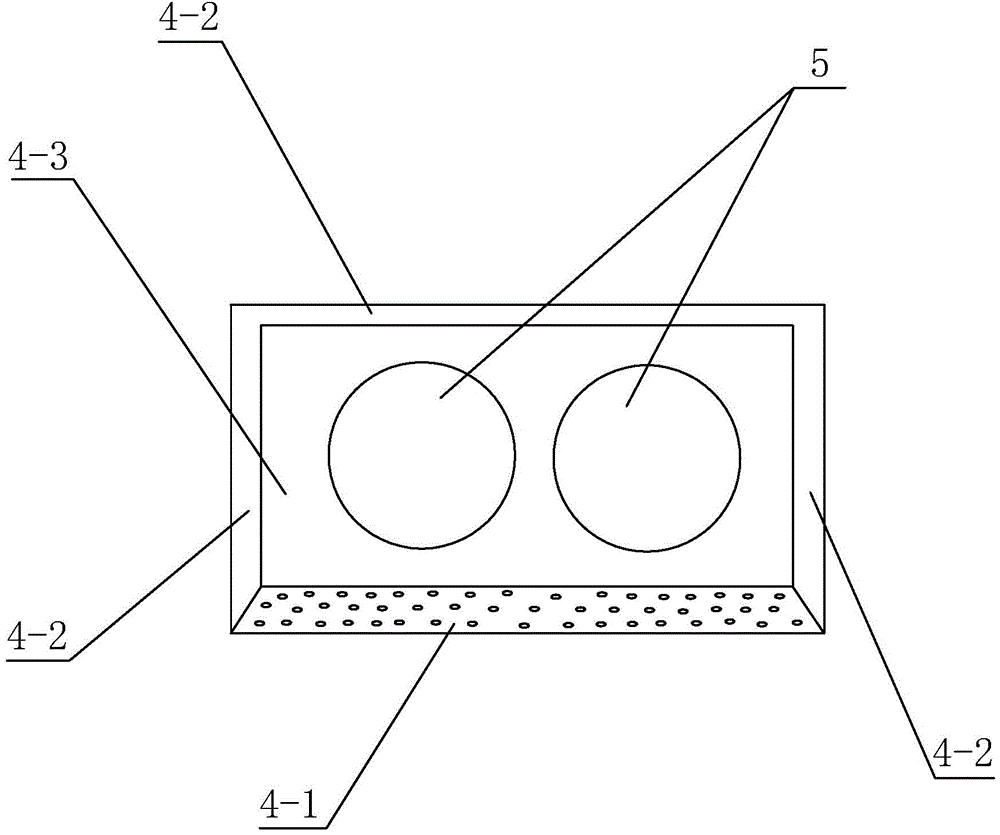

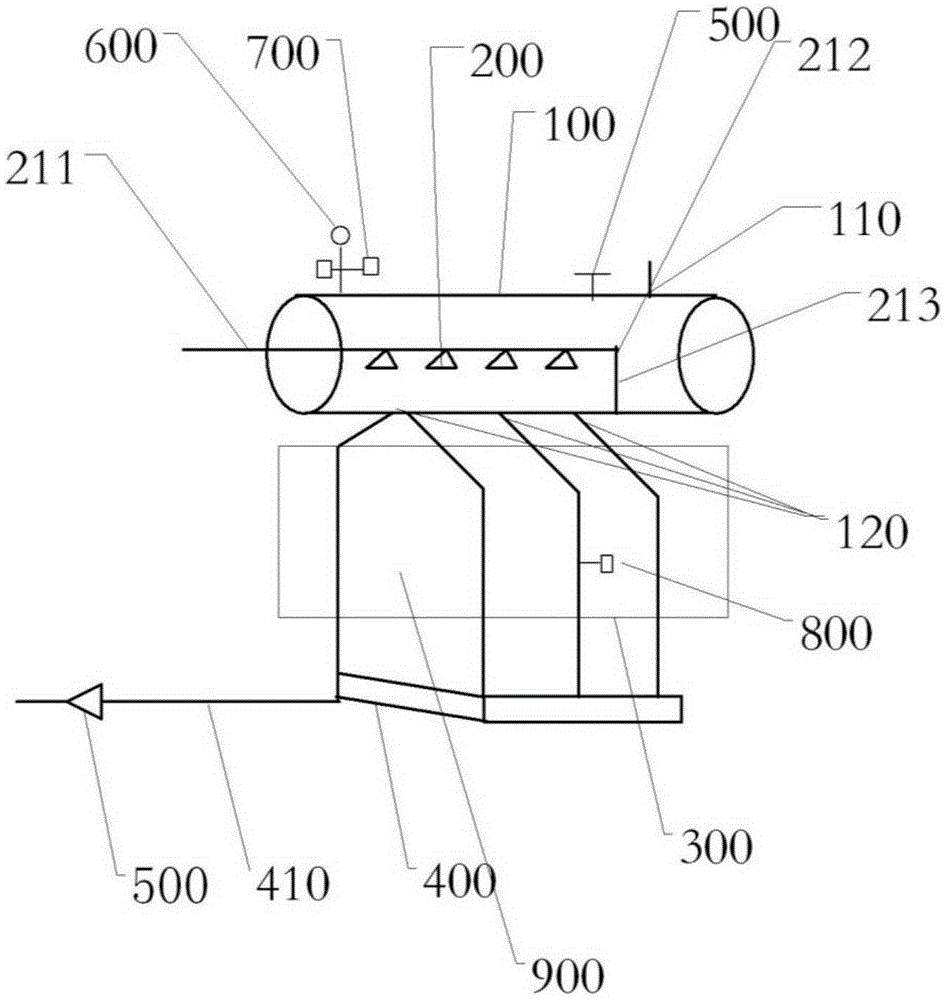

Three-dimensional heat exchange electromagnetic energy steam generator device

A three-dimensional heat exchange electromagnetic energy steam generator device comprises an electromagnetic energy heating device and a three-dimensional heat exchange evaporator device. The outer portion of the device is connected with a water inlet pipe, a steam output pipe, a water return pipe, an air bleeding valve, a temperature and pressure gauge and other components. The three-dimensional heat exchange electromagnetic energy steam generator device has the beneficial effects that based on the efficient electromagnetic energy heating technology, by means of the specially-designed three-dimensional heat exchange steam evaporator device, heat conversion efficiency is high, steam is generated quickly, and equipment safety is good; and the device is a novel steam generation device which saves energy, is environment-friendly, achieves zero emission and is free of pollution, efficient and safe, and the device is an ideal replacement product for various traditional steam boilers.

Owner:SHENZHEN SANNENG NEW ENERGY TECH

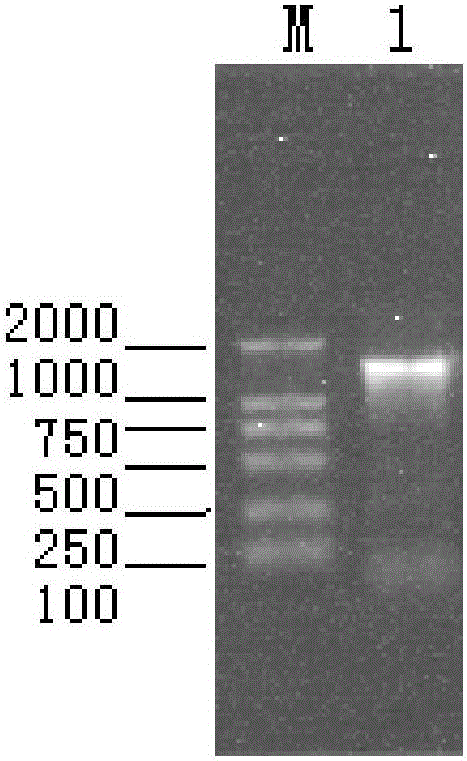

Bivalent inactivated vaccine for porcine parvovirus and porcine epizootic diarrhea

ActiveCN105879023AImproving immunogenicityPassive immunity is goodSsRNA viruses positive-senseViral antigen ingredientsSingle injectionCanine parvovirus

The invention provides bivalent inactivated vaccine for porcine parvovirus and porcine epizootic diarrhea. The bivalent inactivated vaccine comprises antigen and a vaccine adjuvant, wherein the antigen is a porcine epidemic diarrhea virus with the preservation number being CGMCC No. 8503 and porcine parvovirus VP2 protein with the preservation number being CCTCC M 2016098, wherein the porcine parvovirus VP2 protein is expressed by an X33-VP2 strain; the strain was preserved in China Center for Type Culture Collection on 9, March, 2016. The bivalent inactivated vaccine for porcine parvovirus and porcine epizootic diarrhea is good in immunogenicity, an immunized antibody is generated quickly, the generated antibody is high in titer and long in holding time and retention period, the immunizing dose is small, the selected vaccine adjuvant is easy to inject, and the two types of diseases can be prevented and treated through single injection; if immune injection is conducted before mating, piglets born by a pregnant sow can obtain good passive immunity, the piglets can generate high immunity and can resist to attack of powerful viruses, and the survival rate of the piglets is raised.

Owner:YEBIO BIOENG OF QINGDAO

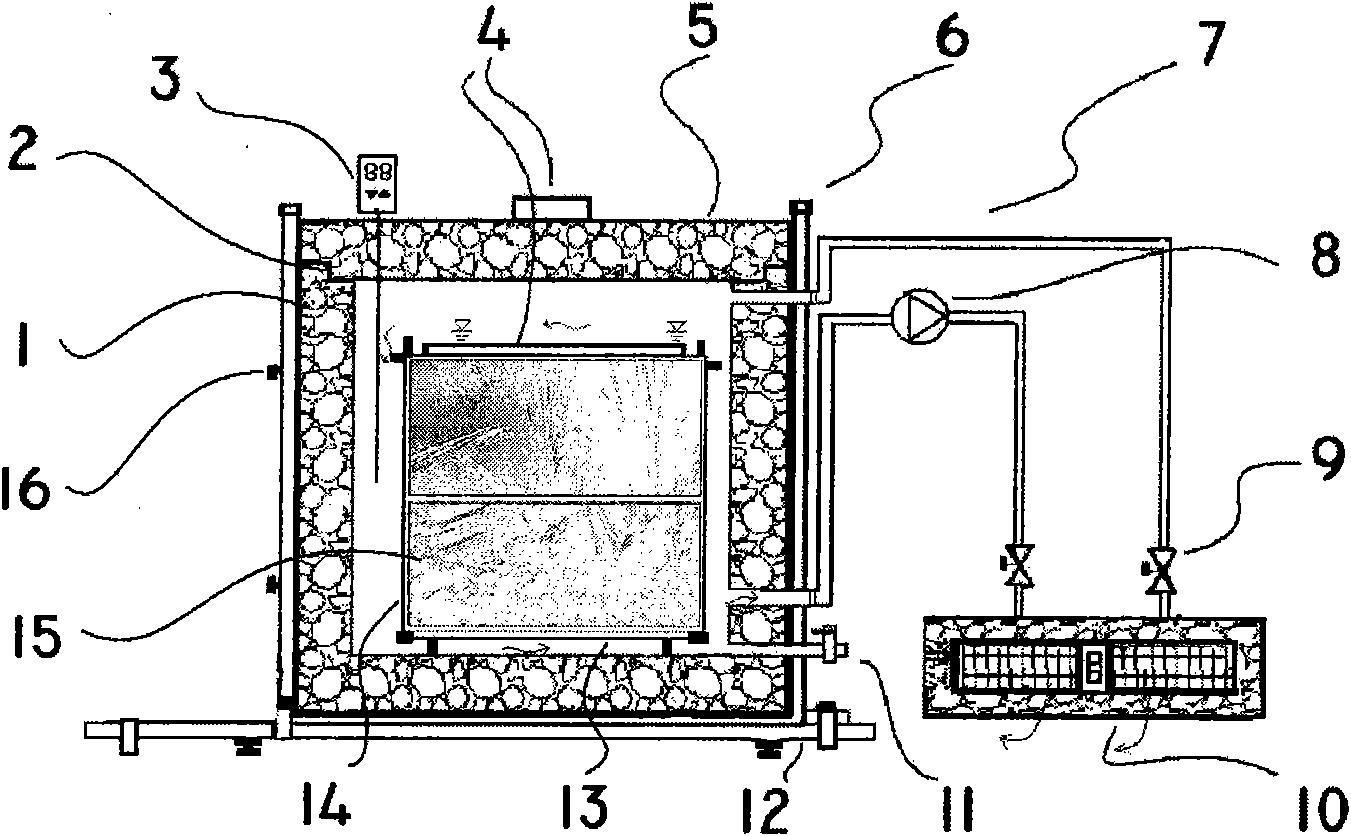

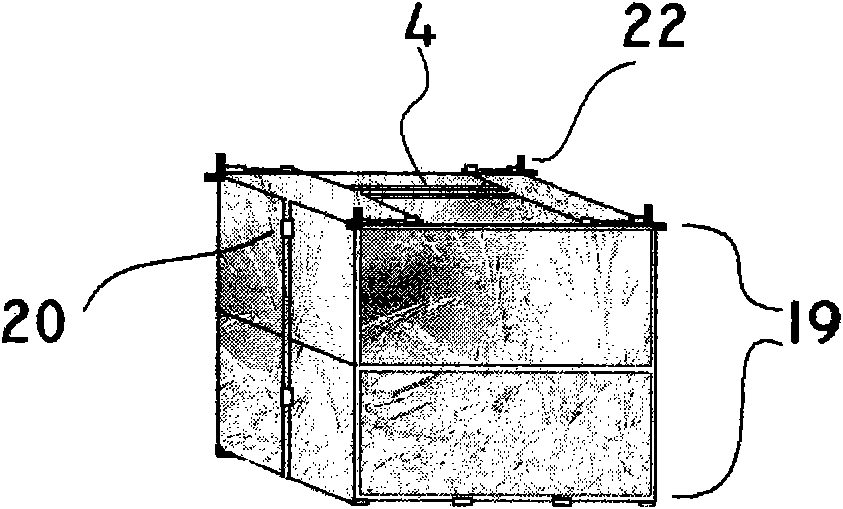

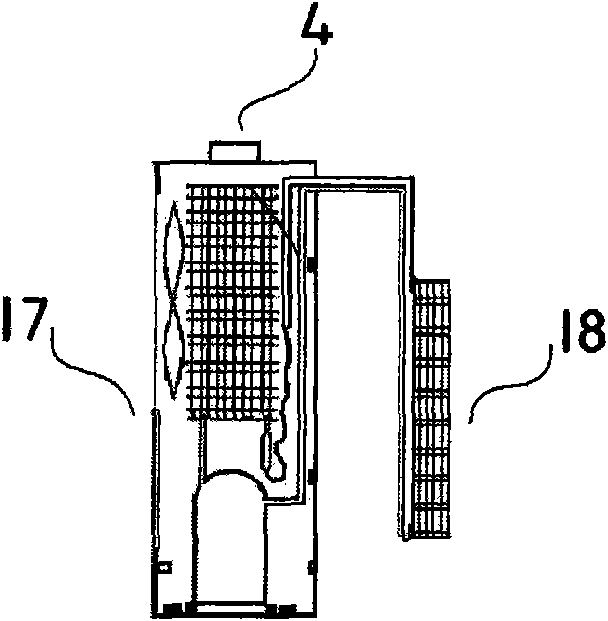

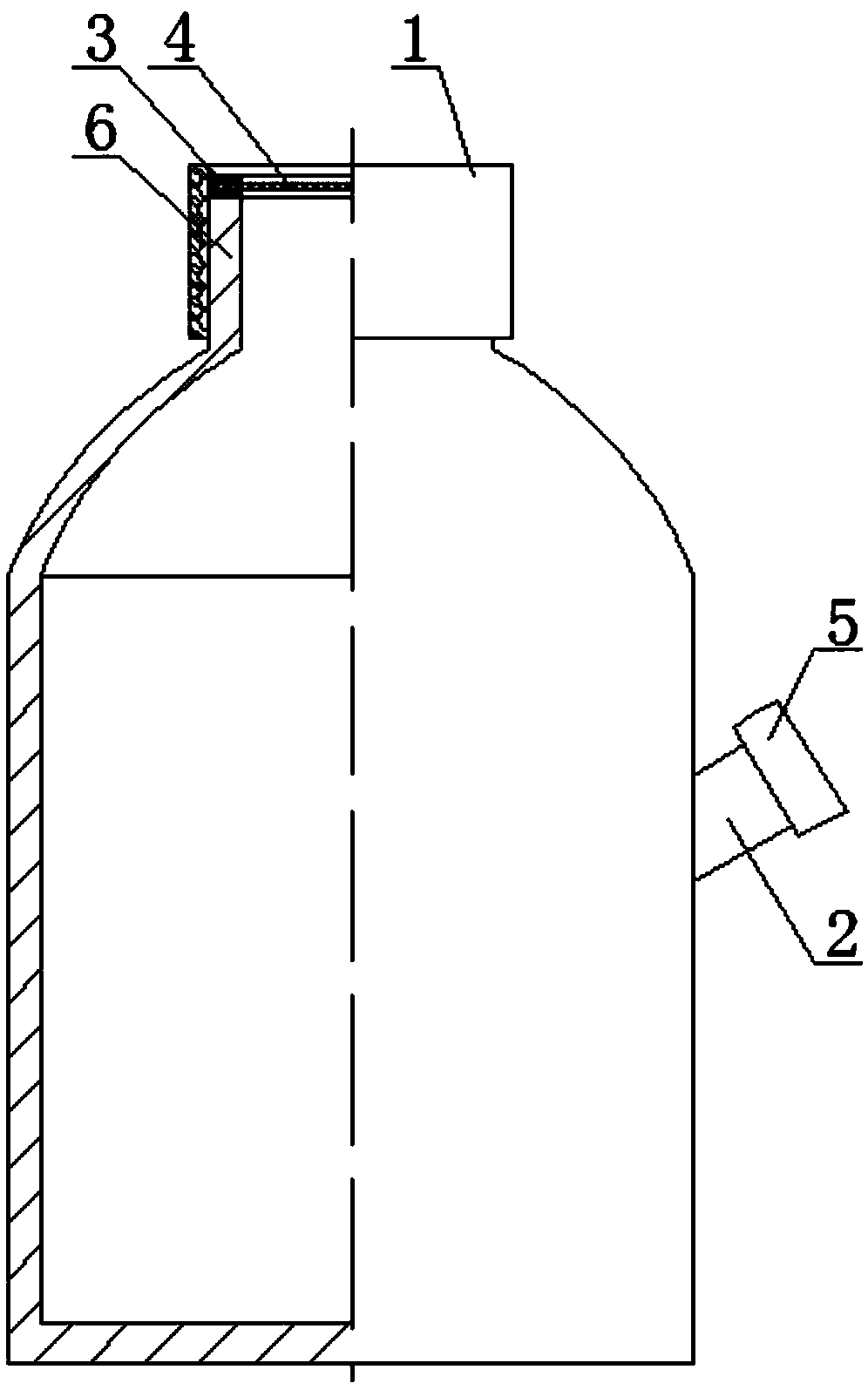

Refrigerating machine of pure electric automobile

InactiveCN102139617ASolve power consumptionProduced fastAir-treating devicesLighting and heating apparatusElectricityCold air

The invention relates to a refrigerating machine of a pure electric automobile. The refrigerating machine is characterized by comprising a thermal-insulation refrigerator body (1) and a housing (6), wherein the side surface of the housing (6) is connected with an n-shaped whole auxiliary refrigeration host machine (17) and an evaporator (18) through movable fastening screws (16) and a base plate (12); the evaporator (18) is arranged in the thermal-insulation refrigerator body (1); and thermal-insulation hoses (7), a water pump (8) and valves (9), which are externally connected with the thermal-insulation refrigerator body (1), are connected to a driving cab exchanger (10). A novel mode of ice block replacement and auxiliary refrigeration is adopted in the refrigerating machine, and the thermal-insulation refrigerator body and the auxiliary refrigeration host machine are matched, separated and combined so that the comfortable effect the same with that of cold air in an automobile with an internal combustion engine is achieved. The refrigerating machine has the advantages of low cost, environment friendliness, simple manufacture, safety and reliability, prolongs the actual service life, saves users' time for charging electricity, and reduces various expenses and automobile purchase cost.

Owner:福安市振中电器制造有限公司

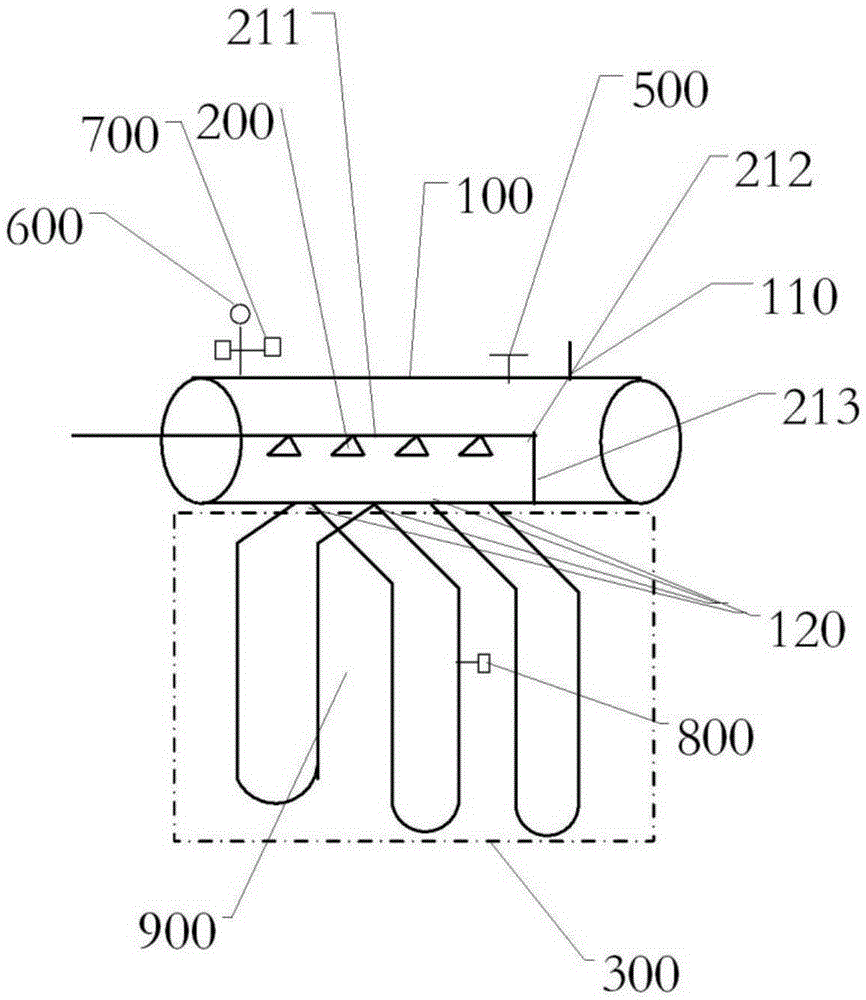

Control method for steam production process and pipeline directly-heated type steam generator

InactiveCN110319427AReduce Control LatencyAvoid Explosion HazardsBoiler controlElectrode boilersAutomatic controlEngineering

The invention belongs to the technical field of steam generators and provides a control method for a steam production process. The steam production process is controlled by controlling the water inflow quantity. Meanwhile a steam generator applying the control method is provided. The core of the steam generator is an evaporator. The evaporator is a section of pipeline. An electrode connected withan alternating current power supply is arranged in the pipeline. Water is supplied to the evaporator, electric currents are generated, and steam is generated. The water supply is increased, electric currents are increased, and more steam is generated. The water supply is reduced, electric currents are reduced, and less steam is generated. The water supply is stopped, electric currents return to zero, and no steam is generated. Through the steam generator, water inflow can be controlled automatically according to the needs for steam, constant current output or constant pressure output of steamis achieved, and thus the needs of different users for steam can be met. The steam generator can be fast started and stopped in seconds, is started if used, and is stopped if not used. The steam generator is far smaller than a traditional electric boiler, does not belong to pressure vessels, but can provide high pressure steam. The steam generator is not a boiler but can replace a boiler.

Owner:SHIJIAZHUANG JIRUI ENERGY SAVING TECH

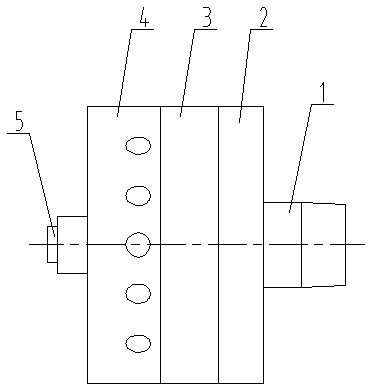

Wire coiling type electronic cigarette atomizer and wire coiling manufacturing tool thereof

PendingCN109512027AHighlight substantive featuresSignificant progressTobacco devicesElectricityEngineering

The invention relates to a wire coiling type electronic cigarette atomizer and a wire coiling manufacturing tool thereof. The wire coiling type electronic cigarette atomizer comprises an atomizer anda manufacturing tool for a coiled wire in the atomizer. The atomizer comprises an electric conductor connected with a battery, the other end of the electric conductor is connected with an atomizationcylinder, the other end of the atomization cylinder is sequentially connected with an oil storage cylinder, a sealing cover and a cigarette holder in a length direction, and an air guide pipe is further mounted in the center of the atomization cylinder. A jackscrew gas guide insulation disc is arranged on the outer circumference of the air guide pipe, the top end of the jackscrew air guide insulation disc is connected with a coiled wire which can conduct electricity and heat and is wound into a spiral shape, the coiled wire comprises a positive electrode and a negative electrode, the positiveelectrode is mounted in a wire coiling clamping groove formed in the right end of the air guide pipe, and the negative electrode is clamped on the outer circumference of the atomization cylinder. Sealing rings are arranged at the connecting position of the cigarette holder and the sealing cover and also at the connecting position of the oil storage cylinder and the sealing cover, and air amount adjusting holes are further formed in the outer circumference of the cigarette holder. The advantages are that the wire coiling type electronic cigarette atomizer has a simple structure, is convenient to operate, is easy in coiled wire manufacturing, good in atomization effect and stable in smoke output, etc.

Owner:陆峰

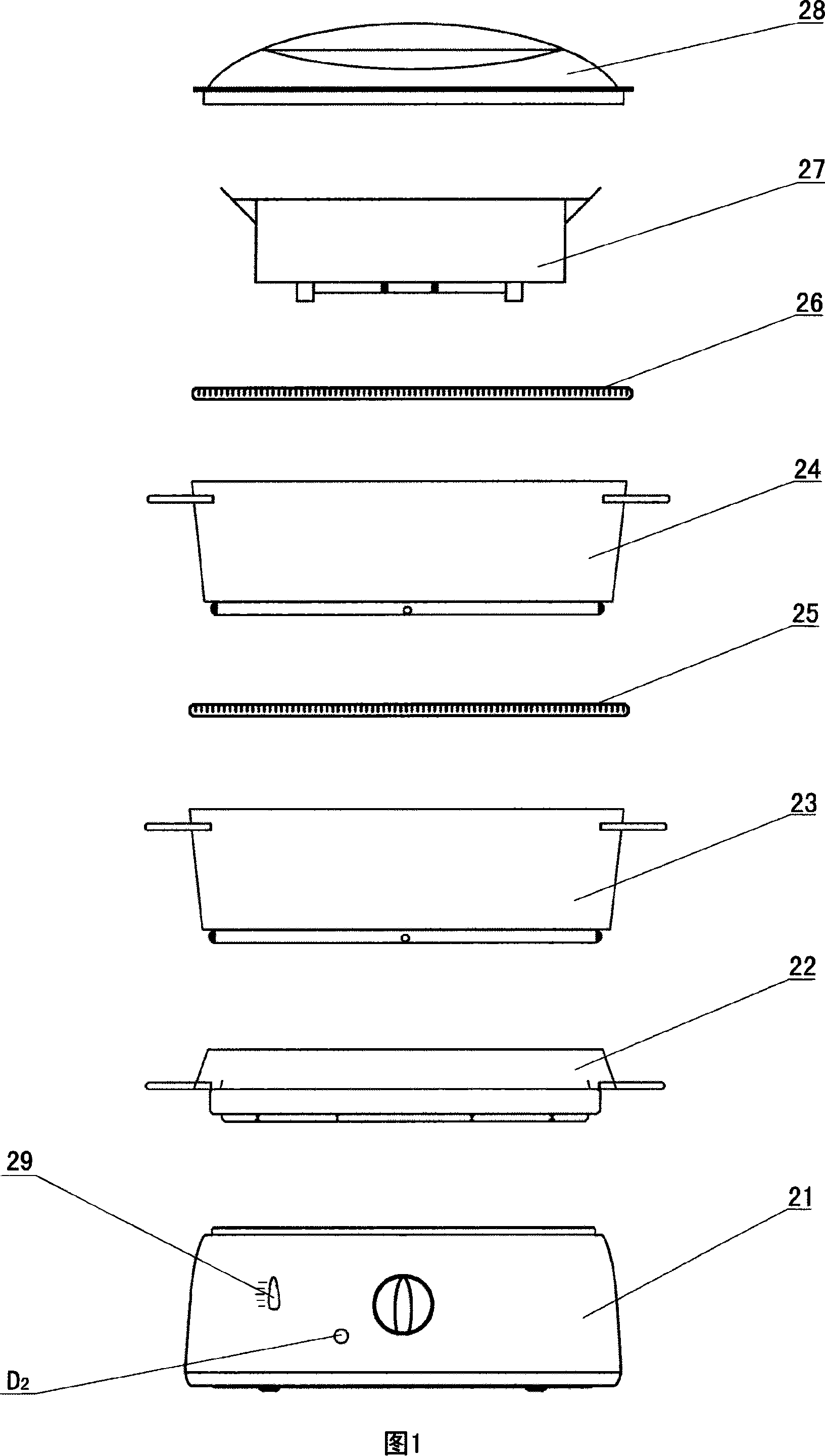

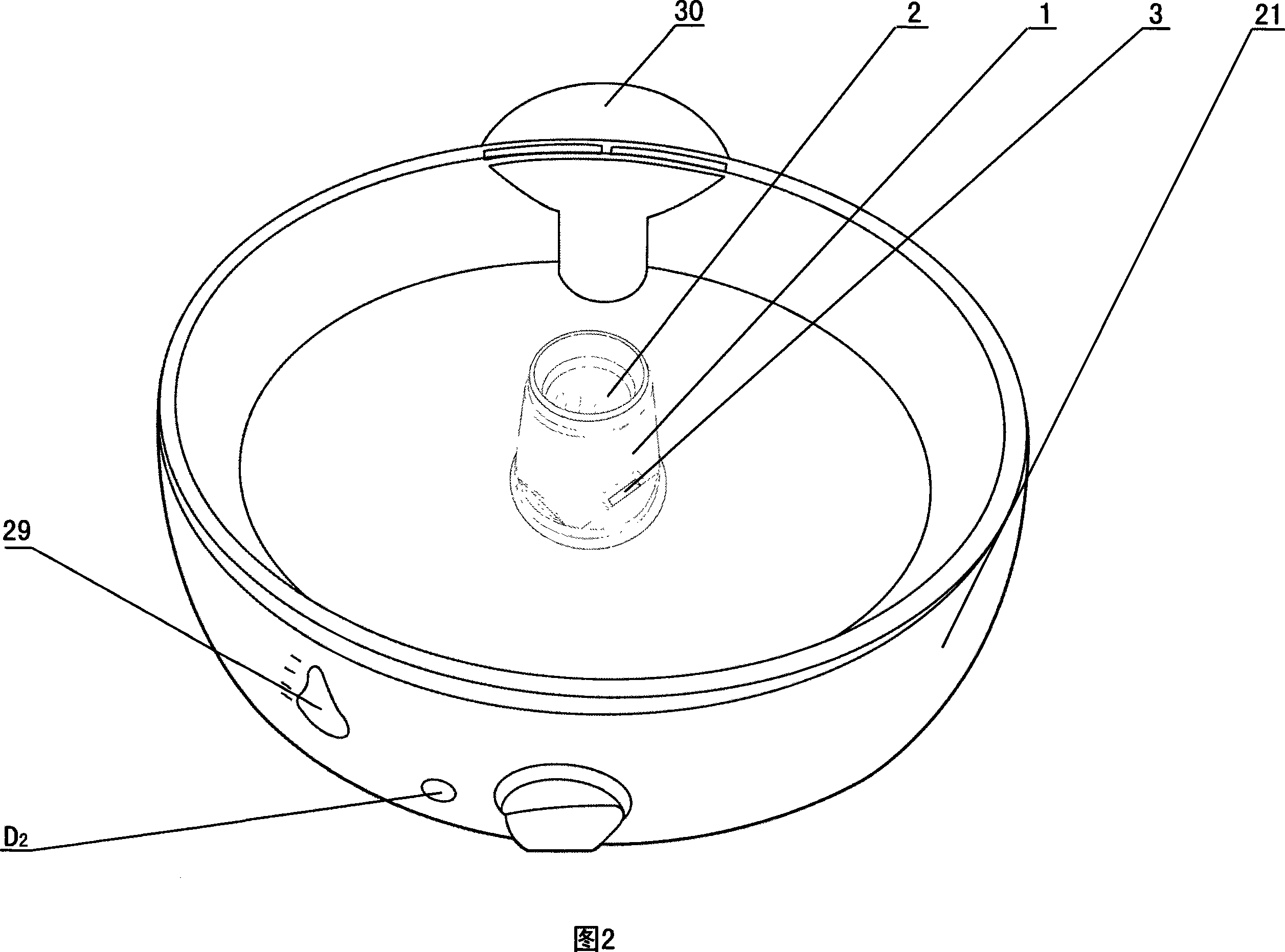

Steam pot

InactiveCN104688016AIncrease profitReduce lossesSteam generation heating methodsSteam cooking vesselsWater storageEngineering

The invention discloses a steam pot. The steam pot comprises a frame and a water storage chamber mounted below the frame, the top of the water storage chamber is provided with a steam chamber, the upper end and the lower end of the side wall of the water storage chamber are provided with a water inlet and a water outlet respectively, and the top of the steam chamber is provided with a steam outlet. The steam pot further comprises heating cavities and a burner, wherein each heating cavity is provided with openings in two ends and hollow inside, and the burner is recessed in the water storage chamber and comprises a stove, a stove panel and a stove skirt, wherein the stove panel is vertically arranged in the water storage chamber, the stove skirt is arranged around the stove panel, and the stove is arranged on the wall of the water storage chamber. One end of each heating cavity is connected with the stove panel, the other end of each heating cavity penetrates the water storage chamber to be connected with a flue, and the flue is provided with a chimney. The steam pot has the advantages of high heat utilization rate, fast steam generation and high efficiency with the heating cavities different from the prior art. Meanwhile, the steam pot can be used for steaming food and boiling water and the like and thus is simple in structure, wide in application and conducive to popularization.

Owner:钦州市钦南区柏政蒸酒设备厂

Spray type steam generator

ActiveCN105371262AReduce capacityThe explosion is powerfulFlash steam boilersSteam boilers componentsWater sourceWater spray

The invention provides a spray type steam generator. The spray type steam generator comprises an upper collecting box and a pipe array communicated from top to bottom, and a spraying device arranged in the upper collecting box, wherein the spraying device is connected with a water source for supplying water in a spraying mode; a steam outlet and a joint are formed in the upper collecting box; the pipe array is connected with the upper collecting box through the joint to be communicated with the interior of the upper connecting box, and is used for vaporizing water sprayed out by the spraying device when the pipe array is heated. The spray type steam generator has the advantages of safety, reliability, high heat efficiency, fast steam generation, high automation degree and low operation cost.

Owner:田景宇

Simple measuring method for trace arsenic in atmosphere

InactiveCN109164096AEasy to operateReduce resistanceSemi-permeable membranesMaterial analysis by observing effect on chemical indicatorPotassium borohydrideEvaporation

The invention relates to a simple measuring method for trace arsenic in atmosphere. The method comprises the following steps: (1) atmospheric sampling: a Na2CO3-glycerin impregnated filter membrane isadopted for collection at the flow of 100 L / min for 10-15 h; (2) digestion: the filter membrane is taken down and placed into an arsenic determining device, HNO3-H2SO4 mixed acid is added, the mixture is heated to 50-60 DEG C for 20 min, and cooling is performed after heating; (3) reducing color development: potassium borohydride is sliced and placed into the arsenic determining device, and aftera mercury bromide test strip is rapidly loaded, the arsenic determining device is horizontally shaken until the slices are completely dissolved and left to stand for 15 min; (4) color comparison. According to the provided measuring method, sample digestion, reduction and measurement are integrated after enrichment, so that original complicated operation links such as digestion, evaporation, acidremoval, evaporation to dryness, dissolution, filtering, volume fixing and the like for samples are omitted, secondary pollution is reduced, and harm to an operator is reduced.

Owner:TIANJIN GUANGFU TECH DEV

Electric food steamer

InactiveCN101066192APromote productionSimple structureElectric heatingSteam cooking vesselsElectricityEngineering

The electric food steamer includes a pedestal, a heating device inside the pedestal, a steam box on the pedestal and a cover on the steam box. The heating device includes one heating element and one control circuit connected electrically, and features that the heating element has at least one vertical through hole and at least one horizontal through hole communicated mutually. When water is fed to the pedestal and the heating element is set inside water, water will fill the horizontal through hole and the vertical through hole. After power on, the water inside the vertical through hole will be heated to boil and to form steam fast. The present invention has the advantages of short preheating time, fast steam generation, low power consumption, high heat efficiency, etc.

Owner:SHANTOU BOAIER TECH

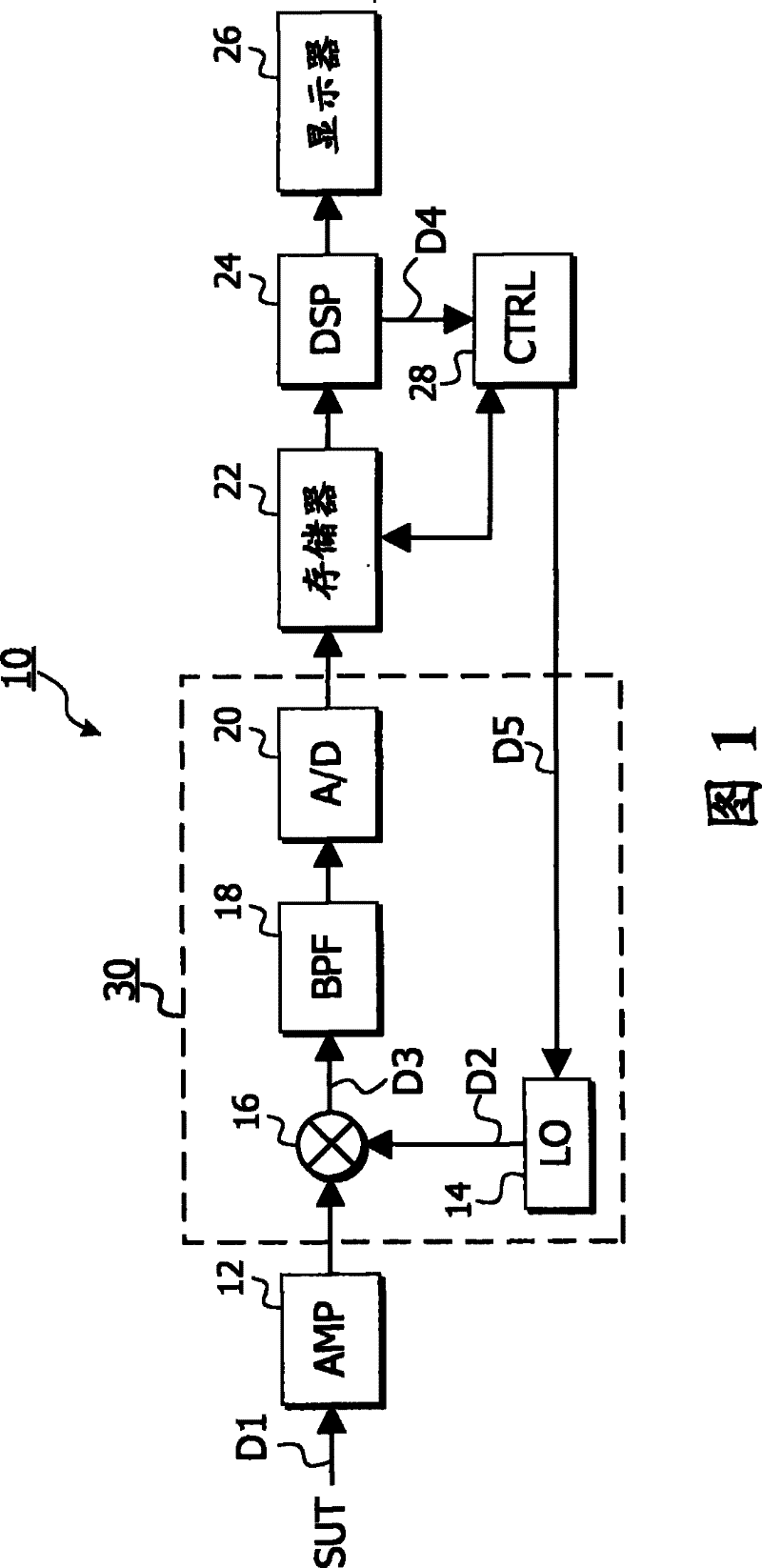

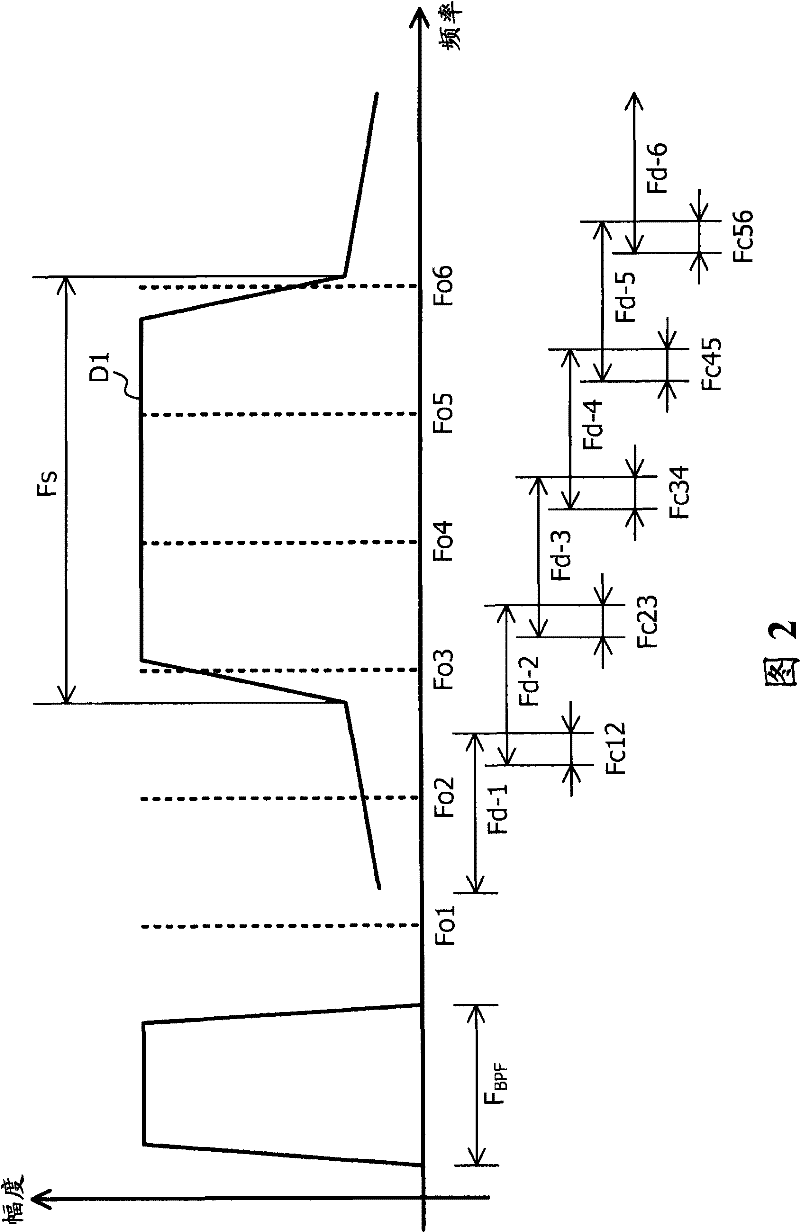

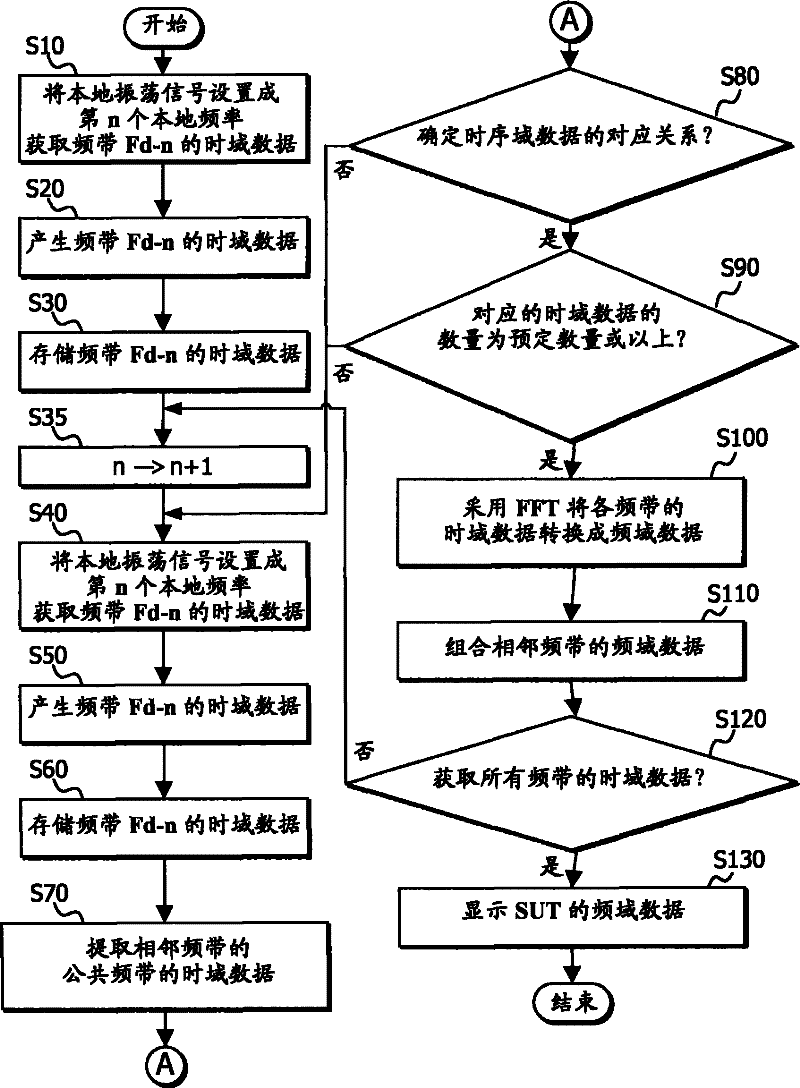

Signal analyzers and frequency domain data production methods

Sets of time domain data of respective frequency bands from Fd-I to Fd-n of a periodic input signal Fs are acquired. Sets of the time domain data of the common frequency band are extracted from the sets of the time domain data of the frequency bands Fd-1and Fd-2 in the acquired frequency bands. Correlativity between the sets of the time domain data of the common frequency band is determined whileshifting time relationship between the sets each other to identify the sets of time domain data having correspondence relationship. The sets of the time domain data having the correspondence relationship in the time domain data of the adjacent frequency band Fd-1 and Fd-2 are converted to the sets of the frequency domain data respectively, and the sets of the frequency domain data are combined toproduce one set of combined frequency domain data.

Owner:TEKTRONIX INT SALES GMBH

Vortex type hydroelectric generation device

InactiveCN103437937AExtended service lifeProduced fastMachines/enginesEngine componentsMetallic materialsEngineering

The invention discloses a vortex type hydroelectric generation device. The vortex type hydroelectric generation device comprises a water pipe made of metal materials. The water pipe is in an inclined state, the side wall of the water pipe is provided with a first electric generator and a second electric generator, the first electric generator is parallel to the second electric generator, the first electric generator is connected with a first blade arranged inside the water pipe, and the second electric generator is connected with a second blade arranged inside the water pipe. The vortex type hydroelectric generation device is simple in structure, convenient to use, capable of fast achieving hydroelectric generation and longer in service life.

Owner:KUNSHAN JIANJIN IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com